Introduction: Navigating the Global Market for cnc camshaft

In today’s competitive landscape, sourcing CNC camshafts can present significant challenges for international B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe. With an array of options available, from high-performance custom camshafts to standard profiles, it’s crucial for buyers to navigate this complex market effectively. This guide serves as an essential resource for understanding the diverse types of CNC camshafts, their applications across various industries, and the nuances of supplier vetting to ensure quality and reliability.

We delve into key factors influencing purchasing decisions, such as cost considerations, material specifications, and lead times, enabling businesses to make informed choices that align with their operational needs. By offering insights into the latest manufacturing technologies and trends, this comprehensive guide equips B2B buyers with the knowledge necessary to enhance engine performance and efficiency.

Whether you’re in the automotive sector looking for performance upgrades or in need of custom solutions for specialized applications, this guide empowers you to streamline your sourcing process, minimize risks, and ultimately secure the best CNC camshaft solutions for your business needs.

Understanding cnc camshaft Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hydraulic Flat Tappet | Designed for smooth operation, adjustable valve lift | Street performance, daily drivers | Pros: Quiet operation, good for everyday use. Cons: Limited performance in high RPM applications. |

| Solid Roller | High rigidity and less friction, designed for high RPMs | Racing, high-performance applications | Pros: Excellent power delivery, ideal for racing. Cons: Requires precise setup and maintenance. |

| Custom Camshafts | Tailored profiles for specific engine needs | Specialized engines, prototypes | Pros: Optimized for unique applications. Cons: Longer lead times, higher costs. |

| Billet Camshafts | Made from solid metal, superior strength and performance | High-stress applications, motorsports | Pros: Enhanced durability, supports aggressive profiles. Cons: Higher manufacturing costs. |

| SADI Camshafts | Selective Austempered Ductile Iron, good performance | Standard applications, moderate performance | Pros: Cost-effective for standard builds. Cons: Less performance compared to billet options. |

What are the Characteristics of Hydraulic Flat Tappet Camshafts?

Hydraulic flat tappet camshafts are characterized by their ability to adjust valve lift automatically, providing smoother operation and reduced noise levels. They are commonly used in street performance and daily driver applications due to their reliability and ease of installation. B2B buyers should consider hydraulic flat tappets for applications where comfort and everyday usability are priorities, though they may not deliver the high RPM performance needed in competitive racing environments.

How Do Solid Roller Camshafts Enhance Performance?

Solid roller camshafts are engineered for high rigidity, resulting in less friction and better performance at elevated RPMs. They are particularly suited for racing and high-performance applications where power delivery is critical. Buyers should note that while solid rollers offer exceptional performance, they require precise setup and regular maintenance to avoid issues like valve float. Thus, they are best suited for businesses focused on competitive motorsports.

Why Choose Custom Camshafts for Specialized Needs?

Custom camshafts provide tailored profiles that meet specific engine requirements, making them ideal for specialized engines or prototypes. These camshafts can be optimized for various parameters like lift, duration, and firing order. B2B purchasers should weigh the benefits of custom camshafts against the potential for longer lead times and increased costs, particularly for unique or high-performance applications where standard options may not suffice.

What Advantages Do Billet Camshafts Offer?

Billet camshafts are manufactured from solid metal, providing superior strength and performance characteristics. They are particularly beneficial in high-stress applications like motorsports, where durability and the ability to handle aggressive profiles are crucial. Buyers should consider the higher manufacturing costs of billet camshafts, but the investment often pays off in terms of longevity and performance enhancements.

When to Use SADI Camshafts?

Selective Austempered Ductile Iron (SADI) camshafts are a cost-effective solution for standard applications, offering moderate performance levels. They are suitable for businesses looking for reliable camshaft options without the premium price tag of billet alternatives. However, B2B buyers should recognize that while SADI camshafts provide decent performance, they may not compete with the capabilities of more advanced materials in high-performance scenarios.

Key Industrial Applications of cnc camshaft

| Industry/Sector | Specific Application of CNC Camshaft | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Custom performance camshafts for racing engines | Enhanced engine performance and reliability | Precision manufacturing capabilities, lead time, and material quality |

| Marine | Camshafts for high-performance marine engines | Improved fuel efficiency and power output | Corrosion resistance, customization options, and compliance with marine standards |

| Aerospace | Camshafts for aircraft engines | High reliability and safety in critical applications | Certification standards, material specifications, and weight considerations |

| Industrial Machinery | Camshafts for heavy machinery and generators | Increased efficiency and reduced downtime | Durability, load capacity, and compatibility with existing systems |

| Rail Transport | Camshafts for locomotives and rail engines | Enhanced performance and lower emissions | Customization for specific engine types, sourcing of high-strength materials, and compliance with safety regulations |

How Are CNC Camshafts Used in the Automotive Industry?

In the automotive sector, CNC camshafts are integral for custom performance applications, particularly in racing engines. These camshafts enhance the engine’s power and torque output, allowing for better acceleration and overall performance. For international buyers, particularly in regions like Brazil and Nigeria, sourcing high-quality camshafts that meet local regulations and performance standards is critical. Buyers should consider the precision of manufacturing processes, the availability of various profiles, and the ability to customize specifications such as lift and duration to suit specific performance needs.

What Role Do CNC Camshafts Play in Marine Applications?

CNC camshafts are crucial for high-performance marine engines, where they contribute to improved fuel efficiency and power output. In this industry, camshafts must withstand harsh marine environments, necessitating corrosion-resistant materials and precise engineering. For buyers in South America and the Middle East, it’s important to source camshafts that comply with environmental regulations while offering robust performance. Considerations should include the supplier’s experience in marine applications and their ability to provide custom solutions to meet specific engine requirements.

Why Are CNC Camshafts Important in Aerospace?

In the aerospace sector, CNC camshafts are used in aircraft engines where reliability and safety are paramount. These camshafts must meet stringent certification standards and are often made from lightweight, high-strength materials to enhance performance without compromising safety. International buyers in this field should focus on suppliers with proven experience in aerospace applications and the capability to produce camshafts that adhere to rigorous quality and safety regulations. The sourcing process should prioritize material specifications and the supplier’s certification status.

How Do CNC Camshafts Benefit Industrial Machinery?

For industrial machinery, CNC camshafts are designed to enhance the efficiency and performance of heavy machinery and generators. These camshafts help in reducing downtime by providing robust performance under heavy loads. Buyers from Africa and other emerging markets should seek suppliers who can deliver durable camshafts capable of withstanding high-stress environments. Key considerations include the material used, load capacity, and compatibility with existing machinery systems to ensure seamless integration and optimal performance.

In What Ways Are CNC Camshafts Utilized in Rail Transport?

In rail transport, CNC camshafts are essential for locomotives and rail engines, providing enhanced performance and lower emissions. These camshafts are designed to meet specific engine configurations and must comply with safety regulations. For buyers in Europe and the Middle East, sourcing camshafts that offer customization for various engine types is crucial. Suppliers should be evaluated based on their ability to provide high-strength materials and ensure compliance with industry-specific standards, ultimately leading to improved operational efficiency in rail transport systems.

3 Common User Pain Points for ‘cnc camshaft’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right CNC Camshaft Profile

The Problem: B2B buyers often face challenges in choosing the appropriate camshaft profile for their specific applications. With a wide variety of camshaft profiles available, it can be overwhelming to determine which one will deliver the desired performance characteristics. Buyers may struggle with technical jargon, differences in lift and duration, or how these factors influence engine performance. Additionally, the stakes are high; selecting an unsuitable camshaft can lead to inefficiencies, increased wear, or even engine failure, impacting both production schedules and profitability.

The Solution: To alleviate this issue, buyers should engage in thorough research and consultation with manufacturers or suppliers who specialize in CNC camshafts. Establishing a clear understanding of the engine specifications and the intended use (e.g., street performance versus racing) is crucial. Buyers can utilize online configurators or consult with technical experts to customize camshaft profiles based on their specific needs, taking into account lift, duration, and lobe separation. Suppliers should provide detailed product specifications and performance data to guide decision-making. Furthermore, buyers can benefit from requesting samples or prototypes to test compatibility with their engines before committing to larger orders.

Scenario 2: Long Lead Times and Delivery Challenges

The Problem: International B2B buyers often encounter long lead times and shipping delays when sourcing CNC camshafts, particularly when dealing with custom orders. These delays can disrupt production schedules and lead to increased costs, affecting the overall efficiency of operations. Additionally, the logistics of international shipping may introduce complications such as tariffs, customs clearance, and unexpected additional charges, further complicating the procurement process.

The Solution: To mitigate lead time issues, buyers should establish relationships with reputable suppliers who have a proven track record of timely deliveries and transparent communication regarding shipping processes. It’s advisable to inquire about the supplier’s inventory levels and their ability to expedite orders, especially for custom profiles. Buyers can also explore regional suppliers to reduce shipping times and costs. Utilizing technology, such as tracking software, can help buyers monitor their orders in real-time, allowing for better planning and resource allocation. Lastly, maintaining an open line of communication with suppliers can help address potential delays proactively, allowing for alternative solutions to be discussed.

Scenario 3: Ensuring Quality and Performance Consistency

The Problem: Quality assurance is a significant concern for B2B buyers when sourcing CNC camshafts. Variations in manufacturing processes can lead to inconsistencies in performance, which can undermine engine reliability and longevity. Buyers may worry about the durability of the materials used, the precision of the CNC machining process, and whether the product meets industry standards. Poor-quality camshafts can result in costly recalls or repairs, damaging a company’s reputation and financial standing.

The Solution: To ensure high-quality standards, buyers should prioritize sourcing CNC camshafts from manufacturers who adhere to strict quality control measures and industry certifications. Requesting detailed documentation regarding the manufacturing process, material specifications, and testing results is essential. Buyers should also seek suppliers that offer warranties or guarantees on their products, as this demonstrates confidence in their quality. Engaging in regular communication with the supplier and providing feedback can foster a collaborative relationship that encourages continuous improvement. Finally, establishing a rigorous inspection protocol upon receiving shipments can help identify any discrepancies before the parts are put into use, thereby safeguarding operational integrity.

Strategic Material Selection Guide for cnc camshaft

What Are the Key Properties of Common Materials Used for CNC Camshafts?

When selecting materials for CNC camshafts, several options are commonly considered, each with unique properties that influence performance, durability, and cost. Understanding these materials is crucial for international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe.

How Does Steel Perform as a Material for CNC Camshafts?

Steel, particularly high-carbon and alloy steel, is a prevalent choice for CNC camshafts due to its exceptional strength and wear resistance. It can withstand high temperatures and pressures, making it suitable for performance applications.

Pros: Steel camshafts offer high durability and can be manufactured with precision to meet specific performance requirements. They are often available at a lower cost compared to other materials, making them an attractive option for various applications.

Cons: While steel is robust, it can be prone to corrosion if not properly treated or coated. Additionally, the manufacturing process can be complex, requiring advanced machining capabilities.

Impact on Application: Steel camshafts are compatible with a wide range of engine types, including high-performance and racing engines. However, buyers should ensure compliance with international standards such as ASTM for quality assurance.

What Advantages Does Aluminum Offer for CNC Camshafts?

Aluminum is another material used in CNC camshaft production, particularly in applications where weight reduction is critical. Aluminum camshafts are lighter than their steel counterparts, which can improve engine efficiency and performance.

Pros: The lightweight nature of aluminum enhances engine responsiveness and fuel efficiency. It also exhibits good corrosion resistance, which is beneficial in humid or coastal environments.

Cons: Aluminum camshafts may not provide the same level of strength and durability as steel, particularly under extreme conditions. They can also be more expensive to produce due to the need for specialized machining techniques.

Impact on Application: Aluminum camshafts are often used in high-performance and racing applications where weight savings are paramount. Buyers should consider regional preferences and standards, as aluminum may not be as widely accepted in all markets.

How Do Billet Camshafts Compare in Performance?

Billet camshafts, made from solid blocks of material, typically steel or aluminum, offer superior performance characteristics. These camshafts are precision-engineered to achieve specific profiles that enhance engine performance.

Pros: Billet camshafts provide excellent rigidity and can be customized to meet exact specifications. Their manufacturing process allows for intricate designs that can optimize engine performance.

Cons: The cost of billet camshafts is generally higher due to the material and machining processes involved. Additionally, they may require longer lead times for production.

Impact on Application: Billet camshafts are ideal for high-performance applications, particularly in motorsports. Buyers should ensure that their suppliers can meet the necessary certifications and standards, especially in regions with strict regulations.

What Role Does Ductile Iron Play in CNC Camshaft Manufacturing?

Ductile iron, known for its strength and toughness, is sometimes used for CNC camshafts, particularly in applications requiring high durability.

Pros: Ductile iron offers excellent wear resistance and can withstand high stress levels. It is also more cost-effective than some high-performance materials.

Cons: While ductile iron is durable, it may not provide the same performance benefits as steel or aluminum in high-speed applications. Additionally, its weight can be a disadvantage in performance-oriented designs.

Impact on Application: Ductile iron camshafts are suitable for a variety of engine types but may not be the preferred choice for racing applications. Buyers should consider the specific requirements of their engines and regional material preferences.

Summary Table of Material Selection for CNC Camshafts

| Material | Typical Use Case for CNC Camshaft | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | High-performance engines | High durability and wear resistance | Prone to corrosion without treatment | Low |

| Aluminum | Racing and performance applications | Lightweight, good corrosion resistance | Lower strength compared to steel | Medium |

| Billet | Custom high-performance engines | Superior rigidity and customization | Higher cost and longer lead times | High |

| Ductile Iron | General-purpose engines | Excellent wear resistance | Heavier, less suitable for high-speed | Low |

This strategic material selection guide provides a comprehensive overview for B2B buyers considering CNC camshafts, emphasizing the importance of material properties, application suitability, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc camshaft

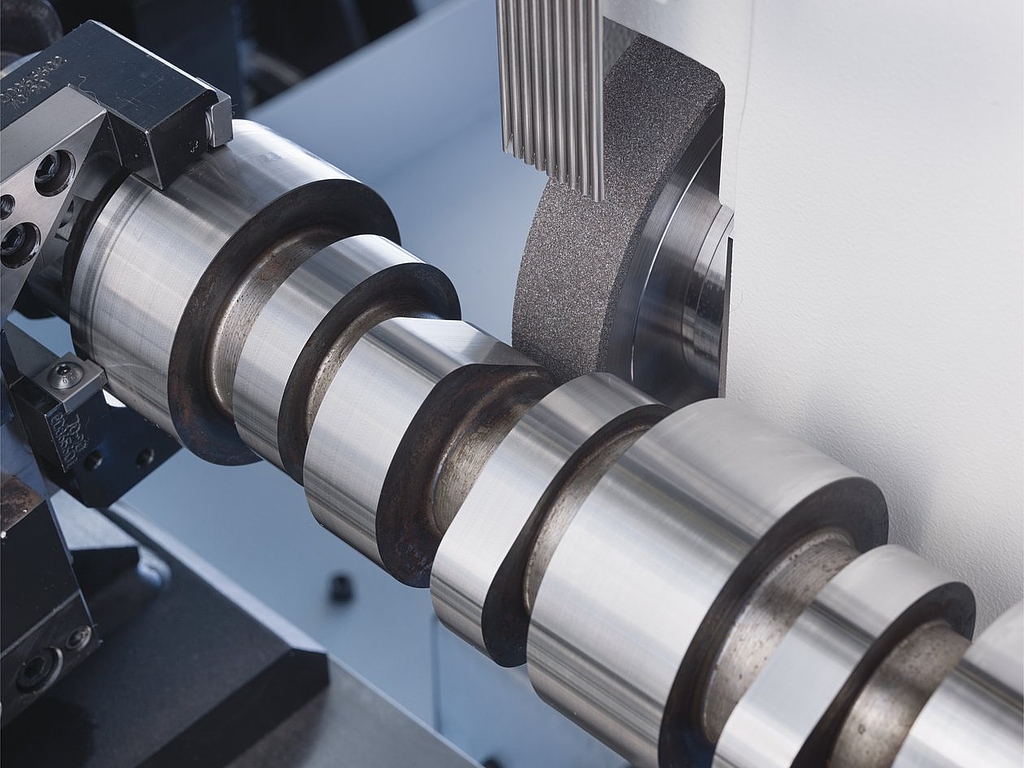

What Are the Key Manufacturing Processes for CNC Camshafts?

The manufacturing of CNC camshafts involves several critical stages, each designed to ensure precision, durability, and optimal performance. Understanding these processes can help B2B buyers make informed decisions when sourcing camshafts for their applications.

How Is Material Prepared for CNC Camshaft Manufacturing?

The first stage in the manufacturing process is material preparation. CNC camshafts are typically made from high-quality materials such as aerospace-grade steel or Selective Austempered Ductile Iron (SADI). The choice of material significantly impacts performance characteristics such as strength, rigidity, and resistance to wear.

-

Material Selection: Buyers should look for suppliers who use premium materials known for their performance. For instance, 8620 steel is often favored for its strength and ability to withstand high stress.

-

Material Inspection: Before processing, materials undergo rigorous inspection to verify compliance with specifications. This includes checking for defects and ensuring that the material meets industry standards.

What Techniques Are Used in CNC Camshaft Forming?

Once the material is prepared, the next step is forming, which primarily involves CNC machining. This process ensures that each camshaft is produced to exact specifications.

-

CNC Grinding: Using CNC grinders allows manufacturers to create highly precise cam profiles. This technology enables customization of lift, duration, and lobe separation, which are crucial for performance tuning.

-

Profile Development: Manufacturers can grind any desired profile without limitations posed by traditional methods. This flexibility is particularly beneficial for B2B buyers looking for custom solutions tailored to specific engine requirements.

-

Heat Treatment: Post-grinding, the camshafts often undergo heat treatment to enhance their hardness and durability. This process is vital for ensuring that the camshafts can withstand the rigors of high-performance applications.

How Is Assembly Conducted for CNC Camshafts?

After forming, the assembly phase involves integrating various components to create a complete camshaft system.

-

Component Integration: This may include installing cam bearings, seals, and other necessary components. Each part must meet strict tolerances to ensure optimal functionality and performance.

-

Balancing: Proper balancing is essential to reduce vibrations and enhance the lifespan of the camshaft. Manufacturers use specialized equipment to ensure that the assembled camshaft operates smoothly at high RPMs.

What Finishing Processes Are Involved in CNC Camshaft Production?

The finishing stage is crucial for both aesthetics and performance.

-

Surface Finishing: Techniques such as polishing and coating are employed to enhance the surface finish of the camshaft. A smoother finish reduces friction, leading to better performance and longevity.

-

Final Inspection: Before shipment, each camshaft undergoes a final inspection to ensure it meets all specifications and quality standards. This step is critical for maintaining the integrity of the product.

How Is Quality Assurance Managed in CNC Camshaft Manufacturing?

Quality assurance (QA) is a cornerstone of CNC camshaft manufacturing, ensuring that products meet both industry standards and customer expectations.

What International Standards Apply to CNC Camshaft Quality Assurance?

B2B buyers should be aware of the international and industry-specific standards that govern the quality of CNC camshafts.

-

ISO 9001 Certification: This standard outlines criteria for a quality management system, ensuring that companies consistently provide products that meet customer and regulatory requirements.

-

Industry-Specific Certifications: Depending on the application, certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may also be relevant. These certifications indicate compliance with industry-specific safety and performance standards.

What Are the Key Quality Control Checkpoints in CNC Camshaft Manufacturing?

Effective quality control (QC) involves multiple checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial inspection verifies the quality of raw materials before they enter the production process.

-

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring ensures that processes adhere to established standards. This includes real-time inspections and adjustments as necessary.

-

Final Quality Control (FQC): This final inspection confirms that the finished product meets all specifications before it is shipped to customers.

What Testing Methods Are Commonly Used for CNC Camshaft Quality Assurance?

To ensure the performance and durability of CNC camshafts, various testing methods are employed:

-

Dimensional Inspection: This involves measuring critical dimensions using precision instruments to ensure compliance with specifications.

-

Material Testing: Techniques such as hardness testing and tensile strength testing are conducted to verify that materials meet required performance criteria.

-

Performance Testing: For high-performance applications, camshafts may undergo dynamic testing to assess their performance under real-world conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential.

-

Supplier Audits: Conducting audits allows buyers to assess a supplier’s manufacturing processes, quality control measures, and compliance with industry standards.

-

Quality Reports: Requesting detailed quality reports can provide insights into a supplier’s QC processes and historical performance.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of a supplier’s products and processes, ensuring that they meet specified standards.

What Are the Quality Control and Certification Nuances for International Buyers?

When sourcing CNC camshafts from international suppliers, buyers should consider the following nuances:

-

Regional Standards Compliance: Different regions may have specific standards and certifications. Understanding these can help buyers ensure that products are suitable for their markets.

-

Logistics and Shipping Considerations: Quality control can extend to logistics, where the handling and transportation of camshafts can impact their integrity. Buyers should inquire about how suppliers manage these aspects.

-

Cultural and Regulatory Differences: Awareness of cultural and regulatory differences in manufacturing practices can help buyers navigate potential challenges when sourcing from international suppliers.

In summary, a thorough understanding of the manufacturing processes and quality assurance measures for CNC camshafts enables B2B buyers to make informed decisions. By prioritizing suppliers that adhere to international standards and robust quality control practices, buyers can ensure the reliability and performance of their camshaft investments.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc camshaft’

Introduction

Sourcing CNC camshafts can be a complex process, especially for international B2B buyers seeking high-performance components for automotive applications. This guide provides a step-by-step checklist to streamline your procurement process, ensuring you make informed decisions that meet your technical requirements and business goals.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements. This includes the type of camshaft (e.g., hydraulic or solid), desired lift, duration, and lobe separation angles. A well-defined specification helps suppliers provide accurate quotes and ensures that the camshaft will meet your engine’s performance needs.

- Consider Application: Determine if the camshaft is for street use, racing, or a custom engine project.

- Performance Goals: Specify performance metrics such as horsepower and torque increases.

Step 2: Research Potential Suppliers

Identify suppliers who specialize in CNC camshafts. Look for companies with a strong reputation in the industry, particularly those that offer custom solutions tailored to your specifications.

- Evaluate Experience: Check how long the supplier has been in business and their expertise in manufacturing camshafts.

- Customer Reviews: Seek feedback from previous clients to assess reliability and product quality.

Step 3: Verify Supplier Certifications

Ensure that potential suppliers hold relevant certifications, such as ISO 9001 for quality management. This step is vital for guaranteeing that your supplier adheres to industry standards and best practices.

- Request Documentation: Ask for copies of certifications and quality assurance processes.

- Compliance with Standards: Confirm that the supplier meets regional and international standards applicable to your market.

Step 4: Request Samples and Prototypes

Before placing a bulk order, request samples or prototypes of the camshafts. Testing these samples allows you to evaluate the quality, fit, and performance against your specifications.

- Conduct Testing: Use the samples in a controlled environment to analyze performance metrics.

- Assess Craftsmanship: Examine the machining quality and material used in the samples.

Step 5: Understand Lead Times and Shipping Options

Discuss lead times for production and shipping with your suppliers. Understanding these timelines is crucial for project planning and meeting delivery schedules.

- Production Capacity: Inquire about the supplier’s capacity to fulfill large orders within your required timeframe.

- International Shipping: Ensure they offer reliable shipping options, especially if you are sourcing from regions with different logistical challenges.

Step 6: Negotiate Terms and Pricing

Once you have identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and warranty conditions. This step is essential to ensure you receive the best value for your investment.

- Bulk Order Discounts: Inquire about discounts for larger orders or long-term contracts.

- Warranty and Support: Ensure you understand the warranty policy and after-sales support available for the camshafts.

Step 7: Finalize Your Order and Monitor Delivery

After negotiations, finalize your order with a clear contract that outlines all terms agreed upon. Monitor the delivery process to ensure compliance with the agreed timelines and product specifications.

- Keep Communication Open: Maintain regular contact with the supplier during the production and shipping phases.

- Quality Control upon Arrival: Inspect the camshafts immediately upon delivery to confirm they meet your specifications before use.

By following this checklist, you can confidently source CNC camshafts that align with your technical needs and business objectives, paving the way for successful engine performance and reliability.

Comprehensive Cost and Pricing Analysis for cnc camshaft Sourcing

When sourcing CNC camshafts, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. This analysis will cover the essential components that contribute to the overall cost, factors influencing pricing, and provide actionable tips for negotiating favorable terms, particularly for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in CNC Camshaft Manufacturing?

-

Materials: The choice of material significantly impacts the cost. Common materials for CNC camshafts include high-strength steels and aluminum alloys. Premium materials like aerospace-grade steel may yield higher performance but also come at a premium price.

-

Labor: Skilled labor is essential for CNC machining. Labor costs can vary based on the region, with countries offering lower wages potentially providing cost advantages. However, the skill level required for precision engineering should not be compromised.

-

Manufacturing Overhead: This includes costs related to factory operations such as utilities, rent, and equipment maintenance. Suppliers with advanced manufacturing capabilities may have higher overhead but can offer superior quality and faster turnaround times.

-

Tooling: The cost of tools and dies used in CNC machining can be significant. Custom tooling for specific camshaft profiles adds to initial costs, but can lead to better precision and reduced cycle times in production.

-

Quality Control (QC): Ensuring that camshafts meet stringent specifications requires investment in quality control processes. This may involve testing for durability and performance, which can increase the overall cost but is vital for maintaining high standards.

-

Logistics: Shipping costs, including freight and insurance, must be factored in, especially for international buyers. The choice of Incoterms can influence these costs significantly, affecting who bears the responsibility for shipping and duties.

-

Margin: Suppliers typically incorporate a profit margin into their pricing. Understanding the industry standards for margins can help buyers assess whether a quote is competitive.

What Influences the Pricing of CNC Camshafts?

Several factors can influence the pricing of CNC camshafts:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs due to economies of scale. Buyers should inquire about discounts for bulk purchases.

-

Specifications and Customization: Custom camshaft designs may incur additional costs. Clear specifications can help streamline the manufacturing process and reduce unexpected expenses.

-

Quality Certifications: Suppliers with industry certifications (e.g., ISO) may charge more due to their commitment to quality. However, sourcing from certified suppliers can lead to long-term cost savings through reduced failure rates.

-

Supplier Reputation: Established suppliers may have higher pricing due to their reliability and proven track record. Engaging with reputable suppliers can mitigate risks associated with poor-quality products.

-

Incoterms: Understanding the implications of Incoterms is crucial. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect the total landed cost of the camshafts.

What Are Effective Buyer Tips for Sourcing CNC Camshafts?

-

Negotiation: Approach negotiations with a clear understanding of the cost structure and be prepared to discuss specific cost components. Leverage volume commitments to negotiate better pricing.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price, but also potential maintenance costs, performance reliability, and longevity when evaluating suppliers.

-

Understand Pricing Nuances for International Transactions: Currency fluctuations, tariffs, and local taxes can affect pricing. Buyers should factor these into their overall budget and seek suppliers who can provide stable pricing mechanisms.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing and service. Suppliers may be more willing to accommodate custom requests or price reductions for loyal customers.

-

Seek Multiple Quotes: Obtaining quotes from multiple suppliers allows buyers to compare prices and services, ensuring they secure the best deal possible.

Disclaimer on Pricing

Prices for CNC camshafts can vary widely based on the aforementioned factors. The analysis presented here aims to provide a general understanding of the cost structure and pricing influences. Buyers are encouraged to conduct thorough market research and consult with multiple suppliers to obtain accurate pricing tailored to their specific needs.

Alternatives Analysis: Comparing cnc camshaft With Other Solutions

In today’s competitive landscape, businesses often seek to optimize their engine performance through various technologies. While CNC camshafts are a popular choice for precision and customization, several alternative solutions exist that can also enhance engine efficiency and power output. This section will explore these alternatives, providing a comprehensive comparison to help international B2B buyers make informed decisions.

| Comparison Aspect | Cnc Camshaft | Custom Camshaft Manufacturing | Billet Camshaft |

|---|---|---|---|

| Performance | High precision and custom profiles enhance performance across RPM ranges | Tailored to specific engine needs, but may have longer lead times | Offers superior strength and performance, particularly at high RPM |

| Cost | Higher initial investment due to precision machining | Variable costs based on customization; can be expensive | Generally more affordable than custom options but may lack specific tuning |

| Ease of Implementation | Requires specialized knowledge for installation | Installation may require professional assistance | Typically easier to install as they fit standard specifications |

| Maintenance | Low maintenance; durable under high-stress conditions | Maintenance depends on specific engine applications | Low maintenance; built to withstand high performance |

| Best Use Case | Ideal for high-performance racing and custom builds | Suitable for unique or rare engine types needing specific tuning | Best for general performance upgrades in standard engines |

What Are the Pros and Cons of Custom Camshaft Manufacturing?

Custom camshaft manufacturing allows for a high degree of personalization, enabling companies to design cam profiles that match their specific performance goals. One of the main advantages is the ability to tailor the lift, duration, and lobe separation to optimize engine function. However, this option often comes with longer lead times and potentially higher costs, which may not be feasible for all buyers. Additionally, the need for professional installation can add to the overall expense.

How Does a Billet Camshaft Compare to CNC Camshafts?

Billet camshafts are crafted from solid blocks of high-grade steel, providing excellent rigidity and strength. This construction allows them to perform well at high RPMs, making them a popular choice for performance enthusiasts. While they are generally more affordable than custom camshaft options, they may not offer the same level of precision tuning that CNC camshafts provide. Therefore, they might be more suitable for standard performance upgrades rather than specialized applications.

Conclusion: How Should B2B Buyers Choose the Right Camshaft Solution?

When selecting the appropriate camshaft solution, B2B buyers should consider their specific application needs, budget constraints, and installation capabilities. CNC camshafts are ideal for those requiring tailored performance and precision, while custom camshaft manufacturing offers unique solutions for specific engine types. Billet camshafts serve as a robust alternative for those looking for solid performance without the need for extensive customization. By evaluating these factors, buyers can make informed decisions that align with their operational goals and engine performance requirements.

Essential Technical Properties and Trade Terminology for cnc camshaft

When sourcing CNC camshafts, understanding the essential technical properties and trade terminology is crucial for making informed purchasing decisions. This section outlines key specifications and common jargon that B2B buyers should be familiar with to enhance their procurement process.

What Are the Key Technical Properties of CNC Camshafts?

-

Material Grade

The material used for CNC camshafts significantly affects performance and durability. Common materials include 8620 steel, known for its strength and resistance to wear, and Selective Austempered Ductile Iron (SADI), which provides good performance under stress. Understanding material grades allows buyers to select products that meet specific operational demands, especially in high-performance applications. -

Lift

Lift refers to how far the valve is opened by the camshaft and is measured in millimeters or inches. Higher lift can improve airflow into the engine, enhancing performance. Buyers should consider lift specifications in relation to their engine’s design and intended use, as it impacts power output and efficiency. -

Duration

Duration is the length of time the valve remains open during the engine cycle, typically measured in degrees of crankshaft rotation. This specification influences engine behavior at different RPM ranges. Buyers must align duration with their performance goals, as it affects both torque and horsepower. -

Lobe Separation Angle (LSA)

LSA is the angle between the centers of two cam lobes and is crucial for tuning engine performance characteristics. A wider LSA generally results in a smoother idle and better fuel efficiency, while a narrower angle can increase power output at higher RPMs. Understanding LSA helps buyers achieve desired performance outcomes in their engines. -

Tolerance

Tolerance refers to the allowable deviation in the dimensions of the camshaft. Precise tolerances are essential for ensuring that camshafts fit correctly within the engine and function optimally. Buyers should prioritize manufacturers who provide detailed tolerance specifications to ensure compatibility with their systems. -

Finish Quality

The surface finish of a camshaft impacts its wear resistance and performance. CNC machining allows for high-quality finishes that minimize friction and improve longevity. Buyers should inquire about the finish specifications to ensure that the camshafts will perform reliably in their applications.

What Are Common Trade Terms Related to CNC Camshafts?

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle or engine. Understanding OEM standards is vital for buyers looking for compatibility and reliability in performance parts. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their purchases effectively, especially when dealing with custom or specialized products. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products. This is essential for comparing costs and negotiating terms, ensuring that buyers secure the best deals. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. Familiarity with these terms is critical for understanding shipping costs, risk management, and delivery timelines, particularly for international buyers. -

Lead Time

Lead time is the period from placing an order to receiving the product. This metric is crucial for project planning and inventory management, as extended lead times can affect production schedules. -

Custom Camshaft

A custom camshaft is tailored to specific engine requirements, offering unique profiles that enhance performance. Understanding the process and benefits of custom camshafts allows buyers to optimize their engine setups for better results.

By grasping these technical properties and trade terms, B2B buyers can navigate the CNC camshaft market more effectively, ensuring they make informed decisions that align with their performance and operational needs.

Navigating Market Dynamics and Sourcing Trends in the cnc camshaft Sector

What Are the Key Drivers and Trends Shaping the CNC Camshaft Market?

The CNC camshaft market is currently experiencing a transformative phase driven by several global factors. The increasing demand for high-performance vehicles and the growing popularity of motorsports are propelling manufacturers to innovate and produce specialized camshaft profiles tailored to various applications. Additionally, advancements in CNC machining technology are enabling higher precision and customization, which is crucial for meeting the specific requirements of different engine types.

Internationally, B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are witnessing a shift toward integrated supply chains. This trend emphasizes the importance of sourcing from manufacturers who not only offer quality products but also provide comprehensive support services, such as installation kits and technical expertise. Moreover, the rise of e-commerce platforms is simplifying the procurement process, allowing buyers to compare products and prices easily, thus enhancing their purchasing power.

Emerging technologies, including artificial intelligence and machine learning, are also influencing the CNC camshaft sector. These technologies facilitate predictive maintenance and performance optimization, allowing manufacturers to enhance their offerings. Buyers in international markets must stay informed about these trends to leverage opportunities and make informed sourcing decisions.

How Is Sustainability and Ethical Sourcing Impacting the CNC Camshaft Sector?

Sustainability is becoming a pivotal concern for B2B buyers in the CNC camshaft market. The environmental impact of manufacturing processes, particularly in metalworking, has prompted many companies to adopt greener practices. As a result, sourcing camshafts made from sustainable materials and utilizing eco-friendly manufacturing techniques is gaining traction.

Ethical sourcing is equally important. Buyers are increasingly seeking suppliers who prioritize responsible supply chains, ensuring that materials are sourced ethically and that labor practices comply with international standards. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential benchmarks for suppliers.

In response to these demands, manufacturers are exploring alternative materials and processes that reduce waste and energy consumption. For instance, the use of recycled metals in camshaft production not only minimizes environmental impact but also appeals to a growing segment of environmentally conscious buyers. By prioritizing sustainability and ethical sourcing, companies can enhance their brand reputation and establish long-term partnerships with buyers who value corporate responsibility.

What Is the Historical Context of CNC Camshaft Development for B2B Buyers?

The evolution of CNC camshaft manufacturing dates back to the early days of automotive engineering, where camshafts were primarily produced using traditional machining methods. As automotive performance demands grew, so did the need for more precise and customizable camshaft designs. The introduction of Computer Numerical Control (CNC) technology revolutionized the manufacturing landscape, allowing for intricate designs and rapid prototyping.

In the 1980s and 1990s, advancements in CNC machining led to the ability to produce camshafts that could be tailored to specific engine configurations, enhancing performance and efficiency. This period marked a significant shift toward customization, which is now a hallmark of the industry. Today, CNC camshaft manufacturers leverage advanced materials and precision engineering to meet the rigorous demands of modern automotive applications, making them indispensable partners for B2B buyers focused on performance and reliability.

Understanding this historical context equips buyers with insights into the technological advancements that shape current sourcing strategies and product offerings in the CNC camshaft market.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc camshaft

-

How do I ensure the quality of CNC camshafts before purchasing?

To ensure the quality of CNC camshafts, request certifications from suppliers, such as ISO 9001, which indicates adherence to quality management systems. It’s essential to ask for detailed specifications regarding the materials used, machining processes, and any testing conducted. Additionally, consider requesting samples or references from previous customers to gauge their satisfaction with the products. Establishing a clear communication channel with your supplier can also help address any concerns regarding quality. -

What customization options are available for CNC camshafts?

Many manufacturers offer extensive customization options for CNC camshafts, including adjustments to lift, duration, lobe separation, and firing orders. When discussing your requirements with suppliers, be specific about your engine type and performance goals. Custom camshafts can significantly enhance engine efficiency and power. Ensure that the supplier has the capability for rapid prototyping, which allows for quick adjustments based on your feedback and testing results. -

What are the typical minimum order quantities (MOQ) for CNC camshafts?

Minimum order quantities for CNC camshafts can vary significantly based on the manufacturer and the complexity of the design. Generally, MOQs can range from 10 to 100 units for standard designs, while custom designs may require higher quantities. It’s advisable to discuss your needs directly with potential suppliers, as many are willing to accommodate smaller orders for new customers or pilot projects to build a long-term partnership. -

What payment terms should I expect when purchasing CNC camshafts internationally?

Payment terms for international purchases of CNC camshafts typically include options such as advance payment, letter of credit, or payment upon delivery. Standard practice often involves a deposit upfront, with the balance due before shipment. It’s essential to clarify payment methods, currency exchange rates, and any potential fees in advance. Establishing clear payment terms can help mitigate risks associated with international transactions. -

How can I vet suppliers for CNC camshafts effectively?

To effectively vet suppliers, start by researching their reputation within the industry. Look for reviews, testimonials, and case studies that highlight their experience and reliability. Engaging in direct communication can also provide insights into their responsiveness and customer service. Additionally, consider visiting their facility if feasible, or request a virtual tour to assess their capabilities and quality control processes. Certifications and compliance with international standards are also critical indicators of a trustworthy supplier. -

What shipping and logistics considerations should I keep in mind for CNC camshaft orders?

When ordering CNC camshafts internationally, consider shipping options, lead times, and associated costs. Discuss with your supplier their preferred logistics partners and any available options for expedited shipping if needed. Ensure that you understand customs regulations in your country to avoid delays and additional fees. It’s also wise to confirm that the supplier provides tracking information and insurance for your shipment to mitigate potential losses during transit. -

What should I know about the warranty and return policy for CNC camshafts?

Understanding the warranty and return policy is crucial before finalizing your purchase. Most reputable suppliers offer warranties that cover manufacturing defects and performance issues for a specified period. Familiarize yourself with the terms, including what is covered and any conditions that apply. Inquire about the return process in case of receiving defective or incorrect items, as well as any associated costs. This knowledge will help you navigate potential issues smoothly. -

How do I stay informed about the latest trends in CNC camshaft technology?

To stay informed about the latest trends in CNC camshaft technology, subscribe to industry journals, newsletters, and forums. Participating in trade shows and conferences can also provide valuable insights and networking opportunities with industry experts. Following leading manufacturers and industry thought leaders on social media can keep you updated on innovations and best practices. Engaging with online communities focused on automotive engineering can also enhance your knowledge and connections within the field.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Cnc Camshaft Manufacturers & Suppliers List

1. Texas Speed – In-House Camshaft Grinding

Domain: texas-speed.com

Registered: 2002 (23 years)

Introduction: Texas Speed & Performance offers in-house camshaft grinding specifically for LS and Gen 5 LT engines. They utilize state-of-the-art Landis CNC camshaft grinders, ensuring high precision and quality control. The facility maintains over 1,500 camshaft cores, primarily made in America, with options for both three-bolt and single-bolt configurations. Proprietary lobe designs are developed for maximum …

2. LSM Engineering – Custom Camshafts

Domain: lsmeng.com

Registered: 1999 (26 years)

Introduction: Custom camshaft manufacturer specializing in camshafts for standard engines customized to client needs. Cores available for GM, Ford, and Chrysler engines. Utilizes ultra-precision CNC cam grinders for custom profiles. Customizations include lift, duration, lobe separation, journal diameter, and firing order. Offers large journal cams for increased rigidity and power. Provides alternative firing o…

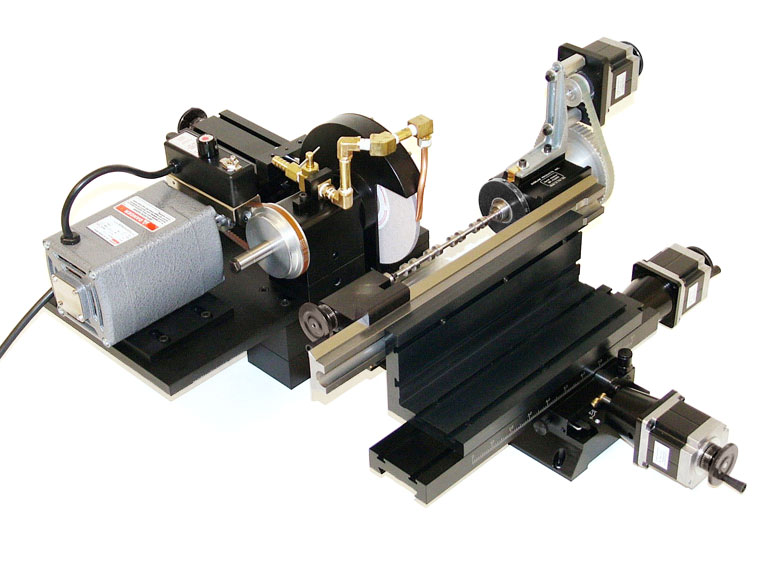

3. Sherline – CNC Cam Grinder

Domain: sherline.com

Registered: 1995 (30 years)

Introduction: Product Name: CNC Cam Grinder

SKU: 8650

Lead Time: 4 weeks

Description: Designed for building model engine camshafts with computer control for precision grinding. Can also grind small cams for other prototype applications.

Features:

– Powerful 1/2 HP grinder motor (120 VAC)

– 3 DC stepper motors with manual control handwheels

– Flexible way covers on Y-axis to keep debris off leadscrew

– Holds cam…

4. Andrews Products – CNC Camshaft Manufacturing

Domain: andrewsproducts.com

Registered: 2000 (25 years)

Introduction: This company, Andrews Products – CNC Camshaft Manufacturing, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Kelford Cams – High-Performance Camshafts

Domain: kelfordcams.com

Registered: 2007 (18 years)

Introduction: Kelford Cams specializes in high-performance camshaft manufacturing and valve train solutions for modified engines, established in 1969. They offer a variety of camshaft options for multiple engine brands including Toyota, Mitsubishi, Honda, Ford, and more. The manufacturing process includes steps such as cutting camshaft blanks with a CNC bandsaw, precision machining with a mill-turn machine, and…

6. Reddit – CNC Lathe Capabilities for Camshafts

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: CNC lathe capabilities for machining camshafts, specifically the need for live tooling, the rarity and expense of lathes that can cut cam profiles through fast X-axis movement, and the limitations of standard CNC lathes in achieving accurate cam profiles without live tooling.

7. Psiconversion – L99HC-CS Cylinder Head

Domain: psiconversion.com

Registered: 2009 (16 years)

Introduction: L99HC-CS Cylinder Head, designed for high-performance applications, features a lightweight aluminum construction, 64cc combustion chamber, and 2.165″ intake valve diameter. It is compatible with L99 engines and offers improved airflow and efficiency. The product is ideal for racing and performance builds, ensuring enhanced power output and reliability.

Strategic Sourcing Conclusion and Outlook for cnc camshaft

The landscape of CNC camshaft sourcing presents a multitude of opportunities for international B2B buyers. By leveraging strategic sourcing, businesses can tap into high-quality products tailored to specific performance needs, ensuring competitive advantage in their respective markets. The ability to customize camshaft profiles, materials, and specifications not only enhances product offerings but also fosters innovation within automotive applications.

As markets in Africa, South America, the Middle East, and Europe continue to grow, the demand for advanced engine components will rise. Buyers should focus on establishing robust relationships with reputable manufacturers that offer precision-engineered solutions and fast shipping options. This approach not only minimizes lead times but also supports ongoing operational efficiency.

Looking ahead, the future of CNC camshaft production is poised for transformation with advancements in technology and materials. Companies that proactively engage with suppliers and invest in custom solutions will be better positioned to meet evolving consumer expectations. It is time for B2B buyers to embrace these strategic sourcing practices to fuel their growth and drive industry innovation. Partner with leading manufacturers today to unlock the full potential of your automotive projects.