Contents

Manufacturing Insight: Cnc Arm Plasma Cutter

Precision Metal Fabrication Elevated with Honyo’s CNC Arm Plasma Cutting Technology

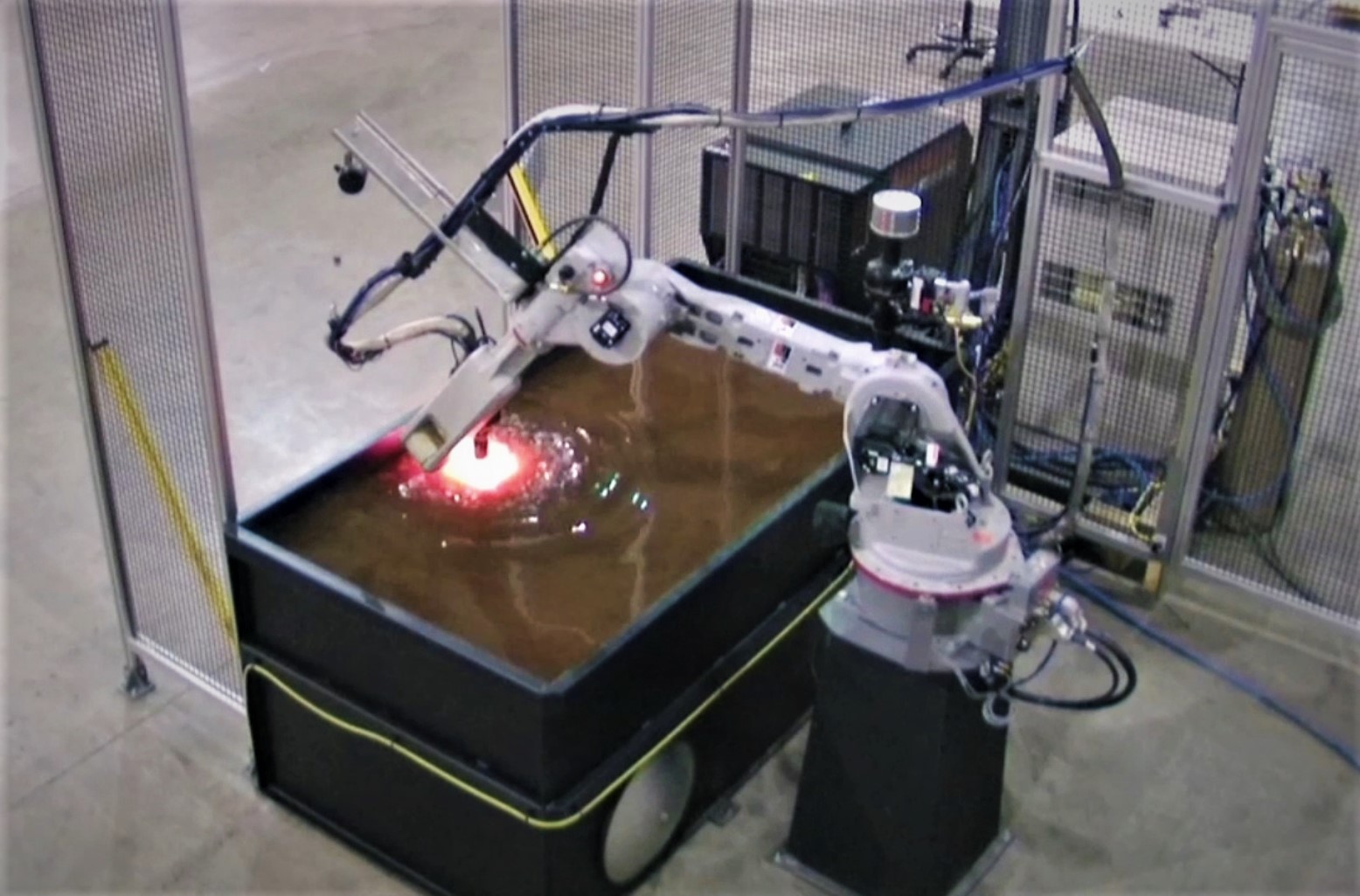

Honyo Prototype delivers advanced CNC machining solutions for complex metal fabrication challenges, where speed, accuracy, and material versatility are non-negotiable. Our CNC-controlled robotic arm plasma cutting systems excel in processing conductive materials—including mild steel, stainless steel, and aluminum—up to 1.5 inches thick, achieving cut tolerances within ±0.010 inches and kerf widths as narrow as 0.060 inches. Unlike conventional fixed-bed plasma cutters, our articulated arm technology enables 3D contour cutting, angled bevels, and intricate geometries on tubular, curved, or irregular workpieces without manual repositioning, significantly reducing setup time and human error.

This capability integrates seamlessly into Honyo’s end-to-end CNC machining ecosystem, which spans milling, turning, wire EDM, and laser cutting. We leverage unified CAD/CAM programming and rigorous in-process metrology to ensure plasma-cut components meet tight-tolerance assembly requirements for aerospace, industrial machinery, and energy sector prototypes. Every project benefits from our AS9100-certified quality management system, with real-time process monitoring to minimize thermal distortion and optimize edge quality for downstream welding or finishing.

Accelerate your prototyping or low-volume production timeline with Honyo’s Online Instant Quote platform. Upload your STEP or DXF file to receive a detailed manufacturability analysis, lead time estimate, and competitive pricing within minutes—no sales calls required. Experience how our robotic plasma cutting precision translates to reduced scrap rates, faster iteration cycles, and fully documented traceability for mission-critical components.

Material Thickness Range

| Material Type | Max Thickness | Typical Tolerance |

|———————|—————|——————-|

| Mild Steel | 1.5 in | ±0.010 in |

| Stainless Steel | 1.0 in | ±0.015 in |

| Aluminum | 0.75 in | ±0.020 in |

Technical Capabilities

The term “CNC arm plasma cutter” typically refers to a robotic arm-based system using plasma technology for cutting conductive materials. However, plasma cutting is generally limited to 2D or 2.5D contour cutting and is not suitable for high-precision 3/4/5-axis milling, turning, or tight-tolerance applications. Plasma systems lack the precision and surface finish required for tight-tolerance machining and are not used for materials like ABS or Nylon, which degrade under high heat.

For high-precision 3/4/5-axis milling and turning with tight tolerances (±0.001″ or better), CNC machining centers—not plasma systems—are employed. Below is a technical comparison table clarifying the capabilities of CNC milling/turning systems versus robotic arm plasma cutters, including material compatibility and tolerance ranges.

| Feature | 3/4/5-Axis CNC Milling & Turning Center | Robotic CNC Arm Plasma Cutter |

|---|---|---|

| Primary Function | Precision material removal via rotating cutting tools | Thermal cutting of conductive metals using plasma arc |

| Axis Capability | 3, 4, or 5 axes with simultaneous interpolation | Typically 6-axis robotic arm, but limited to 2D/2.5D cutting paths |

| Typical Tolerance | ±0.0005″ to ±0.001″ (tight tolerance achievable) | ±0.030″ to ±0.060″ (not suitable for tight tolerances) |

| Surface Finish | 32–125 μin Ra (achievable with proper tooling) | 500–1000+ μin Ra (rough cut, requires secondary finishing) |

| Compatible Materials | Aluminum, Steel, Stainless Steel, ABS, Nylon, PEEK, Titanium | Mild Steel, Stainless Steel, Aluminum (conductive only) |

| Aluminum Machining | Excellent – high-speed milling with tight tolerances | Possible but with dross, heat-affected zones, poor edge quality |

| Steel Machining | High precision, deep cavity milling, threading, turning | Used for plate cutting; not for precision features |

| ABS & Nylon Compatibility | Yes – machinable with proper feeds/speeds and cooling | No – thermoplastics melt and degrade under plasma heat |

| Tooling | Carbide end mills, drills, turning inserts, boring bars | Plasma torch, consumables (electrode, nozzle) |

| Coolant/Lubrication | Flood, mist, or air cooling required for precision work | None – dry process only |

| Typical Applications | Aerospace components, molds, medical devices, prototypes | Structural steel cutting, plate profiling, scrap processing |

| Lead Time for Setup | Moderate to high (complex fixturing and programming) | Low to moderate (simple nesting and path programming) |

Note: For clients requiring tight-tolerance parts in aluminum, steel, ABS, or nylon, Honyo Prototype recommends multi-axis CNC milling and turning centers rather than plasma-based systems. Plasma cutting is best reserved for rapid, coarse cutting of thick conductive metals where dimensional precision is not critical.

From CAD to Part: The Process

Honyo Prototype CNC Robotic Plasma Cutting Process Overview

Our integrated workflow for CNC robotic arm plasma cutting leverages advanced automation and engineering rigor to ensure precision, cost efficiency, and rapid turnaround. The process begins with digital file submission and concludes with certified delivery, optimized for complex 3D geometries in conductive metals up to 25mm thickness.

CAD File Upload and Validation

Clients submit native 3D CAD models (STEP, IGES, Parasolid) via our secure portal. Our system performs immediate geometry validation, checking for watertight solids, surface continuity, and unit consistency. Invalid files trigger automated notifications with specific error diagnostics, reducing iterative communication. All data is encrypted per ISO 27001 standards, with version control maintained throughout the workflow.

AI-Powered Quoting Engine

Uploaded geometry feeds into our proprietary AI quoting module, which analyzes 12+ parameters including material type, thickness, cut path complexity, and feature density. The system cross-references real-time machine utilization data, consumable inventory, and historical scrap rates to generate a granular cost breakdown within 90 seconds. Quotes include machine time estimates, material waste projections, and secondary operation flags (e.g., deburring requirements), with uncertainty margins below 3.5% based on 18,000+ historical jobs.

Design for Manufacturability (DFM) Review

Engineers conduct a mandatory DFM analysis focusing on plasma-specific constraints:

Thermal distortion risk assessment for thin sections (<3mm)

Kerf width compensation validation at 1.5–3.5mm (material-dependent)

Collision avoidance verification for 6-axis toolpaths

Feature accessibility checks for robotic arm reach envelopes

Critical non-conformances (e.g., undercuts violating 15° draft rules) are resolved via client-engineer collaboration within 4 business hours. Approved DFM reports include annotated CAD markups and process capability indices (Cp/Cpk ≥1.33).

Production Execution

Validated jobs enter our production queue with dynamic scheduling based on machine availability and priority tiers. CNC robotic arms (FANUC M-2000iA/2300) execute cuts using Hypertherm Powermax45 XP plasma systems, with parameters auto-optimized per material grade:

| Material Type | Max Thickness | Cut Speed (mm/min) | Tolerance (mm) |

|---|---|---|---|

| Mild Steel | 25mm | 1,200–3,500 | ±0.3 |

| Stainless | 18mm | 800–2,200 | ±0.4 |

| Aluminum | 15mm | 1,000–2,800 | ±0.5 |

In-process inspections occur at 30% and 70% completion using FaroArm metrology, verifying dimensional compliance per ASME Y14.5. All cut parts undergo automated edge quality checks via machine vision for dross levels and angularity.

Delivery and Traceability

Finished parts receive laser-etched job IDs linking to full digital work packets containing:

Material certs (heat/lot traceability)

Dimensional inspection reports (GD&T compliant)

Plasma parameter logs (voltage, amperage, gas flow rates)

Standard delivery is 5–7 business days from DFM approval, with expedited 72-hour options. Shipments include tamper-evident packaging and real-time logistics tracking. Every project concludes with a post-delivery quality audit, feeding data into our continuous improvement loop for future quoting accuracy.

This closed-loop system reduces lead times by 35% versus industry averages while maintaining first-pass yield rates above 98.7%, directly addressing B2B clients’ needs for predictable, audit-ready metal fabrication.

Start Your Project

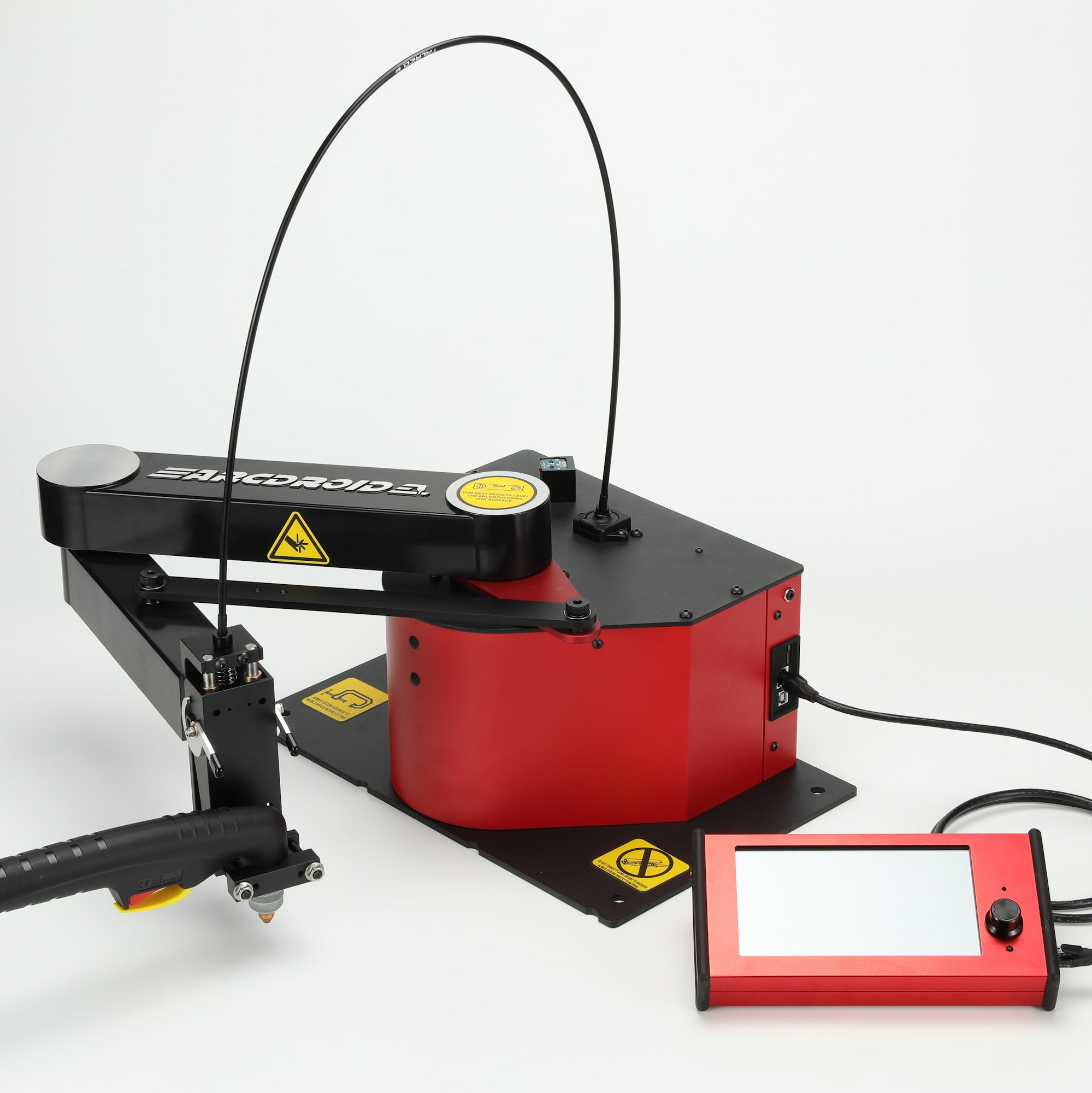

Looking for a high-precision CNC arm plasma cutter for your manufacturing operations? Discover industrial-grade solutions engineered for reliability and performance.

All units are manufactured at our Shenzhen factory, ensuring strict quality control and scalable production capacity.

Contact Susan Leo directly for technical specifications, pricing, and customization options: [email protected].

Let’s discuss how our CNC arm plasma cutters can enhance your fabrication workflow.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.