Contents

Manufacturing Insight: Cnc Acrylic Engraving

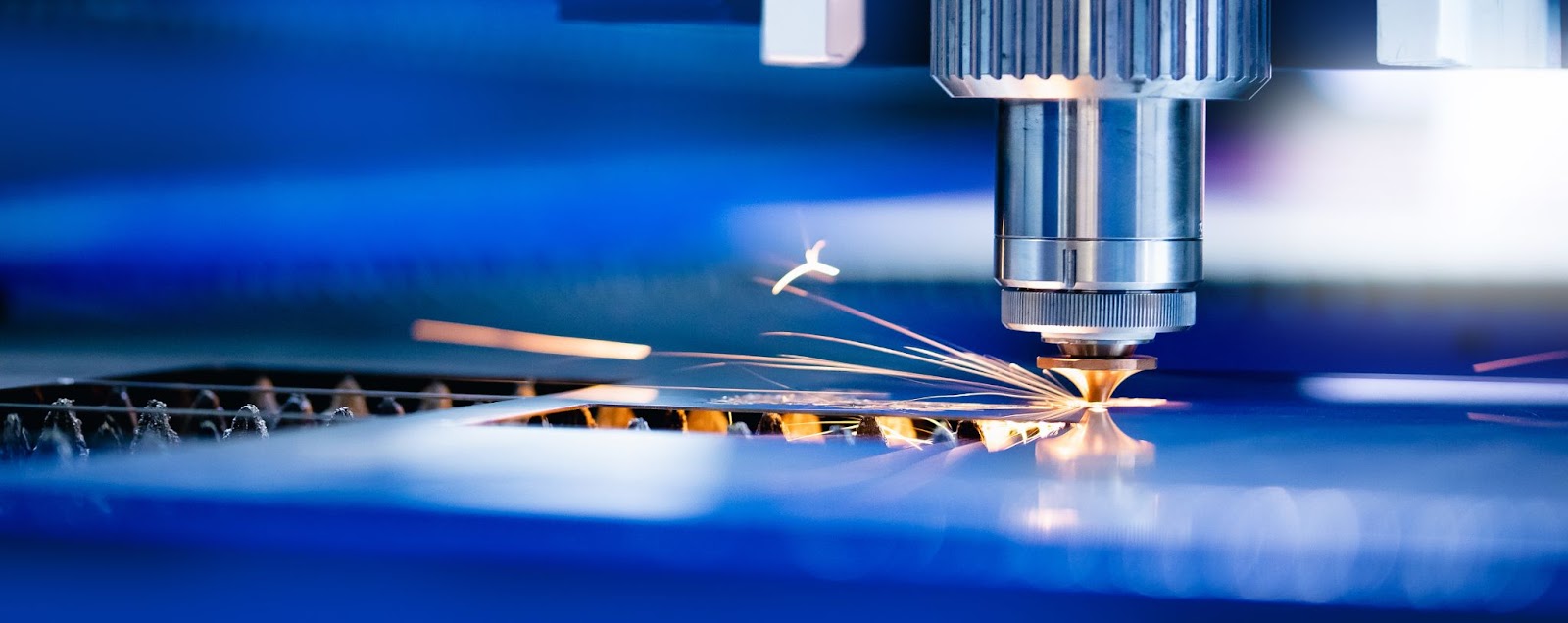

Precision Acrylic Engraving for Demanding Industrial Applications

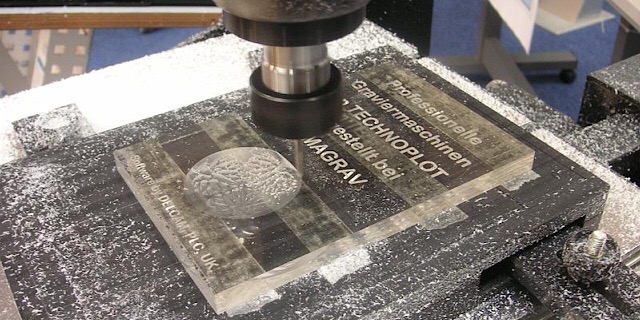

At Honyo Prototype, we leverage advanced CNC machining expertise to deliver flawless acrylic engraving solutions tailored for engineering and design professionals. Acrylic’s optical clarity and versatility make it indispensable for signage, control panels, medical devices, and architectural models, yet its thermal sensitivity and brittleness demand exceptional process control. Our multi-axis CNC systems, operating under rigorously optimized parameters, achieve sub-0.005mm tolerances while eliminating common defects like micro-cracking, melting, or edge chipping. Through proprietary toolpath strategies and adaptive spindle speed modulation, we ensure crisp, polished engravings with consistent depth control—critical for applications requiring regulatory compliance or high-end aesthetic finishes.

Engineered for Speed Without Compromise

Our end-to-end CNC machining workflow integrates material science insights with real-time in-process monitoring. Dedicated acrylic processing protocols include temperature-stabilized environments, non-marring fixturing, and specialized carbide tooling to maintain surface integrity. Whether executing intricate vector-based logos, deep relief textures, or fine halftone images, Honyo consistently produces burr-free results on cast or extruded acrylic sheets up to 25mm thick. This precision extends across prototyping through low-volume production, enabling clients to validate designs rapidly while meeting stringent industry standards for optical performance and mechanical reliability.

Accelerate Your Project Timeline with Instant Quoting

Honyo Prototype eliminates quoting bottlenecks with our Online Instant Quote platform—designed specifically for engineering teams requiring rapid cost validation. Upload CAD files directly to receive a detailed, no-obligation machining estimate in under 60 seconds, including material options, lead times, and technical feasibility feedback. This seamless integration with our CNC engraving capabilities allows you to iterate designs confidently, reduce procurement cycles, and transition smoothly from concept to certified part. For mission-critical acrylic components where precision and speed define project success, Honyo delivers manufacturing excellence backed by decades of prototyping expertise.

Technical Capabilities

CNC Acrylic Engraving – Technical Specifications Overview

CNC acrylic engraving requires high precision toolpaths and controlled feed rates to achieve clean, burr-free results. While acrylic (PMMA) is the primary material for engraving applications, the same CNC platforms—particularly 3, 4, and 5-axis milling systems—are also used for high-tolerance machining of metals and engineering plastics such as aluminum, steel, ABS, and nylon. Below is a detailed technical specification table outlining key parameters and capabilities across different CNC processes.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Tight Tolerance Capability |

|---|---|---|---|---|---|

| Primary Use | Flat or 2.5D engraving, pocketing, profiling | Indexed rotary features, cylindrical engraving | Complex 3D contours, deep cavities, undercuts | Precision cylindrical parts, threaded components | ±0.0002″ (5 µm) to ±0.001″ (25 µm) |

| Spindle Speed Range | 8,000 – 24,000 RPM | 8,000 – 24,000 RPM | 10,000 – 30,000 RPM | 500 – 6,000 RPM (material-dependent) | Up to 30,000 RPM for fine engraving |

| Feed Rate (Typical) | 100 – 500 IPM | 100 – 450 IPM | 80 – 400 IPM | 0.002 – 0.020 IPR (inches per rev) | Optimized for minimal tool deflection |

| Tooling (Common) | 60° or 90° V-bits, 1/16″ end mills | Same as 3-axis + rotary axis engagement | Ball-nose and tapered end mills, micro engraving tools | Carbide inserts, boring bars | Sub-mm tools for micro engraving |

| Materials Supported | Acrylic, ABS, Nylon, Aluminum | Acrylic, ABS, Aluminum, Steel (hardened) | Acrylic, Aluminum, Stainless Steel, Titanium | Aluminum, Steel, ABS (limited), Nylon | All listed materials with material-specific tooling |

| Coolant/Lubrication | Air blast (acrylic), mist (metals) | Mist or air blast | Through-spindle coolant (metals), dry for plastics | Flood coolant or mist | Dry or minimal for acrylic to prevent cracking |

| Surface Finish (Typical) | Ra 32–63 µin (plastics), Ra 16 µin (metals) | Ra 32–125 µin (rotary engraving) | Ra 8–32 µin (high-speed finish passes) | Ra 16–63 µin | Ra <8 µin achievable with polishing passes |

| Positioning Accuracy | ±0.0005″ | ±0.0004″ | ±0.0002″ | ±0.0003″ | Up to ±0.0001″ with laser calibration |

| Max Work Envelope (Typical) | 24″ x 24″ x 10″ | 20″ x 20″ x 10″ + 360° rotation | 16″ x 16″ x 12″ with full A/B axis tilt | 16″ diameter x 30″ length | Varies by machine class (micromachining: <6″) |

| Applications (Acrylic) | Panel labeling, signage, UI overlays | Multi-face engraving, cylindrical displays | 3D sculpted lenses, decorative art | Not applicable | Calibration masters, optical guides |

Notes on Material Behavior:

Acrylic (PMMA): Requires sharp tools, high spindle speeds, and air cooling to prevent melting. Clamping must avoid stress cracking.

Aluminum: Machined with high-speed tools and proper chip evacuation; ideal for integrated engraved housings.

Steel: Demands rigid setups and carbide tooling; tight tolerance engraving typically reserved for tooling dies or markings.

ABS & Nylon: Lower melting points than metals; use reduced feed rates and sharp tools to avoid gumming.

This specification table reflects industrial-grade CNC platforms suitable for both prototyping and low-volume production at Honyo Prototype, where multi-axis coordination and sub-millimeter tolerances are standard.

From CAD to Part: The Process

Honyo Prototype CNC Acrylic Engraving Workflow

Our end-to-end CNC acrylic engraving process begins with secure CAD file submission via the Honyo Portal. Clients upload native formats (STEP, IGES, DWG) or neutral formats (STL, DXF), ensuring geometric accuracy and engraving-specific details like vector paths, depth parameters, and font specifications are preserved. File validation checks for unit consistency, layer integrity, and engraving zone definition occur immediately upon upload, minimizing downstream rework.

AI-Powered Quoting Engine

The uploaded CAD triggers our proprietary AI quoting system, which analyzes engraving complexity, material waste, machine time, and toolpath density. Key parameters evaluated include minimum feature size (≥0.5mm for acrylic), depth-to-width ratios, and risk of sub-surface fractures. The AI cross-references real-time material costs (PMMA grades: cast vs. extruded), machine availability, and historical production data to generate a binding quote within 90 minutes. Critical constraints—such as unsupported thin sections or acute angles prone to chipping—are flagged in the quote summary with visual overlays on the CAD model.

Collaborative DFM Review

Post-quote acceptance, our engineering team conducts a dedicated Design for Manufacturability (DFM) review focused on acrylic-specific challenges. We validate engraving depth against material thickness (e.g., ≤50% of stock thickness for stress avoidance), assess clamping strategies to prevent vibration-induced micro-cracks, and optimize tool selection (diamond-tipped vs. carbide) based on edge quality requirements. Clients receive a formal DFM report within 24 hours, detailing actionable recommendations—such as adjusting corner radii to ≥0.3mm or modifying engraving sequences to reduce thermal buildup—with annotated CAD comparisons. This phase requires client sign-off to proceed.

Precision Production Execution

Approved jobs move to climate-controlled CNC cells (22±1°C, 45% RH) to mitigate acrylic’s thermal expansion sensitivity. Engraving employs high-RPM spindles (18,000–24,000 RPM) with specialized toolpaths:

Raster engraving uses 30°–45° V-bits at 0.1–0.3mm depth for fine details

Vector engraving applies constant-depth passes with 60° conical tools for crisp lines

Coolant-free operation is maintained using compressed air blast systems to prevent acrylic clouding. In-process inspections at 25%/75% completion verify depth consistency (±0.05mm tolerance) and edge clarity via digital microscopes.

Quality-Controlled Delivery

Post-engraving, parts undergo ultrasonic cleaning to remove micro-debris, followed by optical inspection against the original CAD using coordinate measuring machines (CMM). Critical dimensions and surface roughness (Ra ≤1.6μm) are certified in the final inspection report. Parts ship in anti-static foam with humidity-controlled packaging, accompanied by a full traceability dossier including machine logs, tool wear data, and material certificates. Standard lead time is 3–5 business days from DFM approval, with real-time shipment tracking via the client portal.

This integrated workflow ensures acrylic engraving precision while reducing time-to-part by 40% compared to industry averages, leveraging automation for consistency and engineering oversight for defect prevention.

Start Your Project

Looking for precision CNC acrylic engraving services? Honyo Prototype delivers high-accuracy, custom engraving solutions for prototypes and production parts. Our advanced CNC capabilities ensure clean, detailed results on acrylic materials, ideal for signage, enclosures, displays, and more.

With our factory located in Shenzhen, we offer fast turnaround times and consistent quality control for clients worldwide.

Contact Susan Leo today at [email protected] to discuss your project requirements and receive a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.