Guide Contents

Project Insight: Cnc Computer Program

The Critical Role of Speed and Precision in Modern Product Development

In today’s hyper-competitive hardware landscape, innovation moves at the speed of iteration. Delays in prototyping or dimensional inaccuracies can stall product development, inflate costs, and miss critical market windows.

Precision isn’t optional—it’s foundational. Functional prototypes must meet exacting tolerances to validate performance, while end-use parts demand reliability under real-world conditions.

The right manufacturing partner must eliminate bottlenecks without sacrificing accuracy—turning design intent into tangible results, faster.

Honyo Prototype: Precision Meets Velocity

Online Instant Quote

Get a transparent, accurate cost estimate in seconds—not days. Our platform analyzes your CAD file in real-time, factoring in geometry, materials, and tolerances to deliver a no-obligation quote with zero hidden fees.

AI-Powered Programming

Our proprietary AI optimizes toolpaths, minimizes machine idle time, and ensures error-free CNC programs. This slashes programming time by 40% while maintaining ±0.01mm tolerances across 3/4/5-axis systems—ensuring first-time-right precision for functional prototypes and end-use parts.

Fast Turnaround

From quote to delivery, our integrated digital workflow and Shenzhen-based production hub compress lead times to 3-5 days. Test, validate, and iterate at the speed of innovation—no compromises on quality.

Honyo Prototype: Where cutting-edge software meets precision engineering to accelerate your vision from concept to reality.

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

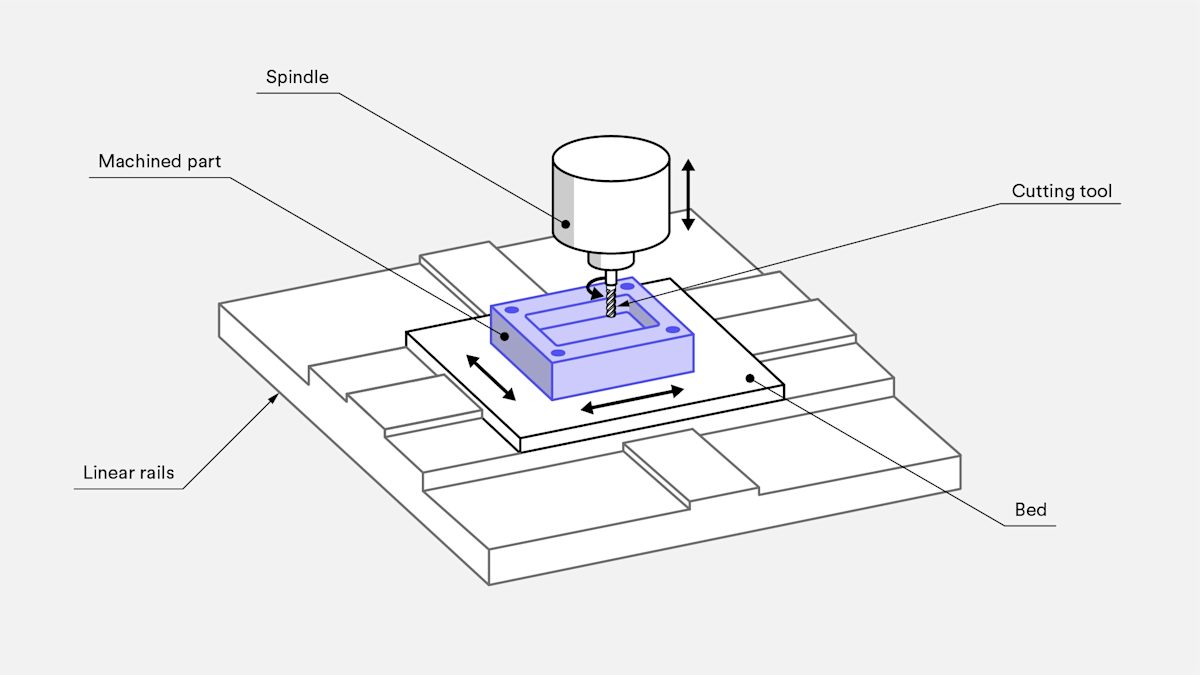

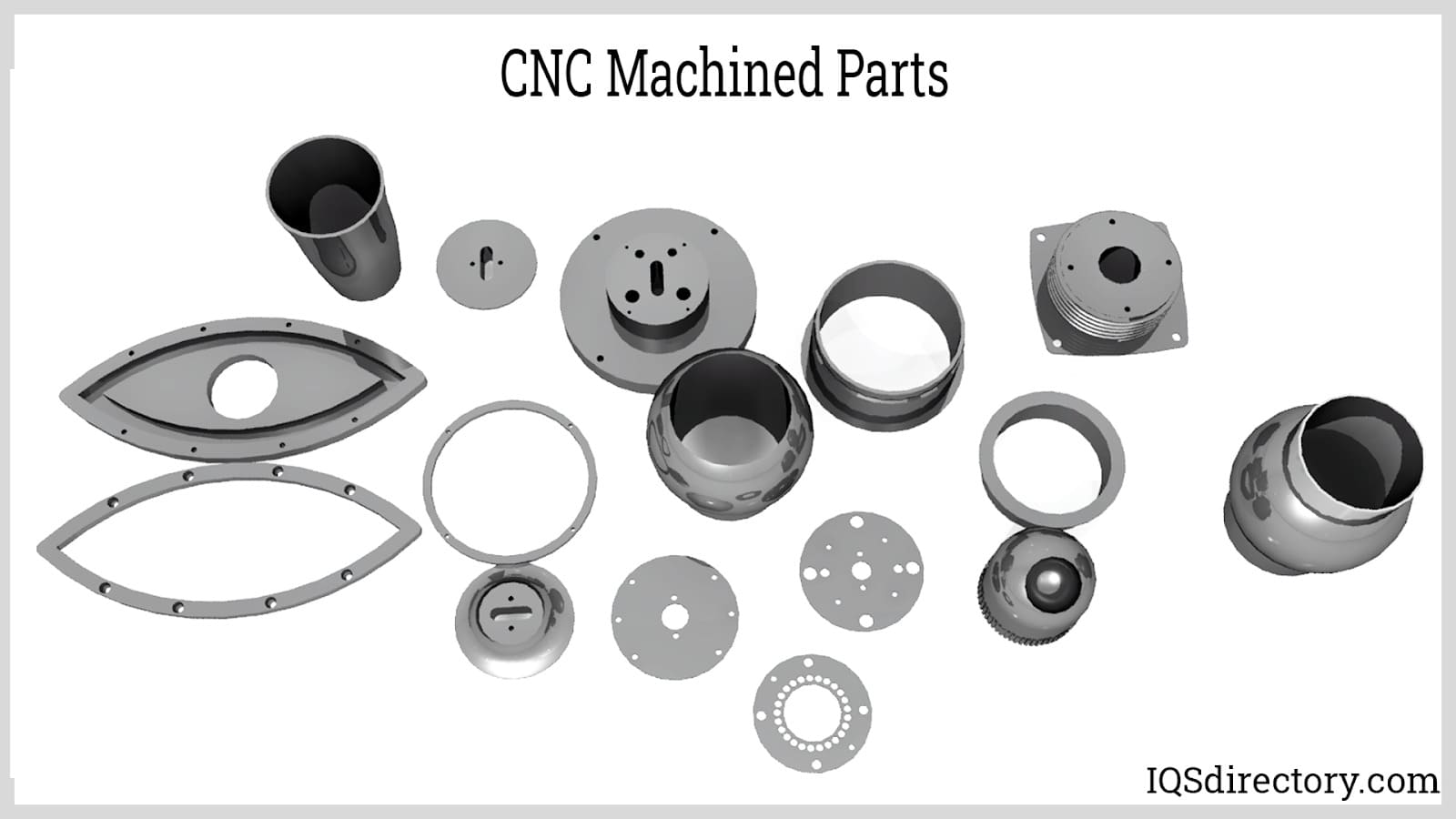

Precision Multi-Axis Machining

3/4/5-axis CNC capabilities for complex geometries and intricate designs

Industry-leading tolerances of ±0.01mm ensuring functional accuracy for prototypes and end-use components

Scalable Production Solutions

Seamless scaling from single prototypes to 10,000+ production parts

Zero minimum order quantities – ideal for startups validating designs or enterprises scaling volume

AI-Optimized Manufacturing Workflow

Instant online quotes with real-time cost breakdowns via our AI-powered platform

Automated DFM (Design for Manufacturing) analysis to optimize designs and eliminate production bottlenecks before machining begins

24–72 hour prototype turnaround with expedited options for critical projects

Rigorous Quality Control

ISO 9001-certified processes with in-process and final inspections at every stage

Advanced metrology tools (CMM, optical comparators) verifying dimensional accuracy and surface integrity

At Honyo Prototype, we don’t just machine parts – we engineer solutions. Our AI-driven platform and precision capabilities ensure your innovation moves from concept to reality faster, with zero compromise on quality.

Materials & Surface Finishes

Material Options & Finishes

At Honyo Prototype, we combine advanced CNC capabilities with intelligent material selection to ensure your parts meet exacting precision standards (+/- 0.01mm). Our AI-powered platform streamlines material and finish decisions—delivering optimized solutions for functional prototypes and end-use parts in record time.

Key Material Options

Aluminum 6061: Exceptional machinability, corrosion resistance, and strength-to-weight ratio. Ideal for aerospace, automotive, and structural prototypes where precision and weight savings matter.

Aluminum 7075: Highest-strength aluminum alloy for high-stress applications (e.g., military components, racing parts). Maintains tight tolerances under extreme loads.

Stainless Steel 304: Versatile, corrosion-resistant, and FDA-compliant. Perfect for medical devices, food processing equipment, and general industrial parts.

Stainless Steel 316: Superior chloride resistance for marine, chemical, and surgical environments. Critical for parts exposed to harsh conditions.

Brass: Excellent electrical conductivity and machinability. Best for electrical connectors, valves, and decorative components requiring fine details.

PEEK: High-performance polymer with thermal/chemical resistance. Used in aerospace, medical implants, and semiconductor manufacturing for ultra-precision needs.

Surface Finish Options

Anodizing: Enhances durability and aesthetics for aluminum. Choose clear, black, or custom colors for wear resistance and visual appeal.

Powder Coating: Durable, UV-resistant finish for outdoor applications. Ideal for enclosures and structural components needing long-term protection.

Polishing: Mirror-smooth surfaces for optical clarity or premium aesthetics. Common in medical devices and luxury consumer products.

Passivation: Removes surface contaminants from stainless steel without altering dimensions—essential for medical and food-grade parts.

Painting: Custom color matching for prototypes requiring visual accuracy or branding. Fast turnaround for early-stage testing.

How to Optimize Material Selection for Your CNC Program

Choosing the right material isn’t just about properties—it’s about aligning with your project’s unique constraints. Honyo’s AI-powered platform automates this process for unmatched efficiency:

✅ Real-time cost analysis: Upload your CAD file to instantly calculate material costs, machining time, and finish options—no manual estimates.

✅ Performance-driven recommendations: Input your application environment (e.g., temperature, load, exposure), and our AI suggests ISO-certified materials tailored to your needs.

✅ Fast-turnaround validation: Receive a material optimization report within minutes—no back-and-forth, no delays.

Ready to optimize your design?

Get an instant, accurate quote in seconds—our platform cross-references material availability, machining complexity, and finish requirements to deliver the most cost-effective solution for your precision needs.

Powered by Honyo Prototype (Shenzhen, China) | Founded by Susan Leo

From Quote to Part: Our Process

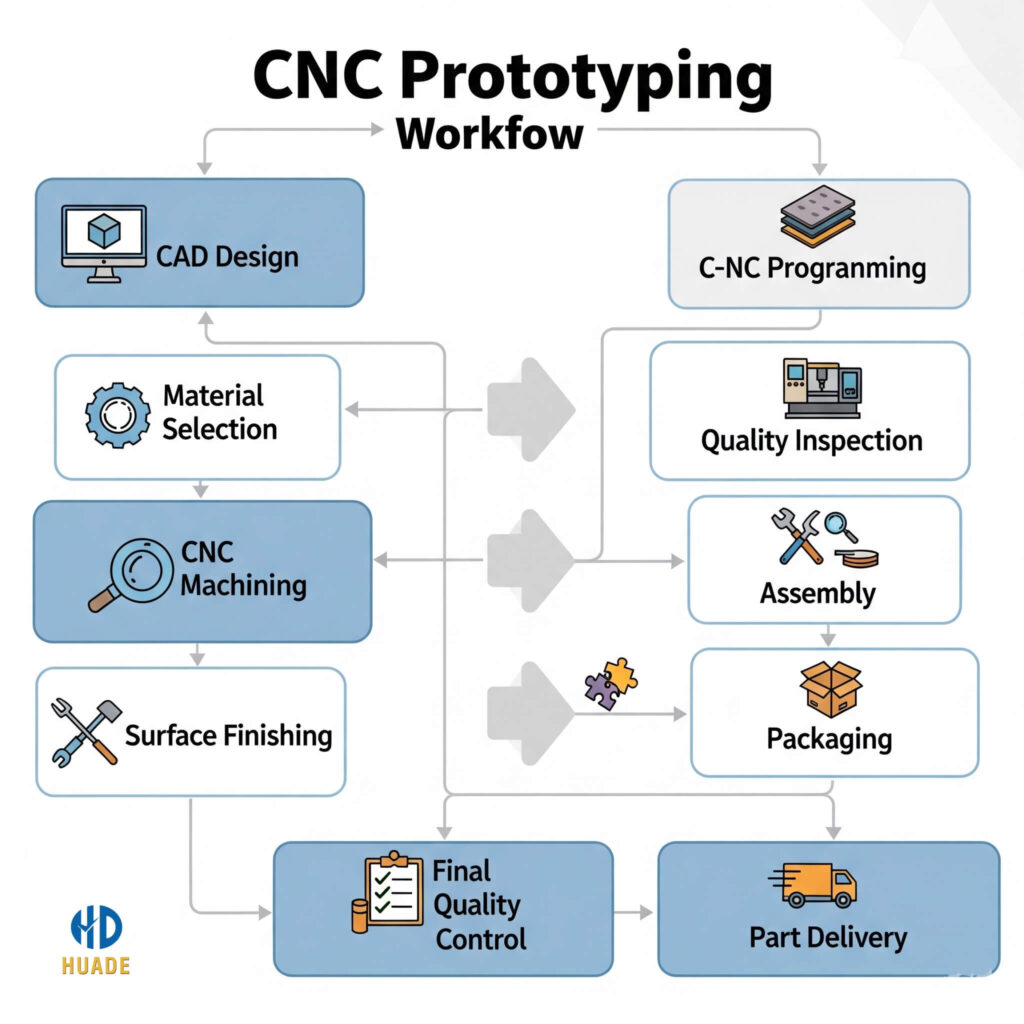

How It Works: From CAD to Precision Part in Record Time

Honyo Prototype’s AI-driven platform eliminates traditional manufacturing delays, delivering transparent pricing and precision-engineered parts in record time. Here’s the streamlined process:

Step 1: Upload CAD File – Instant Digital Handoff

Submit your design via our web platform in seconds – supports STEP, STL, IGES, and more

AI-driven validation checks file integrity and manufacturability upfront

Eliminate manual review delays with automated compatibility checks

Step 2: AI-Powered Instant Quote – Transparent Pricing in Real Time

Get an accurate cost breakdown within 60 seconds – no waiting, no surprises

Dynamic pricing adjusts for geometry complexity, material, quantity, and tolerances (±0.01mm precision)

See exactly what you’re paying for: machining time, setup, shipping, and quality control

Step 3: Automated DFM Analysis – Optimize Before Production

Proactive feedback identifies design improvements to reduce costs and improve functionality

Receive actionable suggestions for wall thickness, tolerances, and material selection

Collaborate seamlessly with our engineering team via integrated feedback loops

Step 4: Precision Manufacturing & Rapid Delivery

Shenzhen-based facility with 3/4/5-axis CNC machines for micron-level accuracy

Dedicated production tracking with real-time progress updates

Prototypes delivered in as little as 24 hours; production runs optimized for speed and precision

No guesswork. No hidden fees. Just engineering excellence, delivered on your timeline.

Start Your Project with Honyo

Start Your Project with Honyo: Precision CNC Machining, Simplified

AI-Powered Instant Quote Engine

Upload your CAD file in seconds—our AI-driven platform delivers transparent, accurate quotes in real-time, eliminating guesswork and delays.

Optimized pricing based on geometry, material, and tolerances—no hidden fees, just clear cost breakdowns tailored to your project’s complexity.

Engineered for Precision & Speed

Achieve ±0.01mm tolerances with 3/4/5-axis machining for functional prototypes and end-use parts—perfect for high-stakes hardware innovation.

24-hour quotes, 3–5 day prototype turnaround, and scalable production for any volume—without compromising quality.

Seamless workflow from design validation to post-processing, maximizing efficiency while minimizing lead times.

Founder-Led Expertise You Can Trust

Led by Susan Leo, our team combines 15+ years of CNC innovation with a startup-first mindset—solving complex challenges so you can focus on scaling.

Collaborative partnerships: We optimize designs for manufacturability, reduce costs, and accelerate time-to-market for your next breakthrough.

Ready to Bring Your Design to Life?

📧 Email: [email protected]

📞 Phone: +86 139 2843 8620

🏭 Visit: State-of-the-art facilities in Shenzhen & Dongguan for hands-on collaboration

→ Get Your Instant Quote Now

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.