Contents

Manufacturing Insight: Cnc Clamping Solutions

Precision Clamping Solutions: The Foundation of Reliable CNC Machining at Honyo Prototype

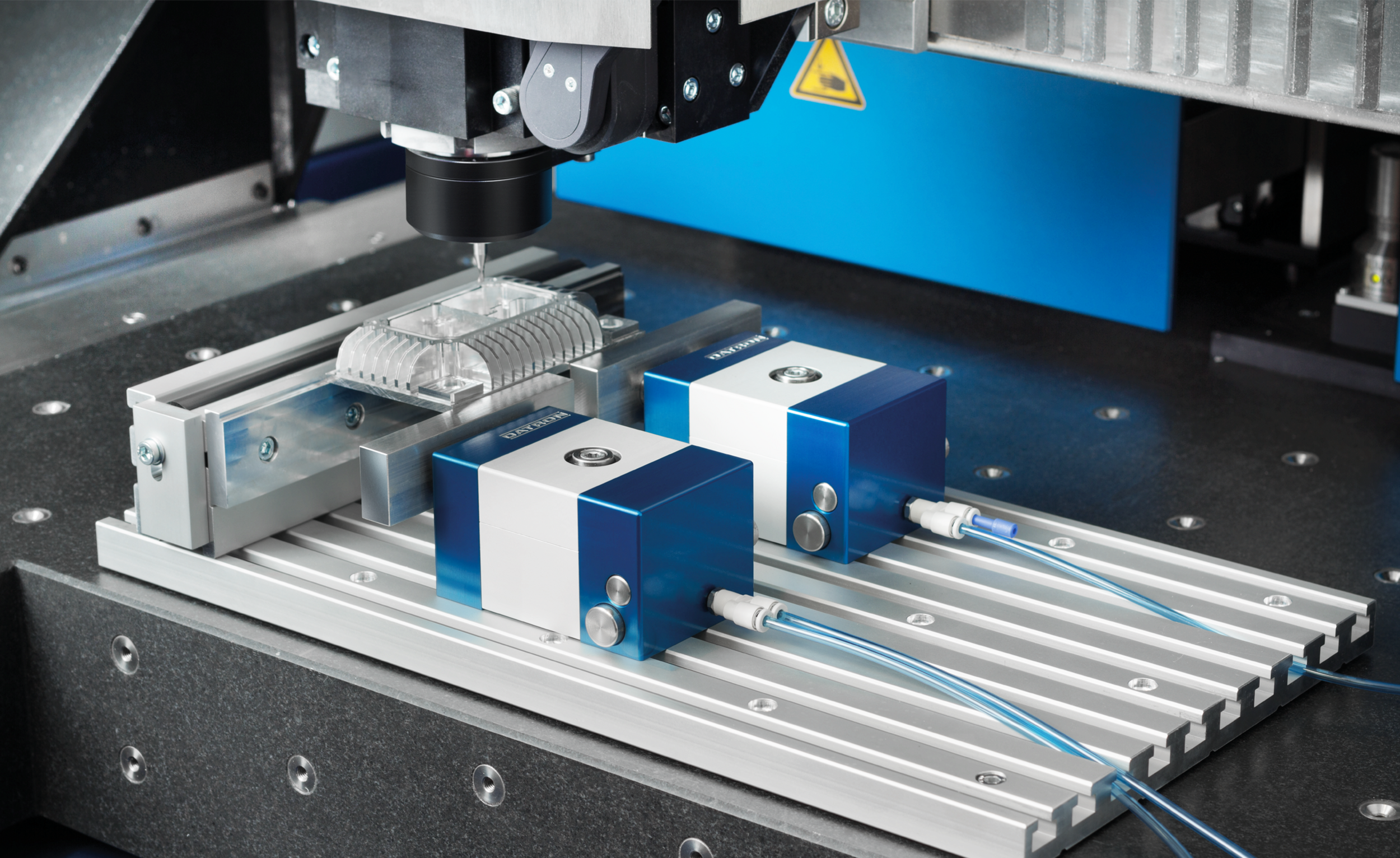

Achieving micron-level accuracy and repeatability in CNC machining demands more than advanced spindle technology or high-grade tooling—it starts with intelligent workholding. Suboptimal clamping solutions introduce critical errors: part shift during high-speed operations, inconsistent datum referencing, and extended non-cutting time due to complex fixture setups. These issues directly impact yield rates, geometric tolerances, and time-to-prototype, often turning minor design iterations into costly production delays.

At Honyo Prototype, our CNC Machining services integrate precision clamping solutions as a core engineering discipline, not an afterthought. Our in-house fixture design team develops application-specific workholding—from modular vise systems and custom soft jaws to vacuum tables and tombstone setups—that ensures rigid part immobilization while maximizing machine accessibility. This approach guarantees consistent ±0.005mm tolerances across materials ranging from aerospace-grade aluminum alloys to hardened tool steels, directly reducing scrap rates by up to 30% compared to generic fixturing methods.

We recognize that rapid prototyping hinges on speed at every workflow stage. That’s why Honyo Prototype offers an Online Instant Quote platform engineered for manufacturing professionals. Upload your STEP or IGES file, specify material and quantity, and receive a detailed machining assessment—including recommended clamping methodology and lead time—within minutes. No manual back-and-forth; just actionable data to accelerate your design-to-part timeline.

Partner with Honyo Prototype where clamping intelligence drives machining excellence, and quoting friction vanishes. Your next precision component starts with a fixture designed for zero compromise.

Technical Capabilities

CNC Clamping Solutions – Technical Specifications for 3/4/5-Axis Milling and Turning Applications

CNC clamping solutions are engineered to provide secure workholding during high-precision machining operations. For 3/4/5-axis milling and turning applications requiring tight tolerances (±0.005 mm to ±0.025 mm), clamping systems must deliver high rigidity, repeatable positioning, thermal stability, and compatibility with a variety of workpiece materials including aluminum, steel, ABS, and nylon.

The table below outlines key technical specifications and performance characteristics of advanced CNC clamping systems tailored for high-accuracy manufacturing environments.

| Feature | Specification | Application Relevance |

|---|---|---|

| Clamping Force Range | 5 kN to 30 kN (adjustable) | Ensures secure fixation of materials with varying mechanical strength (e.g., soft aluminum vs. hardened steel) without deformation |

| Repeatability | ±0.002 mm | Critical for tight tolerance machining and multi-setup operations in 4/5-axis workflows |

| Maximum Spindle Speed Compatibility | Up to 30,000 RPM | Supports high-speed milling and complex contouring with minimal vibration |

| Material Compatibility | Aluminum (6061, 7075), Steel (1018, 4140, Stainless), ABS, Nylon (PA6, PA66) | Allows use across diverse prototyping and production applications; non-marring jaws available for plastics |

| Jaw Options | Hardened steel, soft jaws (custom machinable), polymer-coated, zero-point modular | Enables material-specific gripping: soft jaws for precision aluminum, polymer faces for ABS/nylon to prevent surface damage |

| T-slot/Table Interface | ISO 1932, DIN 6499, or HSK variants | Ensures compatibility with standard CNC machine tables and pallet systems |

| Thermal Stability | Operates from 0°C to 80°C without drift | Maintains accuracy during extended machining cycles and coolant exposure |

| Corrosion Resistance | Anodized aluminum housings, stainless steel fasteners | Suitable for wet machining environments and prolonged use |

| Integration Capability | Compatible with robotic loading, zero-point systems, and modular fixturing | Enables automation and rapid setup changes in 3/4/5-axis cells |

| Accuracy Retention | < 0.005 mm deviation over 10,000 cycles | Ensures long-term reliability for high-volume precision turning and milling |

These clamping systems are designed to minimize workpiece deflection and vibration, directly contributing to achieving tight geometric tolerances (e.g., flatness < 0.01 mm, positional accuracy < 0.015 mm). For non-metallic materials like ABS and nylon, low-pressure clamping modes and custom-fitted support fixtures prevent deformation while maintaining machining stability. In multi-axis operations, compact clamp profiles allow for improved tool access and reduced collision risk.

From CAD to Part: The Process

Honyo Prototype employs a rigorously optimized workflow for CNC clamping solutions, designed to minimize lead times while ensuring manufacturability and precision. This integrated process leverages automation and engineering expertise at critical control points.

CAD Upload and Initial Processing

Clients initiate the process by uploading native or neutral format CAD files (STEP, IGES, Parasolid) via our secure portal. Our system performs immediate file validation, checking for geometric integrity, unit consistency, and feature recognition specific to fixturing requirements. This step ensures the design data is suitable for downstream automated analysis without manual intervention delays.

AI-Powered Quoting Engine

Validated CAD data feeds directly into our proprietary AI quoting system. This engine analyzes part geometry, material specifications, tolerance stack-ups, and required clamping forces to generate an accurate, detailed quote within hours. The AI cross-references historical production data from over 15,000 completed clamping solution projects, factoring in machine time, material costs, and complexity metrics such as undercuts or thin-wall sections. Clients receive a transparent cost breakdown with clear rationale for pricing variables.

Dual-Layer DFM Analysis

Following quote acceptance, designs undergo comprehensive Design for Manufacturability review in two distinct phases. First, an automated DFM scan identifies potential issues like non-standard tapped holes, inadequate fixture mounting surfaces, or features requiring complex multi-axis setups. Second, a Senior Manufacturing Engineer conducts a manual review focusing on clamping strategy optimization, stress distribution analysis, and material selection validation against application requirements (e.g., vacuum compatibility, thermal stability). Clients receive a formal DFM report with actionable recommendations before production commitment.

Modular Fixture Production

Approved designs move to production using our standardized modular fixture system. Key advantages include:

Pre-qualified base plates with grid patterns for rapid component mounting

Reusable precision locating elements (dowels, pins, v-blocks)

Custom-machined interface components only where absolutely necessary

This methodology reduces setup time by 40-60% compared to fully custom fixtures. All clamping components undergo in-process CMM verification at critical stages, with full GD&T validation against the original CAD model upon completion. Material certifications and heat treatment documentation are maintained for full traceability.

Delivery and Integration Support

Completed clamping solutions ship with comprehensive documentation including:

As-built inspection reports with dimensional verification data

Fixture setup instructions and torque specifications

3D assembly models for digital twin integration

Recommended maintenance schedules

We provide remote setup assistance via AR-guided tools and offer onsite technician support for complex integrations, ensuring seamless deployment on the client’s CNC equipment.

Process Efficiency Comparison

The following table demonstrates quantifiable improvements versus traditional fixture manufacturing approaches:

| Process Stage | Traditional Approach | Honyo Prototype Method | Improvement |

|---|---|---|---|

| Quote Generation | 3-5 business days | < 24 hours | 80% faster |

| DFM Iterations | 2-3 rounds | 1 round (95% first-pass yield) | 60% fewer iterations |

| Production Setup | 8-12 hours | 3-5 hours | 55% reduction |

| First Article Lead Time | 15-20 days | 7-10 days | 45% acceleration |

This structured workflow eliminates common prototyping bottlenecks through strategic automation and engineering oversight. The result is certified clamping solutions delivered with repeatable precision, directly supporting clients’ production ramp-up schedules while reducing non-recurring engineering costs. Our process is certified to ISO 9001:2015 with specific controls for fixture manufacturing traceability and performance validation.

Start Your Project

For reliable and precision-engineered CNC clamping solutions, contact Susan Leo at [email protected]. Our manufacturing facility is based in Shenzhen, ensuring high-quality production and efficient turnaround for your custom fixturing needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.