Contents

Manufacturing Insight: Cnc Auto Care

Precision CNC Machining for Demanding Automotive Applications

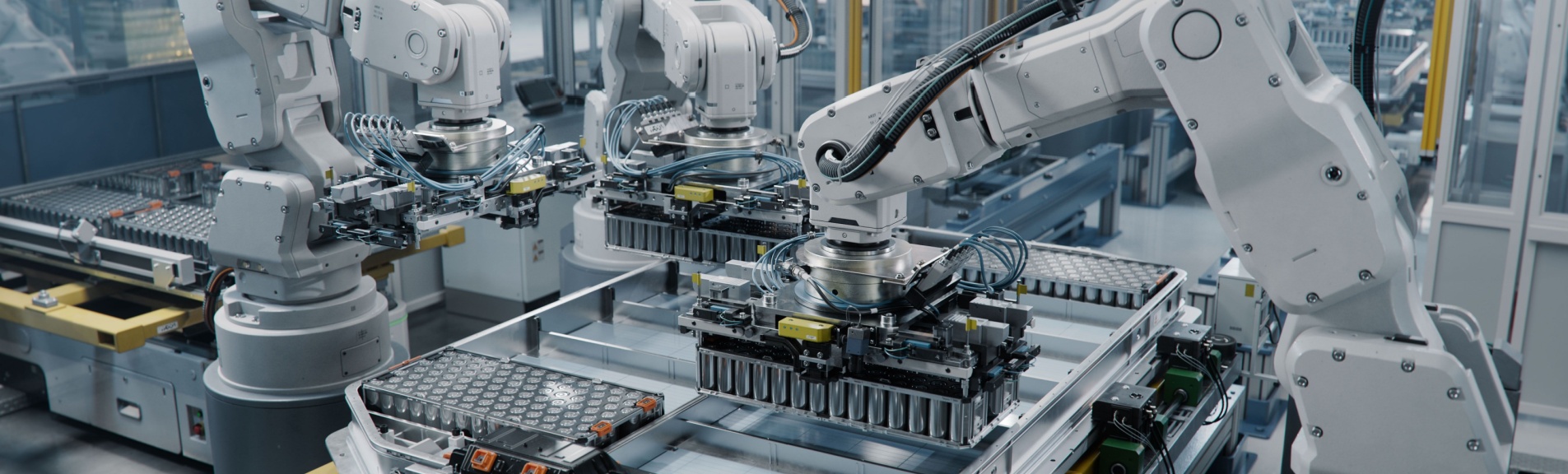

Honyo Prototype delivers mission-critical CNC machining services engineered specifically for the automotive sector, where dimensional accuracy, material integrity, and repeatability directly impact vehicle safety and performance. Our ISO 9001-certified facility leverages advanced 3-, 4-, and 5-axis milling and turning centers to produce complex components—from fuel system housings and transmission subassemblies to sensor brackets and EV battery components—with tolerances held to ±0.0002 inches. We specialize in challenging materials including aerospace-grade aluminum alloys, stainless steels, and high-temperature polymers, ensuring parts meet stringent automotive validation protocols and OE specifications.

Accelerate Development with Real-Time Quoting

Eliminate procurement delays with Honyo’s Online Instant Quote platform, designed for engineering teams requiring rapid feedback on complex automotive geometries. Upload CAD files directly to receive a detailed manufacturability analysis, material-cost breakdown, and lead time estimate within hours—not days—enabling faster iteration cycles for prototyping and low-volume production. This seamless integration between design intent and manufacturing execution reduces time-to-test by up to 40% while maintaining full traceability for PPAP documentation. Partner with Honyo to transform automotive component challenges into validated, production-ready solutions backed by rigorous first-article inspection and CMM reporting.

Technical Capabilities

Honyo Prototype provides high-precision CNC machining services under the “CNC Auto Care” program, optimized for automotive and industrial applications requiring tight tolerances, complex geometries, and superior surface finishes. Our capabilities span 3-axis, 4-axis, and 5-axis milling, as well as precision turning, supporting a wide range of engineering-grade materials.

| Feature | Specification |

|---|---|

| Machining Types | 3-Axis Milling, 4-Axis Indexing Milling, 5-Axis Simultaneous Milling, CNC Turning (Swiss and Standard) |

| Tolerance Capability | ±0.005 mm (±0.0002″) typical; tight tolerance down to ±0.002 mm (±0.0001″) with process control |

| Positioning Accuracy (Milling) | ±0.003 mm |

| Repeatability (Milling) | ±0.002 mm |

| Spindle Speed (Milling) | Up to 24,000 RPM (high-speed options available) |

| Turning Diameter Range | Ø2 mm to Ø300 mm |

| Max Work Envelope (5-Axis) | 1,200 mm × 800 mm × 600 mm (X×Y×Z) |

| Surface Finish (As-Machined) | Ra 0.8 μm standard; down to Ra 0.4 μm with fine finishing |

| Supported Materials | Aluminum (6061, 7075, 2024), Steel (1018, 4140, 4340, Stainless 303, 304, 316), ABS, Nylon (PA6, PA66), and other engineering plastics |

| Aluminum Machining | High-speed cutting with optimized feeds and speeds; excellent for lightweight structural and heat-dissipating components |

| Steel Machining | Hard turning and milling up to 60 HRC; suitable for high-strength drivetrain and chassis parts |

| ABS Machining | Low-force cutting parameters to prevent melting; ideal for prototypes and non-structural housings |

| Nylon Machining | Controlled depth of cut and specialized tooling to manage material flexibility and thermal expansion; used in wear-resistant bushings, gears, and insulators |

| Coolant & Lubrication | High-pressure through-spindle coolant for metals; air blow or mist for plastics |

| Inspection & Quality Control | In-process and final CMM inspection, optical comparators, and surface roughness testers; full FAI and PPAP reporting available |

All CNC Auto Care operations are performed on state-of-the-art machining centers with FANUC, Siemens, or Heidenhain controls, ensuring consistent repeatability and compliance with ISO 9001 standards. Our engineering team supports DFM feedback and rapid prototyping-to-production transitions.

From CAD to Part: The Process

Honyo Prototype employs a rigorously optimized workflow for CNC machining projects, branded internally as our Automated CNC Quoting Process. This structured sequence ensures technical precision, cost transparency, and manufacturability from initial concept to delivery. Below is a technical breakdown of each phase:

CAD Upload and Specification Finalization

Clients initiate the process by uploading native CAD files (STEP, IGES, or Parasolid formats preferred) via our secure portal. Critical parameters including material grade (e.g., 6061-T6 aluminum per ASTM B221), geometric dimensioning and tolerancing (GD&T) requirements, surface finish specifications (e.g., Ra 1.6 µm), and quantity must be explicitly defined. Our system validates file integrity and completeness before proceeding, rejecting submissions with ambiguous features or missing critical data to prevent downstream errors.

AI-Powered Preliminary Quoting

Upon CAD validation, our proprietary AI engine processes the geometry through a multi-parameter algorithm. This analyzes machinable volume, feature complexity (e.g., deep cavities >5:1 aspect ratio), toolpath collision risks, and material utilization efficiency. The output is a real-time preliminary quote with cost breakdowns for machining hours, material waste, and secondary operations. Crucially, this AI stage flags potential manufacturability concerns but does not override engineering judgment—it serves as a data-driven starting point for human review. Typical turnaround: under 90 seconds for standard geometries.

Human-Led DFM Analysis and Quote Finalization

All projects undergo mandatory Design for Manufacturability (DFM) review by Honyo’s senior CNC engineers. This phase involves:

Cross-referencing AI-identified risks against our 12,000+ part historical database

Proposing actionable optimizations (e.g., suggesting chamfers instead of sharp internal corners to prevent tool breakage)

Validating fixture strategy feasibility for 5-axis vs. 3-axis machining

Confirming tolerance stack-up compliance per ASME Y14.5 standards

The final quote, issued within 4 business hours, includes detailed DFM feedback, revised lead times, and cost-saving alternatives. No project advances to production without explicit client approval of this engineering-reviewed quote.

Precision Production Execution

Approved orders enter our tiered production system:

| Stage | Process Control | Verification Method |

|——–|—————–|———————|

| Setup | CAM programming via Mastercam 2024; tooling validated in offline simulators | G-code dry-run on Haas UMC-750 |

| Machining | Real-time spindle load monitoring; in-process probing for feature verification | On-machine touch-trigger probes per ISO 10360-2 |

| Post-Processing | Deburring via automated vibratory systems; optional anodizing/heat treat | First-article inspection (FAI) per AS9102 |

All critical dimensions undergo 100% inspection using Zeiss CONTURA CMMs, with full inspection reports accessible via client portal.

Logistics and Delivery Assurance

Finished parts undergo final packaging in ESD-safe foam inserts within humidity-controlled environments. Every shipment includes:

Dimensional conformance certificate with actual vs. nominal measurements

Material test report (MTR) traceable to mill certificate

Digital twin of the manufactured part (point cloud scan)

Standard delivery is 7–10 business days from DFM approval, with expedited 72-hour options for urgent orders. All shipments include real-time GPS tracking and customs documentation for international clients.

This closed-loop process eliminates quoting guesswork while ensuring every component meets aerospace-grade quality standards (NADCAP accredited). The integration of AI speed with mandatory human engineering oversight reduces prototyping lead times by 40% compared to industry averages, without compromising on first-pass yield rates (98.7% in Q1 2024). We recommend initiating projects with our CAD template to maximize process efficiency.

Start Your Project

Looking for precision CNC auto care solutions? Contact Susan Leo at [email protected] to discuss your project requirements. Our manufacturing facility is located in Shenzhen, ensuring fast turnaround and high-quality production for automotive prototypes and components. Partner with Honyo Prototype for reliable, precision-driven results.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.