Contents

Manufacturing Insight: Cnc Anodized Aluminum

Precision CNC Machined Anodized Aluminum Components from Honyo Prototype

For demanding applications requiring exceptional strength-to-weight ratios, corrosion resistance, and refined surface finishes, CNC machined anodized aluminum remains the material of choice across aerospace, medical, and industrial automation sectors. At Honyo Prototype, we specialize in transforming complex aluminum alloys—from 6061-T6 to 7075—into mission-critical components with sub-micron tolerances and repeatable precision. Our integrated in-house process combines advanced 5-axis CNC machining with controlled anodizing protocols, ensuring dimensional accuracy is maintained through every stage of production. This eliminates supply chain dependencies while guaranteeing consistent oxide layer integrity, color uniformity, and enhanced wear properties critical for end-use performance.

Our technical expertise spans tight-tolerance geometries, thin-wall features, and multi-axis milling operations, all executed under stringent ISO 9001-certified workflows. By leveraging proprietary toolpath optimization and real-time in-process inspection, we deliver components that meet exacting surface roughness (Ra 0.8 µm achievable) and dimensional specifications without secondary handling risks. The result is a finished anodized part that performs reliably in harsh environments while reducing total assembly costs.

Validate feasibility and accelerate your project timeline immediately using Honyo’s Online Instant Quote platform. Upload CAD files to receive manufacturability feedback, material-specific pricing, and lead time estimates within minutes—streamlining the transition from prototype to production.

Technical Capabilities

CNC Machined Anodized Aluminum – Technical Specifications

CNC machining of anodized aluminum involves precision manufacturing using 3, 4, or 5-axis milling and turning processes to achieve tight tolerances and high surface quality. Anodizing is a post-machining surface treatment that enhances corrosion resistance, surface hardness, and aesthetic finish. Below are the technical specifications and capabilities for CNC-machined anodized aluminum components, with comparative insights for other commonly machined materials.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Tight Tolerance Capability |

|---|---|---|---|---|---|

| Max Work Envelope (mm) | 1000 x 600 x 400 | 800 x 600 x 500 | 700 x 500 x 400 | Ø400 x 600 (length) | N/A |

| Positioning Accuracy | ±0.01 mm | ±0.01 mm | ±0.005 mm | ±0.01 mm | ±0.005 mm (typical) |

| Repeatability | ±0.005 mm | ±0.005 mm | ±0.003 mm | ±0.005 mm | ±0.002 mm (tight tolerance) |

| Surface Finish (as-machined) | Ra 0.8 – 3.2 µm | Ra 0.8 – 1.6 µm | Ra 0.4 – 1.6 µm | Ra 0.8 – 1.6 µm | Ra 0.4 – 0.8 µm (precision) |

| Post-Process: Anodizing | Type II (Sulfuric) or Type III (Hard Coat), 10–25 µm thickness, color options (clear, black, red, etc.) | ||||

| Lead Time (Standard) | 5–7 days | 7–10 days | 10–14 days | 5–8 days | +2–4 days (for tight tolerances) |

Material Capabilities

| Material | Machinability | Max Tensile Strength | Typical Applications | Compatible with Anodizing | Notes |

|---|---|---|---|---|---|

| Aluminum (6061-T6) | Excellent | 310 MPa | Aerospace, enclosures, heat sinks | Yes | Most common for anodizing; ideal for tight tolerance parts |

| Aluminum (7075-T6) | Good | 572 MPa | High-stress aerospace, military | Yes (hard anodizing only) | Higher strength but more abrasive on tools |

| Steel (1018, 4140) | Moderate | 440–850 MPa | Shafts, fixtures, structural components | No | Not anodizable; passivation or plating used |

| ABS | Excellent | 40 MPa | Prototypes, housings, jigs | No | Limited to non-structural parts; post-processing for paint |

| Nylon (PA6, PA66) | Moderate | 70–80 MPa | Insulators, gears, bushings | No | Hygroscopic; requires pre-drying; not suitable for anodizing |

Tight Tolerance Notes

Tight tolerance machining (±0.005 mm or better) requires thermal-stable environments, high-precision tooling, and in-process inspection (e.g., CMM or laser probing). 5-axis CNC systems provide the best capability for complex geometries with tight tolerances due to reduced setup次数 and improved tool access.

Anodizing Process Notes

Anodizing is applicable only to aluminum and its alloys. Type II (decorative) and Type III (hard coat) anodizing are standard. Dimensional growth of 5–10 µm per surface must be accounted for in tight tolerance designs. Critical bores or mating surfaces may require masking or post-anodize re-machining.

For non-aluminum materials such as steel, ABS, or nylon, alternative surface treatments (e.g., powder coating, plating, or painting) are used based on application requirements.

From CAD to Part: The Process

Honyo Prototype CNC Anodized Aluminum Process Overview

Honyo Prototype executes CNC anodized aluminum production through a streamlined, quality-focused workflow designed for precision and efficiency. The process begins with CAD Upload, where clients submit 3D models in industry-standard formats (STEP, IGES, or native CAD files). Our system validates geometric integrity, material specifications, and critical tolerances. Clients must specify anodizing requirements upfront—including alloy type (e.g., 6061-T6, 7075-T6), color (e.g., black, clear, custom), thickness (e.g., Type II 8–12μm or Type III 25μm), and masking needs—to ensure downstream alignment.

The AI-Powered Quoting Phase follows immediately. Our proprietary algorithm analyzes the CAD data to generate instant cost and lead time estimates. This system evaluates material utilization, machine time, toolpath complexity, and anodizing parameters while cross-referencing real-time shop floor capacity. Unlike generic quoting tools, our AI factors in anodizing-specific variables such as racking requirements, pre-treatment steps, and color consistency controls, providing a technically grounded estimate within minutes.

Design for Manufacturability (DFM) Review is a collaborative, iterative step. Honyo’s engineering team conducts a full technical assessment focusing on CNC and anodizing constraints. Key checks include: ensuring adequate wall thickness to prevent warpage during anodizing, verifying hole/tap depths for post-anodizing threading, confirming proper radii for even coating, and identifying areas needing chemical film masking. We provide actionable feedback via annotated CAD markups or a detailed DFM report, resolving conflicts like insufficient anodizing clearance or non-optimal grain direction before programming begins.

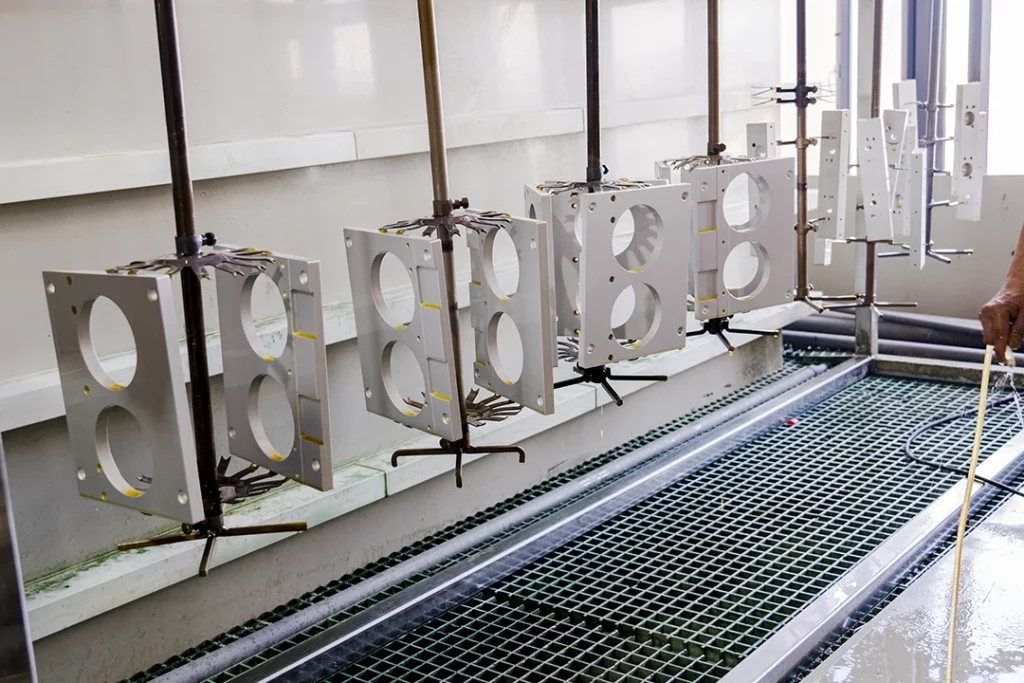

Production Execution integrates CNC machining and anodizing under strict process controls. CNC operations use 3–5 axis mills with tool wear monitoring and in-process CMM checks for critical features. Machined parts undergo rigorous cleaning and etching before anodizing. Our certified anodizing partners apply coatings per AMS-C-5541 (Type II) or MIL-A-8625 (Type III) standards, with bath chemistry monitored hourly. All runs include first-article inspection against AS9102 aerospace standards, with real-time adjustments for color consistency and coating adhesion.

Delivery and Certification concludes the process. Each shipment includes traceable documentation: material certs (mill test reports), anodizing process records (voltage, time, temperature logs), and final inspection reports (CMM data, coating thickness verification per ASTM B137). Parts are packaged with anti-corrosion protection and delivered with full digital records accessible via our client portal. Typical lead time from CAD upload to delivery is 7–12 business days, with expedited options for urgent requirements.

This end-to-end workflow ensures dimensional accuracy, coating reliability, and seamless scalability from prototype to low-volume production—meeting stringent demands in aerospace, medical, and industrial sectors.

Start Your Project

Looking for high-quality CNC anodized aluminum parts? Honyo Prototype delivers precision manufacturing with fast turnaround times. Our state-of-the-art CNC machining and in-house anodizing capabilities ensure durable, corrosion-resistant components ideal for aerospace, automotive, medical, and industrial applications.

All production is handled at our Shenzhen factory, giving you direct access to competitive pricing and strict quality control under ISO standards.

Contact Susan Leo today to request a quote or technical consultation. Email at [email protected] for expert support on your next project.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.