Contents

Manufacturing Insight: Cnc 5-Axis

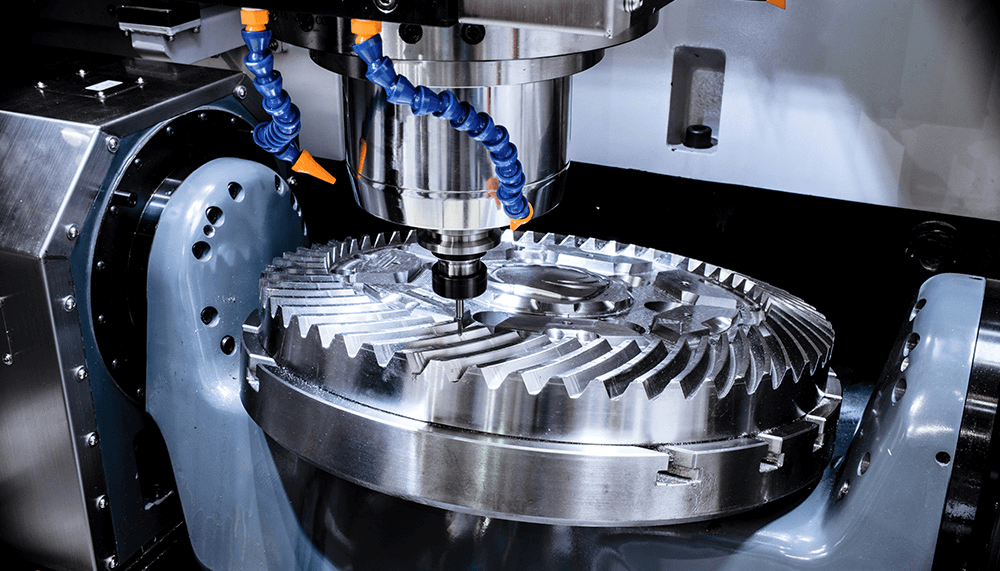

Advanced 5-Axis CNC Machining: Precision for Complex Prototypes and Low-Volume Production

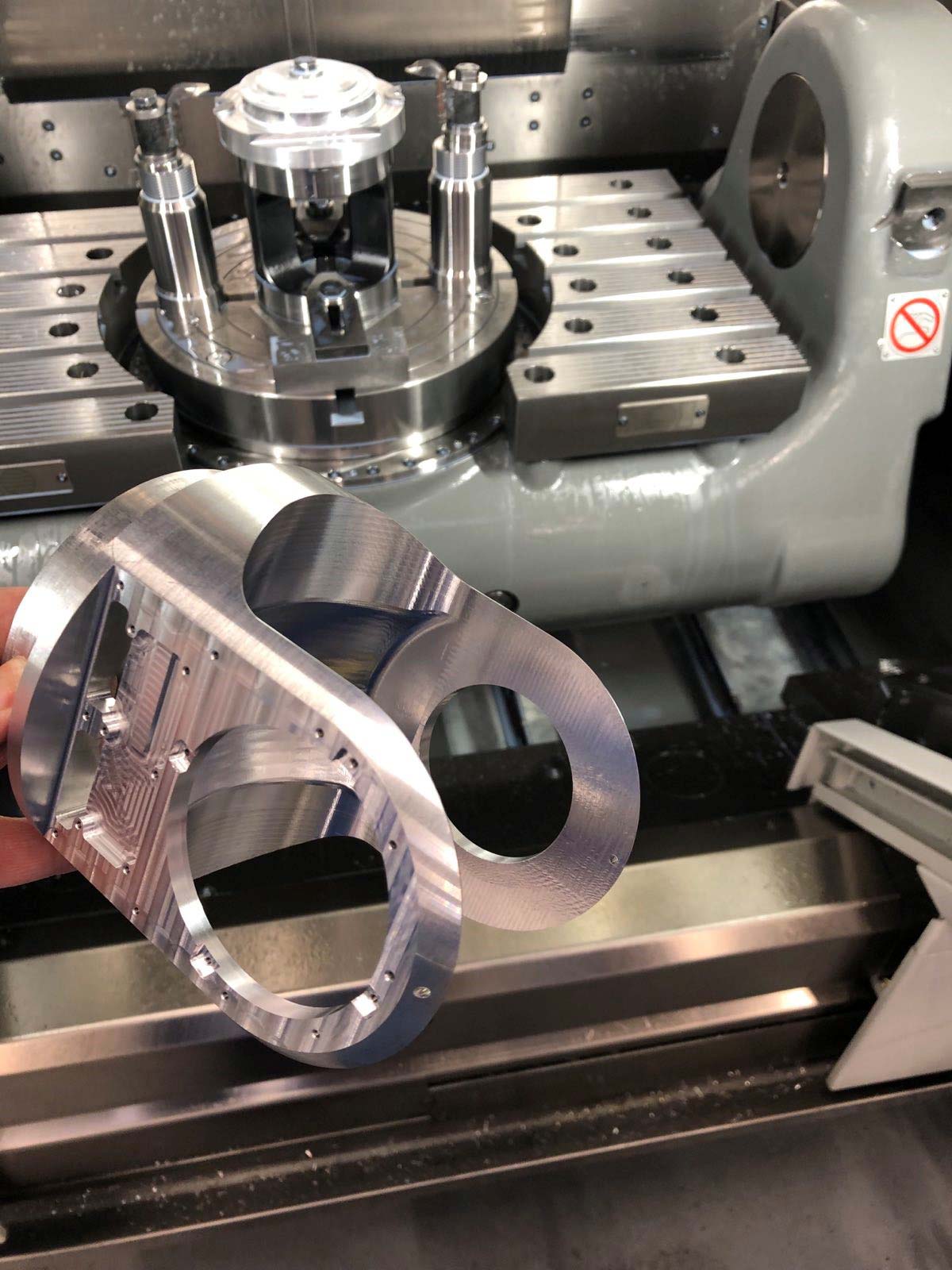

At Honyo Prototype, our 5-axis CNC machining capabilities redefine precision engineering for demanding prototyping and low-volume production requirements. By leveraging simultaneous multi-axis movement, we eliminate the need for multiple setups and complex fixtures, achieving intricate geometries, superior surface finishes, and sub-micron tolerances unattainable with conventional 3-axis systems. This technology is essential for industries such as aerospace, medical device development, and advanced robotics, where part complexity directly impacts performance and time-to-market.

Our state-of-the-art 5-axis machining centers process a comprehensive range of materials—from aerospace-grade titanium and Inconel to high-performance plastics and composites—ensuring optimal material integrity and dimensional stability. Whether machining turbine blades, orthopedic implants, or fluid dynamics components, Honyo delivers fully finished parts in a single operation, reducing lead times by up to 40% while maintaining ISO 9001-certified quality standards.

Accelerate your development cycle with Honyo’s Online Instant Quote system. Upload your CAD file, specify materials and finishes, and receive a detailed, transparent cost estimate within minutes—no manual RFQ delays. This seamless integration of advanced manufacturing capability and digital efficiency ensures your complex 5-axis projects move from design to certified production-ready hardware faster than industry benchmarks. Partner with Honyo Prototype to transform engineering challenges into precision realities.

Technical Capabilities

Honyo Prototype delivers precision CNC machining services across 3-axis, 4-axis, and 5-axis platforms, optimized for tight-tolerance components in demanding industries. Our multi-axis milling and turning capabilities support a wide range of engineering-grade materials, including aluminum, steel, ABS, and nylon. Below is a detailed technical specification table outlining key performance parameters.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning (Multi-Axis Capable) |

|---|---|---|---|---|

| Axis Configuration | X, Y, Z linear axes | X, Y, Z + A (rotary table) | X, Y, Z + A/B or A/C rotary | Live tooling with C-axis control |

| Maximum Work Envelope (mm) | 1000 x 600 x 500 | 800 x 600 x 500 | 700 x 500 x 400 | Ø300 x 500 length |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.005 mm | ±0.003 mm |

| Repeatability | ±0.003 mm | ±0.003 mm | ±0.002 mm | ±0.002 mm |

| Typical Tolerance Capability | ±0.01 mm | ±0.01 mm | ±0.005 mm to ±0.01 mm | ±0.005 mm |

| Surface Finish (Ra) | 0.8 – 3.2 µm | 0.8 – 1.6 µm | 0.4 – 1.6 µm | 0.4 – 1.6 µm |

| Spindle Speed (max) | 24,000 rpm | 20,000 rpm | 20,000 rpm | 6,000 rpm |

| Tool Changer Capacity | 24–30 tools | 24 tools | 30 tools | 12–20 live tools |

| Materials Supported | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon |

| Key Applications | Flat geometries, prismatic parts | Indexing features, angled holes | Complex contours, aerospace components | Shafts, bushings, threaded parts |

All CNC systems are equipped with high-precision linear guides, thermal compensation, and on-machine probing to ensure dimensional stability and repeatability. Tight-tolerance machining down to ±0.005 mm is routinely achieved on aluminum and steel alloys such as 6061-T6, 7075, 4140, and 17-4 PH stainless steel. Engineering plastics including ABS and nylon are machined with optimized feeds and speeds to prevent melting or deformation, maintaining tight geometric tolerances per ISO 2768-mK or customer-specific GD&T requirements.

From CAD to Part: The Process

Honyo Prototype’s CNC 5-axis manufacturing process is engineered for precision, speed, and seamless integration from initial concept to final delivery. This streamlined workflow minimizes client effort while ensuring manufacturability and quality at every stage.

CAD Upload and AI-Powered Quoting

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid) or 3D mesh formats via our secure customer portal. Our proprietary AI engine immediately analyzes the geometry, material selection, tolerances, and surface finish requirements. Unlike basic quoting systems, this AI performs preliminary manufacturability screening against 5-axis machining constraints, identifying potential collisions, undercuts, or fixturing challenges. The system generates a detailed technical quote within 2 hours, including DFM flags, cost breakdown by operation, and realistic lead time estimates—all before human engineering review.

Integrated DFM and Engineering Validation

Quoted projects enter our concurrent DFM phase where senior manufacturing engineers collaborate with the AI findings. This is not a separate approval gate but a value-added refinement step. Engineers validate AI-identified issues, optimize toolpaths for minimal setup changes, and suggest geometry modifications to reduce cycle time without compromising function. Critical DFM checks include:

| DFM Check Category | Specific 5-Axis Focus Areas | Client Impact Mitigation |

|---|---|---|

| Geometric Complexity | Deep cavities, thin walls, compound angles | Suggests strategic parting lines |

| Tool Access & Collision | Simulated 5-axis kinematics, spindle interference | Proposes custom fixture solutions |

| Tolerance Stack-Up | GD&T analysis across rotational axes | Recommends datum alignment strategies |

| Material Utilization | Raw stock nesting efficiency, chip evacuation paths | Reduces material waste by 15-30% |

Clients receive annotated DFM reports with visual markup within 24 hours, enabling rapid iteration. Approved modifications are incorporated directly into the production-ready CAD model.

Precision 5-Axis Production

Validated jobs move to our Haas DMG MORI and Makino 5-axis vertical machining centers. Each part undergoes:

Dynamic fixture setup using Renishaw probes for sub-0.005mm positional accuracy

Real-time tool wear compensation via laser tool setters

In-process CMM verification at critical stages per ISO 2768-mK

Environmental controls maintaining ±0.5°C temperature stability

Our CAM team employs hyperMILL and Mastercam for optimized toolpath generation, leveraging tilt strategies to maintain constant tool engagement and surface finish. Complex geometries requiring multiple setups are executed in a single chucking where possible, eliminating rework errors.

Certified Delivery and Documentation

Finished parts undergo final inspection per AS9102 or client-specific FAI requirements. Delivery includes:

Traceable material certificates and heat treatment reports

Full CMM inspection data in PDF and XML formats

First-article approval packages with dimensional photos

Packaging engineered for international shipment compliance

Standard lead time from CAD approval to doorstep delivery is 7-12 business days for quantities under 50 units, with expedited options available. All processes are certified to ISO 9001:2015 and ITAR registered, ensuring compliance for aerospace, medical, and defense sectors. This integrated approach reduces prototyping iterations by 40% compared to traditional vendor workflows.

Start Your Project

Discover the precision and efficiency of CNC 5-axis machining for your next project. Ideal for complex geometries, tight tolerances, and high-speed production, our advanced 5-axis capabilities ensure superior part quality and reduced lead times.

All manufacturing is performed at our state-of-the-art factory in Shenzhen, where strict quality control and engineering expertise meet international standards.

Contact Susan Leo to discuss your technical requirements and receive a fast, competitive quote.

Email: [email protected]

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.