Introduction: Navigating the Global Market for cnc auto care

In an increasingly interconnected world, sourcing reliable CNC auto care solutions poses significant challenges for international B2B buyers. Whether you are a company in Africa, South America, the Middle East, or Europe, understanding the nuances of CNC auto care—from equipment types to maintenance applications—can be daunting. This comprehensive guide is designed to demystify the complexities of the CNC auto care market, equipping you with the knowledge to make informed purchasing decisions.

We delve into various aspects of CNC auto care, including the types of services available, common applications across different industries, and effective strategies for vetting suppliers. Additionally, we will explore cost factors, ensuring you understand the financial implications of your choices. By offering actionable insights and expert recommendations, this guide empowers you to navigate the global market with confidence.

As you seek to optimize your auto care operations, this resource will serve as a vital tool, enabling you to identify quality suppliers and establish productive partnerships. With the right information at your fingertips, you can enhance your procurement processes and ensure the longevity and performance of your CNC machinery. Let’s embark on this journey together, transforming the way you approach CNC auto care.

Understanding cnc auto care Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Preventive Maintenance | Regular inspections and servicing to prevent issues | Fleet management, logistics companies | Pros: Reduces long-term repair costs. Cons: Upfront costs can be high. |

| Emergency Repairs | On-demand services for urgent vehicle issues | Transportation companies, delivery services | Pros: Minimizes downtime. Cons: Can be more expensive due to urgency. |

| Diagnostic Services | Comprehensive checks to identify vehicle problems | Automotive manufacturers, repair shops | Pros: Early detection of issues. Cons: May require specialized tools and expertise. |

| Specialized Repairs | Focused services for specific vehicle types | Luxury car dealerships, specialty auto shops | Pros: High-quality, tailored solutions. Cons: Limited to certain vehicle types. |

| Fleet Management Services | Comprehensive vehicle management solutions | Corporations with vehicle fleets | Pros: Streamlines operations and costs. Cons: Requires ongoing commitment and monitoring. |

What are the Characteristics of Preventive Maintenance in CNC Auto Care?

Preventive maintenance involves routine inspections and servicing aimed at identifying and rectifying potential issues before they escalate. This type of care is essential for businesses that rely heavily on their vehicles, such as logistics and transportation companies. By investing in preventive maintenance, B2B buyers can significantly reduce long-term repair costs and enhance vehicle longevity. However, the initial investment can be substantial, making it crucial for companies to weigh the benefits against their operational budgets.

How Do Emergency Repairs Benefit B2B Buyers?

Emergency repairs are designed to address urgent vehicle problems that can disrupt business operations. This service is invaluable for companies that depend on timely deliveries or transportation, such as delivery services and logistics providers. The primary advantage of emergency repairs is the ability to minimize vehicle downtime, allowing businesses to maintain their service levels. However, these services often come at a premium, so buyers should prepare for potential higher costs associated with urgent repairs.

Why are Diagnostic Services Critical for B2B Operations?

Diagnostic services are essential for accurately identifying vehicle issues through comprehensive checks and assessments. This type of care is particularly relevant for automotive manufacturers and repair shops that require precise information to make informed decisions about repairs. Early detection of issues can save businesses significant costs down the line. However, buyers should be aware that these services may necessitate specialized tools and expertise, which could impact overall costs.

What Should Buyers Consider About Specialized Repairs?

Specialized repairs focus on specific vehicle types or brands, catering to high-end or unique automotive needs. This service is particularly beneficial for luxury car dealerships and specialty auto shops that want to offer tailored solutions to their clients. The primary advantage of specialized repairs is the assurance of high-quality service that meets specific requirements. However, buyers should note that such services may not be available for all vehicle types, limiting their options.

How Can Fleet Management Services Streamline Operations?

Fleet management services offer comprehensive solutions for managing a company’s vehicle fleet, encompassing maintenance, repairs, and tracking. This service is particularly advantageous for corporations with extensive fleets, as it helps streamline operations and control costs. By implementing fleet management, businesses can achieve better resource allocation and efficiency. However, this requires an ongoing commitment and monitoring, which may necessitate additional resources and personnel.

Key Industrial Applications of cnc auto care

| Industry/Sector | Specific Application of cnc auto care | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Precision machining of automotive components | Enhanced product quality and reduced waste | Supplier reliability, quality certifications, and lead times |

| Aerospace | Maintenance of aircraft components | Improved safety and compliance with regulations | Compliance with international standards, material specifications |

| Heavy Machinery | Repair and maintenance of CNC machinery | Reduced downtime and increased operational efficiency | Technical support, availability of spare parts, and service agreements |

| Renewable Energy | Fabrication of components for wind turbines | Increased durability and performance | Material sourcing, sustainability practices, and certifications |

| Electronics | Production of precision parts for electronic devices | Higher accuracy and reduced production costs | Technology compatibility, precision capabilities, and delivery timelines |

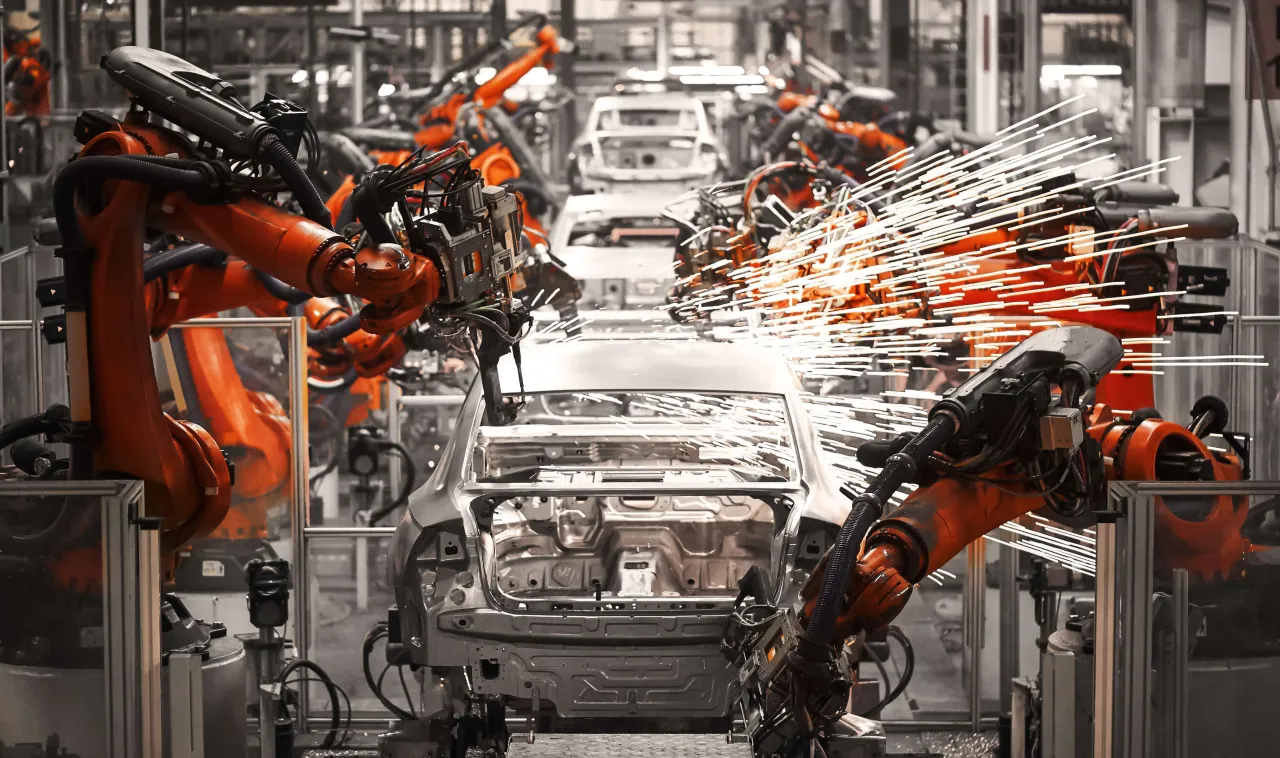

How is CNC Auto Care Applied in Automotive Manufacturing?

In the automotive manufacturing sector, CNC auto care is pivotal for the precision machining of various components such as engine parts, transmission systems, and chassis elements. This technology ensures that parts meet stringent quality standards, reducing the likelihood of defects and waste. Buyers in this sector must prioritize suppliers with proven reliability and quality certifications, as any failure in component quality can lead to significant production delays and financial losses.

What Role Does CNC Auto Care Play in Aerospace?

CNC auto care is essential for the aerospace industry, where the maintenance and production of aircraft components must adhere to rigorous safety standards. Precision machining ensures that parts like turbine blades and fuselage sections are manufactured to exact specifications, enhancing overall safety and compliance with international regulations. B2B buyers must focus on suppliers that can demonstrate compliance with aerospace standards and provide detailed material specifications to ensure optimal performance.

How Does CNC Auto Care Benefit Heavy Machinery Operations?

In the heavy machinery sector, CNC auto care is utilized for the repair and maintenance of CNC machinery, which is critical for operations involving large-scale manufacturing and construction. By employing CNC auto care, businesses can minimize downtime and enhance operational efficiency through timely repairs and maintenance. Key considerations for sourcing include the availability of technical support, spare parts, and comprehensive service agreements to ensure continuous operation.

In What Ways is CNC Auto Care Utilized in Renewable Energy?

CNC auto care is increasingly important in the renewable energy sector, particularly in the fabrication of components for wind turbines. Precision machining enhances the durability and performance of these components, contributing to more efficient energy production. Buyers must consider the sourcing of materials that meet sustainability practices and certifications, ensuring that suppliers align with their environmental goals while providing high-quality components.

How is CNC Auto Care Applied in Electronics Manufacturing?

In the electronics industry, CNC auto care is critical for producing precision parts used in various electronic devices, from smartphones to industrial machinery. The high accuracy achieved through CNC machining can significantly reduce production costs while improving product reliability. When sourcing, businesses should evaluate the technology compatibility of potential suppliers, their precision capabilities, and adherence to delivery timelines to maintain a competitive edge in the market.

3 Common User Pain Points for ‘cnc auto care’ & Their Solutions

Scenario 1: Managing Downtime Due to Unexpected Repairs

The Problem: B2B buyers in the automotive sector often face significant challenges when their vehicles experience unexpected breakdowns or require urgent repairs. This not only disrupts operations but can also lead to financial losses, especially if the vehicles are vital for transportation or delivery services. The uncertainty of repair timelines and costs can cause frustration and anxiety, as businesses rely heavily on their fleets to meet customer demands and maintain service levels.

The Solution: To mitigate downtime and manage repair expectations effectively, B2B buyers should establish relationships with reliable CNC auto care providers who offer transparent communication regarding repair processes. Buyers should prioritize workshops that provide detailed diagnostics and clear timelines for repairs. Additionally, implementing a proactive maintenance schedule can help identify potential issues before they escalate into costly repairs. This involves regular check-ups and utilizing diagnostic tools to monitor vehicle health. By fostering a partnership with a trusted auto care provider, businesses can ensure quicker turnaround times and minimize the impact of unexpected repairs.

Scenario 2: Difficulty in Sourcing Quality Parts

The Problem: Sourcing quality parts for vehicle maintenance and repairs can be a daunting task for B2B buyers, especially when dealing with international suppliers. Issues such as counterfeit parts, long lead times, and inconsistent quality can compromise vehicle performance and safety. Buyers often find themselves in a position where they must balance cost, quality, and availability, which can lead to frustration and decision paralysis.

The Solution: To navigate the complexities of sourcing quality parts, B2B buyers should leverage a network of reputable suppliers who specialize in CNC auto care components. Establishing partnerships with suppliers who have a proven track record in quality assurance and certification can significantly reduce the risk of counterfeit parts. Additionally, buyers should invest in supplier audits and require documentation of parts provenance to ensure quality standards are met. Utilizing technology, such as inventory management systems, can also aid in tracking parts usage and predicting future needs, enabling timely reordering and avoiding stockouts.

Scenario 3: Navigating Compliance and Regulatory Standards

The Problem: B2B buyers in the automotive industry must adhere to various compliance and regulatory standards that can vary significantly between regions, such as emissions regulations and safety standards. This complexity can lead to confusion, potential fines, and costly compliance failures. Understanding and implementing these regulations within CNC auto care practices can be overwhelming, particularly for businesses operating in multiple countries.

The Solution: To effectively navigate compliance and regulatory standards, B2B buyers should engage with experts in automotive law and industry best practices. Partnering with CNC auto care providers who have in-depth knowledge of local regulations can streamline compliance processes. Additionally, investing in training for staff on regulatory requirements and conducting regular audits can help ensure adherence to standards. Buyers should also consider implementing a compliance management system that provides real-time updates on changes in regulations, enabling proactive adjustments to operations and maintenance practices. By staying informed and partnering with knowledgeable providers, businesses can mitigate risks associated with non-compliance and maintain operational integrity.

Strategic Material Selection Guide for cnc auto care

What Are the Key Materials Used in CNC Auto Care?

In the realm of CNC auto care, the selection of materials is crucial for ensuring the longevity and efficiency of automotive components. This guide analyzes four common materials used in this sector, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Aluminum: A Lightweight and Versatile Choice

Aluminum is widely used in automotive applications due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating up to 400°F (204°C) and can withstand moderate pressure.

Pros: Aluminum is durable and offers a good strength-to-weight ratio, making it ideal for components like engine blocks and transmission housings. Its ease of machining also simplifies manufacturing processes, reducing lead times.

Cons: However, aluminum can be more expensive than steel, and its lower tensile strength may limit its use in high-stress applications. Additionally, the welding of aluminum requires specialized techniques, which can complicate repairs.

Impact on Application: Aluminum is compatible with various automotive fluids, making it suitable for coolant systems and fuel tanks.

International Considerations: Buyers should ensure compliance with standards such as ASTM B221 for extruded aluminum products. In regions like Europe and Germany, adherence to DIN standards is also critical.

Steel: The Backbone of Automotive Manufacturing

Steel remains a staple in automotive manufacturing due to its high strength and durability. It can handle high temperatures and pressures, making it suitable for critical components like frames and suspensions.

Pros: Steel is relatively inexpensive and offers excellent wear resistance, making it ideal for parts that undergo significant stress. Its versatility allows for various manufacturing processes, including forging and stamping.

Cons: On the downside, steel is heavier than aluminum, which can negatively impact fuel efficiency. It is also prone to corrosion if not properly treated, necessitating additional coatings or treatments.

Impact on Application: Steel’s robustness makes it suitable for high-stress applications, but its weight may limit its use in performance-oriented vehicles.

International Considerations: Compliance with standards like ASTM A36 for structural steel is essential. Buyers in the Middle East should also consider local corrosion resistance requirements due to the region’s climate.

Composite Materials: A Modern Solution

Composite materials, such as carbon fiber and fiberglass, are increasingly popular in automotive applications for their lightweight and high-strength properties. They can withstand high temperatures and offer excellent fatigue resistance.

Pros: Composites are exceptionally lightweight, which can significantly improve fuel efficiency and performance. They also provide superior corrosion resistance compared to metals.

Cons: The main drawback is the high cost of composite materials and the complexity of their manufacturing processes. Repairing composite components can also be challenging, requiring specialized skills.

Impact on Application: Composites are ideal for performance vehicles and racing applications where weight savings are critical. However, they may not be suitable for all automotive parts due to cost constraints.

International Considerations: Compliance with standards such as ASTM D7264 for composite materials is crucial. Buyers from South America should be aware of local regulations regarding the use of composites in automotive applications.

Rubber: Essential for Sealing and Vibration Damping

Rubber is commonly used in automotive applications for seals, gaskets, and vibration dampers. It can withstand a range of temperatures, typically from -40°F to 250°F (-40°C to 121°C), depending on the formulation.

Pros: Rubber is highly flexible and provides excellent sealing properties, making it ideal for preventing leaks in fluid systems. Its vibration-damping characteristics also enhance ride comfort.

Cons: However, rubber can degrade over time due to exposure to heat, ozone, and certain chemicals, requiring regular replacement.

Impact on Application: Rubber’s compatibility with various automotive fluids makes it suitable for seals in engines and transmissions.

International Considerations: Buyers should ensure compliance with ASTM D2000 for rubber materials. In Europe, adherence to REACH regulations regarding chemical safety is essential.

Summary Table

| Material | Typical Use Case for cnc auto care | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Engine blocks, transmission housings | Lightweight, corrosion-resistant | Higher cost, lower tensile strength | Medium |

| Steel | Frames, suspensions | High strength, cost-effective | Heavier, prone to corrosion | Low |

| Composite | Performance vehicles, racing parts | Lightweight, high strength | High cost, complex repairs | High |

| Rubber | Seals, gaskets | Excellent sealing, flexible | Degradation over time | Low |

This guide serves as a valuable resource for international B2B buyers in selecting the right materials for CNC auto care, ensuring compliance with local standards and meeting specific application needs.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc auto care

What Are the Key Stages in the Manufacturing Process for CNC Auto Care?

The manufacturing process for CNC auto care components involves several critical stages, each designed to ensure that the final products meet stringent quality and performance standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in the manufacturing process involves selecting the right materials for CNC machining. Common materials used in auto care components include aluminum, steel, and various polymers, which are chosen based on their durability, weight, and resistance to corrosion. Once selected, materials undergo thorough inspection for quality assurance. This includes checking for defects, dimensions, and chemical composition, ensuring they meet the specified standards.

What Techniques Are Used in the Forming Stage?

Forming is a crucial stage where raw materials are shaped into specific components using CNC machines. Techniques such as milling, turning, and grinding are commonly employed. Each of these methods utilizes computer numerical control (CNC) technology to achieve high precision in shaping parts. For instance, milling machines can create complex geometries, while lathes are used for cylindrical parts. The CNC process minimizes human error and increases efficiency, allowing manufacturers to produce high volumes of components with consistent quality.

How Is Assembly Conducted in CNC Auto Care Manufacturing?

Once individual components are formed, they move to the assembly stage. This involves fitting together the various parts to create a complete unit. Automated assembly lines are often used to streamline this process, allowing for rapid production while maintaining quality control. Skilled technicians may also perform manual assembly for more complex components requiring intricate fitting. During assembly, components are checked against specifications to ensure proper alignment and functionality.

What Are the Finishing Techniques in CNC Auto Care Production?

The finishing stage includes processes such as surface treatment, coating, and polishing, aimed at enhancing the aesthetic and functional qualities of the components. Techniques like anodizing, powder coating, and electroplating are commonly used to improve corrosion resistance and durability. Additionally, finishing processes may include quality checks to ensure that the surface characteristics meet industry standards.

How Is Quality Assurance Implemented in CNC Auto Care Manufacturing?

Quality assurance is paramount in the manufacturing of CNC auto care components, involving a series of checks and balances throughout the production process. International standards such as ISO 9001 provide frameworks for quality management systems, ensuring consistency and reliability in manufacturing.

What International Standards Are Relevant for CNC Auto Care Manufacturing?

ISO 9001 is one of the most recognized quality management standards globally. It requires organizations to demonstrate their ability to consistently provide products that meet customer and regulatory requirements. Other industry-specific certifications include CE marking for compliance with European safety standards and API standards for oil and gas components. These certifications assure B2B buyers of the quality and safety of the products they are purchasing.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process, including:

- Incoming Quality Control (IQC): This initial stage inspects raw materials and components before production begins.

- In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC ensures that each stage meets quality standards.

- Final Quality Control (FQC): After assembly, FQC involves comprehensive testing and inspection of the final product before it is shipped to customers.

These checkpoints help identify and rectify issues at various stages, reducing the risk of defective products reaching the market.

What Common Testing Methods Are Used in Quality Assurance?

Testing methods vary based on the component type and its intended use. Common methods include dimensional inspection using calipers and gauges, non-destructive testing (NDT) for detecting internal flaws, and performance testing under simulated operating conditions. These methods help verify that products not only meet specifications but also perform reliably in real-world applications.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in international markets such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is critical to ensuring product reliability. Here are several approaches:

- Conducting Audits: Regular audits of suppliers can reveal their manufacturing processes and quality assurance practices. Buyers should look for compliance with relevant international standards.

- Requesting Quality Reports: Suppliers should be able to provide detailed quality reports that outline their testing methods, results, and any corrective actions taken.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control measures and manufacturing capabilities.

What Are the QC and Certification Nuances for International Buyers?

International buyers must be aware of the specific quality assurance requirements and certifications relevant to their regions. For instance, European buyers may prioritize CE marking, while buyers in the Middle East might look for compliance with local regulations. Understanding these nuances can help buyers make informed decisions and ensure that they are sourcing products that meet their specific needs.

Conclusion

In conclusion, the manufacturing processes and quality assurance measures for CNC auto care components are intricate and essential for delivering high-quality products. By understanding the stages of manufacturing, relevant quality standards, and verification methods, B2B buyers can make informed decisions that ensure they source reliable components suitable for their markets. This knowledge not only mitigates risks but also fosters long-term partnerships with reputable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc auto care’

Introduction

This practical sourcing guide is designed to assist B2B buyers in procuring CNC auto care services effectively. With the automotive industry becoming increasingly competitive, understanding the essential steps for sourcing high-quality services is vital. This checklist will help you navigate the complexities of vendor selection and ensure you partner with reliable suppliers that meet your business needs.

Step 1: Define Your Technical Specifications

Clearly outline the specific services you require in CNC auto care. This includes detailing the types of repairs, maintenance schedules, and any specialized services needed, such as diagnostics or emergency repairs. Defining these specifications upfront ensures that you communicate your expectations effectively to potential suppliers.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers in the CNC auto care sector. Utilize online platforms, industry directories, and trade shows to gather a list of candidates. Focus on their service offerings, industry reputation, and customer reviews to create a shortlist of viable partners.

Step 3: Evaluate Supplier Certifications

Verify the certifications and qualifications of potential suppliers. Look for industry-standard certifications such as ISO or specific automotive repair certifications, which indicate a commitment to quality and safety. This step is crucial as it ensures that the supplier adheres to industry regulations and best practices.

Step 4: Request Proposals and Quotes

Once you have shortlisted suppliers, request detailed proposals and quotes. Ensure that these documents include pricing, service descriptions, timelines, and warranty information. Comparing proposals not only helps you gauge the cost-effectiveness of each option but also allows you to assess the comprehensiveness of their services.

Step 5: Check References and Case Studies

Ask for references from previous clients, particularly those in your industry or region. Reviewing case studies can provide insight into the supplier’s problem-solving capabilities and service quality. This step is essential to ensure that the supplier has a proven track record of success and customer satisfaction.

Step 6: Assess Customer Support and Communication

Evaluate the level of customer support and communication offered by the suppliers. Consider their responsiveness to inquiries, clarity in communication, and willingness to provide ongoing support. A supplier that prioritizes customer service can significantly enhance your experience and resolve issues swiftly.

Step 7: Finalize Contract Terms

Once you have selected a supplier, carefully review and finalize the contract terms. Pay close attention to service level agreements (SLAs), payment terms, and any warranties or guarantees provided. A well-defined contract protects both parties and establishes clear expectations for the partnership.

By following these steps, B2B buyers can make informed decisions when sourcing CNC auto care services, ensuring they partner with suppliers who are reliable, qualified, and capable of meeting their specific needs.

Comprehensive Cost and Pricing Analysis for cnc auto care Sourcing

What Are the Key Cost Components in CNC Auto Care?

When sourcing CNC auto care services, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The quality and type of materials used significantly influence costs. For CNC auto care, premium materials can lead to higher durability and performance, affecting the overall price.

-

Labor: Skilled labor is essential in CNC machining and auto care. Labor costs can vary based on the technician’s experience and the complexity of the service provided. Regions with higher labor costs may require negotiation to balance quality and pricing.

-

Manufacturing Overhead: This includes costs associated with running the facility, such as utilities, rent, and equipment maintenance. Understanding the overhead can help buyers evaluate the total cost of service.

-

Tooling: Specialized tools and machinery are often necessary for precise CNC operations. Buyers should inquire about the tooling costs and whether these are included in the service price or billed separately.

-

Quality Control (QC): Rigorous QC measures can add to costs but are essential for ensuring that the final product meets specifications. Buyers should assess the QC processes in place and their impact on pricing.

-

Logistics: Shipping and handling can be significant, especially for international transactions. Costs will vary based on the delivery method, distance, and any customs or tariffs involved.

-

Margin: Suppliers will typically include a profit margin in their pricing. Understanding industry standards can help buyers negotiate better terms.

How Do Price Influencers Affect CNC Auto Care Sourcing?

Several factors can influence pricing in CNC auto care sourcing:

-

Volume/MOQ (Minimum Order Quantity): Ordering in bulk can lead to significant cost savings. Suppliers often provide discounts for larger volumes, making it beneficial for businesses with ongoing needs.

-

Specifications and Customization: Customized parts or services often come at a premium. Buyers should clearly define their specifications to avoid unexpected costs and delays.

-

Materials: The choice of materials directly affects pricing. Higher-grade materials may incur additional costs but can improve the longevity and performance of the final product.

-

Quality and Certifications: Suppliers with industry certifications may charge higher prices due to the assurance of quality and compliance with standards. Buyers should weigh the importance of certifications against cost.

-

Supplier Factors: The reputation and experience of the supplier can also impact pricing. Established suppliers may command higher prices due to their reliability and service quality.

-

Incoterms: Understanding Incoterms is crucial for international buyers. These terms define the responsibilities of buyers and sellers in shipping costs and risks, which can significantly affect the total cost.

What Are Effective Buyer Tips for Negotiating CNC Auto Care Prices?

To maximize cost-efficiency in CNC auto care sourcing, consider the following tips:

-

Negotiate Terms: Engage in open discussions with suppliers about pricing. Many suppliers are willing to negotiate based on order volume or long-term partnerships.

-

Evaluate Total Cost of Ownership (TCO): Look beyond initial costs to assess the long-term value and expenses associated with maintenance, repairs, and potential downtimes.

-

Understand Pricing Nuances for International Buyers: For B2B buyers from Africa, South America, the Middle East, and Europe, currency fluctuations, shipping costs, and local market conditions can significantly impact pricing. It’s essential to factor in these elements when comparing suppliers.

-

Request for Quotations (RFQs): Sending RFQs to multiple suppliers can help buyers understand market prices and negotiate better deals.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing, priority service, and insights into upcoming promotions or discounts.

Disclaimer for Indicative Prices

The information provided here is for illustrative purposes only. Prices may vary based on market conditions, specific project requirements, and supplier negotiations. It is advisable for buyers to conduct thorough market research and obtain formal quotations to ensure accurate pricing for their specific needs.

Alternatives Analysis: Comparing cnc auto care With Other Solutions

When evaluating solutions for automotive care, B2B buyers have various options available in the market. Understanding the differences between these solutions can help businesses make informed decisions that align with their operational needs and budget constraints. Below is a comparison of ‘Cnc Auto Care’ against two viable alternatives, each with distinct features and benefits.

| Comparison Aspect | Cnc Auto Care | CC Auto Repair | C & C Auto Service |

|---|---|---|---|

| Performance | High precision in CNC machining; tailored services for complex vehicle repairs. | Reliable auto repairs with a focus on local clientele; known for customer satisfaction. | Comprehensive vehicle maintenance and repair services with a family-oriented approach. |

| Cost | Premium pricing due to specialized services and advanced technology. | Affordable rates with transparent pricing; often lower than dealerships. | Competitive pricing with a focus on value-added services, such as free shuttle and Wi-Fi. |

| Ease of Implementation | Requires specialized training and equipment; more complex setup. | Relatively easy to access; well-established local presence. | User-friendly service experience with flexible scheduling options. |

| Maintenance | Ongoing training needed for staff; equipment requires regular calibration. | Standard maintenance for tools and equipment; customer loyalty mitigates costs. | Low maintenance due to established processes; strong focus on preventive care. |

| Best Use Case | Ideal for businesses needing precision-engineered components or specialized vehicle modifications. | Best for local consumers seeking reliable and cost-effective repairs. | Suited for families or businesses looking for comprehensive care with a personal touch. |

What are the pros and cons of CC Auto Repair compared to Cnc Auto Care?

CC Auto Repair excels in affordability and customer service, making it a go-to for individuals and businesses looking for reliable auto repairs without breaking the bank. The shop’s local focus allows it to build strong relationships with customers, which can lead to repeat business. However, its services may not cater to specialized needs that require advanced technology or precision, limiting its appeal for businesses needing high-performance automotive solutions.

How does C & C Auto Service stack up against Cnc Auto Care?

C & C Auto Service offers a comprehensive range of automotive services with a family-owned approach that prioritizes customer satisfaction. Its additional amenities, such as complimentary shuttle services and free Wi-Fi, enhance the customer experience. However, like CC Auto Repair, it may not provide the specialized precision that Cnc Auto Care does, making it less suitable for high-end automotive needs or complex repairs.

Conclusion: How can B2B buyers choose the right solution for their automotive care needs?

When selecting an automotive care solution, B2B buyers should consider their specific requirements, including the complexity of repairs, budget constraints, and desired service level. For businesses that require precision and specialized services, Cnc Auto Care may be the ideal choice, despite its higher cost. Conversely, for those prioritizing affordability and convenience, CC Auto Repair or C & C Auto Service could provide effective alternatives. Ultimately, assessing the unique needs of the business and evaluating the strengths of each option will lead to the best decision.

Essential Technical Properties and Trade Terminology for cnc auto care

What Are the Key Technical Properties in CNC Auto Care?

In the CNC auto care industry, understanding specific technical properties is crucial for ensuring quality and reliability in automotive components and systems. Below are some of the critical specifications that B2B buyers should consider:

1. Material Grade

Material grade refers to the classification of materials based on their mechanical properties and chemical composition. In CNC auto care, common materials include aluminum, steel, and various alloys. The selection of the appropriate material grade is essential as it affects durability, weight, and resistance to corrosion. For instance, higher-grade steel may be more expensive but offers greater strength and longevity, making it a worthwhile investment for manufacturers looking for durability in their parts.

2. Tolerance

Tolerance is the permissible limit of variation in a physical dimension. In CNC machining, maintaining tight tolerances is critical to ensure parts fit together properly. For example, a tolerance of ±0.001 inches is often required in automotive components to guarantee proper assembly and function. Inaccurate tolerances can lead to increased wear, malfunction, and costly rework, highlighting the importance of precision in production processes.

3. Surface Finish

Surface finish denotes the texture and smoothness of a material’s surface after machining. Different automotive applications may require specific surface finishes to reduce friction, improve aesthetics, or enhance corrosion resistance. A smoother finish can lead to better performance and longevity of components, making it a key consideration during the design and manufacturing phases.

4. Hardness

Hardness measures a material’s resistance to deformation or scratching. In CNC auto care, hardness is particularly important for components subject to wear, such as gears and bearings. Harder materials can withstand greater stress and extend the lifespan of automotive parts, thus improving overall vehicle performance and reliability.

5. Coating

Coating refers to the application of a layer of material on the surface of a part to enhance its properties, such as corrosion resistance or wear resistance. For example, powder coating is commonly used in automotive applications to provide a durable and attractive finish. Understanding the types of coatings available can help buyers select components that meet specific environmental and operational demands.

What Are Common Trade Terms in CNC Auto Care?

Familiarity with industry-specific terminology can greatly enhance communication and decision-making in the CNC auto care sector. Here are some essential trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of CNC auto care, purchasing OEM parts ensures compatibility and quality, as these components are made to the original specifications of the vehicle manufacturer.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to manage inventory levels and ensure they are purchasing in economically viable quantities. Negotiating MOQs can lead to cost savings and better supply chain management.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products or services. This process allows buyers to compare offers from different suppliers, ensuring they make informed purchasing decisions based on cost, quality, and delivery timelines.

4. Incoterms

Incoterms (International Commercial Terms) are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping responsibilities, risk management, and cost allocation, which is crucial for international dealings in the auto care sector.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. In CNC auto care, understanding lead times is essential for effective inventory management and ensuring that production schedules are met. Shorter lead times can enhance responsiveness to market demands and reduce downtime in automotive operations.

By comprehensively understanding these technical properties and trade terms, B2B buyers in the CNC auto care sector can make more informed decisions, ultimately leading to improved product quality and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the cnc auto care Sector

What Are the Current Market Dynamics and Key Trends in the CNC Auto Care Sector?

The CNC auto care sector is experiencing notable growth, driven by increasing vehicle ownership globally and a rising demand for advanced automotive technologies. Key trends include the integration of digital solutions, such as telematics and predictive maintenance, which enable auto care businesses to provide enhanced service offerings. B2B buyers from regions like Africa, South America, the Middle East, and Europe are particularly interested in sourcing suppliers that embrace these technological advancements.

Furthermore, the market is witnessing a shift towards automation in repair processes, reducing labor costs and increasing efficiency. This trend is particularly beneficial for international buyers looking to streamline operations and improve turnaround times. The rise of e-commerce platforms has also transformed sourcing dynamics, allowing buyers to access a broader range of products and services with ease.

Emerging markets are fostering competition, leading to innovative service models, such as mobile repair units and subscription-based maintenance plans. For instance, European buyers are increasingly seeking partnerships with suppliers that offer flexible payment terms and scalable solutions to adapt to fluctuating demand. Understanding these dynamics is crucial for international B2B buyers aiming to make informed sourcing decisions in the CNC auto care landscape.

How Is Sustainability and Ethical Sourcing Impacting B2B in the CNC Auto Care Sector?

Sustainability and ethical sourcing are becoming paramount in the CNC auto care sector as environmental concerns gain prominence. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to reducing their carbon footprint and utilizing eco-friendly materials. The automotive industry significantly impacts the environment, and as a result, buyers are looking for partners who align with their sustainability goals.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing the sourcing practices of their suppliers, seeking those who adhere to fair labor practices and sustainable resource management. Certifications such as ISO 14001 for environmental management and LEED for green building can enhance supplier credibility and attract environmentally conscious buyers.

Moreover, the demand for ‘green’ automotive products is rising. This includes biodegradable lubricants, recycled components, and energy-efficient manufacturing processes. Suppliers that can provide these sustainable options will not only meet regulatory requirements but also appeal to a growing segment of buyers who are committed to corporate social responsibility. By prioritizing sustainability, B2B buyers can enhance their brand reputation and foster long-term relationships with eco-conscious consumers.

What Is the Brief Evolution of the CNC Auto Care Sector?

The CNC auto care sector has evolved significantly over the past few decades, transitioning from traditional mechanical services to a more technology-driven approach. Initially focused on basic repair and maintenance, the industry began to incorporate computer numerical control (CNC) technologies to enhance precision in manufacturing and repairs. This shift allowed for more efficient production of automotive parts and improved service delivery.

As vehicle technology advanced, so did the auto care sector, leading to the integration of diagnostics and electronic systems into repair services. The introduction of digital tools, such as vehicle management software and automated inventory systems, revolutionized how businesses operate. Today, CNC auto care encompasses a wide range of services, from routine maintenance to complex repairs, driven by a commitment to quality, efficiency, and customer satisfaction. This evolution continues to shape the landscape, making it essential for B2B buyers to stay informed about the latest trends and technologies in the sector.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc auto care

-

How do I choose the right CNC auto care supplier?

Selecting the right CNC auto care supplier involves evaluating several factors. Start by reviewing their expertise and experience in the industry, focusing on their track record with similar businesses. Check for certifications and adherence to international quality standards. Additionally, assess their customer service capabilities and responsiveness to inquiries. It’s also beneficial to seek testimonials or case studies from existing clients to gauge satisfaction levels. Conducting a site visit can further solidify your decision, allowing you to inspect their facilities and meet the team. -

What are the key quality assurance measures in CNC auto care?

Quality assurance in CNC auto care typically includes regular inspections and adherence to ISO standards. Suppliers should implement rigorous testing protocols for their products and services, including dimensional accuracy, surface finish, and material integrity checks. Many reputable suppliers will have documented QA processes, including the use of calibrated equipment and trained personnel. Additionally, ask about their warranty policies and after-sales support, as these are indicative of their commitment to quality and customer satisfaction. -

What is the minimum order quantity (MOQ) for CNC auto care services?

Minimum order quantities (MOQ) for CNC auto care services can vary significantly based on the supplier and the specific services required. It’s essential to discuss your needs with potential suppliers to understand their MOQ policies. Some may have flexible MOQs for first-time buyers or bulk orders, while others may set strict limits based on production capabilities. Clarifying MOQs upfront can help you avoid unexpected costs and ensure that your order aligns with your operational requirements. -

How can I ensure timely delivery of CNC auto care products?

To ensure timely delivery, establish clear communication with your supplier regarding lead times and shipping methods. Discuss the entire supply chain process, from manufacturing to logistics, to identify potential bottlenecks. Utilizing suppliers with a proven logistics partner can enhance reliability. It’s also advisable to set up regular updates on order status and have contingency plans in place for unforeseen delays. Lastly, consider suppliers who offer express shipping options for urgent needs. -

What payment terms should I expect when sourcing CNC auto care?

Payment terms for CNC auto care can vary based on the supplier’s policies and your negotiation skills. Common terms include upfront payments, net 30/60/90 days, or milestone payments based on project progress. It’s crucial to discuss and agree upon payment terms before finalizing contracts to avoid misunderstandings. Additionally, inquire about any discounts for early payments or bulk orders, as these can significantly affect your overall costs. -

How can I customize CNC auto care solutions for my business?

Customization of CNC auto care solutions is often possible by collaborating closely with your supplier. Discuss your specific requirements, including dimensions, materials, and finishes, during the initial consultation. Many suppliers offer tailored services to meet individual client needs, so it’s vital to communicate your expectations clearly. Additionally, requesting prototypes or samples can help ensure the final product aligns with your specifications before full-scale production. -

What should I know about international shipping for CNC auto care products?

When sourcing CNC auto care products internationally, it’s important to understand the shipping regulations and customs requirements of your destination country. Ensure that your supplier is experienced in international logistics and can provide necessary documentation, such as commercial invoices and certificates of origin. Be aware of potential tariffs and duties that may apply, as these can impact overall costs. Lastly, consider using freight forwarders for better management of shipping processes and to navigate any challenges that may arise. -

How do I vet a CNC auto care supplier for reliability?

Vetting a CNC auto care supplier involves thorough research and due diligence. Start by checking their business credentials, including registration and licenses. Investigate their reputation through online reviews and industry feedback. Request references from previous clients to gain insight into their reliability and service quality. Additionally, assess their operational capacity and technological capabilities to ensure they can meet your demands. Conducting a factory audit or site visit can also provide valuable information about their processes and commitment to quality.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Cnc Auto Care Manufacturers & Suppliers List

1. CNC Auto Care – Local Auto Repair

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, CNC Auto Care – Local Auto Repair, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. C and C Auto Care – Auto Repair Services

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: C and C Auto Care offers auto repair and routine automotive maintenance services. They are located at 110 2nd St, Oakley, California, and are open Monday to Friday from 8:30 AM to 5:30 PM. The business accepts credit cards and provides free Wi-Fi for customers.

3. C&C Automotive – Comprehensive Auto Repair Services

Domain: ccautomotive.com

Registered: 1999 (26 years)

Introduction: C&C Automotive offers a comprehensive range of auto repair services including: Auto AC and Heat Service and Repair, Brake Service and Repair, Car Diagnostics, Engine Service and Repair, Oil Change and Routine Maintenance, Steering and Suspension Service and Repair, Transmission Service and Repair, and Tire Services. They provide 24-hour emergency towing, courtesy shuttle rides, rental cars, and ha…

4. CNC AUTO CARE – Reliable Auto Repair Services

Domain: places.thebest100hotels.com

Registered: 2020 (5 years)

Introduction: CNC AUTO CARE offers reliable auto repair and maintenance services with a focus on fast, dependable, and affordable solutions. Key features include:

– Rapid, Reliable Service: Same-day diagnostics and repairs, emergency repairs with fast turnaround times, and flexible scheduling.

– Full Range of Auto Services: Brake Repair & Replacement, Battery Replacement & Terminal Repairs, Transmission & Clu…

5. C & C Auto Service – Comprehensive Auto Repair Solutions

Domain: candcautoservice.com

Registered: 2009 (16 years)

Introduction: C & C Auto Service offers a range of auto repair and maintenance services including: Auto AC Repair, Brake Repair, Car Inspection, Check Engine Light Diagnostics, Oil Change, and Wheel Alignment. The shop is located at 3929 Western Blvd, Raleigh, NC 27606, and operates Monday to Friday from 7:30 am to 5:00 pm. They provide complimentary shuttle service, free WiFi, and real-time updates on services…

6. CNC Auto Repair – Full Service Auto Repair

Domain: autorepairgonzales.com

Registered: 2014 (11 years)

Introduction: CNC Auto Repair offers full service auto repair, factory auto maintenance, computer auto diagnostics, tire sales and services, foreign and domestic engine repair services, brake repair services, auto A/C repair, oil change and tune up. They are ASE certified and AAA approved, providing a 2 year/24,000 mile warranty on most services. The shop is located at 12501 Airline Hwy, Gonzales, LA 70737 and …

7. C and C Automotive – Comprehensive Auto Repair Services

Domain: autorepairdurhamnc.com

Registered: 2008 (17 years)

Introduction: C and C Automotive offers a range of auto repair services including AC Repair, Asian Vehicle Repair, Brakes, Car & Truck Care, Domestic Cars & Trucks, Electrical Services, Electronic Services, Engine & Transmission, Engine Maintenance, and General Services. The shop is located at 129 Wolfpack Dr, Durham, NC 27704, and operates Monday to Friday from 8:00 AM to 6:00 PM, closed on Saturday and Sunday…

Strategic Sourcing Conclusion and Outlook for cnc auto care

What Are the Key Benefits of Strategic Sourcing in CNC Auto Care?

In the rapidly evolving automotive landscape, strategic sourcing in CNC auto care emerges as a pivotal strategy for businesses seeking to enhance operational efficiency and customer satisfaction. By prioritizing quality over cost, companies can secure reliable suppliers who not only provide superior products but also foster long-term partnerships. This approach mitigates risks associated with supply chain disruptions and ensures that organizations remain competitive in their respective markets.

How Can International Buyers Leverage Strategic Sourcing for Growth?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, embracing strategic sourcing can lead to significant competitive advantages. By tapping into local and regional suppliers, companies can reduce lead times, lower transportation costs, and enhance service responsiveness. Additionally, leveraging diverse sourcing channels opens opportunities for innovation and access to cutting-edge technologies in auto care.

What’s Next for the CNC Auto Care Industry?

As we look to the future, the CNC auto care sector is poised for growth, driven by advancements in technology and increasing consumer expectations. Now is the time for businesses to refine their sourcing strategies, ensuring they are equipped to meet these demands. Engage with suppliers who align with your values and operational goals, and invest in collaborative relationships that drive mutual success. The road ahead is promising—take action now to position your business for a prosperous future in the global automotive market.