Contents

Manufacturing Insight: Cnc 5-Axis Machine

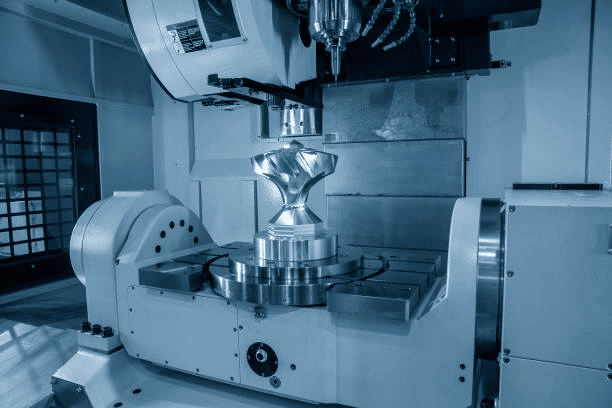

Precision Manufacturing Through Advanced 5-Axis CNC Capabilities

Honyo Prototype delivers exceptional CNC machining services engineered for the most demanding aerospace, medical, and industrial applications. Our state-of-the-art 5-axis CNC machining centers eliminate complex fixturing requirements and enable the production of intricate geometries with micron-level accuracy in a single setup. This capability significantly reduces lead times while enhancing part integrity and surface finish consistency across challenging materials like titanium, Inconel, and high-performance polymers.

Leveraging decades of precision manufacturing expertise, we integrate rigorous quality protocols—including CMM inspection and real-time process monitoring—to ensure every component meets stringent AS9100 and ISO 13485 standards. Our engineering team collaborates closely with clients during design for manufacturability (DFM) reviews to optimize toolpaths, minimize waste, and accelerate time-to-market without compromising tolerances.

Accelerate your prototyping or low-volume production with Honyo’s seamless workflow. Request an Online Instant Quote today to receive a detailed cost and lead time assessment within minutes—empowering faster decision-making for your critical projects.

Technical Capabilities

CNC 5-Axis Machine – Technical Specifications

A high-precision CNC 5-axis machining center is engineered for complex geometries, tight tolerances, and efficient multi-axis milling and turning operations. These machines integrate three linear axes (X, Y, Z) and two rotary axes (typically A/B or A/C), enabling tool access from nearly any direction. Ideal for aerospace, medical, and automotive prototyping and production, 5-axis systems reduce setup time and improve accuracy.

The following table outlines key technical specifications relevant to 3-axis, 4-axis, and 5-axis milling and turning capabilities, with emphasis on tight tolerance machining across common engineering materials.

| Specification | Detail |

|---|---|

| Motion Axes | 5-axis simultaneous: X, Y, Z linear axes; A (rotary about X), B (rotary about Y) or C (rotary about Z) |

| Positioning Accuracy | ±0.005 mm (±0.0002″) |

| Repeatability | ±0.002 mm (±0.0001″) |

| Spindle Speed Range | 10,000 – 30,000 RPM (high-speed options available) |

| Spindle Power | 22 – 45 kW (30 – 60 HP), depending on configuration |

| Tool Capacity (ATC) | 20 – 60 tools (automatic tool changer) |

| Maximum Tool Diameter/Length | Ø80 mm / 300 mm (with clearance) |

| Rapid Traverse Rates | X/Y/Z: 60 m/min; Rotary axes: 30–50 rpm |

| Control System | Fanuc 31i, Siemens 840D, or Heidenhain TNC7 |

| Work Envelope (Typical) | 800 x 600 x 500 mm (X/Y/Z), varies by model |

| Maximum Workpiece Weight | 1,000 kg (2,200 lbs) on rotary tables |

| Tolerance Capability | ±0.01 mm (±0.0004″) standard; down to ±0.005 mm with fine tuning and thermal compensation |

| Surface Finish (Typical) | Ra 0.8 – 3.2 µm, depending on material and toolpath |

| Coolant System | High-pressure through-spindle coolant (up to 70 bar) |

| Probing System | On-machine touch probe for in-process inspection and tool measurement |

| Thermal Compensation | Real-time spindle and guideway temperature monitoring |

| Materials Compatibility | Aluminum (6061, 7075), Steel (4140, 17-4 PH), Stainless Steel (303, 316), ABS, Nylon (PA6, PA66), PEEK, Delrin |

| Machining Processes | 3-axis milling, 4-axis indexing, 5-axis simultaneous contouring, mill-turn (with optional live tooling and C-axis control) |

| Typical Applications | Aerospace impellers, medical implants, mold cores, complex prototypes, high-strength structural components |

This machine platform supports high-accuracy machining across a wide range of materials. Aluminum and steel alloys are machined with carbide end mills under rigid conditions, achieving tight dimensional control. Engineering plastics such as ABS and Nylon are processed with sharp, high-rake tools at optimized speeds to prevent melting and maintain part integrity. The integration of turning functionality (in mill-turn variants) allows for complete part fabrication in a single setup, minimizing cumulative error and improving throughput for turned and milled features.

From CAD to Part: The Process

Honyo Prototype CNC 5-Axis Machining Process Overview

Honyo Prototype delivers precision CNC 5-axis machining through a rigorously defined workflow designed for speed, accuracy, and manufacturability. Our integrated digital pipeline minimizes manual handoffs, reduces lead times by up to 40%, and ensures first-pass yield for complex geometries. Below is the complete process flow.

CAD File Upload and Validation

Clients initiate the process by uploading native or neutral CAD formats (STEP, IGES, Parasolid, or native SOLIDWORKS/Creo) via our secure customer portal. Our system performs automated geometry validation, checking for non-manifold edges, surface gaps, and unit inconsistencies. Files failing validation trigger immediate client notification with specific error diagnostics, preventing downstream delays. This step ensures the digital model is production-ready before quote generation.

AI-Powered Quoting Engine

Validated CAD data feeds into our proprietary AI quoting system, which analyzes 150+ geometric and material parameters within 90 seconds. The AI evaluates feature complexity, stock volume, material grade (e.g., 7075-T6 aluminum vs. Inconel 718), tolerance density (ASME Y14.5), and surface finish requirements to generate a technically accurate cost and lead time estimate. Critical factors include toolpath accessibility analysis and machine time prediction based on historical 5-axis cycle data. Human engineers review all AI outputs for high-risk geometries before client delivery, ensuring quote reliability.

Engineering-Led DFM Analysis

Every project undergoes mandatory Design for Manufacturability (DFM) review by our senior manufacturing engineers. This phase identifies and resolves critical issues such as:

Thin wall instability below 0.5mm

Undercut features requiring specialized tooling

Non-optimal stock dimensions increasing material waste

Tolerance stack-ups exceeding machine capability (±0.005mm typical)

We provide actionable redesign recommendations within 24 hours, including annotated CAD markups and cost-impact analysis. Client collaboration is required to approve modifications before production release, eliminating costly rework.

5-Axis Production Execution

Approved designs move to our climate-controlled machine floor housing DMG MORI and MAZAK 5-axis vertical machining centers with rotary-trunnion tables. Key production protocols include:

Material certification verification (mill test reports traceable to heat number)

Fixtureless machining via 3D probing for <0.01mm positional accuracy

In-process CMM checks at critical stages for features below 0.025mm tolerance

Real-time tool wear monitoring with automatic feed-rate adjustment

All operations follow AS9100-compliant work instructions, with full digital traceability from raw material to finished part.

Quality-Controlled Delivery

Final inspection validates against all client-specified GD&T callouts using Zeiss CONTURA CMMs and optical comparators. Dimensional reports (per ASME Y14.43) and surface roughness data (Ra values) accompany every shipment. Parts are packaged in custom anti-corrosive foam with serialized barcoding for full lot traceability. Standard lead time is 7–12 business days from DFM sign-off, with expedited 72-hour options for qualifying geometries.

Process Efficiency Metrics

The following table demonstrates throughput improvements from our integrated workflow:

| Process Phase | Traditional Workflow | Honyo Prototype Workflow | Improvement |

|---|---|---|---|

| Quote Accuracy | ±25% cost variance | ±8% cost variance | 68% reduction in quote revisions |

| DFM Resolution Time | 3–5 business days | <24 hours | 80% faster iteration |

| First-Pass Yield | 65–75% | 92–95% | 25% reduction in scrap |

| Avg. Lead Time (Complex Part) | 18–22 days | 7–12 days | 45% acceleration |

This closed-loop system ensures technical risk mitigation while maintaining the agility required for rapid prototyping and low-volume production. All process data is accessible to clients via our real-time production dashboard, providing full visibility from CAD submission to delivery.

Start Your Project

Interested in high-precision CNC 5-axis machining for your next project? Honyo Prototype operates a state-of-the-art factory in Shenzhen, delivering advanced machining capabilities with tight tolerances and fast turnaround times.

Contact Susan Leo today to discuss your manufacturing requirements.

Email: [email protected]

Leverage our expertise in 5-axis CNC technology for complex geometries, aerospace components, medical devices, and more.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.