Contents

Manufacturing Insight: Cnc Automatisering

Introduction to CNC Automation at Honyo Prototype

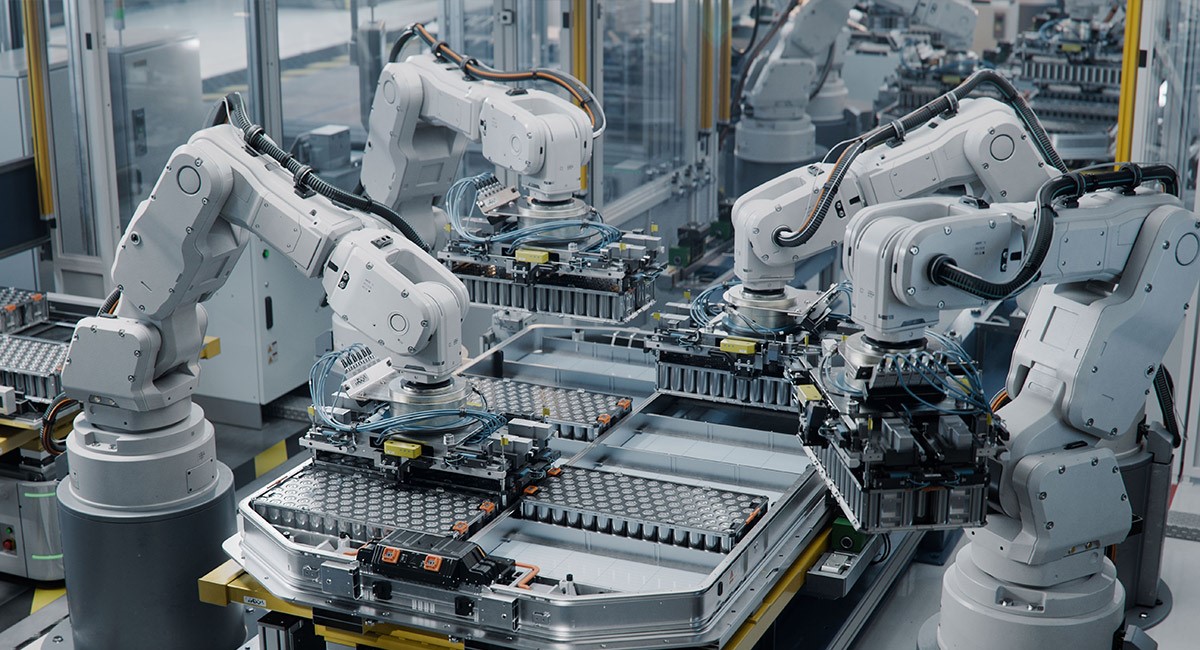

In today’s competitive manufacturing landscape, precision, speed, and repeatability are non-negotiable. Honyo Prototype addresses these demands through advanced CNC Automation solutions, transforming complex prototyping and low-to-mid volume production challenges into streamlined, error-resistant processes. Our integrated automation systems eliminate manual intervention bottlenecks, ensuring consistent part quality while significantly reducing lead times and operational costs. This capability is critical for industries requiring rapid iteration cycles, such as aerospace, medical devices, and robotics, where tolerances demand micron-level accuracy and traceability.

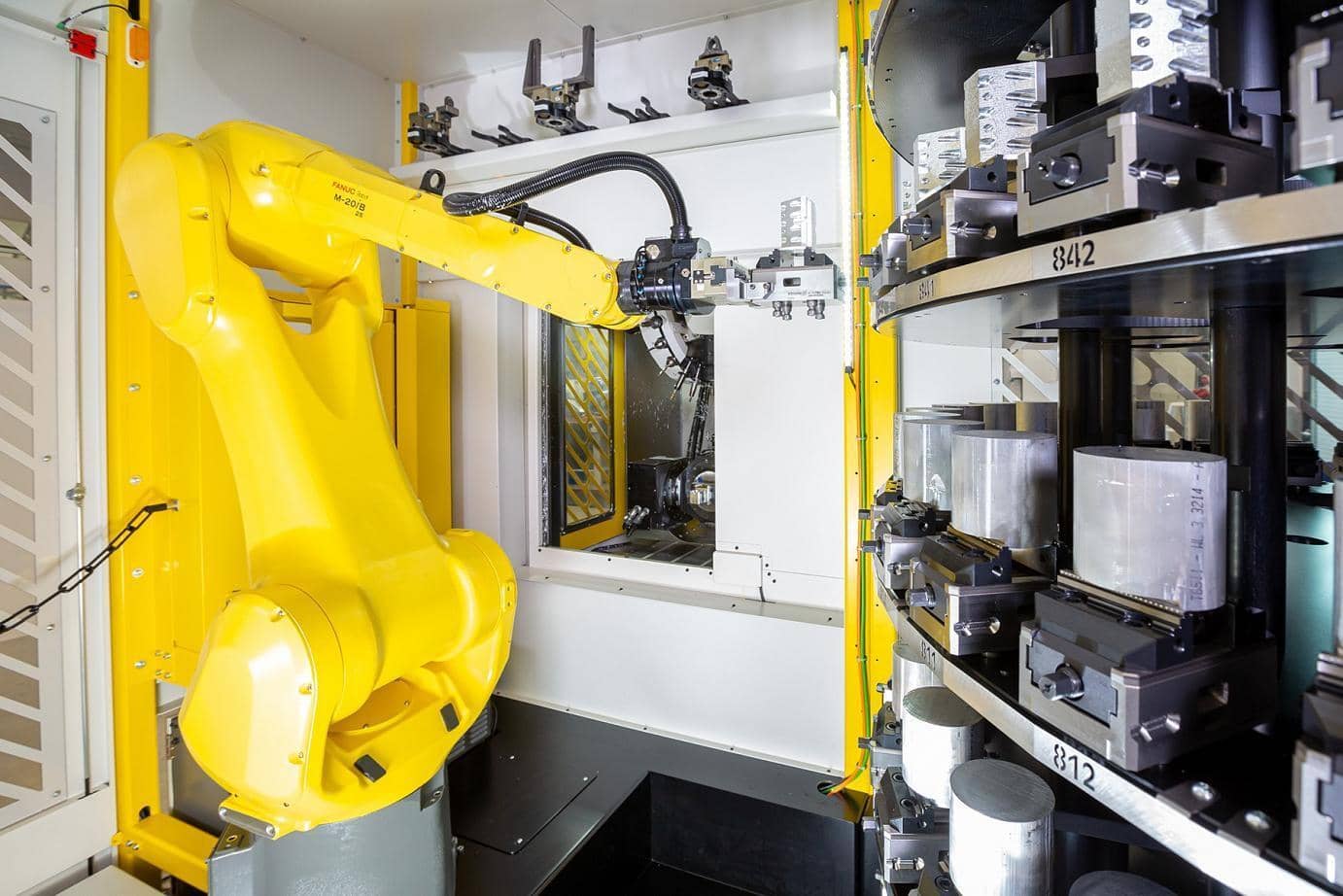

Honyo Prototype delivers end-to-end CNC machining expertise across 3-axis, 4-axis, and 5-axis platforms, handling materials from aluminum and stainless steel to exotic alloys like Inconel and titanium. Our facility combines state-of-the-art Haas and DMG MORI equipment with in-house robotics for unattended machining, palletizing, and part handling. Every process adheres to ISO 9001 standards, supported by rigorous first-article inspections, real-time in-process gauging, and full documentation. This infrastructure enables us to execute tight-tolerance geometries, complex contours, and high-mix part runs with uncompromised reliability—turning conceptual designs into mission-critical components.

Central to our client experience is the Online Instant Quote system, engineered for speed without sacrificing accuracy. Upload your 3D CAD file (STEP, IGES, or native formats), specify material, quantity, and critical tolerances, and receive a detailed cost and lead time assessment within minutes. This transparent, data-driven tool leverages our machining database to evaluate manufacturability upfront, flagging potential design optimizations to reduce costs. No more waiting for manual RFQ reviews; accelerate your project timeline from design validation to shop floor scheduling with a single digital workflow.

Partner with Honyo Prototype to leverage automation not as an add-on, but as the foundation of your precision manufacturing strategy. We bridge engineering intent with flawless execution, ensuring your CNC-machined components meet the highest benchmarks of performance and repeatability. Initiate your next project with confidence—start with an instant quote today.

Technical Capabilities

CNC Automatisering Technical Specifications

The following table outlines the key technical specifications for CNC automation systems focused on 3-axis, 4-axis, and 5-axis milling, as well as turning operations. These systems are engineered for high precision, repeatability, and tight tolerance machining across a range of engineering materials including aluminum, steel, ABS, and nylon.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Axis Configuration | X, Y, Z | X, Y, Z, A (rotary) | X, Y, Z, A, B (dual rotary) | X, Z, (C-axis optional) |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.005 mm | ±0.003 mm |

| Repeatability | ±0.002 mm | ±0.002 mm | ±0.002 mm | ±0.001 mm |

| Typical Tolerance Range | ±0.01 mm to ±0.025 mm | ±0.01 mm to ±0.025 mm | ±0.005 mm to ±0.01 mm | ±0.005 mm to ±0.015 mm |

| Spindle Speed (max) | 24,000 rpm | 24,000 rpm | 30,000 rpm | 6,000 rpm (chuck), 12,000 rpm (collet) |

| Spindle Power | 15 – 22 kW | 15 – 22 kW | 18 – 26 kW | 7 – 15 kW |

| Tool Magazine Capacity | 20 – 30 tools | 20 – 30 tools | 30 – 60 tools | 8 – 12 tool stations |

| Automation Interface | Robotic loader ready, pallet changers, bar feeders (turning), FMS integration | |||

| Materials Compatible | Aluminum, Steel, ABS, Nylon, PEEK, Delrin, Titanium (with appropriate tooling) | |||

| Surface Finish (typical) | Ra 0.8 – 1.6 µm | Ra 0.8 – 1.6 µm | Ra 0.4 – 0.8 µm | Ra 0.4 – 1.6 µm |

| Coolant System | High-pressure through-spindle option, mist collection, chip conveyors | |||

| Control System | Siemens SINUMERIK, Heidenhain, FANUC, or Mitsubishi M80/M800 series | |||

| Cycle Time Reduction (vs manual) | 40–60% | 50–70% | 60–80% | 50–75% |

Notes on Material Machining Performance

Aluminum and ABS are easily machined with high feed rates and minimal tool wear, ideal for automated high-volume runs. Steel and nylon require optimized tool paths and coolant strategies; steel demands robust tooling for tight tolerance work, while nylon benefits from sharp tools and chip control to avoid melting. 5-axis systems enable complete machining of complex geometries in a single setup, critical for maintaining tight tolerances in aerospace and medical components.

From CAD to Part: The Process

Honyo Prototype employs a streamlined CNC automation workflow designed to maximize efficiency and quality for B2B clients. This integrated process eliminates traditional bottlenecks while maintaining rigorous engineering oversight at critical stages.

The process initiates with secure CAD file upload via our client portal. We accept industry-standard formats including STEP AP203/AP214, IGES, Parasolid, and native files from SolidWorks, Creo, NX, and Fusion 360. All uploads undergo automated validation for geometric integrity and unit consistency before entering the quoting phase.

Our AI Quote engine analyzes the validated CAD geometry alongside client-specified parameters to generate instant preliminary pricing and lead time estimates. This system leverages historical production data from 50,000+ completed CNC projects and real-time machine utilization metrics. Critical inputs driving the AI calculation include:

| Parameter | Required Input Format | Impact on Quotation |

|---|---|---|

| Material | ISO standard grade | Raw material cost & machining time |

| Quantity | Integer | Setup amortization & batch logic |

| Tolerance | ISO 2768 or GD&T | Process selection & inspection |

| Surface Finish | Ra value or standard | Toolpath complexity & polishing |

Following AI-generated quoting, all projects undergo mandatory human-led Design for Manufacturing (DFM) review by our applications engineering team. This phase identifies manufacturability improvements such as optimizing wall thicknesses, suggesting alternative tool access strategies, or recommending cost-effective material substitutions. Clients receive a collaborative DFM report with actionable suggestions within 4 business hours, requiring formal sign-off before production release.

Production executes on our network of 127 CNC machines (62% 5-axis, 38% 3-axis) with centralized tool management and automated material handling systems. Key production protocols include:

First-article inspection using calibrated CMMs against client-provided GD&T

Real-time machine monitoring with SPC data logging for critical dimensions

Automated G-code verification via collision simulation software

Dedicated production cells for aluminum, steel, and engineering plastics

Final delivery encompasses comprehensive documentation including first-article inspection reports, material certifications (mill test reports), and as-machined 3D scan data upon request. Shipments are dispatched via tracked logistics partners with climate-controlled options for precision components. Standard lead time from DFM approval to delivery is 7-12 business days for quantities under 500 units, with expedited options available for time-critical projects. All components undergo final dimensional validation against the approved CAD model prior to shipment release.

Start Your Project

Interested in CNC automation solutions to enhance your manufacturing efficiency? Contact Susan Leo today at [email protected] to discuss tailored automation strategies for your production needs.

Honyo Prototype operates a fully equipped factory in Shenzhen, enabling rapid prototyping, precision machining, and integrated CNC automation systems—all under one roof.

Let us help you optimize throughput, reduce labor costs, and improve repeatability with smart automation. Reach out now to schedule a consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.