Introduction: Navigating the Global Market for cnc acrylic cutting machine

In today’s competitive landscape, sourcing a reliable CNC acrylic cutting machine can pose significant challenges for international B2B buyers. The need for precision, efficiency, and adaptability in applications ranging from signage and architectural models to custom packaging has never been more critical. This guide provides an in-depth exploration of CNC acrylic cutting machines, detailing various types, their applications, and essential features to consider during the purchasing process.

Moreover, we will discuss the intricacies of supplier vetting, helping you identify reputable manufacturers and distributors who meet your specific quality and service standards. Understanding the cost structures associated with these machines is also crucial; we will break down factors influencing pricing, including technology, capabilities, and regional variations that may impact your procurement budget.

Designed specifically for B2B buyers from regions such as Africa, South America, the Middle East, and Europe—like Germany and Saudi Arabia—this guide aims to empower you with the knowledge necessary for informed purchasing decisions. By equipping you with insights into market trends, machine specifications, and supplier dynamics, we aim to streamline your sourcing journey and enhance your operational efficiency in acrylic cutting applications.

Understanding cnc acrylic cutting machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CO2 Laser Cutting Machines | Utilizes CO2 laser technology for high precision cutting | Sign making, displays, custom parts | Pros: High precision, versatile materials; Cons: Higher initial cost. |

| Diode Laser Cutting Machines | Compact, energy-efficient, suitable for small projects | Hobbyists, small-scale production | Pros: Cost-effective, easy to use; Cons: Limited cutting depth. |

| Hybrid Laser & Blade Cutters | Combines laser and mechanical cutting for diverse applications | Prototyping, arts and crafts | Pros: Versatile, can handle various materials; Cons: More complex operation. |

| Fiber Laser Cutting Machines | Uses fiber optics for cutting metal and acrylic with high efficiency | Industrial manufacturing, automotive | Pros: Fast cutting speeds, low maintenance; Cons: Not ideal for thicker acrylic. |

| CNC Router Machines | Employs rotating bits for cutting, engraving, and shaping acrylic | Furniture making, signage, architectural elements | Pros: Excellent for large sheets; Cons: Less precise than laser options. |

What Are the Key Characteristics of CO2 Laser Cutting Machines?

CO2 laser cutting machines are renowned for their precision and versatility, making them ideal for cutting various materials, including acrylic. They operate using a high-powered CO2 laser beam, which can easily slice through thick sheets with clean edges. These machines are particularly suitable for applications in sign making, displays, and custom parts manufacturing. When considering a CO2 laser cutter, buyers should assess the power output, cutting speed, and the availability of support and maintenance services.

How Do Diode Laser Cutting Machines Compare for Small Projects?

Diode laser cutting machines are compact and energy-efficient, making them perfect for small-scale projects and hobbyist applications. They typically have a lower price point compared to CO2 lasers, which makes them attractive for startups and smaller businesses. However, they may have limitations in cutting depth and material thickness. Buyers should consider their specific project needs, including the types of materials they plan to cut and the desired precision level.

Why Choose Hybrid Laser & Blade Cutters for Diverse Applications?

Hybrid laser and blade cutters combine the benefits of both laser and mechanical cutting technologies, providing flexibility in handling various materials. They are particularly useful for prototyping and artistic applications where intricate designs are needed. While these machines offer versatility, they can be more complex to operate than single-method machines. B2B buyers should evaluate their operational capabilities and training requirements when considering this option.

What Advantages Do Fiber Laser Cutting Machines Offer?

Fiber laser cutting machines are becoming increasingly popular in industrial applications due to their speed and efficiency. They utilize fiber optics to deliver laser energy, allowing for rapid cutting of materials, including thin acrylic sheets. While they excel in speed and maintenance, they may not be the best choice for thicker acrylic materials. Companies should weigh their production volume and material specifications when selecting fiber laser options.

How Do CNC Router Machines Fit into Acrylic Cutting?

CNC router machines employ rotating bits for cutting and engraving, making them suitable for large-scale acrylic projects. They can handle larger sheets and create detailed shapes, which is beneficial for furniture making and signage. However, they may not achieve the same level of precision as laser machines. Buyers should consider the scale of their projects and whether the ability to work with larger materials outweighs the need for precision.

Key Industrial Applications of cnc acrylic cutting machine

| Industry/Sector | Specific Application of cnc acrylic cutting machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Signage and Advertising | Creation of custom signs, logos, and displays | Enhanced brand visibility and customization options | Quality of cutting precision, machine compatibility with various acrylic types, and support services. |

| Automotive | Production of interior components and displays | Lightweight components with high aesthetic appeal | Durability of materials, precision cutting capabilities, and availability of replacement parts. |

| Architecture and Design | Fabrication of architectural models and prototypes | Accurate representations for client presentations | Size of the machine, ease of use, and software compatibility for design files. |

| Retail and Display | Development of point-of-purchase displays and fixtures | Increased sales through attractive presentations | Versatility in material handling, cutting speed, and post-purchase support. |

| Medical and Healthcare | Manufacturing of protective shields and signage | Enhanced safety and compliance with regulations | Material safety certifications, cutting accuracy, and ease of cleaning. |

How Is the CNC Acrylic Cutting Machine Used in Signage and Advertising?

In the signage and advertising industry, CNC acrylic cutting machines are employed to create custom signs, logos, and promotional displays. These machines allow businesses to produce intricate designs with high precision, ensuring that their branding is visually appealing and accurately represents their identity. Buyers in this sector should consider the machine’s cutting precision and compatibility with various acrylic types, as well as the availability of technical support and service to ensure smooth operation.

What Role Does CNC Acrylic Cutting Play in the Automotive Industry?

The automotive industry utilizes CNC acrylic cutting machines to produce lightweight interior components, such as dashboard panels and decorative trims. The ability to cut and engrave acrylic allows manufacturers to enhance the aesthetic appeal of vehicles while maintaining performance standards. Buyers should focus on the durability of the materials used in the cutting process, the precision of the cuts, and the availability of replacement parts to ensure long-term operational efficiency.

How Do Architects and Designers Benefit from CNC Acrylic Cutting Machines?

Architects and designers leverage CNC acrylic cutting machines for the fabrication of architectural models and prototypes. This technology enables them to create detailed and accurate representations of their designs, which are crucial for client presentations and project approvals. Buyers in this field should prioritize the machine’s size, ease of use, and compatibility with design software to streamline the workflow from conception to execution.

In What Ways Does the Retail Sector Utilize CNC Acrylic Cutting Technology?

In retail, CNC acrylic cutting machines are pivotal in developing point-of-purchase displays and fixtures that attract customers. The ability to create eye-catching, customized displays can significantly enhance product visibility and sales. Buyers should consider the machine’s versatility in handling different materials, cutting speed, and the availability of post-purchase support to maximize their investment.

How Is CNC Acrylic Cutting Employed in the Medical Sector?

The medical and healthcare industries use CNC acrylic cutting machines to manufacture protective shields, signage, and various other equipment that comply with safety regulations. These machines provide the precision required to create components that are not only functional but also meet stringent health standards. Buyers should ensure that the materials used are certified for safety, and that the machine offers high cutting accuracy and ease of cleaning to maintain hygiene standards.

3 Common User Pain Points for ‘cnc acrylic cutting machine’ & Their Solutions

Scenario 1: Difficulty Achieving Precision Cuts for Complex Designs

The Problem: B2B buyers often face the challenge of achieving high precision when cutting intricate designs in acrylic. This is particularly problematic for industries such as signage, architecture, and custom fabrication, where even minor deviations can lead to costly errors and material waste. In regions like Africa and South America, where access to high-quality machinery may be limited, buyers might struggle with machines that cannot consistently maintain the desired accuracy, ultimately compromising project quality.

The Solution: To overcome precision issues, buyers should invest in CNC acrylic cutting machines equipped with advanced motion control systems and high-quality linear guides, such as those from Taiwan’s HIWIN. These features ensure smoother operation and minimize vibration, which are critical for maintaining cutting accuracy. Additionally, buyers should request demonstrations or trial periods to test machine capabilities before purchase. Implementing a robust training program for operators can also help maximize the machine’s precision by ensuring that users are familiar with the correct settings and operational techniques, such as optimal feed rates and laser power adjustments.

Scenario 2: High Operating Costs and Material Waste

The Problem: Operating costs can skyrocket for businesses using CNC acrylic cutting machines, particularly due to material waste from inefficient cutting processes. This is a significant concern for manufacturers in Europe and the Middle East, where margins can be tight. Inadequate nesting software and poor machine setup can lead to excessive scrap material, resulting in financial losses and environmental concerns.

The Solution: Investing in a CNC acrylic cutting machine that includes advanced software for material optimization can significantly reduce waste. Buyers should prioritize models with integrated nesting algorithms that arrange cut patterns in a way that maximizes material usage. Additionally, regular maintenance of the cutting equipment is crucial to maintain its efficiency. Establishing a preventive maintenance schedule can help identify wear and tear before it impacts performance. Finally, consider training staff on best practices for material handling and machine operation to further minimize waste and improve overall productivity.

Scenario 3: Technical Support and Reliability Concerns

The Problem: Many B2B buyers experience anxiety over the reliability and support for their CNC acrylic cutting machines, particularly in regions with less established service networks. If a machine breaks down, it can halt production, leading to missed deadlines and dissatisfied customers. In markets like South America and parts of Africa, where local technical support may not be readily available, this concern is amplified.

The Solution: Buyers should thoroughly research manufacturers that offer comprehensive after-sales support, including warranty options, technical assistance, and readily available spare parts. Opting for machines with a strong international presence can ensure better support and access to resources. Furthermore, consider establishing a relationship with local distributors who can provide ongoing training and emergency support. This investment not only enhances machine reliability but also builds confidence in the operational capabilities of the equipment. Regularly scheduled maintenance checks can also preemptively address potential issues before they escalate into significant problems.

Strategic Material Selection Guide for cnc acrylic cutting machine

What Are the Key Materials for CNC Acrylic Cutting Machines?

When selecting materials for CNC acrylic cutting machines, it is essential to consider various types of acrylic and other compatible materials. Each material has unique properties that can influence the performance of the cutting machine, the quality of the finished product, and the overall cost-effectiveness of manufacturing. Below are four common materials, their properties, advantages and disadvantages, and considerations for international B2B buyers.

1. Clear Acrylic (PMMA)

Key Properties:

Clear acrylic, also known as polymethyl methacrylate (PMMA), is renowned for its clarity and UV resistance. It has a temperature rating of up to 80°C and is lightweight yet strong, making it an excellent alternative to glass.

Pros & Cons:

The primary advantage of clear acrylic is its optical clarity, which is ideal for applications requiring transparency, such as displays and signage. However, it can be more susceptible to scratching than glass, which may affect its durability in certain environments.

Impact on Application:

Clear acrylic is widely used in signage, displays, and protective barriers. Its compatibility with various adhesives and coatings enhances its versatility in different applications.

Considerations for International Buyers:

Buyers from regions like Europe and the Middle East should ensure compliance with relevant standards such as ASTM D4802 for acrylic plastics. The availability of clear acrylic may vary by region, affecting lead times and costs.

2. Colored Acrylic

Key Properties:

Colored acrylic sheets are available in a range of hues and finishes, including opaque, translucent, and frosted. They maintain similar temperature ratings and UV resistance as clear acrylic.

Pros & Cons:

The advantage of colored acrylic is its aesthetic appeal and ability to diffuse light, making it suitable for decorative applications. However, the manufacturing process can be more complex, leading to higher costs.

Impact on Application:

Colored acrylic is often used in artistic installations, signage, and custom displays. Its color options allow for creative designs that can enhance branding and visual impact.

Considerations for International Buyers:

B2B buyers should verify the color consistency and quality certifications, especially when sourcing from suppliers in Africa or South America, where standards may differ.

3. Extruded Acrylic

Key Properties:

Extruded acrylic is produced through a continuous process, resulting in sheets with a uniform thickness and surface finish. It has good impact resistance and can withstand temperatures up to 70°C.

Pros & Cons:

The main advantage of extruded acrylic is its cost-effectiveness, making it suitable for large-scale projects. However, it may have lower optical clarity compared to cast acrylic, which can limit its use in high-visibility applications.

Impact on Application:

Commonly used in interior applications, extruded acrylic is ideal for point-of-purchase displays and light fixtures. Its lower cost makes it a popular choice for bulk orders.

Considerations for International Buyers:

Buyers should consider the availability of extruded acrylic in their regions, as well as potential shipping costs and tariffs that may affect overall pricing.

4. Polycarbonate

Key Properties:

Polycarbonate is a high-performance thermoplastic with excellent impact resistance and a temperature rating of up to 120°C. It is also UV resistant, making it suitable for outdoor applications.

Pros & Cons:

The key advantage of polycarbonate is its superior durability and resistance to shattering, making it ideal for safety applications. However, it is generally more expensive than acrylic, which may deter budget-conscious buyers.

Impact on Application:

Polycarbonate is often used in safety goggles, protective shields, and outdoor signage due to its toughness. Its compatibility with CNC cutting machines makes it a viable option for various industries.

Considerations for International Buyers:

International buyers should be aware of the specific regulations regarding polycarbonate in their regions, particularly in Europe, where environmental regulations may impact material sourcing.

Summary Table of Material Selection for CNC Acrylic Cutting Machines

| Material | Typical Use Case for cnc acrylic cutting machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Clear Acrylic (PMMA) | Signage, displays, protective barriers | Excellent optical clarity | Susceptible to scratching | Medium |

| Colored Acrylic | Artistic installations, custom displays | Aesthetic appeal and light diffusion | Higher manufacturing complexity | High |

| Extruded Acrylic | Point-of-purchase displays, light fixtures | Cost-effective for large-scale projects | Lower optical clarity | Low |

| Polycarbonate | Safety goggles, protective shields, outdoor signage | Superior durability and impact resistance | Generally more expensive | High |

This strategic material selection guide provides a comprehensive overview for B2B buyers considering CNC acrylic cutting machines, ensuring informed decisions that align with their specific application needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc acrylic cutting machine

What Are the Key Stages in the Manufacturing Process of CNC Acrylic Cutting Machines?

The manufacturing of CNC acrylic cutting machines is a multi-stage process that ensures precision and quality in the final product. Understanding these stages can help B2B buyers evaluate suppliers effectively.

1. Material Preparation: What Materials Are Used?

The initial stage involves selecting high-quality materials, primarily focusing on the frame and the laser components. Common materials include:

- Steel and Aluminum: Used for the machine structure due to their strength and durability.

- Laser Tubes: Typically CO2 lasers are chosen for their efficiency in cutting acrylic.

- Electronics: High-grade circuit boards and components for the control systems.

Proper material sourcing is essential, as the quality will directly affect the machine’s performance and longevity.

2. Forming: How Are the Components Shaped?

Once materials are prepared, they undergo various forming processes, including:

- CNC Machining: Components like the frame and laser mounts are precisely cut and shaped using CNC machines to ensure accuracy.

- Welding and Assembly: For metal frames, welding techniques are employed to assemble parts, followed by stress testing to ensure structural integrity.

- Injection Molding: This may be used for plastic parts, enabling high-volume production of intricate designs.

These processes ensure that all components fit together seamlessly and perform as intended.

3. Assembly: How Are the Machines Assembled?

The assembly stage is where all the individual components come together:

- Mechanical Assembly: This includes fitting the laser tube, mirrors, and lens systems, as well as assembling the motion system (belts, motors, and rails).

- Electrical Assembly: Wiring the control panels, power supply, and safety features is critical. This stage often includes installing software for machine operation.

- Calibration: After assembly, the machine is calibrated for precision cutting. This involves setting the laser focus and testing the motion system.

Proper assembly practices are vital for machine reliability and cutting accuracy.

4. Finishing: What Are the Final Touches?

The finishing stage enhances the machine’s aesthetic and functional qualities:

- Surface Treatment: This could involve powder coating or anodizing the metal parts to prevent corrosion and enhance durability.

- Quality Checks: Before shipment, machines undergo thorough quality checks to ensure they meet specified tolerances and performance criteria.

A well-finished machine not only looks professional but is also built to withstand rigorous usage.

What Are the Quality Assurance Standards for CNC Acrylic Cutting Machines?

Quality assurance is a critical aspect of manufacturing CNC acrylic cutting machines, ensuring they meet international and industry-specific standards.

What International Standards Should Buyers Be Aware Of?

- ISO 9001: This standard focuses on quality management systems and is crucial for suppliers aiming to demonstrate their commitment to quality.

- CE Marking: Particularly relevant for European markets, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For certain applications, especially in industrial contexts, adherence to API standards may also be required.

Understanding these standards helps buyers assess the credibility of suppliers.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is integrated throughout the manufacturing process and typically includes:

- Incoming Quality Control (IQC): Inspection of raw materials and components upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during production stages to identify and rectify any issues immediately.

- Final Quality Control (FQC): A comprehensive inspection of the finished product before it is packaged and shipped.

These checkpoints help maintain high standards of quality throughout the manufacturing process.

How Can B2B Buyers Verify Supplier Quality Assurance?

Buyers must employ various strategies to verify the quality assurance practices of their suppliers, especially when dealing internationally.

What Methods Can Be Used for Supplier Audits?

- On-Site Audits: Conducting physical inspections of the manufacturing facilities can provide insights into the supplier’s processes and quality control measures.

- Document Review: Requesting and reviewing quality assurance documentation, including ISO certifications, QC reports, and previous inspection results, can also be beneficial.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing processes and product quality.

These methods help mitigate risks associated with international purchasing.

What Are the Nuances for International Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe may encounter specific challenges:

- Regulatory Compliance: Ensure that suppliers are compliant with local regulations and international standards, which can vary significantly across regions.

- Cultural Considerations: Understanding cultural differences in business practices can facilitate smoother negotiations and partnerships.

- Logistics and Shipping: Consider the logistics involved in international shipping, including customs clearance and potential delays, which can impact the overall project timeline.

By being aware of these nuances, buyers can make more informed decisions and establish successful partnerships with suppliers.

Conclusion

The manufacturing processes and quality assurance practices of CNC acrylic cutting machines are intricate and crucial for ensuring the reliability and performance of these machines. By understanding the various stages of production and the importance of quality control, B2B buyers can effectively evaluate potential suppliers and make informed purchasing decisions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc acrylic cutting machine’

In the competitive landscape of manufacturing and design, sourcing a CNC acrylic cutting machine requires a strategic approach. This guide serves as a practical checklist to assist international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, in making informed purchasing decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of sourcing a CNC acrylic cutting machine. Consider factors such as the maximum sheet size, cutting thickness, and the type of acrylic (clear, colored, or mirrored) you plan to work with. This will help narrow down your options and ensure that the machine meets your production needs.

- Cutting Precision: Look for machines that offer high precision and repeatability to achieve intricate designs.

- Speed Requirements: Determine the cutting speed necessary for your operations to enhance productivity.

Step 2: Research Different Machine Types

Understanding the various types of CNC acrylic cutting machines available on the market is vital. Machines may differ in their cutting technology, such as CO2 lasers or diode lasers, which impact performance and cost.

- Laser Power: Higher wattage typically results in faster cutting speeds and thicker material capabilities.

- Versatility: Some machines may also handle other materials, which could be beneficial if you plan to diversify your production.

Step 3: Evaluate Potential Suppliers

Before making a commitment, vet potential suppliers thoroughly. Review their company profiles, customer testimonials, and case studies from buyers in similar industries.

- Certifications and Standards: Ensure the supplier meets international quality and safety standards, such as CE certifications.

- After-Sales Support: Look for suppliers that offer comprehensive technical support and warranty options.

Step 4: Request Quotes and Compare Prices

Once you have identified potential machines, request detailed quotes from multiple suppliers. Comparing prices allows you to assess the cost-effectiveness of each option.

- Total Cost of Ownership: Don’t just consider the initial purchase price; factor in maintenance, consumables, and potential upgrades.

- Payment Terms: Clarify payment options and terms, as this can significantly affect your cash flow.

Step 5: Ask About Customization Options

Customization can be crucial for specific applications. Inquire whether the supplier can accommodate modifications to the machine to better suit your production needs.

- Software Compatibility: Ensure that the CNC machine’s software integrates well with your existing design software for seamless operations.

- Additional Features: Consider features such as automatic loading and unloading systems that can improve efficiency.

Step 6: Review Delivery and Installation Services

Understand the delivery timeline and installation process of the CNC acrylic cutting machine. Timely delivery is critical to maintaining your production schedule.

- Logistics and Shipping: Check if the supplier has experience with international shipping and can handle customs clearance.

- Installation Support: Ensure the supplier provides installation assistance and training for your staff to maximize the machine’s capabilities.

Step 7: Read User Reviews and Testimonials

Finally, seek feedback from other users who have purchased the same model. This can provide valuable insights into the machine’s performance and reliability.

- Long-Term Performance: Look for reviews that discuss the machine’s durability and efficiency over time.

- Customer Support Experiences: Understanding the level of support other buyers received can guide your expectations regarding after-sales service.

By following this checklist, B2B buyers can confidently navigate the procurement process for CNC acrylic cutting machines, ensuring they select a solution that aligns with their operational requirements and business goals.

Comprehensive Cost and Pricing Analysis for cnc acrylic cutting machine Sourcing

What Are the Key Cost Components of CNC Acrylic Cutting Machines?

When sourcing CNC acrylic cutting machines, understanding the cost structure is critical for B2B buyers. The primary cost components include:

-

Materials: The cost of raw materials, including the laser tubes and components used in manufacturing, is a significant factor. High-quality materials often lead to better performance and longevity, but they also increase initial costs.

-

Labor: Skilled labor is required for both manufacturing and assembly. Labor costs can vary significantly based on geographic location, with regions like Europe typically incurring higher labor costs than parts of Africa or South America.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize these overheads, affecting the overall pricing of the machines.

-

Tooling: Specialized tools and molds for creating specific machine parts can represent a substantial investment. Customization often requires additional tooling, which can increase costs.

-

Quality Control (QC): Ensuring that machines meet quality standards incurs costs related to testing and inspection processes. Machines with higher quality certifications may carry a premium price tag but can offer better reliability and reduced maintenance costs.

-

Logistics: Shipping and handling costs, especially for international buyers, can significantly impact the final price. Incoterms play a crucial role in determining who bears these costs.

-

Margin: Suppliers typically add a markup to cover their costs and profit. Understanding the average margin in your specific market can help in negotiations.

How Do Price Influencers Affect CNC Acrylic Cutting Machine Costs?

Several factors can influence the pricing of CNC acrylic cutting machines:

-

Volume/MOQ: Buyers purchasing in bulk often receive better pricing due to economies of scale. Minimum Order Quantities (MOQs) can also affect the overall cost per unit.

-

Specifications and Customization: Tailoring machines to specific needs or configurations can lead to increased costs. Custom features may require additional materials and labor, impacting the final price.

-

Material Quality and Certifications: Machines built with higher-grade materials or those that meet specific industry certifications tend to have higher upfront costs but may provide long-term savings through durability and efficiency.

-

Supplier Factors: The reputation, experience, and location of the supplier can greatly influence pricing. Established suppliers with a track record of quality may charge a premium.

-

Incoterms: Understanding the terms of shipment and responsibility for costs can help buyers manage their budgets effectively. Different Incoterms can lead to variations in total landed costs.

What Tips Can Help Buyers Negotiate Better Prices for CNC Acrylic Cutting Machines?

To ensure cost-efficiency when sourcing CNC acrylic cutting machines, consider the following strategies:

-

Negotiate Terms: Engage suppliers in discussions about pricing and payment terms. Many suppliers may be willing to offer discounts for larger orders or extended contracts.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the initial purchase price but also maintenance, operational costs, and potential downtime. A lower initial price may result in higher long-term expenses.

-

Research Pricing Nuances for International Markets: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of local market conditions, currency fluctuations, and import duties that can affect total costs.

-

Request Multiple Quotes: Obtaining quotes from various suppliers can provide leverage in negotiations and help identify competitive pricing.

-

Utilize Local Distributors: In regions where logistics costs are a concern, working with local distributors can reduce shipping expenses and lead times.

Disclaimer on Indicative Prices

Prices for CNC acrylic cutting machines can vary widely based on the factors discussed above. It is essential for buyers to conduct thorough market research and engage directly with suppliers to obtain accurate and up-to-date pricing information tailored to their specific needs.

Alternatives Analysis: Comparing cnc acrylic cutting machine With Other Solutions

Exploring Alternatives to CNC Acrylic Cutting Machines

In the rapidly evolving landscape of manufacturing and design, businesses often face the challenge of choosing the most efficient method for their specific needs. While CNC acrylic cutting machines are renowned for their precision and versatility in handling acrylic materials, there are several alternative solutions that may also serve various applications effectively. This analysis compares CNC acrylic cutting machines with laser cutting and traditional manual cutting methods, helping B2B buyers make informed decisions.

| Comparison Aspect | Cnc Acrylic Cutting Machine | Laser Cutting Machine | Manual Cutting Method |

|---|---|---|---|

| Performance | High precision, fast speeds | Excellent for intricate designs; high speed | Variable, dependent on skill |

| Cost | Moderate to high initial investment | Moderate, varies by machine type | Low, requires basic tools |

| Ease of Implementation | Requires training and setup | User-friendly with software integration | Simple, requires manual skill |

| Maintenance | Moderate; regular upkeep needed | Low; generally requires minimal maintenance | High; depends on tool condition |

| Best Use Case | High-volume production, detailed designs | Intricate cuts, diverse materials | Small projects, low volume |

What Are the Pros and Cons of Laser Cutting Machines?

Laser cutting machines utilize focused light to cut through materials, offering exceptional accuracy and speed. They are particularly effective for intricate designs, making them ideal for businesses needing detailed cuts in various materials, including acrylic. However, the initial investment can be significant, and while they require less maintenance than CNC machines, they may still need specialized training for effective operation.

How Does Manual Cutting Compare?

Manual cutting methods, such as using hand tools or saws, are the most cost-effective option for small-scale projects. They allow for immediate adjustments and flexibility during the cutting process. However, the performance heavily relies on the operator’s skill level, and achieving consistent precision can be challenging. Additionally, manual methods can be time-consuming and less efficient for high-volume production compared to CNC or laser cutting.

Conclusion: Choosing the Right Solution for Your Business Needs

When selecting the right cutting solution, B2B buyers should evaluate their specific requirements, including production volume, material types, and budget constraints. CNC acrylic cutting machines are well-suited for high-volume applications requiring precision, while laser cutting machines excel in detailed designs and intricate patterns. Manual cutting may suffice for smaller projects or businesses with limited budgets but may lack the efficiency and precision of automated solutions. Ultimately, aligning the chosen method with the company’s operational goals and resource capabilities will lead to optimal outcomes.

Essential Technical Properties and Trade Terminology for cnc acrylic cutting machine

What Are the Key Technical Properties of CNC Acrylic Cutting Machines?

Understanding the technical specifications of CNC acrylic cutting machines is crucial for making informed purchasing decisions. Here are some of the most important properties to consider:

1. Laser Power

Laser power is measured in watts (W) and significantly affects the cutting speed and material thickness that the machine can handle. Machines typically range from 30W for small, intricate cuts to over 100W for industrial applications. Higher wattage allows for faster cuts and the ability to work with thicker acrylic sheets, making it essential for businesses that require efficiency and versatility in production.

2. Working Area

The working area refers to the maximum dimensions of the material that the machine can accommodate. It is often expressed in millimeters (mm) and varies widely among models. A larger working area enables the cutting of bigger sheets or multiple parts in one cycle, which is vital for companies that need to optimize their workflow and minimize waste.

3. Material Compatibility

CNC acrylic cutting machines are designed to work with various types of acrylic, including clear, colored, and mirrored options. Understanding the machine’s compatibility with different materials is crucial for businesses that may want to diversify their product offerings. This adaptability can enhance a company’s competitive edge in the market.

4. Precision and Tolerance

Precision refers to the accuracy of the cuts made by the CNC machine, often measured in micrometers (µm). Tolerance is the allowable deviation from a specified measurement. High precision and tight tolerance are critical for applications requiring intricate designs or components, such as signage and custom displays. This capability can directly impact product quality and customer satisfaction.

5. Control System

The control system of a CNC acrylic cutting machine dictates how easily operators can program and manage the cutting process. Advanced systems, such as DSP (Digital Signal Processor) controllers, allow for complex designs and multiple cutting paths, enhancing operational efficiency. A user-friendly interface is essential for minimizing training time and ensuring smooth operations.

6. Cooling System

A reliable cooling system prevents overheating of the laser tube during operation, which can prolong the machine’s lifespan and maintain cutting quality. Efficient cooling is particularly important in high-volume production settings, where machines are operated continuously. Businesses should consider the cooling methods employed, such as water or air cooling, as part of their investment.

What Are Common Trade Terms in the CNC Acrylic Cutting Machine Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some common terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of CNC machines, it often relates to the sourcing of components. Understanding OEM relationships can help buyers gauge product reliability and quality.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for budgeting and inventory management, especially for businesses looking to minimize upfront costs while ensuring they meet production demands.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. It is a critical step in the procurement process, allowing businesses to compare offers and negotiate better deals based on their requirements.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in global trade. Familiarity with these terms helps companies understand their obligations regarding shipping, insurance, and tariffs, thereby mitigating risks associated with international procurement.

5. Lead Time

Lead time refers to the time taken from placing an order to its delivery. Understanding lead times is vital for production planning and inventory management, ensuring that businesses can meet customer demands without overstocking.

By grasping these essential technical properties and trade terms, international buyers can make more informed decisions regarding CNC acrylic cutting machines, ultimately leading to improved operational efficiency and profitability.

Navigating Market Dynamics and Sourcing Trends in the cnc acrylic cutting machine Sector

What Are the Current Market Dynamics and Key Trends in the CNC Acrylic Cutting Machine Sector?

The global CNC acrylic cutting machine market is witnessing significant growth driven by rising demand across various industries, including signage, automotive, and packaging. Key market drivers include the increasing adoption of automation in manufacturing processes and the growing need for precise and efficient cutting solutions. In regions like Africa, South America, the Middle East, and Europe, buyers are increasingly looking for machines that offer versatility, such as the ability to cut both clear and colored acrylic sheets.

Emerging B2B technology trends are characterized by advancements in laser cutting capabilities, such as higher wattage lasers that improve cutting speed and precision. Additionally, the integration of user-friendly interfaces and advanced software solutions is streamlining operations, making it easier for operators to manage complex designs. The trend towards compact, desktop-sized machines is particularly relevant for small and medium enterprises (SMEs) in developing regions, where space and budget constraints are prevalent.

Market dynamics are also shaped by the competitive landscape, where manufacturers are focusing on product differentiation through innovative features and enhanced customer support services. International buyers, particularly from Europe and the Middle East, are increasingly favoring suppliers that offer comprehensive warranties and reliable after-sales support, ensuring minimal downtime in operations.

How Is Sustainability and Ethical Sourcing Influencing B2B Decisions in the CNC Acrylic Cutting Machine Market?

Sustainability is becoming a central concern for B2B buyers in the CNC acrylic cutting machine market. The environmental impact of acrylic production and disposal is prompting companies to seek more sustainable sourcing options. Ethical supply chains are increasingly important, with buyers prioritizing suppliers who demonstrate responsible sourcing practices, such as using recycled materials or ensuring that their acrylic sheets are manufactured with minimal environmental degradation.

Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are becoming essential for manufacturers looking to appeal to eco-conscious buyers. Additionally, the use of ‘green’ materials and technologies, like energy-efficient laser tubes and environmentally friendly cooling systems, is gaining traction. Buyers are also interested in suppliers who provide clear documentation of their sustainability practices, as this transparency fosters trust and strengthens business relationships.

The demand for eco-friendly solutions is not only a regulatory response but also a market differentiator. Companies that embrace sustainability in their operations often see improved brand loyalty and customer retention, making ethical sourcing a crucial consideration for B2B transactions in this sector.

How Has the CNC Acrylic Cutting Machine Sector Evolved Over Time?

The evolution of CNC acrylic cutting machines can be traced back to the early days of laser technology. Initially, laser cutting was limited to industrial applications, but advancements in technology have democratized access to these machines. Over the years, the introduction of CO2 lasers significantly improved the precision and quality of cuts, making them ideal for acrylic materials.

The transition from traditional cutting methods to CNC technology has transformed manufacturing processes, allowing for increased automation and efficiency. Today, CNC acrylic cutting machines are equipped with sophisticated features such as integrated software for design customization, enhanced safety protocols, and real-time monitoring capabilities. This evolution reflects a broader trend towards digitization in manufacturing, where data-driven insights guide operational improvements and customer satisfaction.

As the market continues to evolve, international buyers can expect ongoing innovations that not only enhance cutting capabilities but also prioritize sustainability and ethical practices, ensuring a competitive edge in a rapidly changing global landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc acrylic cutting machine

-

1. How do I choose the right CNC acrylic cutting machine for my business needs?

Selecting the right CNC acrylic cutting machine involves assessing your production volume, material thickness, and desired cutting precision. Consider machines with a CO2 laser source for optimal acrylic cutting capabilities. Evaluate features like the working area size, laser power, and control systems, ensuring they align with your specific applications. Additionally, look for machines with robust customer support and warranty options to safeguard your investment. -

2. What is the average cost of a CNC acrylic cutting machine?

The price of CNC acrylic cutting machines varies significantly based on features, brand, and specifications. Basic models may start around $1,000, while high-end machines with advanced capabilities can exceed $10,000. For B2B buyers, it’s essential to consider not only the initial purchase price but also ongoing costs such as maintenance, operating expenses, and potential customization, which can impact the overall investment. -

3. How can I ensure the quality and reliability of the CNC acrylic cutting machine?

To ensure quality and reliability, conduct thorough research on suppliers by checking their certifications, client reviews, and warranty policies. Request product samples or demonstrations to evaluate performance firsthand. It’s also beneficial to inquire about the manufacturing process and materials used. Establishing a solid communication channel with the supplier can help clarify any concerns and ensure they meet your quality standards. -

4. What customization options are available for CNC acrylic cutting machines?

Many manufacturers offer customization options to suit specific business requirements. Customizations may include modifications to the working area size, laser power upgrades, or specialized software for unique cutting patterns. Discuss your specific needs with suppliers to explore available options, and request documentation on the implications of these customizations on machine performance and warranty. -

5. What are the typical minimum order quantities (MOQs) for CNC acrylic cutting machines?

Minimum order quantities (MOQs) for CNC acrylic cutting machines can vary by supplier and model. Some manufacturers may allow single-unit purchases, while others may require orders of multiple units to secure better pricing or shipping terms. It’s advisable to clarify MOQs upfront with potential suppliers to ensure they align with your purchasing capabilities and business strategy. -

6. What payment terms should I expect when purchasing a CNC acrylic cutting machine internationally?

Payment terms can differ widely based on the supplier and your negotiation. Common practices include partial upfront payments (20-50%) with the balance due upon shipment or delivery. Some suppliers may accept letters of credit or provide financing options. Always review the payment terms carefully and ensure they are clearly stated in the contract to avoid misunderstandings. -

7. How do I handle logistics and shipping for CNC acrylic cutting machines?

Handling logistics for international shipments of CNC acrylic cutting machines requires careful planning. Coordinate with your supplier to understand shipping options, lead times, and costs. Consider using freight forwarders who specialize in heavy machinery for efficient transport. Additionally, ensure all customs documentation is prepared in advance to facilitate smooth clearance and avoid delays. -

8. What after-sales support should I expect from CNC acrylic cutting machine suppliers?

After-sales support is crucial for the longevity of your CNC acrylic cutting machine. Reputable suppliers typically offer technical support, maintenance services, and access to spare parts. Inquire about the availability of online resources, training sessions, and customer service responsiveness. A solid after-sales support structure can significantly enhance your operational efficiency and machine performance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Cnc Acrylic Cutting Machine Manufacturers & Suppliers List

1. Reddit – CNC Machine Recommendations for Acrylic Cutting

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Looking for a desktop CNC machine for cutting acrylic sheets of 5-7mm thickness. Desired work surface size is 12×12 inches or larger. Budget ideally under $1,000, preferably under $500. User-friendly machine is preferred. Recommendations include considering a smaller WorkBee CNC or a DIY CO2 laser for better results.

2. FLUX – Beamo 30W Laser Cutter & Engraver

Domain: top3dshop.com

Registered: 2018 (7 years)

Introduction: Acrylic Laser Cutter Machines include various models with specific features:

1. FLUX Beamo 30W Laser Cutter & Engraver – Price: $1,596.00, Laser power: 30W, Condition: Refurbished due to shipping damage.

2. xTool F1 Laser Engraver – Price: $1,199.00 (discounted from $1,999.00), Working area: 100 x 100 mm.

3. xTool P2 55W CO2 Laser Cutter and Engraver – Price: $3,699.00 (discounted from $4,999.00)…

3. STYLECNC – STJ1610 Acrylic Laser Cutting Machine

Domain: stylecnc.com

Registered: 2015 (10 years)

Introduction: 2025 Best Acrylic Laser Cutting Machine for Sale – STYLECNC

– Brand: STYLECNC

– Model: STJ1610

– Price: $3,800 (Standard Edition) / $12,000 (Pro Edition)

– Stock: 360 Units in Stock Available for Sale Every Month

– Standards: Meeting CE Standards in Terms of Quality & Safety

– Warranty: One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

– Money Back Guaran…

4. Trotec – Acrylic Laser Cutter

Domain: troteclaser.com

Registered: 2002 (23 years)

Introduction: Acrylic laser cutter machine: Engrave or cut signs, displays, letters, or jewelry made of PLEXIGLAS®, Perspex, and PMMA. Cut sheet material up to a thickness of 30 mm. Produces crystal-clear edges without post-processing. Excellent cutting quality meets high cutting speed. Types of acrylic for laser processing include cast (GS) and extruded (XT), both suitable for CO2 laser cutting. Cast acrylic i…

5. Omni – 5-Axis CNC Router Machines

Domain: omni-cnc.com

Registered: 2009 (16 years)

Introduction: Omni 5-Axis CNC Router Machines provide exceptional precision and reliability in woodworking, plastic & foam cutting, making them ideal for complex projects. The guide emphasizes the importance of understanding acrylic properties, selecting suitable tools, and optimizing machine setup for precise and clean cuts. Key features of CNC routers include versatility, precision, cost-effectiveness, automa…

6. Walmart – 40W CO2 USB Engraving Cutting Machine

Domain: walmart.com

Registered: 1995 (30 years)

Introduction: This company, Walmart – 40W CO2 USB Engraving Cutting Machine, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. CNC Machines – Preferred Options for Acrylic Cutting

Domain: reef2reef.com

Registered: 2008 (17 years)

Introduction: Preferred CNC machines for cutting acrylic include: 1. Avid CNC – recommended as a low-cost option; 2. Servo drive machines – provide the best cut but are expensive (around $100,000); 3. KOMO – noted for high performance; 4. Onsrud – mentioned as a good router option; 5. Shapeoko Pro – user-friendly option under $5,000. Custom-built CNC machines can also be created for around $5,000 with specifica…

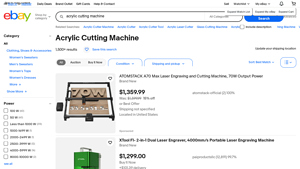

8. Acrylic Cutting Machines – Various Brands Available

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Acrylic Cutting Machine listings on eBay include various brands such as OMTech, VEVOR, and Unbranded. The machines vary in power, with options ranging from 50W to 8000-10000W. They are designed to cut materials like acrylic, aluminum, glass, metal, plastic, rubber, steel, and wood. The machines can be used for engraving applications, including gift personalization, signage, and jewelry. The condit…

9. Varisigns – Top Acrylic Cutting Machines

Domain: varibend.com

Registered: 2007 (18 years)

Introduction: Top Acrylic Cutting Machine: Varisigns best laser acrylic cutting machine can cut acrylics of up to 40mm (1.57″) thickness. Models include: GY-1325M (400W, cuts stainless steel up to 1.5mm and acrylic up to 40mm), GY-1325L (400W with CCD camera, cuts acrylic up to 40mm), GY-1309S (400W, small desktop cutter, cuts acrylic up to 40mm), GY-1309N (150W, affordable for small business, cuts acrylic up t…

Strategic Sourcing Conclusion and Outlook for cnc acrylic cutting machine

In today’s competitive landscape, strategic sourcing of CNC acrylic cutting machines is vital for businesses aiming to enhance productivity and reduce operational costs. By prioritizing quality, technological advancements, and supplier reliability, international buyers can ensure they invest in machines that not only meet their immediate needs but also support future growth.

Key takeaways include the importance of understanding machine specifications, such as laser power and cutting area, as well as the benefits of sourcing from manufacturers that offer comprehensive support, including warranties and technical assistance. Buyers should also consider the evolving market trends, such as eco-friendly technologies and automation features, which can further streamline production processes.

Looking ahead, the demand for CNC acrylic cutting machines is expected to grow significantly across Africa, South America, the Middle East, and Europe. As businesses seek to innovate and expand their capabilities, now is the time to act. By engaging with reputable suppliers and investing in high-quality machinery, companies can position themselves for success in an increasingly demanding market. Don’t miss the opportunity to elevate your operations—explore your options today.