Contents

Manufacturing Insight: Cnc Coolant Hose

Precision Coolant Delivery for Demanding CNC Operations

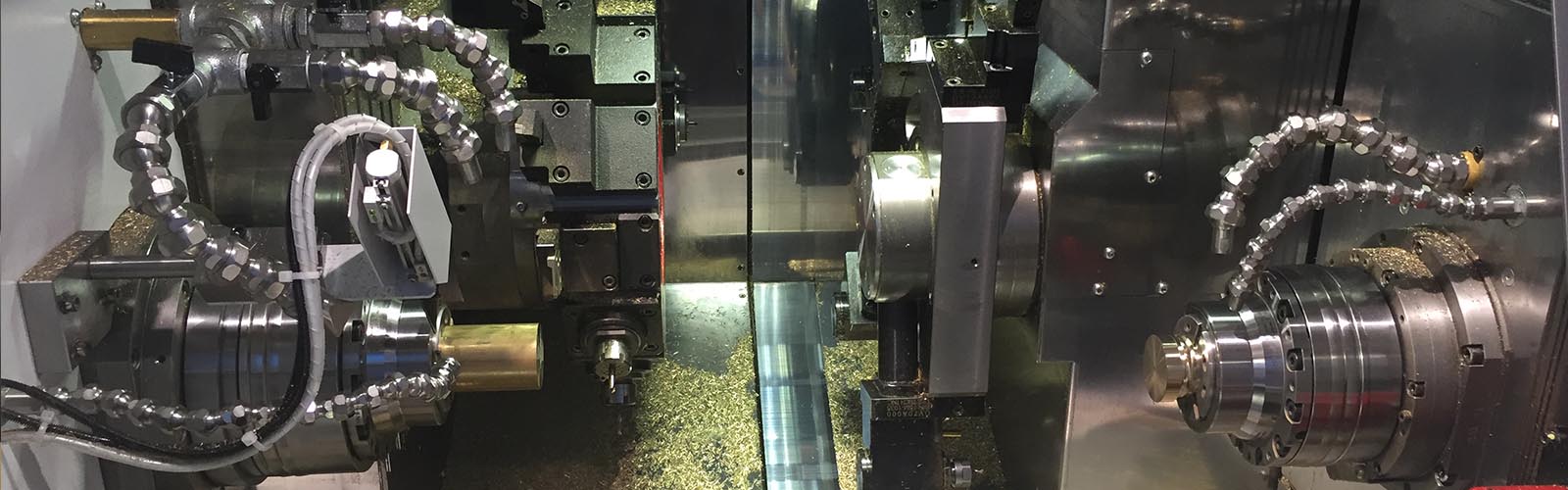

In high-speed CNC machining environments, reliable coolant delivery is non-negotiable for thermal management, tool longevity, and dimensional accuracy. Substandard coolant hoses risk catastrophic failures—leaks, pressure drops, or contamination—that disrupt production and compromise part quality. Honyo Prototype addresses this critical need through precision-engineered CNC coolant hose solutions, manufactured in-house using our advanced 3-, 4-, and 5-axis CNC machining capabilities.

Our ISO 9001-certified facility specializes in producing coolant hoses with exacting tolerances (±0.005mm), robust material compatibility (including stainless steel, PEEK, and reinforced thermoplastics), and rigorous pressure testing up to 10,000 PSI. Every component undergoes stringent validation for leak integrity, chemical resistance, and seamless integration with OEM spindle systems. By leveraging our end-to-end CNC machining expertise—from prototyping to volume production—we ensure consistent performance under extreme industrial conditions, minimizing downtime and extending tool life.

Accelerate your procurement cycle with Honyo’s Online Instant Quote platform. Upload CAD files for coolant hose assemblies or related components, and receive a detailed, factory-validated quotation within minutes—not days—including lead times, material certifications, and DFM feedback. This transparency empowers engineering teams to iterate faster while maintaining uncompromising quality standards.

For mission-critical coolant delivery systems engineered to perform, partner with Honyo Prototype where precision machining meets operational reliability.

Technical Capabilities

Technical specifications for CNC coolant hoses are critical in high-precision machining environments such as 3/4/5-axis milling and turning operations, where tight tolerances and consistent tool cooling are essential. These hoses must withstand high pressure, resist chemical degradation from coolants, and maintain flexibility under continuous motion. Below is a detailed specification table covering common materials and performance characteristics.

| Parameter | Aluminum | Steel (Stainless) | ABS (Acrylonitrile Butadiene Styrene) | Nylon (Polyamide) |

|---|---|---|---|---|

| Operating Pressure Range | 80 – 150 psi | 150 – 300 psi | 60 – 100 psi | 125 – 250 psi |

| Temperature Range | -20°C to +120°C | -40°C to +200°C | -10°C to +80°C | -40°C to +125°C |

| Chemical Resistance | Good (limited with chlorides) | Excellent (especially 316 SS) | Moderate (degrades with oils) | Excellent (resists oils, coolants) |

| Flexibility | Moderate (rigid, limited bending) | Low (rigid, used in fixed lines) | Moderate (semi-flexible) | High (excellent dynamic flexing) |

| Weight | Light | Heavy | Lightweight | Lightweight |

| Abrasion Resistance | Moderate | High | Low to Moderate | High |

| Common Applications | Fixed coolant delivery in 3-axis mills | Permanent installations in turning centers | Prototypes, low-cost setups | Multi-axis mills with moving nozzles |

| Durability in Dynamic Use | Poor (not suited for constant motion) | Poor (prone to fatigue if flexed) | Fair (limited cycle life) | Excellent (ideal for robotic arms) |

| EMI/RFI Shielding | Yes (conductive) | Yes (conductive) | No | No (unless static-dissipative grade) |

| Typical Inner Diameter | 6 mm, 8 mm, 10 mm, 1/4″, 3/8″, 1/2″ | 6 mm to 1/2″ | 1/4″ to 3/8″ | 6 mm to 1/2″ |

Notes:

Aluminum and steel hoses are typically used in semi-permanent or fixed coolant routing due to their rigidity. They are suitable for high-pressure delivery but not ideal for 5-axis machines requiring continuous articulation. ABS plastic hoses are cost-effective for prototyping or light-duty use but lack durability under high thermal or mechanical stress. Nylon hoses, particularly reinforced grades, are the preferred choice for dynamic CNC environments, offering superior flexibility, chemical resistance, and long service life in tight-tolerance machining where precise coolant targeting is required.

From CAD to Part: The Process

Honyo Prototype CNC Coolant Hose Manufacturing Process Overview

Honyo Prototype executes a streamlined, quality-focused workflow for CNC coolant hose production, integrating digital efficiency with rigorous engineering validation. This process ensures optimal manufacturability, cost control, and on-time delivery for precision fluid handling components.

CAD Upload and Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, or native SOLIDWORKS formats preferred) via our secure customer portal. Our system performs an automated integrity check for geometric completeness, unit consistency, and file compatibility. Critical parameters such as hose inner/outer diameters, bend radii, thread specifications (e.g., NPT, BSP), and port orientations are extracted for downstream analysis. Non-conforming files trigger an immediate notification requesting resubmission with specific correction guidance.

AI-Powered Quoting with Engineering Oversight

Uploaded geometry feeds into our proprietary AI quoting engine, which analyzes material requirements, machine time estimates, and secondary operations. The AI cross-references real-time data on material costs (e.g., polyurethane, nylon, or reinforced rubber), machine availability, and labor rates to generate a preliminary cost breakdown. Crucially, this output undergoes mandatory review by a Senior Manufacturing Engineer who validates the AI’s assumptions against geometric complexity, tolerance stack-ups (e.g., ±0.05mm positional tolerances), and historical production data. Clients receive a formal quote within 4 business hours, inclusive of lead time estimates and non-conformance risk flags.

Engineering-Led DFM Analysis

Upon quote acceptance, our DFM (Design for Manufacturability) team conducts a comprehensive review using specialized simulation tools. Key focus areas include:

Verification of minimum bend radii against material elongation limits to prevent kinking

Assessment of thread engagement depth and chamfer requirements for leak-proof assembly

Evaluation of wall thickness uniformity to withstand operational pressure (typically 10–30 bar)

Identification of potential CNC tool access conflicts in complex 3D hose paths

We provide actionable feedback within 24 hours, proposing optimized geometries (e.g., adjusted sweep paths for Swiss-type lathe compatibility) or material substitutions to reduce costs without compromising function. Client approval of DFM recommendations is required before proceeding.

Precision Production Execution

Approved designs enter production on our CNC Swiss lathes (Tornos Deco 2000/32) or multi-axis mills, depending on part complexity. Coolant hoses are typically machined from solid rod stock (e.g., PA66, PU) or fabricated via extrusion with CNC-machined end fittings. Each batch undergoes:

In-process CMM checks at critical stages (e.g., post-turning inner diameter verification)

Pressure testing at 150% of rated operational pressure per ISO 1402

Surface finish validation (Ra ≤ 1.6 μm) to minimize fluid turbulence

Thread gaging with Go/No-Go pins per ASME B1.20.1 standards

All processes adhere to ISO 9001:2015 controls, with full material traceability from certified suppliers.

Quality-Controlled Delivery

Final inspection includes dimensional reporting against all critical-to-function (CTF) features and functional flow testing. Parts are packaged in anti-static, moisture-resistant containers with serialized labels linking to digital quality records. Standard lead time is 7–10 business days from DFM sign-off, with expedited options available. Delivery includes:

Comprehensive inspection report (including CMM data plots)

Material certification (e.g., RoHS, REACH compliance)

Pressure test validation documentation

Real-time logistics tracking via client portal integration

We maintain a 99.2% on-time delivery rate for coolant hose projects, with post-shipment technical support for integration validation.

Start Your Project

Looking for high-quality CNC coolant hose solutions? Contact Susan Leo at [email protected] to discuss your requirements. Our manufacturing facility is based in Shenzhen, ensuring efficient production and reliable delivery for both prototypes and volume orders. Let Honyo Prototype support your precision engineering needs with durable, custom-fit coolant hose components.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.