Guide Contents

Project Insight: Climb Machining

Climb Milling: The Precision Engine Behind Rapid Prototyping

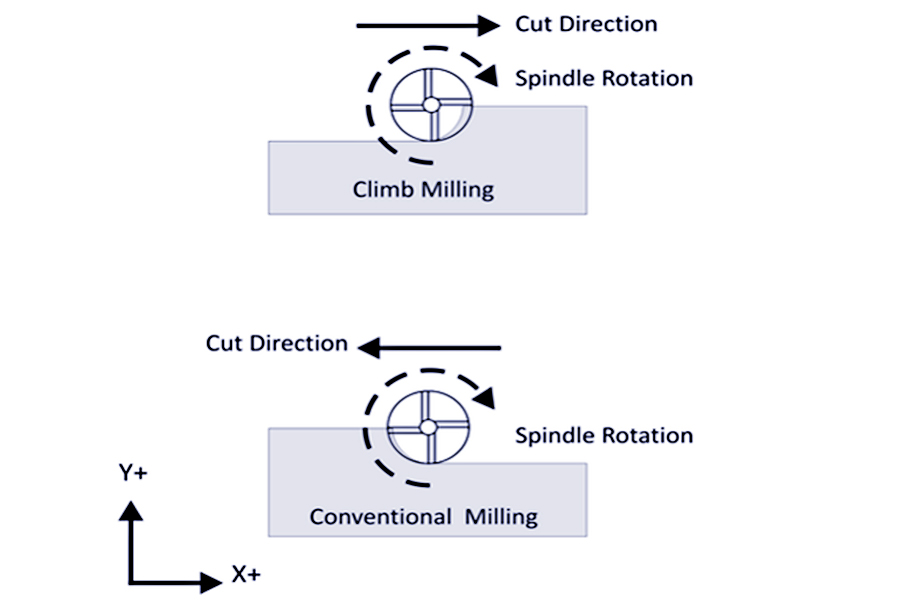

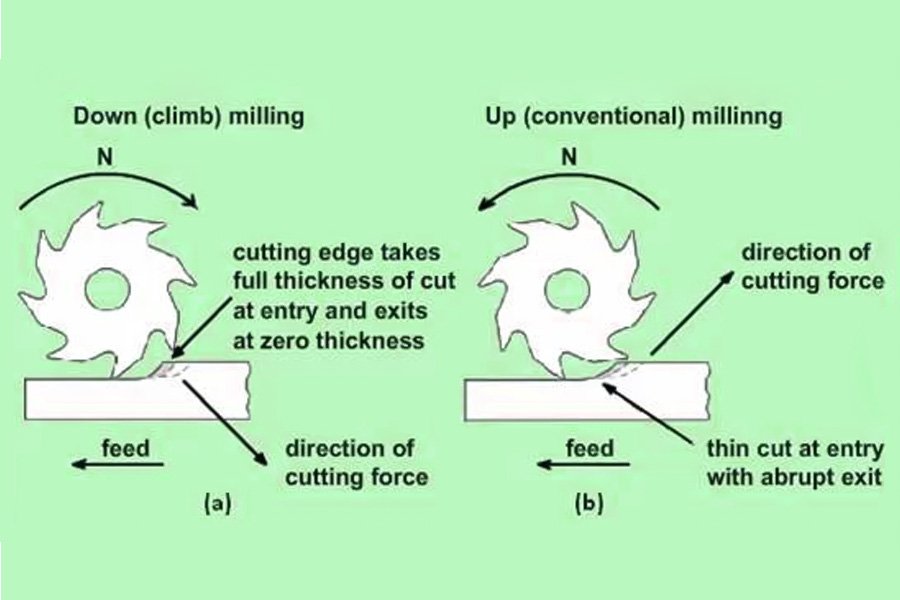

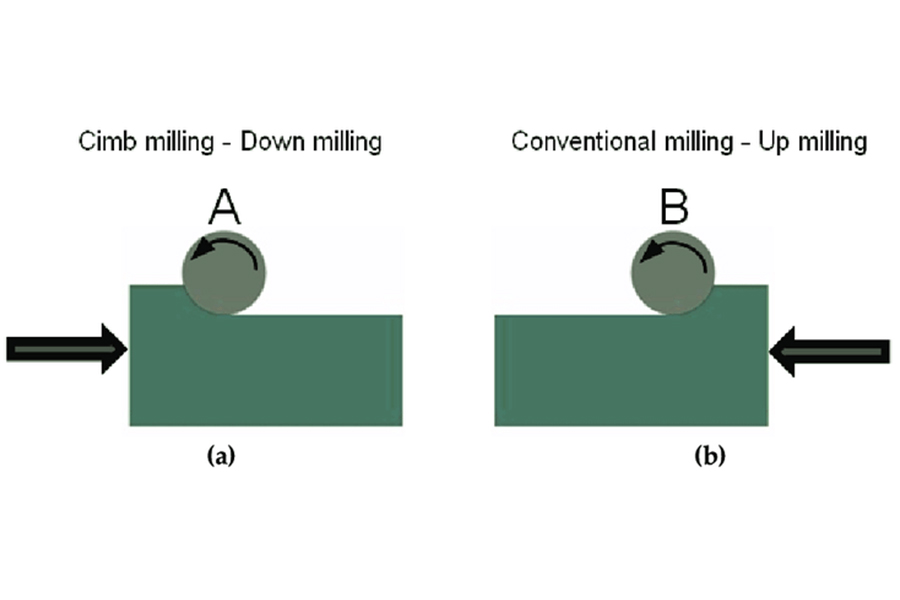

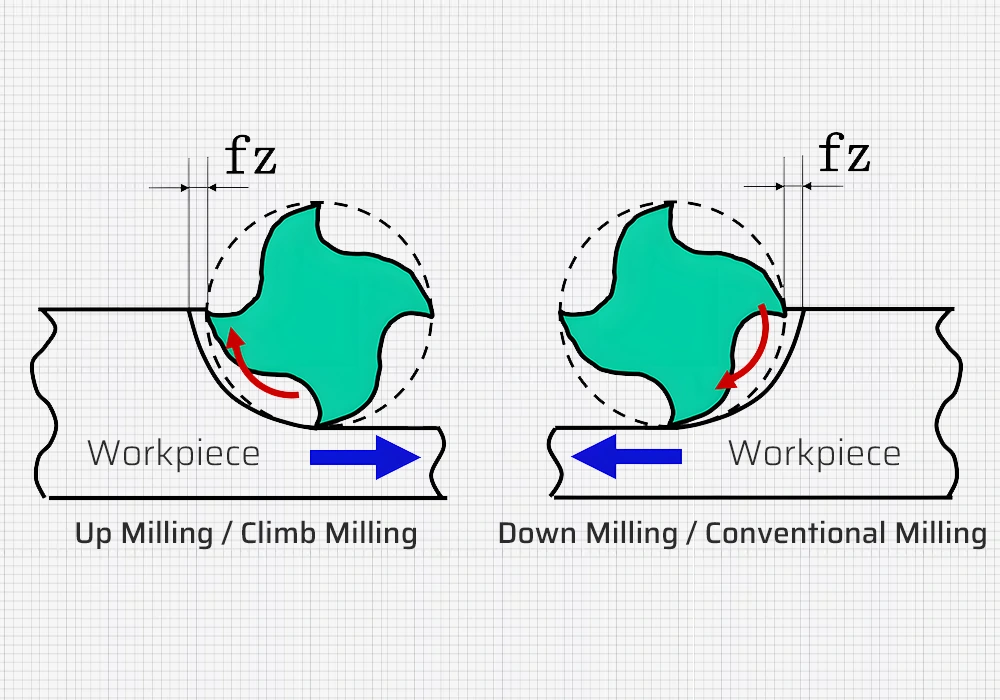

In today’s fast-paced product development landscape, precision and speed aren’t just advantages—they’re non-negotiable. Climb milling (a precision machining technique where the cutter rotates with the feed direction) delivers superior surface finishes, reduced tool wear, and faster production cycles. At Honyo Prototype, we’ve perfected this technique through advanced 5-axis CNC capabilities and AI-driven optimization, ensuring your designs meet exacting tolerances (+/- 0.01mm) without compromising on lead times.

Why Climb Milling Matters for Modern Product Development

Superior Surface Finish: Minimizes chatter and vibration, producing smoother surfaces that often eliminate secondary finishing steps—critical for functional prototypes requiring precise fit and assembly.

Increased Efficiency: Up to 20% higher feed rates and optimized chip evacuation cut cycle times, accelerating time-to-market while maintaining micron-level accuracy.

Extended Tool Life: Consistent chip thickness reduces tool wear, lowering maintenance costs for complex geometries and high-volume runs.

How Honyo Optimizes Climb Milling for Your Needs

5-Axis Precision Control: Our state-of-the-art CNC machines dynamically adjust climb milling parameters for intricate 3D contours, ensuring micron-level accuracy even in aerospace-grade materials like titanium or Inconel.

AI-Powered Toolpath Optimization: Our digital platform analyzes your CAD model in real-time to automatically select the ideal milling strategy—whether climb, conventional, or hybrid—maximizing efficiency and precision.

Tight Tolerance Mastery: Every operation is calibrated to maintain +/- 0.01mm tolerances, validated through in-process monitoring for repeatable quality across materials from aluminum to PEEK.

Your Project, Accelerated with Honyo’s Digital Edge

Online Instant Quote: Upload your design and receive an accurate, transparent quote in seconds—no hidden fees, no delays. Our system factors in climb milling advantages to optimize cost and speed.

AI-Driven Workflow: From upload to production, our platform intelligently optimizes tool selection, feed rates, and machining strategy, slashing lead times while preserving precision.

Industry-Leading Turnaround: Typical prototype delivery in 3–5 business days—faster than industry averages—thanks to streamlined climb milling processes and automated quality checks.

“At Honyo Prototype, we don’t just machine parts—we engineer solutions. Let’s turn your vision into reality, faster and with unparalleled precision.”

— Susan Leo, Founder

Ready to prototype with confidence? Get an instant quote in under 60 seconds.

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

Precision Climb Machining Technology

Multi-Axis Precision: Execute climb machining strategies across 3/4/5-axis CNC platforms with ±0.01mm tolerances—ideal for complex aerospace, medical, and automotive components where surface finish and dimensional accuracy are critical.

AI-Optimized Toolpaths: Machine learning algorithms dynamically adjust feed rates, spindle speeds, and depth of cut to minimize tool wear and thermal distortion, ensuring consistent quality across metals (aluminum, steel, titanium) and engineering plastics.

Material-Specific Strategies: Tailored climb machining parameters for each material, delivering superior chip evacuation, reduced vibration, and flawless surface finishes without secondary polishing.

Scalable Production from Prototype to Volume

Seamless Scale-Up: From 1 prototype to 10,000+ production parts, maintain identical precision with automated setup adjustments—no compromises during volume transitions.

ISO 9001 Certified Quality: Real-time monitoring during climb machining with in-process gauging and final CMM verification, ensuring every part meets strict dimensional and surface quality standards.

Smart Cost & Speed Optimization

Instant Online Quoting: Upload your CAD file to our AI-powered platform for real-time climb machining cost estimates—transparent pricing based on actual machining parameters, no manual estimates.

24-Hour Prototyping: Leverage optimized climb machining workflows to cut lead times by up to 40% for urgent projects, with expedited shipping options for critical deadlines.

Transparent Cost Breakdown: See exactly where your budget goes—machining time, material, finishing, and tooling costs displayed clearly on our platform before you commit.

Why Honyo?

As pioneers in precision CNC machining, we combine AI-driven efficiency with ISO-certified rigor to turn your designs into functional prototypes and end-use parts faster and more cost-effectively than traditional providers. Founded by Susan Leo, Honyo Prototype delivers innovation at scale—no compromises, no delays.

Materials & Surface Finishes

Material Options & Finishes for Precision Climb Machining

Why Material Choice Matters for Climb Machining

Climb machining (down milling) delivers superior surface finish and reduced tool wear by aligning cutter rotation with feed direction. However, material properties directly impact toolpath efficiency, thermal management, and dimensional stability. Selecting the right material ensures your part meets ±0.01mm tolerances while minimizing secondary operations—critical for functional prototypes and end-use components.

Optimized Material Selection for Climb Milling

Aluminum 6061: Engineered for climb machining excellence—its thermal conductivity and softness enable high-speed cutting with minimal tool deflection, achieving ±0.01mm tolerances for structural prototypes. Ideal for lightweight, corrosion-resistant applications.

Aluminum 7075: High-strength aerospace alloy that thrives in climb milling; optimized feed rates prevent work hardening while maintaining dimensional stability for critical components like drone frames or medical devices.

Stainless Steel 304/316: Climb milling reduces heat buildup in stainless steel, preventing work hardening and ensuring corrosion-resistant surfaces for medical implants or marine hardware.

Brass: Natural lubricity and machinability make brass ideal for climb milling—delivering mirror-like finishes with fewer secondary operations. Perfect for electrical contacts or decorative fixtures.

PEEK: High-performance polymer that maintains dimensional accuracy during climb machining, critical for aerospace and medical end-use parts where thermal stability and chemical resistance are paramount.

Surface Finishes That Amplify Precision

Anodizing (Type II/III): Seamlessly integrates with climb-machined aluminum surfaces to create uniform, wear-resistant coatings—ideal for functional prototypes requiring both precision and aesthetics.

Precision Polishing: Climb-machined parts require up to 40% less polishing time, preserving tight tolerances for optical lenses or surgical instruments.

Electroless Nickel Plating: Applied after climb milling for stainless steel to enhance wear resistance without compromising surface smoothness—perfect for high-stress industrial components.

Powder Coating: Uniform adhesion on climb-machined surfaces ensures vibrant, durable finishes for consumer electronics housings and enclosures.

Smart Material Selection with Honyo’s AI Platform

Online Instant Quote: Upload your CAD file—our AI instantly analyzes material, finish, and geometry to generate a transparent quote in seconds. No engineering delays, no hidden costs.

AI-Powered Optimization: Our platform cross-references material properties, toolpath strategies, and finish requirements to optimize climb machining parameters—ensuring ±0.01mm tolerances for every part, every time.

Fast Turnaround Guarantee: 24-hour prototype delivery and 5–7 day production runs. Climb-machined parts shipped faster without sacrificing precision—because time-to-market is everything.

Pro Tip: For high-volume production, our platform recommends material/finish combinations that reduce cycle time by up to 30% while maintaining aerospace-grade tolerances. Let our AI do the math—so you focus on innovation.

From Quote to Part: Our Process

How It Works: From CAD to Part

Step 1: Upload CAD File

Seamless digital submission of your design files (STEP, STP, IGES, SolidWorks, etc.)

Real-time validation checks to ensure file integrity and manufacturability

Zero manual delays—our system processes your upload instantly

Step 2: AI-Powered Instant Quote

Get a transparent, accurate quote in seconds—no waiting for manual estimates

Our AI engine analyzes geometry, tolerances (+/- 0.01mm precision), and material to calculate costs based on actual climb machining parameters

Clear breakdown: material costs, machining time (optimized for climb machining efficiency), and setup fees

Step 3: DFM Analysis with Precision Engineering

Expert review of your design to optimize toolpaths for climb machining, ensuring minimal vibration and superior surface finish

Actionable recommendations to reduce tool wear, improve surface quality, and minimize cycle times

Collaborative feedback loop—our engineers suggest tweaks to enhance manufacturability without compromising functionality

Step 4: Rapid Production & Delivery

State-of-the-art 3/4/5-axis CNC machines with automated climb machining toolpaths for unmatched precision

Quality control at every stage—guaranteed tolerances and surface finishes for functional prototypes or end-use parts

Fast turnaround: prototypes in 3–5 days, production runs scaled to your needs

Global shipping with real-time tracking—full transparency from factory to doorstep

Start Your Project with Honyo

Start Your Project with Honyo Prototype

Precision CNC Machining, Optimized for Speed and Accuracy

Online Instant Quote: Submit your CAD file and receive an accurate, no-obligation quote in under 60 seconds—powered by our AI-driven cost estimator.

AI-Powered Optimization: Smart algorithms refine climb milling strategies to maximize tool life, surface finish quality, and material efficiency—reducing costs without compromising ±0.01mm tolerances.

24-Hour Prototyping Turnaround: From design review to delivery, our streamlined workflow delivers rapid iterations for hardware startups and complex end-use parts.

Founder-Led Expertise for Your Success

Susan Leo and our engineering team provide end-to-end support—from DFM analysis and material selection to final quality inspection—ensuring your parts exceed performance expectations.

State-of-the-art facilities in Shenzhen and Dongguan equipped with 3/4/5-axis CNC machines for scalable precision manufacturing.

Contact Us Today

📧 Email: [email protected]

📞 Phone: +86 139 2843 8620

🌍 Visit: Schedule a tour of our Shenzhen/Dongguan facilities to see precision engineering in action

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.