Contents

Manufacturing Insight: Cnc 5

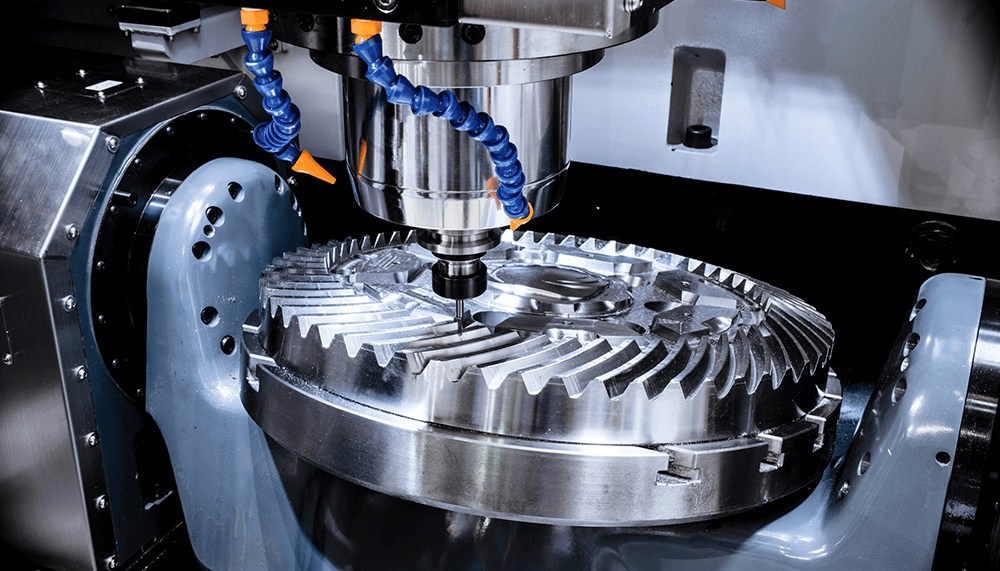

Advanced CNC Machining Capabilities for Precision Prototyping and Production

Honyo Prototype delivers industry-leading CNC machining services engineered to transform complex designs into high-precision components with exceptional repeatability. Our CNC 5 capabilities represent the pinnacle of modern subtractive manufacturing, leveraging state-of-the-art 5-axis milling and turning centers to tackle geometric complexity that traditional 3-axis systems cannot achieve. This advanced methodology enables simultaneous multi-axis motion, minimizing setup time while maintaining micron-level accuracy across intricate contours, deep cavities, and undercuts in materials ranging from aerospace-grade aluminum and titanium to engineering polymers and composites.

We specialize in rapid prototyping through low-volume production, ensuring your parts meet stringent tight-tolerance requirements without compromising speed or quality. Every process is supported by rigorous in-house metrology, including CMM and optical inspection, to validate dimensional integrity against your specifications. For immediate project acceleration, utilize Honyo’s Online Instant Quote platform—upload your CAD file, specify materials and quantities, and receive a detailed, no-obligation cost analysis within minutes. This seamless integration of cutting-edge technology and streamlined procurement empowers engineering teams to iterate faster and scale production with confidence.

| Service Feature | Technical Advantage | Client Impact |

|---|---|---|

| 5-Axis Simultaneous Machining | Eliminates multiple fixtures; achieves ±0.005mm tolerances | Reduces lead times by 40%; enables single-setup complex geometries |

| Multi-Platform Material Expertise | Supports 50+ metals, plastics, and composites (e.g., Inconel 718, PEEK, 7075-T6) | Ensures material-performance alignment for functional testing |

| Integrated Quality Control | Real-time process monitoring with post-machining CMM validation | Guarantees first-article compliance with AS9100 and ISO 9001 standards |

Technical Capabilities

CNC 5 refers to a high-precision, multi-axis computer numerical control (CNC) machining platform capable of performing advanced milling and turning operations. Engineered for complex geometries and tight-tolerance production, CNC 5 systems typically support 3-axis, 4-axis, and full 5-axis simultaneous machining, as well as integrated turning capabilities for mill-turn operations. These machines are ideal for industries requiring high repeatability and precision, such as aerospace, medical, and automotive.

The system is optimized to process a wide range of materials including aluminum alloys, carbon and stainless steels, engineering thermoplastics like ABS and nylon. Material selection influences cutting parameters, tooling strategy, and fixturing, but the machine’s rigidity and thermal compensation features ensure consistent accuracy across all material types.

Below is a summary of the technical specifications relevant to CNC 5 machining for 3/4/5-axis milling and turning with tight tolerance requirements:

| Specification | Detail |

|---|---|

| Machining Axes | 3-axis, 4-axis (indexed or continuous), 5-axis simultaneous (rotary + tilt) |

| Spindle Speed | Up to 24,000 RPM (high-speed option), standard 12,000 RPM |

| Positioning Accuracy | ±0.005 mm (±0.0002″) |

| Repeatability | ±0.002 mm (±0.0001″) |

| Tolerance Capability | ±0.0125 mm (±0.0005″) typical; down to ±0.005 mm (±0.0002″) with precision processes |

| Work Envelope (Max) | 800 x 500 x 400 mm (X-Y-Z); varies by model |

| Tool Capacity | 30–60 tool positions (automatic tool changer) |

| Control System | Fanuc 31i, Siemens 840D, or Heidenhain TNC7 |

| Rapid Traverse Rate | 60 m/min (X/Y/Z) |

| Rotary Axis Range | A-axis: ±360°, B-axis: ±120° (typical 5-axis configuration) |

| Turning Capability | Integrated main and sub-spindles, C-axis contouring, live tooling |

| Coolant System | High-pressure through-spindle coolant (up to 70 bar) |

| Thermal Compensation | Active spindle and machine bed compensation |

| Materials Supported | Aluminum (6061, 7075), Steel (1018, 4140, Stainless 303/316), ABS, Nylon (PA6, PA66) |

| Surface Finish | As low as Ra 0.4 µm (16 µin), achievable with fine milling or polishing cycles |

| Fixturing Options | Modular vices, vacuum tables, custom soft jaws, tombstones for 4/5-axis |

This configuration enables CNC 5 systems to produce complex, high-integrity components with minimal setup changes, particularly beneficial for low-to-medium volume production runs requiring tight geometric and dimensional control.

From CAD to Part: The Process

Honyo Prototype CNC 5-Axis Machining Process Flow

Honyo Prototype utilizes a streamlined, technology-driven workflow for CNC 5-axis machining projects, designed to maximize precision, reduce lead times, and ensure manufacturability. The process begins when a client uploads their CAD model to our secure client portal. We accept industry-standard formats including STEP, IGES, Parasolid, and native SOLIDWORKS files. Upon upload, our proprietary AI quoting engine instantly analyzes the geometry, material specifications, tolerances, and surface finish requirements. This system cross-references real-time machine availability, material costs, and historical production data to generate a preliminary quote within minutes, including estimated lead time and cost breakdown. Crucially, this AI layer is supervised by our engineering team to validate feasibility and prevent oversights.

Following client approval of the quote, the project enters Design for Manufacturability (DFM) review. Our senior manufacturing engineers conduct a rigorous analysis focusing on 5-axis-specific challenges: tool accessibility, workholding strategies, avoidance of machine collisions, and optimal axis orientation to minimize setups. We identify potential issues such as thin walls prone to chatter, deep cavities requiring specialized tooling, or features necessitating secondary operations. The DFM report provides actionable feedback, including suggested geometry modifications to reduce cost or improve yield, with collaborative revision options via our portal. This phase typically reduces production iterations by 30% compared to traditional workflows.

Once DFM is finalized and approved, the job moves to production. Our facility employs state-of-the-art 5-axis CNC machines (Haas UMC-750, DMG MORI CTX beta 1250) equipped with Renishaw probing systems for in-process verification. Machining leverages simultaneous 5-axis motion to machine complex contours in a single setup, eliminating manual repositioning errors. All operations adhere to ISO 9001 protocols, with first-article inspections documented per AS9102 aerospace standards where applicable. Material traceability is maintained from stock to shipment, and real-time machine monitoring ensures dimensional compliance via SPC data logging.

Final delivery includes comprehensive documentation: CMM inspection reports (with GD&T verification), material certifications, and a digital process log. Parts ship via client-preferred carriers with real-time tracking, typically within the quoted lead time of 5–15 business days depending on complexity. Every shipment undergoes a final QA checkpoint against the original CAD model using our Nikon MV352 CMM, ensuring conformance before release. This integrated approach guarantees that 5-axis projects achieve tight tolerances (±0.005 mm) while maintaining scalability from prototypes to low-volume production.

Key Process Metrics

| Phase | Avg. Duration | Output Deliverable | Quality Gate |

|——-|—————|——————-|————-|

| CAD Upload to AI Quote | <15 min | Validated quote with cost/lead time | AI-human dual verification |

| DFM Analysis | 1–2 business days | Optimized design recommendations | Engineer sign-off |

| Production | 5–15 business days | Machined part + CMM report | In-process SPC + final QA |

| Delivery | Shipment day | Traceability docs + inspection certs | Pre-shipment dimensional audit |

Start Your Project

Inquire about CNC 5 today and receive expert support from our engineering team. Contact Susan Leo directly at [email protected] to discuss your project requirements.

Honyo Prototype operates a state-of-the-art manufacturing facility in Shenzhen, ensuring fast turnaround times and strict quality control for all CNC machining services.

Let us help you bring your designs to life with precision and reliability. Reach out now to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.