Contents

Manufacturing Insight: Cnc 3D Files

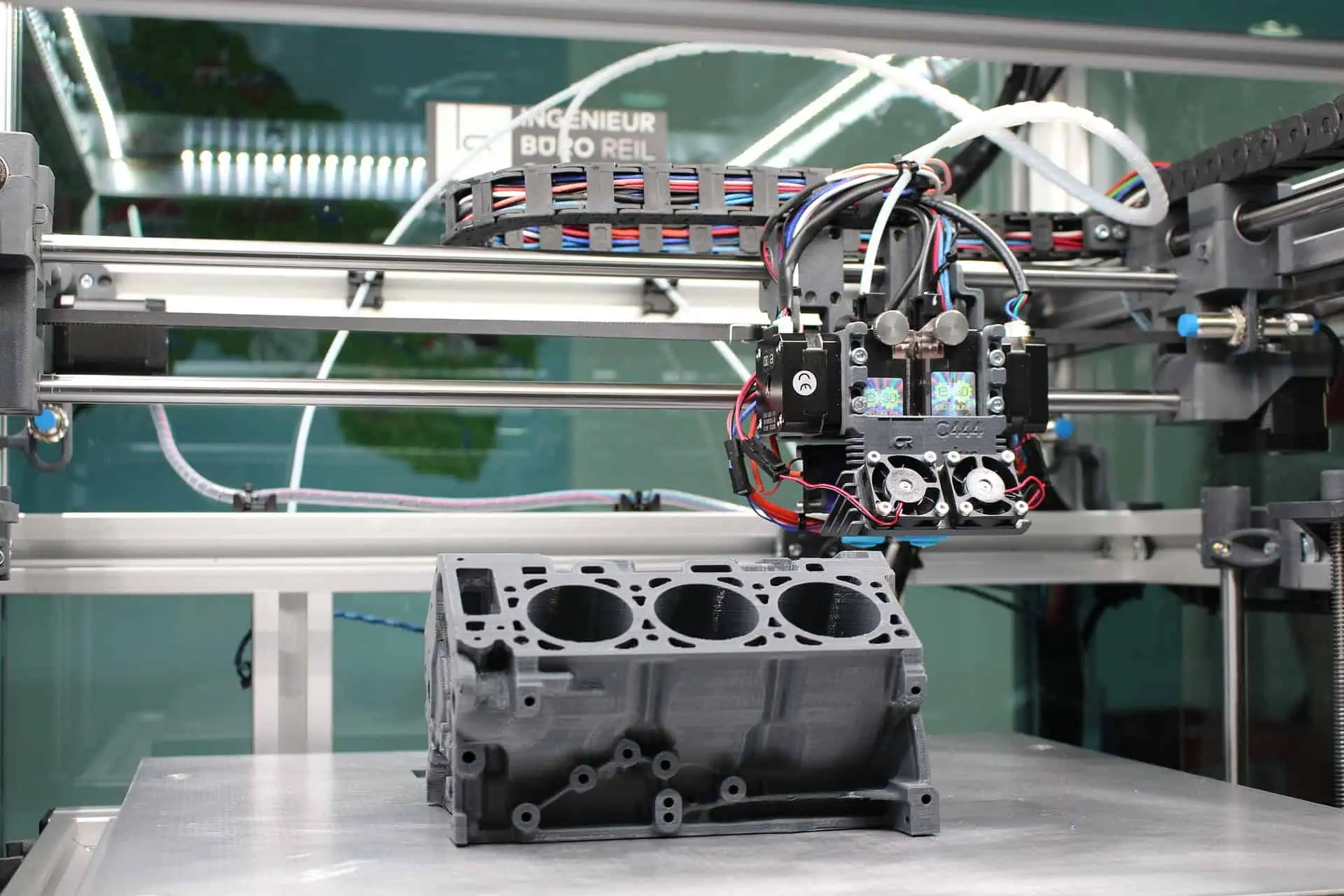

Precision Industrial 3D Printing for Complex CNC-Ready Components

At Honyo Prototype, we transform your 3D CAD models into high-fidelity industrial prototypes and end-use parts with unmatched speed and engineering rigor. Our advanced metal and polymer additive manufacturing capabilities—including direct metal laser sintering (DMLS), selective laser melting (SLM), and high-temperature FDM—deliver components with tight tolerances, superior material properties, and design-for-manufacturability validation critical for CNC integration and functional testing. We specialize in mission-critical applications using aerospace-grade alloys like Inconel 718, titanium Ti-6Al-4V, and engineering thermoplastics such as ULTEM 9085, all produced in ISO 9001-certified facilities with full traceability.

Eliminate quoting bottlenecks with our proprietary Online Instant Quote platform. Upload your STEP or IGES files to receive a detailed, no-obligation cost and lead time estimate in under 60 seconds—validated by our engineering team for manufacturability. Accelerate time-to-market for complex geometries that challenge traditional CNC workflows, with seamless transition from digital model to certified physical part.

Material & Process Capabilities Overview

| Category | Key Offerings | Tolerance Range |

|——————-|———————————————–|———————|

| Metal Printing | DMLS, SLM (Stainless 316L, Inconel, Ti) | ±0.05 mm to ±0.1 mm |

| Polymer Printing | FDM (ULTEM, PEEK), SLS (Nylon 12) | ±0.1 mm to ±0.2 mm |

| Post-Processing | CNC machining, HIP, stress-relief, surface finishing | As per AS9100 |

Upload your design today and experience industrial 3D printing engineered for real-world performance. Your Online Instant Quote awaits at Honyo Prototype.

Technical Capabilities

The term “CNC 3D files” is typically a misnomer when referring to additive manufacturing processes such as SLA, SLS, MJF, and DMLS. CNC (Computer Numerical Control) generally refers to subtractive machining, whereas SLA (Stereolithography), SLS (Selective Laser Sintering), MJF (Multi Jet Fusion), and DMLS (Direct Metal Laser Sintering) are additive manufacturing (3D printing) technologies. Below are the technical specifications for 3D printable file requirements and compatible materials for each of these additive processes, including common materials such as Aluminum, Steel, ABS-like, and Nylon.

| Process | Technology Type | Layer Resolution Range | Typical Accuracy | Minimum Feature Size | Supported Materials | File Format Requirements | Build Volume (Typical Max) |

|---|---|---|---|---|---|---|---|

| SLA (Stereolithography) | Photopolymer Resin (UV Laser) | 25 – 150 microns | ±0.1 mm (±0.004 in) | 0.5 mm | Standard, Tough, Durable, Clear, High-Temp Resins (ABS-like properties available) | STL, OBJ, 3MF (recommended: 0.01 mm chord tolerance, watertight geometry) | 145 x 145 x 185 mm (Desktop), up to 1500 x 750 x 500 mm (Industrial) |

| SLS (Selective Laser Sintering) | Powder Bed Fusion (Nylon-based) | 80 – 120 microns | ±0.3 mm (±0.012 in) | 0.8 mm | Nylon 12 (PA12), Nylon 11 (PA11), Glass-filled Nylon, Flame-Retardant Nylon (ABS-like mechanical behavior not direct, but functional analogs available) | STL, OBJ, 3MF (Watertight, manifold geometry required) | 300 x 300 x 300 mm (common), up to 700 x 380 x 580 mm |

| MJF (Multi Jet Fusion) | Powder Bed Fusion (Inkjet Array + Heating) | 80 – 100 microns | ±0.2 mm (±0.008 in) | 0.8 mm | Nylon 12 (PA12), Glass-filled Nylon, TPU (Flexible), PP-like materials (Nylon-based; no direct ABS but functional equivalents) | STL, OBJ, 3MF (High-quality mesh, no non-manifold edges) | 380 x 280 x 380 mm |

| DMLS (Direct Metal Laser Sintering) | Metal Powder Bed Fusion (Laser) | 20 – 50 microns | ±0.1 mm (±0.004 in), post-machining improves | 0.4 mm (dependent on geometry) | Aluminum (AlSi10Mg, AlSi7Mg), Stainless Steel (17-4 PH, 316L), Tool Steel (Maraging, H13), Titanium (Ti6Al4V), Inconel | STL, 3MF (Fine resolution recommended: 0.001–0.01 mm chord tolerance, support structures required) | 250 x 250 x 325 mm (typical), up to 500 x 400 x 400 mm (large-format systems) |

Notes:

File Quality: For all processes, watertight, manifold 3D geometry is critical. Non-manifold edges, gaps, or flipped normals can cause build failure.

Materials: ABS as a thermoplastic is not directly used in SLS, MJF, or DMLS, but Nylon-based materials (especially in SLS/MJF) offer similar toughness and thermal resistance. Aluminum and Steel are exclusively used in metal processes such as DMLS.

Supports: SLA requires support structures for overhangs; SLS and MJF use unsintered powder as natural support; DMLS requires metal support structures to manage warping and heat dissipation.

Post-Processing: All processes benefit from post-processing (e.g., sandblasting, heat treatment, machining) to improve surface finish and mechanical properties, especially for metal parts.

From CAD to Part: The Process

Honyo Prototype executes a streamlined, technology-driven workflow for CNC machining projects initiated through 3D CAD file submission. This process ensures rapid turnaround while maintaining rigorous quality standards essential for industrial clients.

The process begins with secure CAD file upload via our customer portal. We accept native and neutral formats including STEP AP203/AP214, IGES, Parasolid (.x_t, .x_b), and native SolidWorks, Creo, and Fusion 360 files. Upon submission, our system performs an immediate automated validation check for file integrity, unit consistency, and geometric completeness to prevent downstream delays.

Next, our proprietary AI quoting engine analyzes the validated CAD geometry. This system evaluates critical factors including part complexity, material stock requirements, feature tolerances, surface finish specifications, and machine time estimates. The AI cross-references real-time data on material costs, machine availability, and labor rates to generate a detailed, binding quote within 2 hours for standard parts. This eliminates manual quoting bottlenecks while ensuring cost transparency.

Following quote acceptance, the project enters our Digital Manufacturing Engineering (DFM) phase. A dedicated manufacturing engineer conducts a comprehensive manufacturability review using specialized CAM simulation software. This step identifies potential issues such as problematic tool access, thin wall deflection risks, or non-optimal fixture setups. We provide actionable DFM feedback within 24 hours, including specific recommendations for design modifications to enhance producibility, reduce costs, or accelerate lead times—always with clear engineering justification.

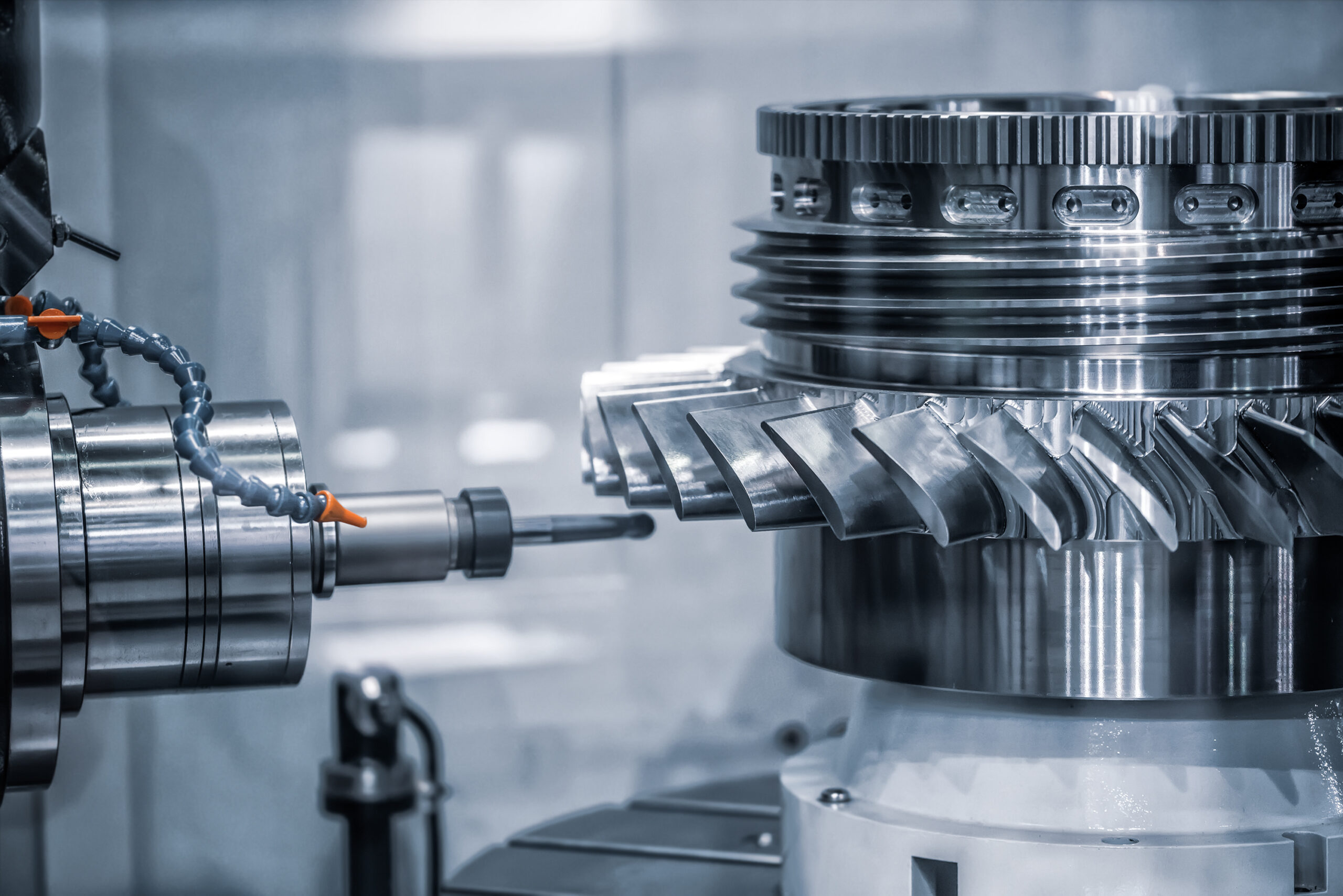

Approved designs proceed directly to production scheduling. Our facility utilizes a certified network of CNC machining centers including 3-axis vertical mills, 5-axis indexed and continuous machines, and precision turning centers. All parts undergo in-process inspections using calibrated CMMs and optical comparators against AS9102 first-article inspection standards where required. Material certifications and process documentation are maintained per ISO 9001:2015 protocols throughout manufacturing.

Final quality verification occurs prior to shipment, with critical dimensions rechecked against the original CAD model. Parts are packaged using ESD-safe and shock-absorbing materials appropriate for the component’s sensitivity. Standard lead times range from 3-7 business days for prototypes depending on complexity, with real-time production tracking accessible through the customer portal. Delivery includes full traceability documentation and optional FAI reports, ensuring seamless integration into client supply chains.

This integrated workflow reduces typical prototype lead times by 40% compared to traditional manufacturing service providers while minimizing design iteration cycles through proactive engineering collaboration.

Start Your Project

Need precision CNC 3D files for your next project? Partner with Honyo Prototype for fast, accurate, and high-quality manufacturing solutions.

Our state-of-the-art facility in Shenzhen ensures tight tolerances, rapid turnaround, and consistent quality for prototyping and low-volume production.

Contact Susan Leo today at [email protected] to request a quote or submit your 3D files for review.

Let’s bring your designs to life with engineering precision and manufacturing excellence.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.