Guide Contents

Project Insight: Cnc Auto Care

Manufacturing Insight: CNC Auto Care

Why Speed and Precision Are Non-Negotiable in Product Development

Accelerate Time-to-Market: Hardware startups face intense competition; delays in prototyping can derail product launches. With Honyo’s 24–72 hour prototype turnaround, you can iterate faster and launch sooner.

Precision Defines Performance: Functional prototypes must replicate end-use behavior. Tight tolerances (±0.01mm) ensure mechanical integrity, fit, and reliability—critical for automotive, medical, and aerospace applications where even minor deviations compromise safety.

Minimize Risk with Iterative Design: Early detection of design flaws through accurate prototypes prevents costly late-stage changes, saving both time and budget. Every iteration is a step closer to a market-ready product.

Honyo Prototype: Precision Engineered for Your Success

Online Instant Quote: Our AI-powered platform calculates real-time pricing in seconds—simply upload your CAD file for transparent, competitive quotes without delays.

Unmatched Turnaround: Prototype delivery in as little as 24 hours. Our optimized workflows and in-house capabilities eliminate traditional bottlenecks, keeping your project on track.

Advanced CNC Capabilities: Achieve ±0.01mm tolerances with 3/4/5-axis machining. Every part is crafted to exact specifications, whether for functional prototypes or end-use production across high-stakes industries.

Seamless Digital Manufacturing Experience

Integrated Workflow: From design validation to production, our platform ensures smooth collaboration with automated DFM checks and real-time feedback—no more guesswork.

Scalable Solutions: Transition seamlessly from prototypes to high-volume runs without retooling. Our processes support both with consistent quality and cost efficiency.

Global Support, Local Expertise: Based in Shenzhen, China, we leverage world-class manufacturing infrastructure while providing dedicated engineering support tailored to your needs.

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities for Precision CNC Automotive Parts

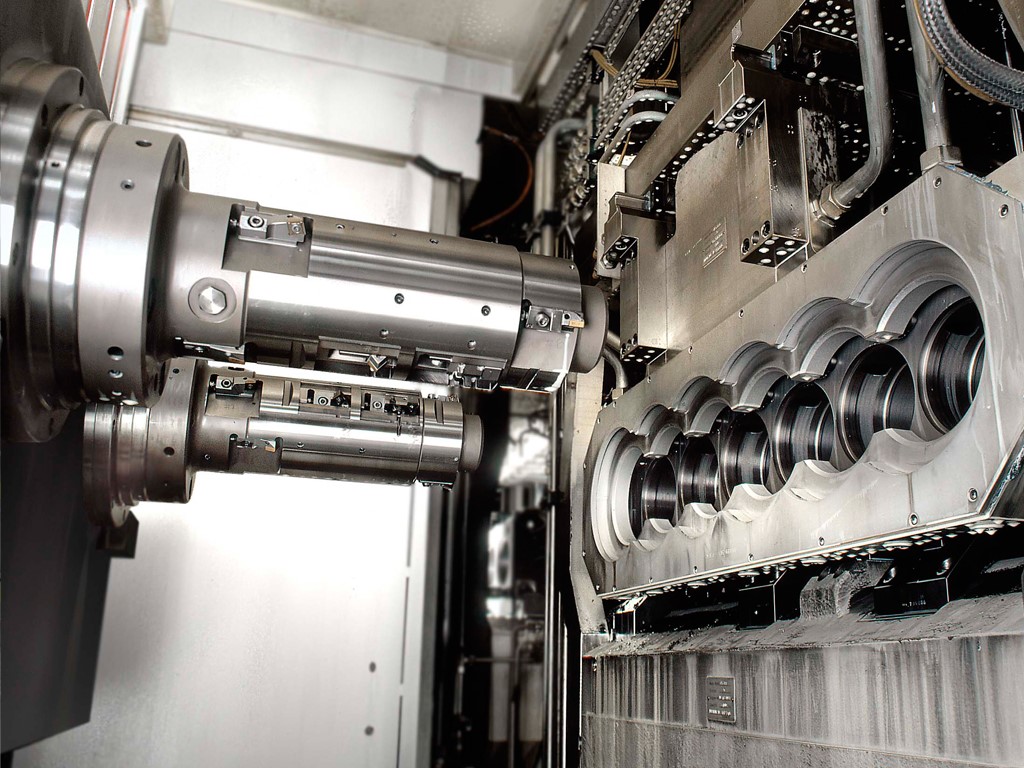

Advanced Multi-Axis Machining Technology

3/4/5-axis CNC machining for complex automotive components requiring intricate geometries and undercuts

Tight tolerances of ±0.01mm ensure precision-critical parts meet stringent automotive industry standards (e.g., ISO 2768, AS9100)

Optimized for functional prototypes and end-use parts with minimal post-processing, reducing time-to-market

Scalable Production from Prototypes to Mass Production

Seamlessly transition from 1 prototype to 10,000+ production parts without retooling or process changes

Flexible capacity tailored to startup MVP validation and high-volume automotive production runs

No minimum order quantities – perfect for iterative design refinement and rapid scaling

ISO-Certified Quality Assurance

Full compliance with ISO 9001 standards across all manufacturing stages, from material sourcing to final inspection

In-process and final inspection using CMM, optical comparators, and laser scanning for dimensional accuracy

Traceable quality documentation for safety-critical automotive applications (e.g., braking systems, engine components)

AI-Powered Instant Quote Platform

Get real-time pricing in seconds via our AI-driven online portal – no manual quotes or delays

Instant analysis of design complexity, material choices, and quantity for accurate cost estimates

AI suggestions to optimize geometry for manufacturability, reducing costs by up to 30% while maintaining precision

Rapid Turnaround Without Compromise

Expedited lead times up to 50% faster than industry average through automated workflow integration

Same-day design review with engineering feedback for DFM (Design for Manufacturing) improvements

Guaranteed on-time delivery with real-time project tracking and proactive communication at every stage

Materials & Surface Finishes

Material Options & Finishes for Automotive Precision Parts

Choosing the Right Material for Automotive Applications

Selecting the optimal material ensures performance, durability, and cost-efficiency for automotive components. Honyo’s expertise in precision CNC machining ensures every part meets strict automotive standards:

Aluminum 6061: Lightweight, corrosion-resistant (especially when anodized), and ideal for structural brackets, housings, and heat sinks. Cost-effective for high-volume production while maintaining ±0.01mm tolerances.

Aluminum 7075: High-strength alloy for critical stress points (e.g., suspension components, racing parts). Delivers superior fatigue resistance without compromising weight savings.

Stainless Steel 304: Excellent oxidation resistance for exterior trim, exhaust systems, and fasteners. Balances durability with machinability for complex geometries.

Stainless Steel 316: Marine-grade corrosion resistance for under-hood components exposed to chemicals, salt, or extreme environments. Critical for safety-critical parts.

Brass: High electrical conductivity and aesthetic appeal for sensors, connectors, and decorative trim. Precision-machined for tight tolerances in intricate designs.

PEEK (Polyether Ether Ketone): High-performance thermoplastic for engine components, fuel systems, and high-temperature sensor housings. Resists chemicals, heat (up to 250°C), and wear.

Surface Finish Options for Enhanced Performance

Surface treatments elevate functionality, aesthetics, and longevity for automotive parts. Honyo’s automated finishing processes ensure consistency and compliance with industry standards:

Anodizing (Type II/III): Hardened surface for aluminum parts requiring wear resistance (e.g., brake components). Type III (hard anodizing) extends service life in high-friction applications. Custom colors for brand integration.

Powder Coating: Ultra-durable, UV-resistant finish for structural parts. Ideal for exterior components needing scratch resistance and vibrant color options.

Electroplating (Chrome/Nickel): Chrome plating delivers mirror-like aesthetics for grilles and emblems; nickel plating enhances corrosion resistance for fuel system parts.

Precision Polishing: Mirror-grade finishes for visible interior/exterior trim. Maintains dimensional accuracy while achieving flawless reflectivity.

Passivation: Removes surface contaminants from stainless steel parts, maximizing corrosion resistance for critical safety components.

Accelerate Your Project with Honyo’s Smart Platform

Leverage AI-driven efficiency to streamline automotive part production from design to delivery:

🚀 Online Instant Quote: Upload your CAD file and receive an accurate cost estimate in seconds. Our AI analyzes geometry, material, and finish requirements for transparent, no-surprise pricing.

⚡ AI-Powered DFM Optimization: Real-time feedback flags potential manufacturing issues before production—reducing costs and ensuring parts meet ±0.01mm tolerances with minimal rework.

🚀 Fast Turnaround Guarantee: Prototype delivery in 3–5 days, production runs in 7–10 days. Our Shenzhen-based facility and automated workflow deliver precision without compromise.

Ready to build? Get Your Instant Quote Now – Optimized for automotive innovation, powered by Honyo Prototype.

From Quote to Part: Our Process

How It Works: From CAD to Part

At Honyo Prototype, we’ve redefined the CNC machining process with an AI-driven workflow that transforms your design into precision parts faster than ever. Here’s how it works:

Upload CAD File in Seconds

Seamless file submission: Upload your CAD files via our cloud-based platform—no software downloads or technical expertise required.

Universal compatibility: Supports all standard formats (STEP, STP, IGES, STL, DWG, etc.) with real-time validation to catch errors before production begins.

Zero delays: AI-powered file processing eliminates manual review bottlenecks, so your project starts immediately.

Get Instant AI-Powered Quote

Real-time cost calculation: Our AI analyzes 15+ variables—including material, geometry, tolerances (+/- 0.01mm), and production volume—to deliver a precise, transparent quote in seconds.

Full cost transparency: Breakdown includes material (30–60% of total cost), setup, machining time, inspection, and shipping—no hidden fees.

Decision-ready pricing: Compare options and approve with a single click—no waiting days for quotes.

DFM Analysis & Optimization

Proactive design validation: AI-driven Design for Manufacturability (DFM) flags issues like thin walls, tool access conflicts, or tolerance challenges before production.

Actionable insights: Receive cost-saving optimization suggestions (e.g., material substitutions, feature adjustments) from our engineering team.

Risk-free iteration: Reduce rework costs by up to 20% while preserving your design intent—no surprises, no delays.

Precision Production & Delivery

Industrial-grade accuracy: 3/4/5-axis CNC machining with ±0.01mm tolerances for functional prototypes and end-use parts.

Automated quality control: First-article inspection, in-process monitoring, and final QA checks ensure every part meets specifications.

Trackable speed: Monitor your project live via our digital dashboard and receive parts in as little as 3 business days—faster than industry averages.

Honyo Prototype: Where innovation meets precision. No guesswork. No delays. Just results.

Start Your Project with Honyo

Start Your Project with Honyo Prototype

AI-Powered Precision, Delivered Fast

Online Instant Quote: AI-powered platform analyzes your CAD file in seconds—delivering transparent, real-time pricing with no hidden fees. Cut quote wait times from days to seconds.

3-5 Day Prototype Turnaround: Leverage our 3/4/5-axis CNC capabilities for rapid production of functional prototypes with ±0.01mm tolerances. Speed without sacrificing precision.

Expert Cost Optimization: Founder Susan Leo and our engineering team optimize designs for manufacturability, reducing material waste and machining time. We help you control material costs (30–60% of total project cost) while maintaining peak accuracy.

Contact: [email protected] | +86 139 2843 8620

Visit: Our Shenzhen & Dongguan facilities for hands-on collaboration and precision manufacturing in action.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.