Contents

Manufacturing Insight: Cnc Coolant Ring

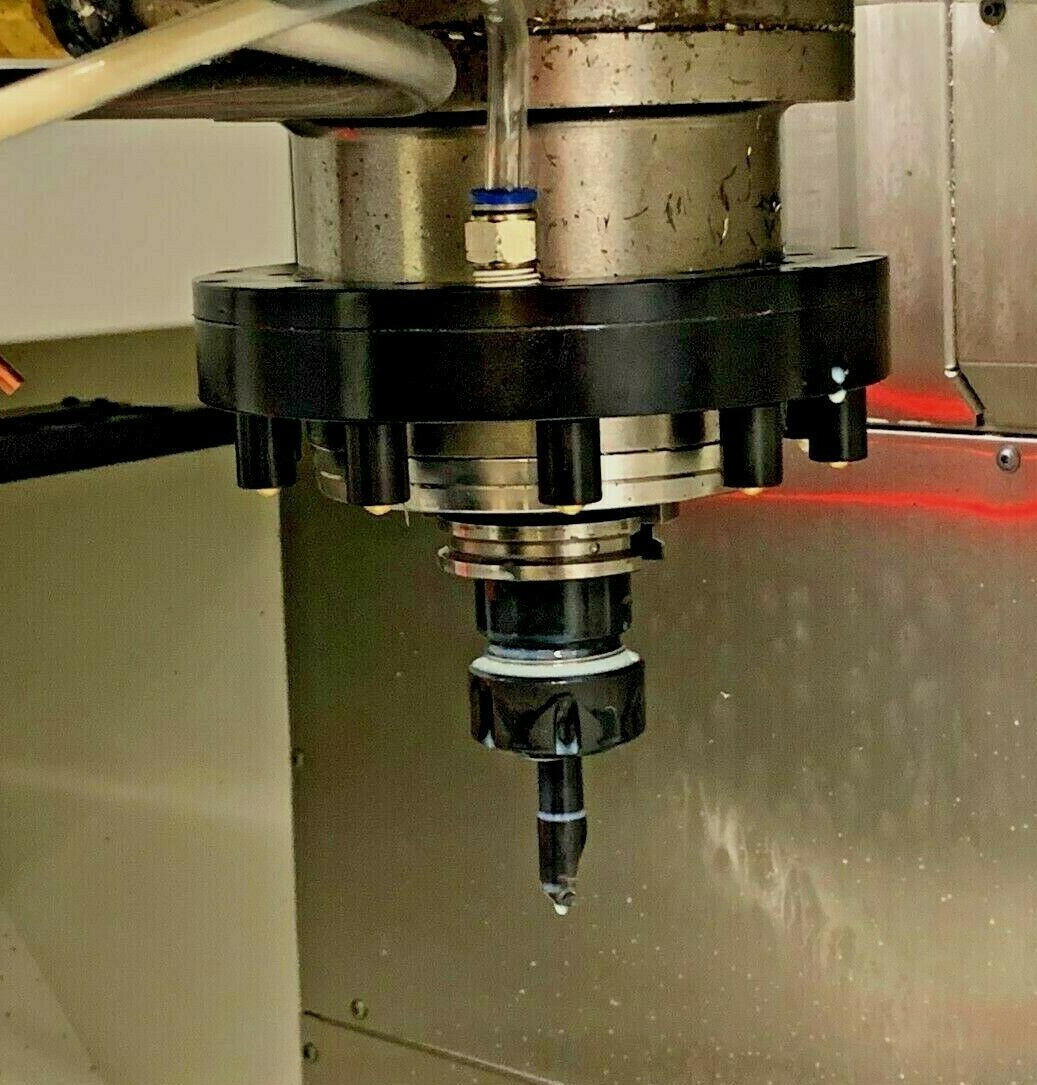

Precision CNC Coolant Rings for Optimal Machining Performance

Honyo Prototype delivers mission-critical CNC-machined components engineered to solve complex thermal management challenges in high-precision manufacturing. Our CNC coolant rings exemplify this expertise, designed to ensure consistent chip evacuation, extended tool life, and dimensional stability during demanding machining operations. These components require exacting tolerances, superior concentricity, and material integrity—attributes we achieve through advanced 3-, 4-, and 5-axis milling capabilities paired with rigorous quality validation.

Honyo Prototype CNC Machining Services

We specialize in producing high-integrity coolant rings and similar precision components from aerospace-grade aluminum, stainless steel, titanium, and engineered plastics. Our ISO 9001-certified processes guarantee repeatability down to ±0.005 mm, supported by in-house metallurgical analysis and real-time process monitoring. Every coolant ring undergoes comprehensive CMM inspection to verify flow dynamics and geometric accuracy, ensuring seamless integration into your spindle systems. Accelerate your prototyping or production timeline with our Online Instant Quote platform, providing detailed cost and lead-time transparency within minutes—no RFQ delays, no estimation ambiguity. Partner with Honyo to transform thermal management challenges into competitive advantages.

Technical Capabilities

CNC Coolant Ring Technical Specifications

A CNC coolant ring is a precision-engineered component used to deliver consistent, high-pressure coolant directly to the cutting zone in machining operations. It is especially critical in 3/4/5-axis milling and turning applications where tight tolerances and surface finishes are required. The coolant ring ensures optimal chip evacuation, thermal management, and tool life, directly impacting dimensional accuracy and process stability.

| Parameter | Specification Detail |

|---|---|

| Compatible Machines | 3-axis, 4-axis, and 5-axis CNC milling centers; CNC turning centers with live tooling |

| Coolant Delivery Type | Annular (ring-shaped) flow via multiple precision orifices; circumferential spray pattern |

| Nozzle Configuration | 8 to 24 radially distributed micro-nozzles; adjustable flow focus (optional) |

| Flow Rate Range | 20–100 L/min (5–26 GPM), depending on pressure and orifice size |

| Operating Pressure | 30–100 bar (435–1450 psi); compatible with high-pressure coolant (HPC) systems |

| Mounting Interface | Custom flange or collar mount; designed for integration with spindle nose (e.g., Capto, HSK, CAT, ISO) |

| Target Applications | Tight tolerance machining (±0.005 mm to ±0.025 mm); high-speed machining (HSM); deep cavity milling; hard turning |

| Material Compatibility | Designed for use with water-soluble emulsions, synthetic coolants, and MQL (Minimum Quantity Lubrication) hybrids |

| Tolerance Maintenance | Enables consistent thermal control, reducing tool deflection and workpiece expansion; supports sub-micron repeatability in precision milling |

| Available Materials | Aluminum 6061-T6: Lightweight, corrosion-resistant, ideal for prototyping and low-load setups Stainless Steel (304/316): High durability, thermal stability, and pressure resistance for production environments ABS Plastic: Low-cost option for non-metallic setups or proof-of-concept; limited to low-pressure applications Nylon (PA6 or PA12): Chemical-resistant, electrically insulating, suitable for specialized environments; moderate pressure rating |

| Surface Finish | Internal flow paths polished to Ra ≤ 0.8 µm to minimize turbulence and clogging |

| Filtration Requirement | Coolant must be filtered to ≤ 10 µm to prevent nozzle clogging |

| Integration Support | Compatible with automated tool changers when designed as a retractable or quick-disconnect module |

Note: Material selection for the coolant ring itself (Aluminum, Steel, ABS, Nylon) depends on operational demands. Steel is preferred in high-precision, high-pressure production environments involving steel or titanium. Aluminum is common in prototype and aerospace applications where weight and corrosion resistance matter. ABS and Nylon are typically used for non-critical or temporary setups where cost and chemical resistance are prioritized over mechanical performance.

From CAD to Part: The Process

Honyo Prototype CNC Coolant Ring Manufacturing Process Overview

Honyo Prototype executes CNC coolant ring production through a rigorously defined workflow optimized for precision, speed, and technical compliance. This process ensures dimensional accuracy, material integrity, and functional performance for critical thermal management applications in high-speed machining environments. Below is the structured workflow.

CAD Upload

Clients initiate the process by uploading native CAD files (STEP, IGES, or Parasolid formats) via Honyo’s secure customer portal. We require fully detailed 3D models with geometric dimensioning and tolerancing (GD&T) per ISO 1101, specifying critical features such as internal coolant channels, sealing surfaces, and mounting interfaces. Non-native formats (e.g., PDF, DWG) trigger an automated request for native geometry to prevent interpretation errors. All data undergoes immediate encryption and access-controlled storage per ISO 27001 standards.

AI-Powered Quoting

Uploaded CAD data feeds into Honyo’s proprietary AI quoting engine, which analyzes geometric complexity, material selection, and tolerance requirements against our production database of 12,000+ historical coolant ring projects. The system cross-references real-time machine availability, material costs, and secondary operation requirements (e.g., pressure testing, anodizing) to generate a technically validated quote within 2 business hours. Critical parameters evaluated include:

| Parameter | Evaluation Criteria | Impact on Quote |

|---|---|---|

| Wall Thickness | Minimum 1.5mm for aluminum; 2.0mm for stainless steel | Material waste, cycle time |

| Channel Geometry | Radius ≥0.8mm; no undercuts | Tooling feasibility |

| Surface Finish | Ra ≤1.6µm for sealing surfaces | Post-processing requirements |

| Material | 6061-T6, 7075-T6, 316L stainless standard options | Cost multiplier |

The output includes a preliminary manufacturability score (1–5 scale) and estimated lead time.

DFM Analysis

All quotes undergo mandatory Design for Manufacturability (DFM) review by senior manufacturing engineers. For coolant rings, this phase focuses on:

Validating pressure integrity of internal channels through hydraulic simulation (ANSYS Fluent) to prevent leakage at operational pressures (typically 7–10 bar).

Assessing fixturing constraints for thin-walled geometries to minimize deflection during milling.

Confirming toolpath feasibility for internal radii using 3D collision-avoidance verification in Mastercam.

Recommendations for tolerance relaxation (e.g., ±0.025mm to ±0.05mm on non-critical faces) to reduce costs without compromising function. Clients receive a formal DFM report with annotated CAD markup within 24 hours of quote acceptance.

Production Execution

Approved designs enter production under AS9100-certified controls:

Machining occurs on 5-axis DMG MORI or Makino centers with through-spindle coolant delivery, using carbide tooling optimized for non-ferrous or stainless alloys. Coolant rings undergo in-process CMM verification at critical stages: after roughing (to confirm wall consistency) and pre-finishing (to validate channel alignment). All sealing surfaces are machined in a single setup to ensure concentricity ≤0.01mm TIR. Final pressure testing at 1.5x operational pressure with helium leak detection (sensitivity 5×10⁻⁹ atm·cm³/s) is standard unless waived per client specification.

Delivery and Compliance

Completed coolant rings ship with full traceability documentation:

Material test reports (MTRs) per ASTM B209/B213

CMM inspection reports showing GD&T compliance

Pressure test certification

Batch-specific RoHS/REACH compliance statements

Parts are vacuum-sealed with VCI paper and shipped in custom foam-lined containers to prevent transit damage. Standard lead time from DFM approval is 7–10 business days for quantities ≤50 units; expedited 72-hour options are available for pre-qualified geometries.

This integrated workflow ensures Honyo delivers coolant rings meeting stringent OEM requirements for flow efficiency, structural reliability, and leak-free operation in demanding CNC spindle environments.

Start Your Project

Looking for a reliable CNC coolant ring solution? Contact Susan Leo at [email protected] to discuss your requirements.

Honyo Prototype offers precision-engineered coolant ring systems designed for optimal performance in CNC machining applications. Our in-house manufacturing facility in Shenzhen ensures tight quality control, fast turnaround times, and scalable production to meet your volume needs.

All products are built to international standards, with materials and designs tailored to your specific coolant delivery challenges. From prototyping to full-scale production, we support OEMs and machining centers worldwide with robust, leak-resistant coolant ring assemblies.

Reach out today to request technical specifications, pricing, or samples. Let’s optimize your CNC coolant delivery together.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.