Guide Contents

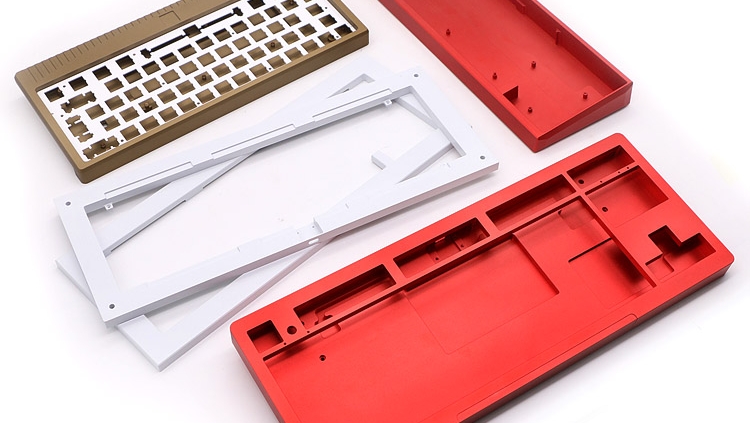

Project Insight: Cnc Aluminum Keyboard Case

Manufacturing Insight: CNC Aluminum Keyboard Cases – Where Precision Meets Speed

Why Speed and Precision Matter for Hardware Innovation

In the hyper-competitive hardware landscape, delays or inaccuracies in CNC machining can derail product launches. For aluminum keyboard cases—where tolerances dictate assembly fit, aesthetics, and user experience—precision isn’t optional. It’s the foundation of market success.

Rapid Iteration Cycles:

Weeks of rework due to imprecise parts can stall product launches. Our ±0.01mm tolerances ensure first-time-right prototypes, slashing development time by 30–50% and accelerating time-to-market.

Cost Efficiency Through Accuracy:

Minor alignment errors in keyboard cases lead to costly assembly failures or returns. Precision machining eliminates rework, reducing total project costs by up to 25% while maintaining premium finishes.

Market Responsiveness:

Traditional suppliers often require 6–8 weeks for aluminum cases. With Honyo, you validate designs, test functionality, and scale production in days—not months—capturing opportunities before competitors.

Honyo Prototype: Your Digital Manufacturing Partner

We merge cutting-edge CNC capabilities with AI-driven efficiency to turn your designs into reality—faster, smarter, and with zero compromise.

Online Instant Quote:

Upload your CAD file and receive real-time pricing, lead times, and material insights in seconds. No waiting weeks for quotes—just transparent, no-obligation estimates tailored to your specs.

AI-Powered Design Optimization:

Our platform analyzes your design for manufacturability, suggesting tweaks to reduce costs, improve tolerances, and enhance aesthetics—without sacrificing function. Say goodbye to costly revisions.

Fast Turnaround, Zero Compromise:

From prototype to production, we compress lead times to 3–5 days for aluminum cases. 48-hour quotes, same-day design reviews, and flexible batch sizes (1–10,000+ parts) let you scale seamlessly.

Ready to accelerate your product development?

Get an instant quote today and experience the Honyo difference—where innovation meets precision.

Honyo Capabilities & Technology

Honyo’s Precision CNC Machining Capabilities

At Honyo Prototype, we merge advanced engineering with agile manufacturing to deliver precision-engineered aluminum keyboard cases that redefine performance for hardware innovators. From functional prototypes to end-use parts, our capabilities ensure uncompromising quality, speed, and scalability—powered by innovation and precision.

Advanced Multi-Axis Machining Technology

3/4/5-axis CNC capabilities for intricate geometries, undercuts, and complex internal features

Tight tolerances of +/- 0.01mm to meet aerospace-grade precision standards

Optimized toolpaths for minimal vibration, superior surface finishes, and zero-defect dimensional accuracy

Scalable Production from Prototype to Volume

Zero minimum order quantity (MOQ) for rapid prototyping and small-batch validation

Seamless scaling from 1 unit to 10,000+ production parts without retooling delays

Flexible scheduling to align with your product lifecycle milestones and budget constraints

ISO-Certified Quality Assurance

ISO 9001-certified processes with in-process and final inspections at every stage

Advanced metrology tools (CMM, laser scanning, optical comparators) for 100% dimensional verification

Full material traceability, compliance documentation, and defect-free guarantees

Digital-Driven Efficiency

Instant online quotes via AI-powered platform with real-time design-for-manufacturability (DFM) feedback

48–72 hour prototype turnaround with expedited options for urgent projects

End-to-end digital workflow: design upload → automated quoting → production tracking → delivery

“Precision isn’t just a spec—it’s the foundation of every part we build. At Honyo, we engineer solutions that accelerate your time-to-market while eliminating guesswork.”

— Susan Leo, Founder

Materials & Surface Finishes

Material Options & Finishes for Precision CNC Keyboard Cases

At Honyo Prototype, material selection is the cornerstone of performance, aesthetics, and cost efficiency for your keyboard case. Our precision CNC machining—backed by ±0.01mm tolerances and 3/4/5-axis capabilities—ensures every detail aligns with your project’s unique demands. Whether prototyping or scaling production, we optimize materials and finishes to deliver exceptional results, faster.

Primary Materials for Keyboard Cases

Aluminum 6061:

The industry standard for mechanical keyboard cases. Balances strength, machinability, and cost-effectiveness. Ideal for vibrant anodized finishes and high-volume production. Perfect for startups prioritizing customization without compromising durability.

Aluminum 7075:

Aerospace-grade strength for high-stress applications. Best for premium or rugged cases requiring maximum structural integrity (e.g., large form factors or commercial use). Slightly higher machining costs but delivers superior wear resistance.

Stainless Steel 304/316:

Exceptional corrosion resistance for harsh environments (e.g., marine or industrial settings). Note: Heavier and costlier than aluminum—reserved for niche applications where durability outweighs weight constraints.

Brass:

High electrical conductivity and warm aesthetic. Typically used for accent components (e.g., keycap stabilizers or electrical contacts), not full cases due to weight and cost inefficiency for standard builds.

PEEK:

High-performance polymer for extreme thermal/chemical resistance. Rarely used for keyboard cases but ideal for specialized medical or aerospace components requiring non-conductive, high-temp stability.

Surface Finish Options

Anodizing (Type II & III):

Type II: Standard for vibrant, durable colors (e.g., matte black, gold, blue). Enhances corrosion resistance while maintaining precision tolerances. Most common for consumer-focused keyboard cases.

Type III (Hard Anodizing): Thicker, wear-resistant coating for high-friction areas (e.g., sliding mechanisms). Ideal for commercial or heavy-use cases needing extended lifespan.

Brushed/Satin Finish:

Subtle linear texture that minimizes fingerprints and adds a premium, professional look. Perfect for minimalist or corporate designs.

Polishing:

Mirror-like shine for luxury aesthetics. Requires meticulous machining and post-processing—best for high-end consumer products where visual appeal is paramount.

Bead Blasting:

Uniform matte texture for a clean, modern appearance. Excellent for reducing glare and ensuring consistency across complex geometries.

Powder Coating:

Durable color options with enhanced scratch resistance. Best for industrial or outdoor applications where anodizing isn’t sufficient.

How to Optimize Your Material & Finish Choice

Standard Cases: Aluminum 6061 + Type II Anodizing (cost-effective, versatile, and widely customizable).

Premium/Rugged Cases: Aluminum 7075 + Type III Anodizing for maximum durability in high-impact scenarios.

Specialized Needs: Stainless steel for corrosion-prone environments; brass for electrical components; PEEK for extreme thermal requirements (rare for keyboards).

Finish Tips: Prioritize anodizing for color consistency and durability. Use bead blasting for industrial aesthetics or polishing for luxury appeal.

At Honyo Prototype, we eliminate guesswork.

→ Instantly compare costs, lead times, and finish options with our AI-powered quote platform—no minimums, no delays.

→ Experience 3–5 day turnaround for prototypes and production runs.

→ Get your precise quote in seconds and build your next keyboard case with confidence.

From Quote to Part: Our Process

How It Works: From CAD to Part

1. Upload CAD File – Simple, Secure, Anywhere

Upload your design in any standard format (STEP, STL, IGES, etc.) via our secure cloud portal

Zero software installation needed – work from anywhere, anytime

Military-grade encryption ensures full data privacy and compliance

2. Get Instant Quote – AI-Powered Precision Pricing

Our AI engine analyzes geometry, materials, and tolerances in under 10 seconds

Transparent cost breakdown: materials (e.g., 6061-T6 aluminum), machining time, surface finishes (anodizing, bead blasting), and shipping

Real-time option comparisons – optimize for cost or performance with one click

No hidden fees – see exactly what you’re paying before confirming

3. DFM Analysis – Optimize Before Production

Automated design-for-manufacturability checks flag issues like undercuts, thin walls, or complex geometries

Engineer-reviewed recommendations to enhance functionality while reducing costs (e.g., simplifying features for faster machining)

Collaborate in real-time with Honyo’s experts to refine your design – no delays, no surprises

4. Production & Delivery – Fast, Traceable, Reliable

Precision 3/4/5-axis CNC machining at ±0.01mm tolerances in our Shenzhen smart factory

100% in-process quality control with automated metrology checks

Live production tracking via customer portal – watch your part being made in real-time

Delivered as fast as 3 business days globally with end-to-end traceability and dedicated support

Start Your Project with Honyo

Start Your Project with Honyo Prototype

Precision Engineered for Your Vision

AI-Powered Instant Quote

Upload your CAD file and receive a real-time, transparent price estimate in seconds—no manual quotes, no hidden fees. Our platform optimizes cost while maintaining ±0.01mm tolerances.

48-Hour Prototyping Guarantee

Accelerate your timeline with rapid turnaround. From design validation to functional prototypes, we deliver precision parts faster than industry standards—ideal for hardware startups iterating at speed.

5-Axis CNC Expertise

Complex geometries and tight tolerances achieved with multi-axis machining. Perfect for functional keyboard cases requiring exact fit, durability, and aerospace-grade surface finishes.

Founder-Led Support

Susan Leo personally oversees your project, ensuring seamless communication and tailored solutions from concept to delivery. No middlemen—just direct engineering expertise.

Ready to Build?

📧 Email: [email protected]

📞 Phone: +86 139 2843 8620

📍 Visit: Shenzhen & Dongguan facilities for a live tour of our precision machining capabilities

Transform your design into reality—where innovation meets precision, every time.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.