Contents

Manufacturing Insight: Cnc Billet Aluminum

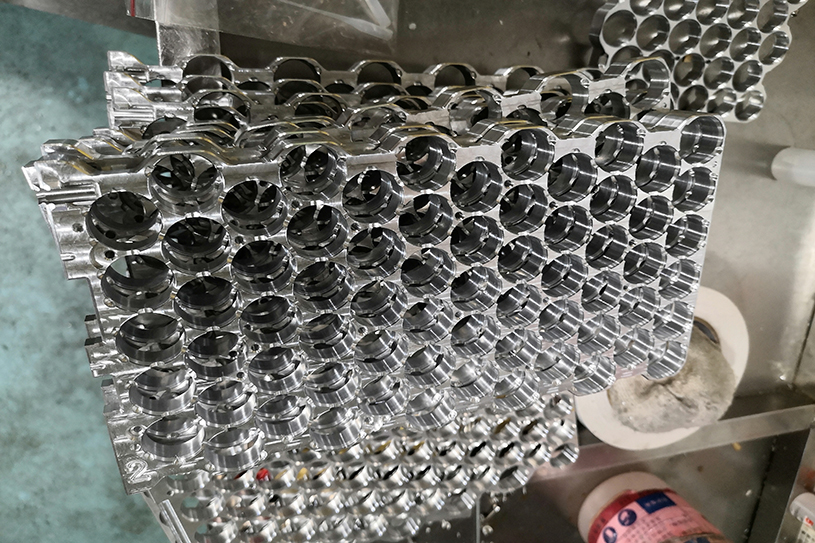

Precision CNC Billet Aluminum Components from Honyo Prototype

Billet aluminum machining delivers unmatched strength, consistency, and thermal properties for mission-critical applications across aerospace, defense, automotive, and medical industries. Unlike cast alternatives, solid aluminum billet ensures homogeneous material integrity, eliminating porosity risks while enabling complex geometries and stringent tolerance requirements down to ±0.0002 inches.

Honyo Prototype leverages state-of-the-art 3-, 4-, and 5-axis CNC machining centers to transform premium 6061-T6, 7075-T6, and custom aluminum alloys into high-performance components. Our ISO 9001-certified processes integrate rigorous in-process inspection, advanced CAD/CAM programming, and expert material handling to guarantee repeatability and surface finishes as fine as 32 RMS. From rapid prototyping to low-volume production runs, we prioritize material optimization and on-time delivery without compromising dimensional accuracy.

Accelerate your timeline with Honyo’s Online Instant Quote platform. Upload your STEP or IGES files to receive a detailed manufacturability analysis and competitive pricing within hours—no callbacks or email delays. This transparent, engineer-driven system empowers procurement teams to validate design feasibility and cost early in the development cycle, reducing time-to-market for your next-generation aluminum assemblies. Partner with Honyo for billet aluminum solutions where precision engineering meets operational efficiency.

Technical Capabilities

CNC Billet Aluminum Technical Specifications

CNC billet aluminum components are machined from solid blocks of aluminum using precision 3-axis, 4-axis, or 5-axis milling centers, as well as CNC turning equipment. These processes enable high accuracy, complex geometries, and tight tolerances required in aerospace, automotive, medical, and industrial applications. While aluminum is the most common material for billet machining due to its machinability and strength-to-weight ratio, similar processes apply to steel, ABS, and nylon—each with distinct properties and machining parameters.

The following table outlines key technical specifications and capabilities for CNC billet aluminum and comparative data for steel, ABS, and nylon under precision milling and turning operations.

| Parameter | Aluminum (6061-T6) | Steel (4140) | ABS (Acrylonitrile Butadiene Styrene) | Nylon (PA6/PA66) |

|---|---|---|---|---|

| Common Grades | 6061-T6, 7075-T6, 2024-T3 | 4140, 1018, 304 Stainless | ABS-M30, ABS-M30i | PA6, PA66, Glass-Filled Nylon |

| Machining Process | 3/4/5-axis milling, CNC turning | 3/4/5-axis milling, CNC turning | 3/4-axis milling, CNC turning | 3/4-axis milling, CNC turning |

| Typical Tolerance | ±0.0005″ (12.7 µm) | ±0.0005″ (12.7 µm) | ±0.001″ (25.4 µm) | ±0.001″ (25.4 µm) |

| Surface Finish (Ra) | 32–16 µin (0.8–0.4 µm) standard; down to 8 µin (0.2 µm) with polishing | 32–16 µin (0.8–0.4 µm) standard | 63–32 µin (1.6–0.8 µm) | 63–32 µin (1.6–0.8 µm) |

| Max Feature Complexity | High (5-axis enables undercuts, contours, deep pockets) | High (limited by tool rigidity) | Medium (suitable for enclosures, brackets) | Medium (gears, bushings, wear parts) |

| Tooling Requirements | Carbide end mills, high-speed spindles (10k–24k RPM) | Carbide or HSS tools, lower RPM (5k–12k), high torque | Sharp carbide tools, low heat buildup | Sharp tools, moderate feed, cooling control |

| Coolant Use | Required (flood or mist) to prevent galling and heat | Required (flood) for heat and chip control | Optional (air blast preferred to avoid stress cracking) | Optional (air blast recommended) |

| Material Removal Rate | High (excellent chip evacuation, soft alloy) | Moderate (harder material, slower feeds) | High (easy to cut, low tool wear) | Moderate (tough, can be gummy) |

| Post-Processing Options | Anodizing, bead blasting, powder coating, polishing | Plating, passivation, heat treat, painting | Vapor polishing, painting, bonding | Dyeing, annealing, dry machining |

| Applications | Aerospace fittings, motor housings, precision brackets | Shafts, tooling, high-strength fixtures | Prototypes, enclosures, jigs | Wear-resistant parts, gears, insulators |

Notes on Tight Tolerance Machining:

5-axis CNC milling allows for single-setup machining of complex billet aluminum parts with tolerances down to ±0.0002″ when combined with in-process probing and thermal compensation.

Turning operations on aluminum achieve concentricity within 0.0003″ TIR on critical diameters using live tooling and C-axis control.

Steel requires slower cutting speeds and rigid setups to maintain tight tolerances due to higher hardness and work hardening tendencies.

Plastics like ABS and nylon are sensitive to heat and clamping pressure; machining must be optimized to prevent deformation and achieve dimensional stability.

All materials are suitable for precision CNC machining, but aluminum remains the preferred choice for high-performance billet components requiring strength, light weight, and tight tolerance repeatability.

From CAD to Part: The Process

Honyo Prototype CNC Billet Aluminum Manufacturing Process

Our streamlined CNC billet aluminum process ensures precision, efficiency, and seamless integration from initial design to final delivery. This workflow is optimized for rapid prototyping and low-to-mid volume production, leveraging advanced technology and rigorous engineering validation.

CAD File Upload

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid, or native formats like SLDPRT, IPT, PRT) via our secure customer portal. The system validates file integrity, confirms geometric completeness, and checks for critical metadata including material specifications, critical tolerances, and surface finish requirements. Accepted file types and size limits are clearly documented to prevent submission errors, ensuring the design intent is accurately captured for downstream processing.

AI-Powered Instant Quoting

Uploaded designs are processed through Honyo’s proprietary AI quoting engine, which analyzes geometric complexity, feature density, stock material requirements, and machine time estimates in real-time. The algorithm cross-references historical production data, current machine utilization rates, and material costs to generate a technically accurate quote within minutes. This system provides transparent cost breakdowns including setup fees, machining hours, material costs, and finishing options, while flagging potential anomalies requiring engineering review before finalization.

Engineering DFM Analysis

All quotes undergo mandatory Design for Manufacturability (DFM) review by our senior manufacturing engineering team. This phase identifies geometric challenges such as thin walls, deep cavities, or tight tolerances that could impact yield or cycle time. We provide actionable feedback on optimizing draft angles, radii, and feature placement to reduce machining steps and cost. Critical outputs include revised tolerance suggestions, recommended stock sizes, and alternative feature configurations—all documented in a collaborative DFM report accessible via the client portal. This step typically reduces production iterations by 40-60% compared to non-DFM-reviewed designs.

Precision CNC Production

Approved designs enter production on our Haas and DMG MORI 3- to 5-axis vertical machining centers. Billet aluminum stock (typically 6061-T6, 7075-T6, or custom alloys) is prepared per material certification requirements. Machining employs high-speed strategies with coolant-through tooling to maintain thermal stability and surface integrity. In-process inspections using Renishaw probes verify critical dimensions after roughing and semi-finishing stages. Final parts undergo CMM validation against the original CAD model, with full inspection reports available upon request. Typical production lead times range from 3-15 business days depending on complexity and volume.

Quality-Controlled Delivery

Completed parts undergo final visual and dimensional verification per AS9102 or client-specific checklists. Each shipment includes traceable documentation: material certs, first-article inspection reports (FAIR), and process validation records. Parts are packaged in anti-static, crush-resistant containers with custom foam inserts for critical geometries. Real-time logistics tracking is provided through our ERP system, with standard delivery via FedEx/UPS or client-designated carriers. Expedited shipping options and kitting services are available for JIT requirements.

Material Specifications Reference

Common aluminum alloys processed through this workflow include:

| Alloy | Temper | Tensile Strength (MPa) | Typical Applications | Machinability Rating |

|---|---|---|---|---|

| 6061 | T6 | 310 | Brackets, housings, fixtures | Excellent (A) |

| 7075 | T6 | 572 | Aerospace components, fittings | Good (B) |

| 2024 | T3 | 470 | Structural aircraft parts | Fair (C) |

| 5052 | H32 | 228 | Marine hardware, enclosures | Excellent (A) |

This integrated process minimizes time-to-part while maintaining ISO 9001:2015 quality standards, with a first-pass yield rate exceeding 98.5% for DFM-optimized designs. Clients receive full process transparency through our digital dashboard, enabling real-time project tracking from quote to shipment.

Start Your Project

Looking for high-precision CNC billet aluminum components? Honyo Prototype delivers tight-tolerance, machined aluminum parts from our state-of-the-art facility in Shenzhen, China. Ideal for aerospace, automotive, and industrial applications, our CNC machining services ensure superior quality and fast turnaround.

Contact Susan Leo today to request a quote or submit your design for review. Email [email protected] and let our engineering team support your next project with expert manufacturing solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.