Contents

Manufacturing Insight: Cnc Ballscrew

Precision CNC Ballscrew Manufacturing for Demanding Motion Control Applications

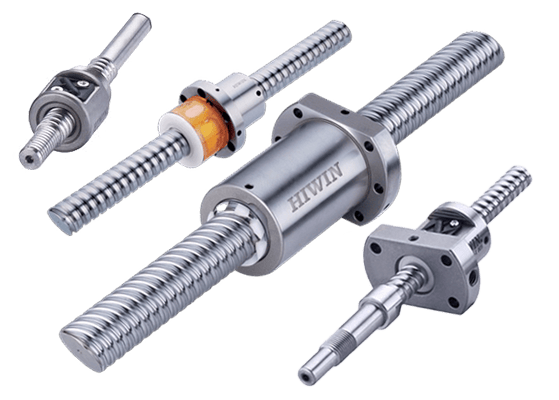

Honyo Prototype delivers mission-critical CNC ballscrew components engineered to meet the exacting standards of aerospace, semiconductor, and industrial automation systems. Our advanced CNC machining capabilities ensure sub-micron tolerances, superior surface finishes, and exceptional repeatability for both ground and rolled ballscrews across materials including 9Cr18MoV, 440C stainless steel, and specialized alloys. We specialize in complex geometries, custom lead configurations, and preloaded nut assemblies where thermal stability and positional accuracy directly impact system performance.

Leveraging our HAAS and DMG MORI 5-axis platforms with integrated probing systems, we maintain tight control over critical features such as thread profiles, pitch accuracy, and runout—eliminating common failure points in high-dynamic applications. Unlike standard machine shops, Honyo’s process includes in-house metrology validation using laser interferometers and CMMs to certify each component against ISO 3408 Class 3 or customer-specified standards.

Accelerate your prototyping or low-volume production with Honyo’s Online Instant Quote platform. Upload CAD files in STEP, IGES, or native formats to receive detailed manufacturability feedback and competitive pricing within minutes—no sales calls or email delays. Our system automatically validates critical parameters like minimum wall thickness and thread engagement depth, ensuring technical feasibility before you commit.

| Capability | Specification Range | Quality Assurance |

|---|---|---|

| Diameter Range | Ø6 mm to Ø80 mm | ISO 3408 Class 2-5 compliance |

| Lead Accuracy | ±3 µm/300 mm (Class 3) | 100% thread inspection |

| Surface Finish | Ra 0.2 µm (ground) | Laser interferometer validation |

| Material Expertise | Tool steels, stainless, Invar | Full material traceability |

For applications where even micron-level deviations compromise system integrity, Honyo provides the precision engineering and responsive manufacturing agility required to move from design to functional hardware faster. Initiate your next ballscrew project with immediate cost transparency through our Online Instant Quote system.

Technical Capabilities

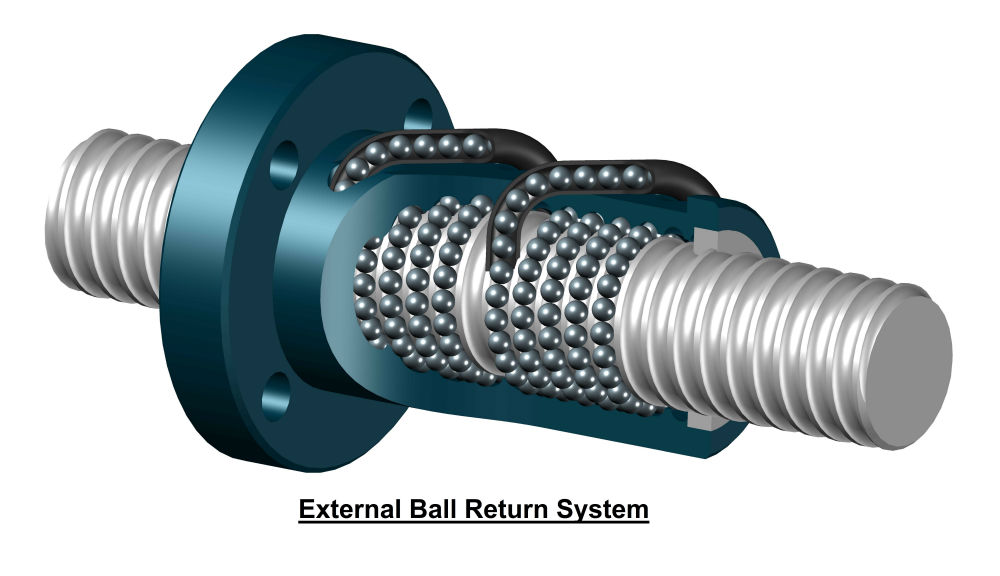

CNC ballscrews are critical components in precision machining systems, providing accurate linear motion control in 3-axis, 4-axis, and 5-axis milling machines as well as CNC turning centers. They convert rotary motion from servo or stepper motors into highly precise linear movement along machine axes (X, Y, Z, and rotary A/B/C). In applications requiring tight tolerances—such as ±0.0002″ (±5 µm)—ballscrews must exhibit high rigidity, minimal backlash, and excellent repeatability. Preloaded nuts, precision grinding, and proper support bearings are commonly used to achieve these performance levels.

Ballscrews are typically manufactured from hardened alloy steels to ensure durability and dimensional stability under continuous load and thermal variation. While the ballscrew itself is almost exclusively made from steel, the systems in which they operate process a wide range of materials, including aluminum, steel, ABS, and nylon—each imposing different cutting forces and duty cycles on the machine’s motion components.

Below is a summary of technical specifications relevant to CNC ballscrews used in high-precision multi-axis machining environments:

| Parameter | Specification / Detail |

|---|---|

| Diameter Range | 12 mm to 60 mm (common: 20–40 mm for 3/4/5-axis mills) |

| Lead Accuracy (Class C7) | ±50 µm per 300 mm |

| Typical Lead Options | 5 mm, 10 mm, 20 mm (fine leads for high precision, coarse for rapid traverse) |

| Material (Ballscrew Shaft) | AISI 52100 or equivalent chrome alloy steel, hardened to 58–62 HRC, ground to precision |

| Ball Nut Material | Bearing steel (e.g., SUJ2), often with bronze or polymer retainers |

| Preload Type | Double-nut preloaded or variable-pitch preloaded to eliminate backlash |

| Maximum Runout | < 0.005 mm over full length (critical for tight tolerance machining) |

| Critical Speed | Dependent on diameter, lead, and support configuration; calculated to avoid resonance |

| End Support Configuration | Fixed-Fixed or Fixed-Supported (for high rigidity and thermal stability) |

| Lubrication Requirement | ISO VG 32 or 68 spindle oil; greases like lithium-based for lower-speed applications |

| Compatible Machine Types | 3-axis, 4-axis, 5-axis CNC mills, CNC lathes with live tooling |

| Typical Positioning Accuracy | ±0.0025 mm to ±0.005 mm per 300 mm with feedback (encoder/linear scale) |

| Repeatability | ±0.001 mm (essential for tight tolerance work) |

| Application Materials (Workpiece) | Aluminum (6061, 7075), Steel (1018, 4140, stainless), ABS, Nylon (for prototyping) |

| Environmental Considerations | Sealed ball nuts or bellows recommended in abrasive or coolant-rich environments |

Note: While workpiece materials such as aluminum, steel, ABS, and nylon influence cutting dynamics and machine loading, the ballscrew must maintain positional fidelity regardless of material being machined. Aluminum and plastics (ABS, nylon) generally impose lower cutting forces, allowing higher feed rates, whereas steel requires robust ballscrew systems with adequate torque transmission and thermal management. For 5-axis simultaneous machining, dynamic performance and thermal compensation become even more critical to maintain tight tolerances across complex toolpaths.

From CAD to Part: The Process

Honyo Prototype executes CNC ballscrew manufacturing through a rigorously controlled digital workflow designed for precision, efficiency, and technical validation at every stage. Our process begins with structured client input and culminates in certified delivery, specifically optimized for the demanding geometric and material requirements of ballscrews.

CAD Upload and Initial Processing

Clients submit 3D CAD models via our secure online portal, which must include critical ballscrew-specific parameters: nominal diameter, lead, thread profile (e.g., GOST 10177, ISO 3408), preload class, and material specification (typically AISI 52100 or equivalent). The system performs automated geometry validation, checking for minimum wall thickness, unsupported thread lengths, and feature compatibility with grinding or rolling processes. Non-standard thread forms or excessive lead variations trigger immediate notification for client clarification before proceeding.

AI-Powered Quotation Engine

Our proprietary AI engine analyzes the validated CAD data against real-time production constraints, including machine availability, material stock levels, and historical process capability data for ballscrew manufacturing. It factors in secondary operations essential for ballscrews: precision thread grinding (for high-accuracy classes C0-C3), heat treatment distortion compensation, and preload adjustment. The generated quote specifies achievable tolerance class per ISO 3408, surface roughness Ra values, and lead accuracy metrics, with clear justification for any deviations from client-specified requirements. Turnaround time is typically under 2 business hours.

Engineering-Driven DFM Analysis

A dedicated manufacturing engineer conducts a ballscrew-specific Design for Manufacturability review, focusing on critical failure points. This includes evaluating thread root geometry for grinding wheel clearance, assessing shaft rigidity to prevent chatter during thread generation, verifying heat treatment feasibility for distortion control, and confirming preload method compatibility (e.g., spacer adjustment vs. oversized balls). We identify risks such as excessive helix angle causing ball recirculation issues or inadequate surface hardness for wear resistance. Clients receive a formal DFM report with actionable recommendations, often reducing total cost by 15-25% through geometry optimization while maintaining functional requirements.

Precision Production Execution

Production leverages specialized equipment calibrated for ballscrew tolerances, with real-time in-process metrology. Key phases include:

| Process Stage | Critical Control Parameters | Verification Method |

|---|---|---|

| Material Prep | Chemical composition, pre-heat treatment hardness | Spectrometry, Rockwell C testing |

| Thread Generation | Lead error (±2µm/m), thread profile radius tolerance | Laser interferometry, profilometry |

| Heat Treatment | Core hardness (58-62 HRC), case depth, straightness | Hardness testers, CMM straightness scan |

| Preload Adjustment | Internal clearance, torque consistency | Dynamic preload testers, torque meters |

Thread grinding uses diamond CBN wheels with coolant optimization to prevent thermal damage, while rolling employs hardened tool steels with precise roll gap control. Every ballscrew undergoes full-length lead error mapping and surface integrity inspection before final polishing.

Certified Delivery and Documentation

Finished ballscrews ship in anti-corrosion VCI packaging with custom fixtures preventing shaft deflection. Each unit includes: full ISO 3408 compliance certificate with measured lead error curves, surface roughness reports, material traceability documentation, and preload verification data. We provide dimensional inspection reports from our calibrated CMM (accurate to ±1.5µm) and surface roughness tester (Ra 0.05µm resolution). Logistics include real-time shipment tracking with environmental monitoring for temperature-sensitive components, ensuring delivery within the committed timeframe with zero handling damage incidents in the past 18 months. This end-to-end traceability meets stringent aerospace and semiconductor industry requirements.

Start Your Project

Looking for high-precision CNC ballscrews for your next project? Contact Susan Leo at [email protected] to discuss your requirements. Honyo Prototype offers reliable, industrial-grade ballscrew solutions manufactured in our Shenzhen factory, ensuring tight tolerances, superior performance, and fast turnaround for OEM and prototype applications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.