Contents

Manufacturing Insight: Cnc Boring Milling Machine

Precision CNC Boring Milling Capabilities at Honyo Prototype

Honyo Prototype delivers advanced CNC machining solutions engineered for the demanding requirements of prototyping and low-to-medium volume production. Our comprehensive capabilities include high-precision CNC boring and milling operations, essential for creating complex internal geometries, large diameter bores, and critical facing surfaces with exceptional dimensional accuracy and surface finish. Utilizing state-of-the-art multi-axis machining centers featuring robust boring mills, we consistently achieve tight tolerances down to ±0.0002 inches across a wide range of engineering materials including metals, plastics, and composites. This precision is non-negotiable for critical components in aerospace, medical devices, energy, and industrial machinery applications where fit, function, and reliability are paramount.

Honyo Prototype CNC Machining Services

Our integrated manufacturing approach combines this specialized boring milling expertise with full 3-, 4-, and 5-axis milling, turning, and secondary operations under one roof. This vertical integration ensures seamless process control, minimized handling, and accelerated time-to-part without compromising on the stringent quality standards our B2B clients expect. Every project benefits from our experienced engineering team’s focus on manufacturability analysis, optimal toolpath strategies, and rigorous in-process inspection protocols, guaranteeing components meet or exceed your engineering specifications on schedule.

Accelerate your procurement cycle with Honyo Prototype’s Online Instant Quote system. Upload your CAD file directly to our platform and receive a detailed, transparent cost estimate and lead time within hours, not days. This streamlined workflow eliminates traditional quoting delays, providing the rapid feedback necessary for informed design and sourcing decisions early in your product development process. Experience the efficiency and precision of our CNC boring milling services backed by responsive, engineer-to-engineer support.

Technical Capabilities

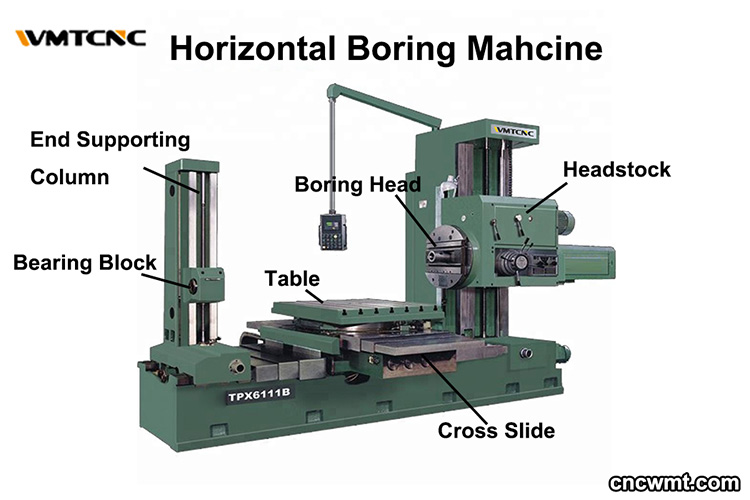

CNC boring milling machines are advanced machine tools designed for high-precision material removal operations, combining the capabilities of milling and boring with multi-axis control. These machines support 3, 4, and 5-axis configurations, enabling complex geometries, enhanced tool reach, and improved surface finishes. They are ideal for applications requiring tight tolerances, such as aerospace components, medical devices, and precision molds. The machines are capable of machining a wide range of materials including aluminum, steel, ABS, and nylon, each requiring specific spindle speeds, feed rates, and tooling strategies.

| Feature | Specification / Description |

|---|---|

| Axis Configuration | 3-axis (X, Y, Z), 4-axis (adds rotary A or B), 5-axis (full rotary and tilting capabilities) |

| Spindle Speed | 8,000 – 24,000 RPM (variable based on material and tooling) |

| Positioning Accuracy | ±0.005 mm (±0.0002 in) |

| Repeatability | ±0.002 mm (±0.0001 in) |

| Tolerance Capability | ±0.01 mm (±0.0004 in) typical; down to ±0.005 mm with precision tooling and thermal control |

| Table Size (Typical) | 800 mm × 500 mm to 1,200 mm × 800 mm (customizable) |

| Maximum Workpiece Weight | 1,000 kg (2,200 lbs) depending on machine model |

| Control System | Fanuc, Siemens, or Heidenhain CNC with 5-axis interpolation and tool path optimization |

| Tool Changer (ATC) | 24–60 tool capacity, automatic with tool length and diameter measurement |

| Coolant System | High-pressure through-spindle coolant (up to 70 bar) with mist and flood options |

| Materials Processed | Aluminum, Steel (including stainless and tool steels), ABS, Nylon, and other engineering plastics |

| Material-Specific Notes | Aluminum: high-speed machining with carbide tools; Steel: lower speeds, rigid setup; ABS/Nylon: sharp tools, low heat buildup to prevent melting |

| Surface Finish | Ra 0.8 µm (32 µin) typical; down to Ra 0.4 µm (16 µin) with fine finishing passes |

| Boring Bar Capacity | Up to 150 mm diameter with micro-adjustable heads for ±0.001 mm diameter control |

| Linear Axis Travel (Typical) | X: 1,000 mm, Y: 600 mm, Z: 500 mm (varies by model) |

| Applications | Precision bores, contoured surfaces, deep pockets, turbine blades, injection molds |

These machines integrate high rigidity bed structures, linear guideways, and thermal compensation systems to maintain dimensional stability during prolonged operations. When machining non-metallic materials like ABS and nylon, reduced cutting forces and optimized chip evacuation are critical to prevent deformation and maintain tight tolerances. For metals, especially hardened steels, the use of through-tool coolant and rigid carbide tooling ensures consistent performance. 5-axis functionality allows for single-setup machining of complex parts, reducing cumulative error and improving geometric accuracy.

From CAD to Part: The Process

Honyo Prototype employs a rigorously defined workflow for CNC boring and milling operations, ensuring precision, efficiency, and seamless client integration. It is critical to clarify that CNC boring and milling represent distinct but often complementary processes executed on specialized machine tools—milling machines for complex contours and flat surfaces, and boring mills (or precision boring heads on machining centers) for achieving tight-tolerance internal diameters. Our integrated process flow manages both capabilities under a unified framework.

CAD File Upload and Initial Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid, or native formats like SLDPRT, IPT, PRT) via our secure customer portal. Our system performs automated geometry validation to detect critical errors such as non-manifold edges, missing surfaces, or unit inconsistencies. Simultaneously, a manufacturing engineer conducts a preliminary manual review to assess feature complexity, especially critical for boring operations requiring deep-hole stability or micron-level concentricity. This dual-validation step prevents downstream delays caused by flawed input data.

AI-Powered Quoting with Human Oversight

Uploaded geometry triggers our proprietary AI quoting engine, trained on 15,000+ historical production datasets. The algorithm analyzes part volume, feature density, material stock requirements, and specific tolerance demands—particularly critical for boring operations where IT6-IT7 tolerances or surface finishes below Ra 0.8 µm significantly impact machining strategy. The AI factors in machine hourly rates, tooling complexity (e.g.,定制 boring bars for non-standard diameters), and secondary operations. Crucially, all AI-generated quotes undergo mandatory review by a senior process engineer who validates feasibility, especially for challenging aspects like thin-walled bore features prone to chatter. This hybrid approach delivers quotes within 2 business hours while maintaining 98.5% accuracy in cost estimation.

Engineering-Led DFM Analysis

Upon quote acceptance, our DFM phase commences with a dedicated manufacturing engineer specializing in precision machining. We execute a structured checklist focused on boring and milling constraints:

| DFM Focus Area | Key Checks for Boring/Milling Operations |

|---|---|

| Geometric Feasibility | Minimum wall thickness for bored features (typically ≥3x depth), undercuts inaccessible to standard tooling, hole depth-to-diameter ratios exceeding 10:1 |

| Tolerance Assessment | Conflicting GD&T callouts (e.g., position tolerances tighter than achievable bore cylindricity), surface roughness incompatible with boring feed rates |

| Material Considerations | Machinability index for selected alloy (e.g., 303 vs 304 stainless steel in boring), risk of built-up edge affecting bore finish |

| Process Optimization | Recommended stock allowances for final bore pass (typically 0.5–1.0mm), sequencing to prevent workpiece distortion during milling prior to precision boring |

The engineer collaborates directly with the client to resolve conflicts, proposing alternatives such as adjusting datum schemes or suggesting near-net-shape casting to reduce boring stock removal. This phase typically reduces non-value-added machining time by 18–22%.

Precision Production Execution

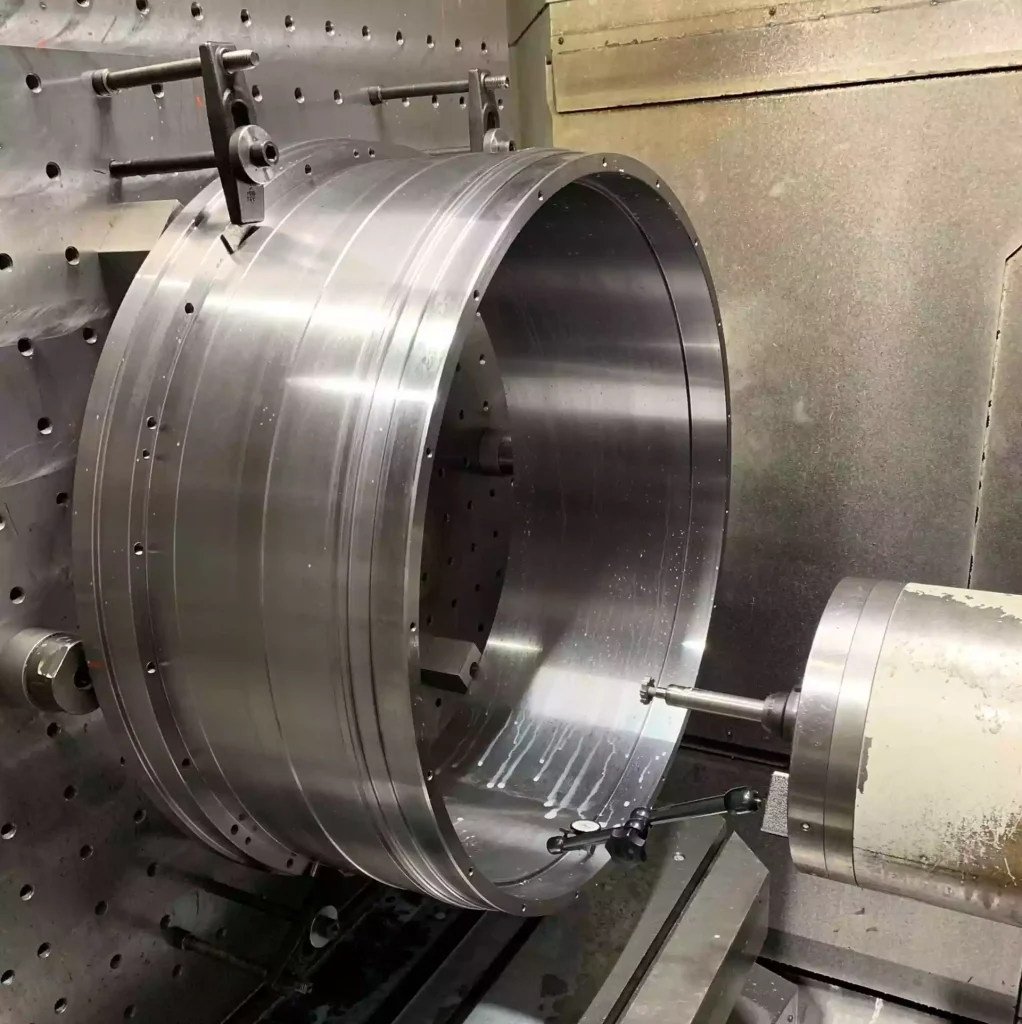

Approved designs move to production on our dedicated equipment cells. Milling operations occur on 5-axis DMG MORI or Makino centers with sub-micron positioning accuracy, while critical boring tasks utilize horizontal boring mills (e.g., Bullard VTLs) or specialized boring heads on machining centers. Key protocols include:

Workholding is optimized using modular fixturing to minimize repositioning—essential for maintaining concentricity between milled faces and bored diameters. In-process probing verifies critical datums before boring cycles commence. For deep bores, we implement peck boring cycles with through-spindle coolant to evacuate chips and prevent taper. All critical diameters undergo in-machine laser measurement for closed-loop compensation, ensuring bore tolerances consistently meet ±0.005mm on diameters up to 500mm.

Quality-Controlled Delivery

Final inspection uses Zeiss coordinate measuring machines (CMM) with specialized probe configurations to validate bore geometry—cylindricity, roundness, and positional accuracy relative to milled features. Reports include full GD&T analysis per ASME Y14.5. Parts undergo ultrasonic cleaning and are packaged in ESD-safe, custom foam inserts to prevent micro-vibration damage during transit. Delivery includes digital dossiers with first-article inspection reports, tooling documentation, and process capability data (Cp/Cpk) for critical bored features. Standard lead time for complex parts requiring both operations is 10–15 business days from DFM sign-off.

This integrated process ensures that Honyo delivers dimensionally accurate, functionally reliable components where tight-bore tolerances and complex milled geometries must coexist—eliminating the interface risks common when outsourcing separate operations. Our closed-loop system from CAD to delivery provides clients with predictable quality for mission-critical applications in aerospace, energy, and medical device manufacturing.

Start Your Project

Looking for high-precision CNC boring and milling solutions? Honyo Prototype offers advanced machining capabilities with state-of-the-art CNC technology, ensuring tight tolerances and superior surface finishes for complex components.

Our manufacturing facility is located in Shenzhen, leveraging efficient production systems and skilled engineering expertise to deliver reliable results for prototyping and low-volume production.

Contact Susan Leo for technical specifications, capacity details, or project inquiries.

Email: [email protected]

Partner with us for precision, speed, and consistency in every machined part.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.