Contents

Manufacturing Insight: Cnc Aluminum Machining Parts

Precision Aluminum Machining for Demanding Applications

Honyo Prototype delivers high-integrity CNC aluminum machining services engineered to meet the rigorous demands of aerospace, medical, and industrial sectors. Our advanced 5-axis CNC milling and turning centers consistently achieve tight tolerances down to ±0.005mm while maintaining exceptional surface finishes critical for functional prototypes and low-to-medium volume production runs. Aluminum alloys including 6061-T6, 7075-T6, and 2024 are optimized for structural efficiency, thermal management, and corrosion resistance—ensuring your components perform reliably in mission-critical environments.

Streamlined Procurement with Online Instant Quote

Accelerate your development timeline through Honyo’s Online Instant Quote platform. Simply upload your STEP or IGES file to receive a detailed manufacturability analysis and competitive pricing within hours—not days. This integrated system eliminates traditional quotation bottlenecks, providing transparent cost breakdowns for material, machining complexity, and finishing options while identifying potential design improvements to reduce part cost and lead time.

Our end-to-end process combines ISO 9001-certified quality control with real-time production tracking, ensuring dimensional accuracy and material integrity from raw billet to finished component. Partner with Honyo to transform aluminum designs into precision-engineered realities with reduced time-to-market and uncompromised quality standards. Upload your CAD file today to initiate a seamless machining workflow.

Technical Capabilities

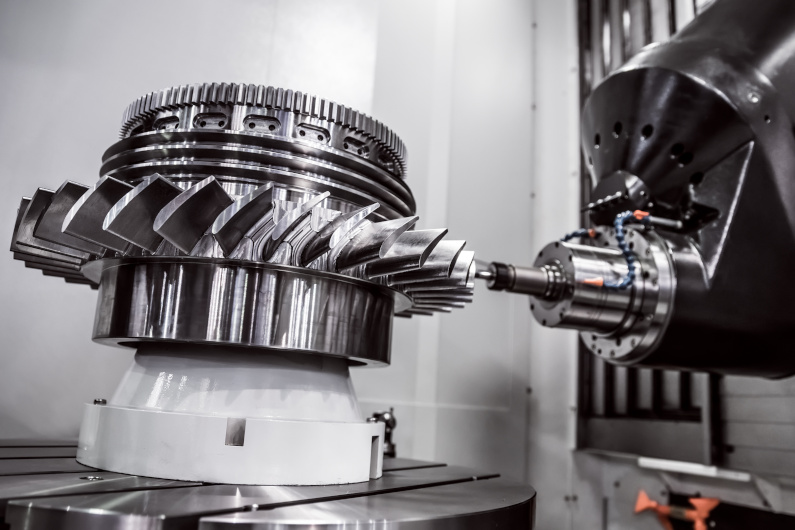

CNC aluminum machining parts are precision-engineered components manufactured using advanced milling and turning processes. These parts are commonly produced using 3-axis, 4-axis, and 5-axis CNC machining centers, enabling high complexity, tight tolerances, and excellent surface finishes. While aluminum is the most frequently used material due to its favorable strength-to-weight ratio and machinability, other materials such as steel, ABS, and nylon are also machined depending on application requirements.

Key capabilities include multi-axis contouring, deep cavity milling, precision hole drilling, and complex feature integration—all held to tight tolerances typically ranging from ±0.005 mm to ±0.025 mm depending on geometry and material. 5-axis machining allows for single-setup production of highly complex geometries, reducing lead time and improving accuracy. Turning operations are used for cylindrical components, often in combination with milling for mill-turn parts.

Below is a summary of technical specifications and capabilities:

| Feature | Specification Details |

|---|---|

| Machining Processes | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning; Mill-Turn with Live Tooling |

| Typical Materials | Aluminum (6061, 7075, 2024, 5052), Steel (1018, 4140, Stainless 303/304/316), ABS, Nylon (PA6, PA66) |

| Tolerance Range | Standard: ±0.025 mm; Tight Tolerance: ±0.005 mm to ±0.012 mm (achievable with process control and inspection) |

| Surface Finish | As-machined: 3.2 μm (125 μin); Optional: 1.6 μm (63 μin) or better with polishing, anodizing, or coating |

| Maximum Work Envelope | Milling: Up to 1200 x 600 x 500 mm (5-axis); Turning: Max Ø300 mm x 500 mm length (bar feed dependent) |

| Inspection & Quality | CMM, Optical Comparator, Micrometers, Calipers; First Article Inspection (FAI) and PPAP available |

| Secondary Operations | Deburring, Anodizing (Type II & III), Passivation, Bead Blasting, Laser Marking, Assembly, Heat Treatment (T6, etc.) |

| Common Applications | Aerospace components, medical devices, robotics, automotive prototypes, industrial fixtures, defense systems |

All parts are manufactured in accordance with ISO 9001:2015 standards, with full traceability and documentation support. Material certifications and inspection reports can be provided upon request.

From CAD to Part: The Process

Honyo Prototype executes CNC aluminum machining parts through a rigorously controlled five-phase workflow designed for precision, efficiency, and material-specific optimization. This process leverages advanced automation while maintaining critical human engineering oversight, particularly for aluminum’s unique thermal and mechanical properties.

CAD Upload & Initial Processing

Clients submit native or standard CAD formats (STEP, IGES, Parasolid) via our secure portal. Our system immediately validates file integrity and extracts geometric data, material specifications (e.g., 6061-T6, 7075-T6), and critical tolerances. Aluminum-specific parameters such as minimum wall thickness, aspect ratios, and anodizing requirements are flagged for downstream review.

AI-Powered Quoting Engine

Our proprietary AI engine generates instant, data-driven quotes by analyzing 12+ real-time variables: machine availability, tooling costs, aluminum billet pricing (scrap rate adjusted), post-processing needs, and historical cycle times for similar geometries. The AI cross-references a database of 500,000+ past aluminum jobs to predict manufacturability risks—such as thin-wall vibration or deep cavity chip evacuation challenges—before formal quoting. Clients receive cost/time estimates within 90 seconds, including material waste calculations specific to aluminum alloys.

Engineering-Led DFM Analysis

All aluminum projects undergo mandatory Design for Manufacturability review by our senior CNC engineers. This phase focuses on aluminum-specific optimizations:

| DFM Check Category | Aluminum-Specific Focus | Common Resolution |

|---|---|---|

| Geometry | Thin walls (<1.5mm), deep pockets, sharp internal corners | Recommend radius increases, ribbing, or staged milling to prevent chatter/warpage |

| Tolerances | Over-specification in non-critical zones | Suggest relaxed tolerances per ISO 2768-mK for cost reduction |

| Material Handling | Heat-sensitive features near high-speed cuts | Propose coolant optimization or step-down strategies |

| Post-Processing | Anodizing clearance requirements | Adjust hole diameters/tapped holes per MIL-A-8625 standards |

Engineers collaborate directly with clients to resolve conflicts—rejecting 12% of submissions that would risk part failure due to aluminum’s low thermal conductivity or modulus of elasticity. Approved DFM reports include annotated CAD models with revision trails.

Precision CNC Production

Aluminum machining occurs in climate-controlled cells using DMG MORI and Haas 5-axis centers with high-RPM spindles (24,000+ RPM) optimized for aluminum. Key protocols include:

Toolpath validation via Vericut simulation to prevent collisions and optimize chip load for aluminum alloys

In-process CMM checks at 25% and 75% production milestones to monitor thermal drift

Dedicated tooling for aluminum (sharp carbide end mills, high-helix angles) with strict chip evacuation protocols

Real-time coolant monitoring (pH, concentration) to prevent surface oxidation during machining

First-article inspection per AS9102 with full FAI report including material certs (mill test reports)

Quality-Controlled Delivery

All aluminum parts undergo final inspection per client-specified standards (e.g., ASME Y14.5, ISO 2768). Critical dimensions are verified using Zeiss CMMs with temperature compensation. Anodized parts receive coating thickness verification via eddy current testing. Every shipment includes:

Traceable material certification (including heat number)

Full inspection report with deviation data

Packaging engineered for aluminum’s susceptibility to scratching (VCI paper, custom foam)

Digital delivery confirmation with process logs accessible via client portal

This integrated workflow reduces aluminum machining lead times by 30% versus industry averages while maintaining 99.2% first-pass yield rates. The strict separation of automated quoting from human-led DFM ensures cost transparency without compromising on material-specific engineering rigor—critical for aerospace, medical, and robotics applications where aluminum performance is non-negotiable.

Start Your Project

Looking for high-precision CNC aluminum machining parts? Partner with Honyo Prototype for reliable, on-time manufacturing with consistent quality. Our Shenzhen-based factory offers advanced CNC machining capabilities tailored to your specifications.

Contact Susan Leo today at [email protected] to discuss your project requirements and receive a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.