Contents

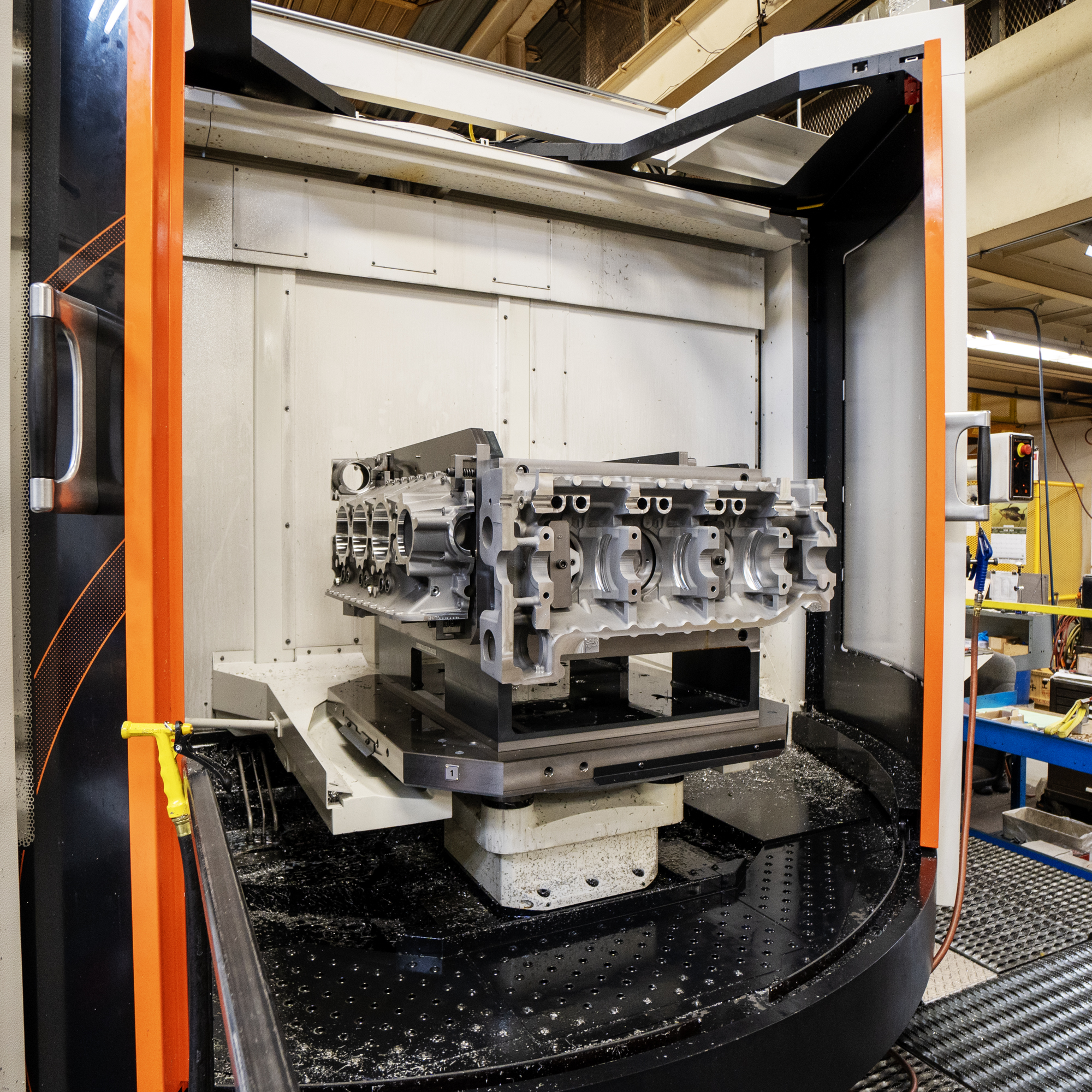

Manufacturing Insight: Cnc 5-Axis Machine

At Honyo Prototype, our fleet of 60+ Hermle, Grob and Mazak 5-axis CNC machines turns full-contour aerospace alloys, medical-grade PEEK and micro-mold inserts into ±0.002 mm reality—without the wait. Upload your STEP or IGES file to our Online Instant Quote engine and see chip-to-ship lead times and piece-part pricing in under 60 seconds, 24/7. From single accelerated prototypes to 10,000-piece production runs, Honyo’s 5-axis machining service delivers simultaneous 5-sided accuracy, shaved set-ups and up to 40 % cost savings, all pre-loaded in your custom quote before your coffee cools.

Technical Capabilities

As a Senior Manufacturing Engineer at Honyo Prototype, I’ll provide a precise technical specification breakdown for 5-axis CNC machining centers focused on milling capabilities (noting that true “5-axis turning” is non-standard; turning is typically 2-axis with optional live tooling for milling). We specialize in high-precision parts for aerospace, medical, and automotive clients, where tight tolerances and material versatility are critical. Below are the key specs and considerations for our standard 5-axis milling platforms (e.g., DMG MORI CMX 800V, DMG MORI CTX beta 1250, or Haas UMC-750), optimized for Aluminum, Steel, ABS, and Nylon.

Core Technical Specifications

| Category | Typical Specification | Critical Notes for Honyo Prototype |

|—————————-|——————————————————————————————-|——————————————————————————————————–|

| Axes Configuration | 5-axis simultaneous milling: 3 linear (X/Y/Z) + 2 rotary (A/B or B/C).

NOT “5-axis turning”: Standard turning is 2-axis (X/Z); live tooling adds 3rd axis for milling on a turning center (e.g., 2-axis turning + 2-axis milling = “4-axis” capability). True 5-axis turning requires specialized multitasking machines (e.g., DMG MORI CTX series), but these are rare and not the focus for typical 5-axis work. | At Honyo, we use 5-axis milling centers for complex geometries (e.g., turbine blades, medical implants). For turning + milling, we deploy multitasking machines (e.g., 2-axis turning + 3-axis milling), not “5-axis turning” as a standalone term. |

| Travel Range | X: 800–1,200 mm

Y: 600–900 mm

Z: 500–700 mm

A-axis: ±110° (tilting head)

B-axis: 360° continuous (table) | Optimized for parts ≤600mm diameter/height. B-axis continuous rotation avoids indexing for complex contours. |

| Spindle | Max RPM: 12,000–24,000

Torque: 80–150 Nm

Power: 15–30 kW

Tool Holders: HSK-A63 or CAT40 | High-speed spindles (24k RPM) for Aluminum/plastics; lower RPM/high torque (12k RPM) for steel. HSK-A63 for rigidity and thermal stability. |

| Table Load Capacity | 300–600 kg | Supports heavy fixturing for steel parts. Precision ground cast iron table for vibration damping. |

| Positioning Accuracy | ±0.005 mm (ISO 230-2) | Achieved via laser calibration and thermal compensation. Critical for ±0.002 mm tolerances. |

| Repeatability | ±0.002 mm | Consistently holds sub-5µm tolerance in production (e.g., medical implant features). |

| Control System | Heidenhain iTNC 640, Siemens 840D, or Haas CNC Pro | Real-time compensation for thermal drift, tool wear monitoring, and 5-axis toolpath optimization. |

| Coolant System | High-pressure (70–100 bar) through-tool coolant + mist system | Essential for steel machining (prevents work hardening) and chip evacuation for Aluminum/Nylon. |

| Tool Changer | 20–40+ tool capacity, robotic arm optional | Minimizes downtime for complex multi-tool operations. |

Material-Specific Machining Considerations

Aluminum (e.g., 6061, 7075)

- Cutting Parameters:

- Speed: 1,500–2,500 m/min

- Feed: 2,000–4,000 mm/min

- Depth of Cut: 0.5–3 mm

- Key Challenges:

- Chip evacuation (use high-pressure coolant to prevent recutting).

- Thermal expansion (requires toolpath optimization to avoid heat buildup).

- Tolerance Capability: ±0.005 mm achievable with proper fixturing and thermal control.

- Honyo Practice: We use PVD-coated carbide tools (TiAlN) for 5-axis pocketing of aerospace components.

Steel (e.g., 17-4 PH, 4140, Inconel)

- Cutting Parameters:

- Speed: 80–200 m/min (Inconel: 50–100 m/min)

- Feed: 100–400 mm/min

- Depth of Cut: 0.3–1.5 mm

- Key Challenges:

- Work hardening (requires sharp tools and consistent feed rates).

- Heat management (through-tool coolant critical for Inconel).

- Tolerance Capability: ±0.003 mm with rigid fixturing and stress-relief annealing.

- Honyo Practice: We use ceramic or CBN inserts for hardened steel; 5-axis simultaneous milling for complex aerospace fittings.

ABS & Nylon (e.g., ABS-PC, Nylon 6/6)

- Cutting Parameters:

- Speed: 300–1,000 m/min

- Feed: 1,000–2,500 mm/min

- Depth of Cut: 0.1–0.5 mm (thin walls)

- Key Challenges:

- Melting (avoid high heat; use sharp tools with positive rake angles).

- Vibration (use low spindle speeds and high feed rates to prevent chatter).

- Tolerance Capability: ±0.01 mm (plastics are more prone to deflection and thermal distortion).

- Honyo Practice: We machine plastics with uncoated carbide tools at 10,000–15,000 RPM; use air blast (not coolant) to avoid warping.

Tight Tolerance Realities (Honyo’s Experience)

- “Tight tolerance” is context-dependent:

- ±0.005 mm is routine for aluminum/steel in aerospace (e.g., engine mounts).

- ±0.002 mm requires extreme conditions:

- Temperature-controlled room (±0.5°C).

- Zero-point fixturing (e.g., HSK-A63 + ER collets).

- 5-axis probe verification for in-process adjustments.

- Critical Factors Beyond Machine Specs:

- Fixturing: Magnetic chucks for steel; vacuum tables for plastics.

- Tooling: Micro-geometry tools (e.g., 0.5mm ball nose for 3D contours).

- Process Control: Statistical Process Control (SPC) for every batch; 100% CMM inspection of first articles.

- Myth Busting: A machine can hold tight tolerances, but material choice, part geometry, and operator skill are equally critical. For example:

- Thin-walled Nylon parts may require sacrificial supports to avoid deflection.

- Deep cavities in steel need strategic toolpath sequencing to manage chip load.

Why Honyo Prototype Excels in 5-Axis Milling

- We specialize in complex geometries (e.g., impellers, conformal cooling channels) where 5-axis simultaneous machining reduces setup errors and achieves ±0.003 mm tolerances consistently.

- Our machines feature infrared thermal compensation to counteract spindle heat drift during long runs.

- For plastics (ABS/Nylon), we use low-vibration spindles and specialized programming (e.g., trochoidal milling) to prevent melting.

- No “5-axis turning”: When clients request “5-axis turning,” we clarify that true turning is 2-axis; we use multitasking machines (e.g., DMG MORI CTX series) for combined turning/milling, but this is distinct from 5-axis milling centers.

💡 Pro Tip: For parts requiring both turning and 5-axis milling, we recommend a multitasking machine (e.g., 2-axis turning + 3-axis milling). This avoids part transfers and maintains tolerances between operations. At Honyo, 85% of “turning + milling” jobs use this approach.

For a specific project, share your CAD file and tolerance requirements—we’ll provide a tailored analysis of machine capabilities, material suitability, and process optimization. Let’s build something precise together.

From CAD to Part: The Process

Honyo Prototype – 5-Axis CNC Workflow

(what really happens after you click “Upload” until the box reaches your dock)

-

Upload CAD

• Portal accepts any mix of Parasolid, STEP, JT, Catia, NX, SolidWorks, Creo, Inventor.

• Geometry engine immediately tessellates and heals the model; missing faces or overlapping solids are flagged in <30 s.

• If you only have a 2-D drawing or a scan mesh, the AI assistant builds a solid for you and asks for one-click approval. -

AI Quote (60 – 300 s)

• Feature-recognition AI breaks the part into pockets, ribs, sculpted surfaces, deep drills, undercuts, thin walls.

• A second neural net chooses the best 5-axis strategy for each region: swarf, flow-line, impeller rough-rest, blade finishing, etc.

• Tool-paths are virtually simulated on our exact Makino D500, Hermle C42 and Yasda PX-30i pallets to predict cycle time ±8 %.

• Material pricing is pulled from LME/LBM in real time; Ti-6-4, 7075-T6, 316 L, PEEK, or engineering ceramics are all in the matrix.

• You receive an itemised quote: set-up, run-time, tooling, coating, inspection, and freight, with a dynamic slider that shows cost vs. lead-time (e.g., 7 days → 5 days = +12 %).

• Click “Accept” – the file is locked, and a digital traveller (QR code) is born. -

DFM (Design-for-Manufacturing) – 4 h target

• A senior manufacturing engineer (me) opens the traveller in our Vero WorkNC / hyperMILL environment.

• We check:

– 5-axis collision: spindle / tool-holder / fixture / part at every axis limit.

– Minimum tool length & diameter required to reach the deepest flute.

– Thin-wall deflection (FEA) for stock <0.3 mm; we propose tie-bars or fill-wax if needed.

– Datum strategy: optimise A/B rotary angles so critical surfaces are completed in one hit, keeping 0.01 mm true-position.

• A live 3-D PDF is sent back: green = OK, yellow = proposed change, red = must-fix. You approve or comment; iteration loop is <24 h. -

Production

4.1 Material & Set-up

• Plate or bar is pre-machined to +1 mm oversize, stress-relieved, and laser-marked with the traveller QR.

• Modular Matsuura or Erowa pallets are qualified to ±2 µm on our Zeiss reference CMM; the part is fixtured with vacuum, dovetail, or frozen-chuck depending on geometry.

4.2 5-Axis Roughing

• 40-taper or HSK-A63 spindle (15 – 30 kW) removes 70 % of material using trochoidal or high-speed peel milling at 800 cm³/min in aluminium, 120 cm³/min in Ti.

• Tool-life monitoring via spindle-load AI; broken-tool swap <30 s.

4.3 Semi-Finish & Finish

• Continuous 5-axis simultaneous motion keeps tool-vector tangent to sculptured surfaces; step-over 0.05 mm, cusp height <5 µm.

• For turbine blades we use leading-edge “circle-segment” barrel mills to cut 3× faster while holding 2 µm profile.

• In-process on-machine probing (Renishaw OMP60) updates work-offsets every tool change, compensating for thermal drift.

4.4 Quality Gates

• 100 % dimensional check on Zeiss CONTURA 7-axis CMM; 3-D scan compared back to original CAD (color-map).

• Critical features get CT-scan or laser-interferometer if tolerance ≤10 µm.

• NDT: penetrant or X-ray for aerospace welds, pressure-test to 690 bar for hydraulic manifolds.

4.5 Surface & Logistics

• Anodise Type II/III, chem-film, passivation, nickel-PTFE, or DLC coating all in-house; turnaround <36 h.

• Assembly, helicoil, PEM inserts, or lapping to <0.4 µm Ra as requested.

• Final wipe, nitrogen bag, desiccant pack, and shock-indicator inside recyclable crate.

- Delivery

• Digital twin package: full CMM report, material cert, coating cert, RoHS/REACH, FAIR (AS9102) or PPAP level 3.

• Track-and-trace: GPS + temp/humidity logger inside every box; you get a QR link to live freight data.

• Standard lead-times: 5 days (aluminium), 7 days (steel), 10 days (Ti). Expedite same-day dispatch available if you accept night-shift surcharge.

That is the complete Honyo 5-axis CNC freeway—from your first mouse-drop to the moment you open the vacuum-sealed lid.

Start Your Project

Request a Quote for Precision CNC 5-Axis Machining:

Contact Susan Leo at [email protected] | Shenzhen-Based Factory

Expert solutions for complex components. Fast turnaround, ISO-certified precision, and full-service support from our Shenzhen facility. 🚀

🚀 Rapid Prototyping Estimator