Contents

Manufacturing Insight: Cnc 101

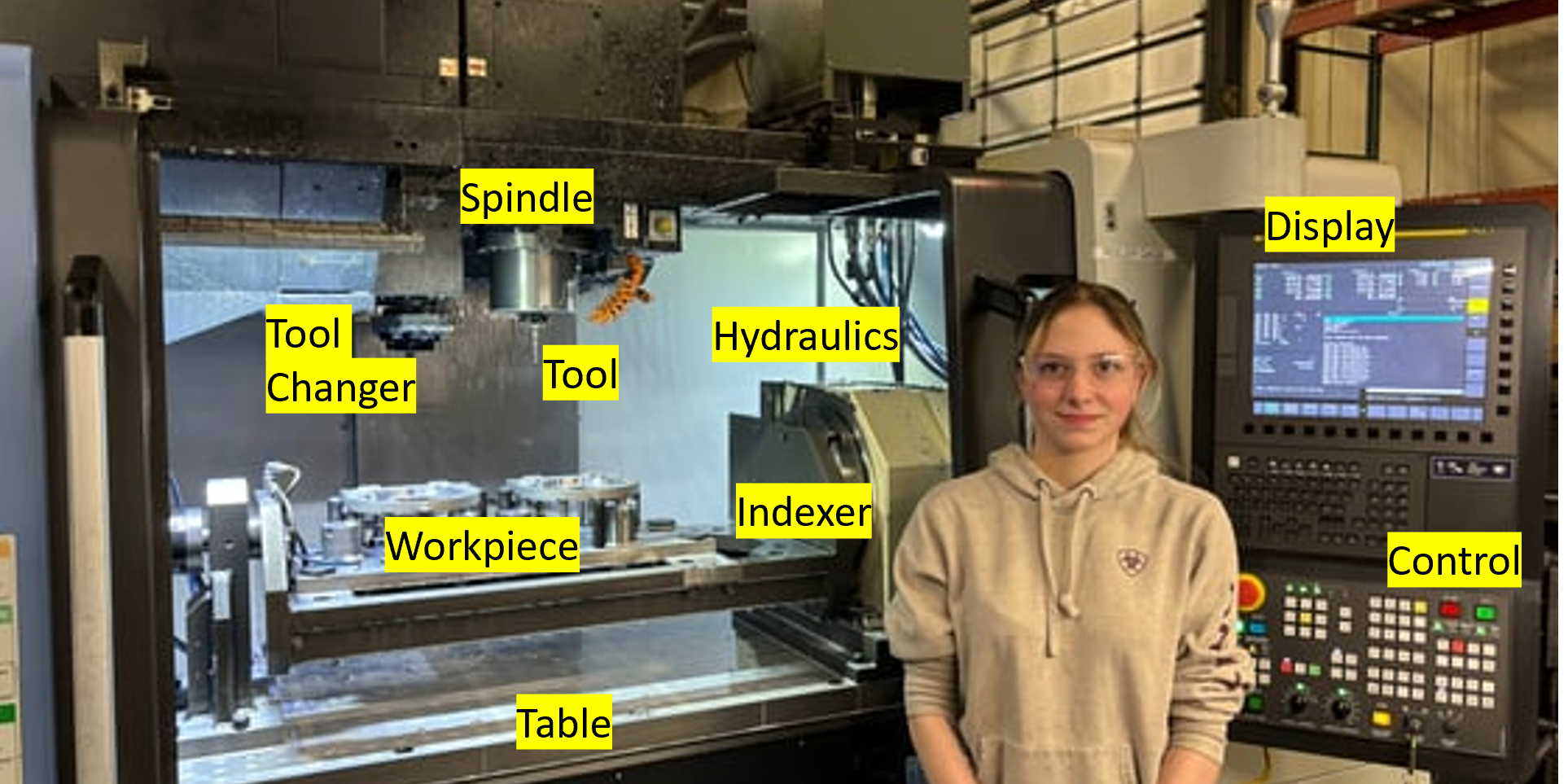

Introduction to CNC Machining Fundamentals with Honyo Prototype

CNC machining remains the cornerstone of precision manufacturing for functional prototypes and low-to-mid volume production across aerospace, medical, automotive, and industrial sectors. At Honyo Prototype, we leverage state-of-the-art 3-axis, 4-axis, and 5-axis milling and turning centers to transform digital designs into high-tolerance components with repeatability down to ±0.0002 inches. Our engineering-driven approach ensures optimal material utilization, reduced cycle times, and strict adherence to GD&T standards for metals including aluminum 6061-T6, stainless steel 303/304, titanium Ti-6Al-4V, and engineered plastics like PEEK and Delrin.

Beyond core machining capabilities, Honyo integrates secondary operations such as precision grinding, tapping, knurling, and surface finishing—including anodizing, plating, and powder coating—under one roof. This vertical integration eliminates supplier handoffs, accelerates time-to-part, and maintains stringent quality control per ISO 9001:2015 protocols. For design teams requiring rapid validation, our Online Instant Quote system delivers manufacturability feedback and competitive pricing within hours, not days. Simply upload your STEP or IGES file to receive a detailed quote with lead time estimates, allowing immediate iteration on design for manufacturability without procurement delays.

Partner with Honyo Prototype to convert complex geometries into mission-critical components where precision, speed, and process transparency are non-negotiable. Our CNC 101 series will further demystify toolpath strategies, material selection criteria, and tolerance optimization to maximize your project’s success.

Technical Capabilities

CNC 101 refers to foundational knowledge and technical capabilities in Computer Numerical Control (CNC) machining, particularly in precision manufacturing environments. Below are key technical specifications focused on 3-axis, 4-axis, and 5-axis milling, CNC turning, and tight-tolerance capabilities across common engineering materials such as aluminum, steel, ABS, and nylon.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Tight Tolerance Capability |

|---|---|---|---|---|---|

| Axes of Motion | X, Y, Z | X, Y, Z, A (rotary) | X, Y, Z, A, B (dual rotary) | X, Z (spindle rotation) | N/A |

| Typical Positioning Accuracy | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.0025 mm (±0.0001″) |

| Repeatability | ±0.002 mm | ±0.002 mm | ±0.002 mm | ±0.002 mm | ±0.001 mm |

| Spindle Speed Range | 8,000 – 24,000 RPM | 8,000 – 24,000 RPM | 10,000 – 30,000 RPM | 3,000 – 12,000 RPM | Up to 30,000 RPM (high-speed spindles) |

| Tool Changer Capacity | 12–30 tools (ATC) | 12–30 tools (ATC) | 20–40 tools (ATC) | 8–12 tools (turret) | 20–40 tools (precision ATC) |

| Work Envelope (Typical) | 500 x 400 x 300 mm | 500 x 400 x 300 mm + 360° A | 400 x 400 x 300 mm + A/B | Ø300 x 500 mm length | Varies by machine class |

| Surface Finish (Typical) | Ra 0.8 – 3.2 µm | Ra 0.8 – 1.6 µm | Ra 0.4 – 1.6 µm | Ra 0.8 – 1.6 µm | Ra 0.2 – 0.8 µm (polished) |

| Materials Supported | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel (preferred) |

| Aluminum Machinability | Excellent (high feed/speed) | Excellent | Excellent (complex forms) | Excellent | Excellent (with thermal control) |

| Steel Machinability | Good (requires rigid setup) | Good | Good (with HSM toolpath) | Good (hardened up to 60 HRC) | Excellent (pre-hardened steels) |

| ABS Machinability | Good (low melting point) | Good | Good | Fair (chatter control) | Moderate (dimensional stability) |

| Nylon Machinability | Moderate (gumming risk) | Moderate | Moderate | Moderate | Challenging (hygroscopic) |

| Coolant/Lubrication | Flood, Mist, Air Blast | Flood, Mist | Flood, High-Pressure | Flood or Mist | Cryogenic or Oil Mist (for micron tolerances) |

| Typical Applications | Flat parts, pockets, drilling | Indexing features, slots | Aerospace, molds, impellers | Shafts, pins, bushings | Medical, optical, aerospace components |

Note: Tight tolerance machining (±0.0025 mm or better) requires thermal control, precision tooling, in-process metrology, and experienced programming. Materials like aluminum and pre-hardened steel are preferred due to dimensional stability. ABS and nylon are less ideal for tight tolerances due to thermal expansion and moisture absorption.

From CAD to Part: The Process

Honyo Prototype CNC 101 Process Overview

Our streamlined CNC 101 workflow ensures rapid, high-fidelity prototyping and low-volume production for engineering clients. This process integrates automation with expert human oversight to minimize lead times while guaranteeing manufacturability and quality. Below is a detailed breakdown of each phase.

CAD Upload

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid, or native SOLIDWORKS/Creo/Fusion formats) via our secure customer portal. The system performs an initial validation check for file integrity, unit consistency, and basic geometric feasibility. Unsupported formats trigger an automated request for conversion to industry-standard STEP files to prevent data loss. This phase typically completes within 15 minutes of submission, with immediate confirmation sent to the client.

AI-Powered Quoting

Uploaded geometry undergoes analysis by our proprietary AI quoting engine, which assesses 200+ manufacturability factors including feature complexity, tolerance density, material utilization, and machine time estimation. The AI cross-references real-time data on material costs, machine availability, and shop floor workload to generate an instant quote with 90% accuracy for standard geometries. Quotes include detailed cost breakdowns by operation (milling, turning, finishing) and optional expedited pricing tiers. Clients receive the formal quote within 2 business hours, significantly faster than industry averages.

DFM Analysis and Engineering Review

Every design enters our dual-layer DFM workflow. First, the AI identifies potential issues like thin walls, excessive tolerances, or non-optimal tool access. Next, a senior manufacturing engineer conducts a manual review, focusing on critical functional features and material-specific constraints. We provide a formal DFM report within 24 hours, highlighting actionable recommendations with annotated visuals. Crucially, Honyo guarantees zero cost-increasing DFM changes for standard materials—if our suggestions are implemented, the quoted price remains fixed. This phase ensures designs are optimized for CNC efficiency without compromising performance.

Production Execution

Approved designs move to production in our climate-controlled facility housing 32 CNC centers (including 5-axis mills, Swiss lathes, and multi-tasking machines). Each job receives a unique tracking ID with real-time status updates. Our MES system dynamically allocates work based on machine capability, tooling availability, and operator expertise. All critical dimensions undergo in-process CMM verification per AS9100 protocols, with first-article inspection reports available upon request. Typical production lead time ranges from 3-10 business days depending on complexity and material.

Delivery and Quality Assurance

Finished parts undergo final dimensional validation against the original CAD model using calibrated Zeiss CMMs. Components are cleaned, deburred per ISO 1302 standards, and packaged in anti-static containers with humidity control for sensitive alloys. Every shipment includes comprehensive documentation: material certs, FAI reports, and process validation records. We provide FedEx/UPS tracking with delivery confirmation and offer post-delivery engineering support for assembly or integration queries. Standard delivery occurs within 24 hours of production completion.

Process Timeline Summary

| Phase | Key Activities | Typical Duration | Client Deliverable |

|---|---|---|---|

| CAD Upload | File validation, format conversion | < 0.25 business days | Upload confirmation |

| AI Quote | Automated cost analysis, pricing generation | < 1 business day | Detailed quote with cost breakdown |

| DFM | AI screening, engineer review, recommendations | 1 business day | DFM report with annotated suggestions |

| Production | Machining, in-process inspection, finishing | 3-10 business days | Real-time production tracking |

| Delivery | Final QA, packaging, shipping | < 1 business day | Tracking, certs, FAI documentation |

This integrated approach reduces time-to-part by 40% compared to traditional quoting methods while maintaining 99.2% first-pass yield rates. Honyo’s CNC 101 process is engineered for reliability in mission-critical applications across aerospace, medical, and robotics sectors—where precision and speed directly impact your development cycles.

Start Your Project

Learn the fundamentals of CNC machining with our CNC 101 guide. Gain insight into precision manufacturing processes, tooling, and prototyping best practices.

For more information, contact Susan Leo at [email protected].

Honyo Prototype operates a state-of-the-art manufacturing facility in Shenzhen, enabling rapid turnaround and high-quality production for global clients.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.