Introduction: Navigating the Global Market for circularity vs cylindricity

In today’s global market, sourcing the right components that meet precise specifications is paramount, especially when it comes to understanding the differences between circularity and cylindricity. These two concepts are critical in manufacturing processes, particularly for products that require optimal performance and durability, such as automotive parts, bearings, and machined components. This guide provides an all-encompassing overview of circularity versus cylindricity, detailing their definitions, applications, measurement techniques, and implications for product integrity.

International B2B buyers navigating the complexities of these tolerances will find valuable insights into how each concept impacts product quality and operational efficiency. The guide emphasizes the importance of supplier vetting to ensure quality compliance across various regions, including Africa, South America, the Middle East, and Europe, where manufacturing standards may vary significantly. It also outlines considerations that influence costs and sourcing strategies, helping buyers make informed decisions that align with their operational goals.

Armed with this knowledge, businesses can effectively assess suppliers, select the right specifications for their products, and ultimately enhance their competitive edge in international trade. By understanding the nuances of circularity versus cylindricity, buyers can ensure robust product design and manufacturing processes that meet the demands of a rapidly evolving marketplace.

Understanding circularity vs cylindricity Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Circularity | Measures the roundness of a surface at any cross-section; 2D zone | Manufacturing shafts, pins, holes | Pros: Simplifies production, cost-effective; Cons: Less stringent control than cylindricity. |

| Cylindricity | 3D tolerance controlling both roundness and straightness; 3D zone | Automotive shafts, precision rods | Pros: Ensures higher accuracy in cylindrical parts; Cons: Measurement can be complex and costly. |

| Form Tolerance | General term highlighting variations of shapes; can include GD&T | Aerospace parts, tooling components | Pros: Assures fit between parts; Cons: Can lead to over-specification and increased costs. |

| Surface Profile | Accounts for the entire contour of a surface as a single entity | High-end consumer products, molds | Pros: Allows for flexible designs; Cons: Complexity in measurement can increase production time. |

| Straightness | Measures the straightness along an axis without considering roundness | Slide rails, linear guides | Pros: Critical for aligning features; Cons: Doesn’t account for circularity, potentially missing key deviations. |

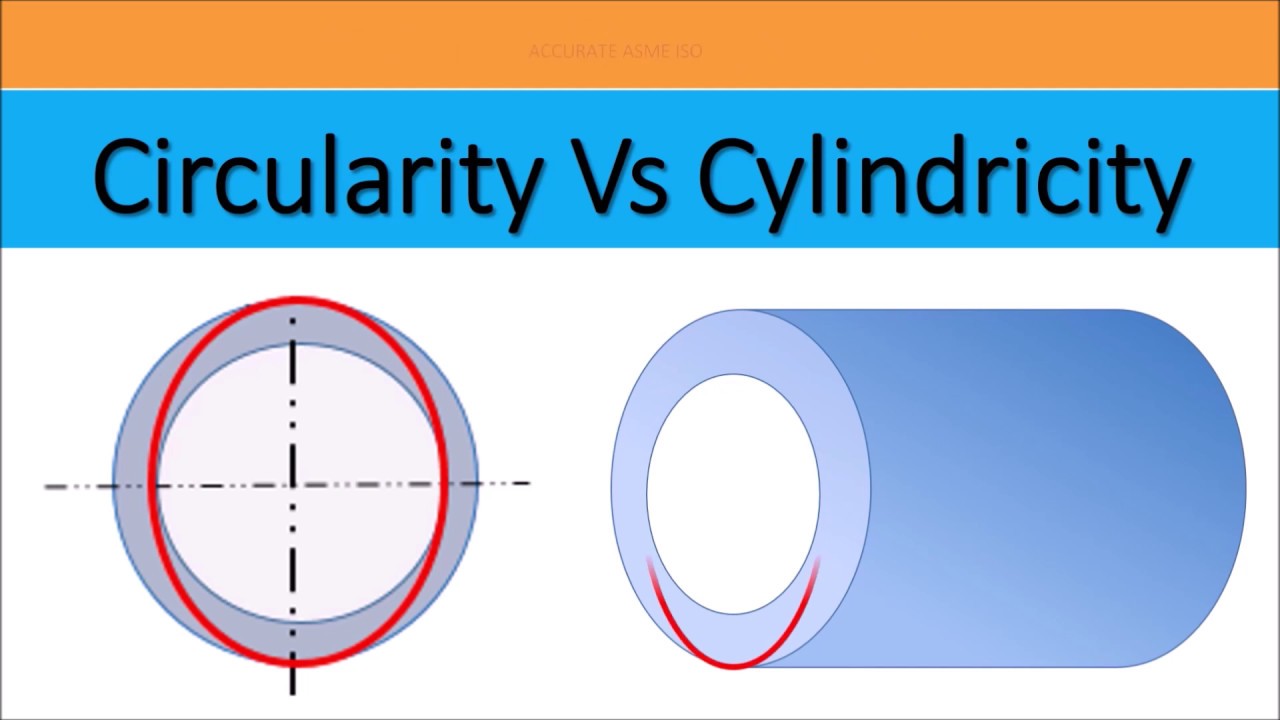

What are the Key Characteristics of Circularity?

Circularity focuses solely on the shape of circular features, such as holes or pins. The inspection is performed at multiple cross-sections to ensure that each maintains a consistent form defined by two concentric circles, representing the tolerance zone. This is particularly suitable for industries like manufacturing, where cost-effective and semi-accurate components suffice. However, while easy to measure and implement, it provides less precision than other tolerances, making it less suitable for high-performance applications.

Why Choose Cylindricity for Precision Components?

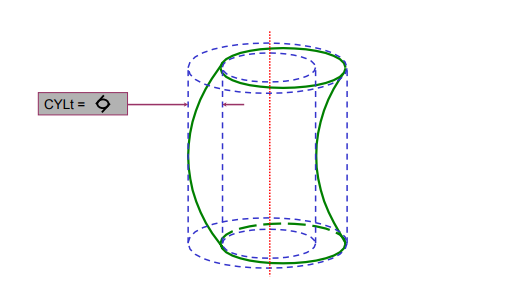

Cylindricity extends the concept of circularity to three dimensions, incorporating both roundness and straightness along the length of the feature. This makes it especially critical for dynamic components such as automotive shafts, where performance can be compromised by minor deviations. Although it offers higher accuracy and improved functional performance, its measurement can be complex and often requires specialized equipment or techniques which could increase production costs.

How Does Form Tolerance Impact B2B Purchases?

Form tolerance is a broader category that includes both circularity and cylindricity alongside other variations of shape control. It emphasizes maintaining the relationship between various features to ensure a fit that meets functional requirements. Key sectors like aerospace and tooling often leverage this, but the trade-off is the potential for over-specification, leading to increased costs and extended production timelines. Understanding the specific needs for form tolerance can help buyers avoid waste and ensure efficient manufacturing processes.

What are the Applications of Surface Profile Measurement?

Surface profile relates to the overall contour of a feature, considering its full 3D shape rather than isolated aspects. This tolerance is ideal for high-end consumer products or complex molds where nuanced features are critical for aesthetic or functional excellence. While this allows for flexible designs, the complexity involved in measuring surface profiles can extend production times, making it a consideration for buyers focused on speed as well as quality in manufacturing.

How Important is Straightness in Component Alignment?

Straightness deals with the axis of features without regard to their roundness. This is particularly relevant in applications such as slide rails or linear guides, where alignment is essential for optimal performance. While it ensures critical alignment, buyers should consider that it does not account for circularity, which could result in overlooked deviations affecting overall functionality. Thus, integrating straightness specifications should carefully align with other tolerances to ensure complete dimensional integrity.

Key Industrial Applications of circularity vs cylindricity

| Industry/Sector | Specific Application of circularity vs cylindricity | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Manufacturing of engine shafts and pistons | Ensures optimal performance and longevity of engine components. | Precision machining capabilities, quality certifications. |

| Aerospace | Production of hydraulic cylinder parts | Critical to ensure safety and reliability of aircraft systems. | Supplier experience in aerospace standards, traceability. |

| Industrial Equipment | Design of conveyor rollers and pulleys | Reduces wear and increases efficiency in material handling. | Tolerance specifications, capacity for large-scale orders. |

| Medical Devices | Fabrication of syringes and delivery systems | Improves patient safety through enhanced precision and functionality. | Regulatory compliance, ability to meet low tolerances. |

| Energy Sector | Manufacturing of turbine components | Improves energy efficiency and reliability in generation systems. | Material quality, ability to manage complex geometries. |

How are circularity and cylindricity critical in the automotive industry?

In the automotive sector, the precise manufacturing of engine shafts and pistons necessitates adherence to circularity and cylindricity tolerances. These components must be both round and straight to ensure proper fitting and functionality within applied mechanics. Poorly defined geometries can lead to increased friction, resulting in energy loss and premature wear of parts. B2B buyers need to ensure their suppliers have advanced precision machining capabilities and quality control measures to meet stringent automotive standards.

What role do circularity and cylindricity play in aerospace applications?

In aerospace manufacturing, cylindrical components such as hydraulic cylinder parts must maintain strict tolerances related to cylindricity. Properly manufactured parts ensure the reliability and safety of aircraft systems, where even minor deviations can result in catastrophic failures. Buyers in this field should prioritize suppliers with expertise in aerospace specifications and robust traceability practices to guarantee that parts can withstand the harsh conditions encountered during flight.

How does circularity vs cylindricity affect industrial equipment?

For industrial equipment, particularly in designs like conveyor rollers and pulleys, maintaining both circularity and cylindricity is essential to reducing wear and tear. Components that do not conform to these tolerances may lead to misalignment, resulting in inefficient material handling and increased operational costs. B2B buyers should focus on sourcing suppliers who can deliver precision components and have the capacity to fulfill large orders while adhering to specified tolerance requirements.

Why are circularity and cylindricity vital in medical device manufacturing?

In the medical industry, the fabrication of syringes and delivery systems requires precise control over circularity to ensure safety and performance. Stringent tolerances prevent leaks and promote reliable dosage delivery, directly impacting patient care. International buyers, particularly those engaged in highly regulated markets, must source from manufacturers who can demonstrate compliance with established medical device regulations and maintain exceptionally low tolerances to safeguard patient outcomes.

How are circularity and cylindricity significant in the energy sector?

In the energy sector, especially with turbine components, circularity and cylindricity are paramount for enhancing efficiency and reliability. Any deviations in these forms can lead to reduced operational performance and increased maintenance costs. B2B buyers in this sector should seek suppliers experienced in handling complex geometries and maintaining high material quality to ensure that components can perform optimally under demanding conditions while minimizing downtime and ensuring cost-efficiency.

3 Common User Pain Points for ‘circularity vs cylindricity’ & Their Solutions

Scenario 1: Navigating Manufacturing Quality Challenges

The Problem: A major automobile supplier in South America struggles with maintaining product quality due to fluctuating tolerance levels in their components. Specifically, the circularity in machined parts, such as shafts and bushings, sometimes exceeds acceptable limits, leading to premature wear of mating components. This poses a significant risk, as it impacts reliability and increases warranty claims, forcing the company to reconsider its manufacturing processes.

The Solution: To address these challenges, the supplier needs to implement a rigorous quality control system that prioritizes measurement methodologies for both circularity and cylindricity. Utilizing advanced measurement tools such as Coordinate Measuring Machines (CMM) will allow for precise verification of part geometry. Establishing tighter tolerances on circularity while incorporating cylindricity controls will ensure that the entire cylindrical shape is maintained throughout production. Additionally, investing in Employee Training on Geometric Dimensioning and Tolerancing (GD&T) will empower engineers to specify tolerances accurately and communicate quality expectations clearly to machinists. Adopting a comprehensive quality framework can streamline the manufacturing process and reduce costs associated with defects.

Scenario 2: Misalignment of Supplier Specifications

The Problem: A European manufacturing firm sources cylindrical components from an overseas supplier in Asia. Recently, the company faced issues where supplied parts often failed quality checks for both circularity and cylindricity. The discrepancies arise due to the supplier’s misunderstanding of tolerance specifications, resulting in costly production delays and inventory shortages.

The Solution: To resolve the misalignment in specifications, the purchasing team should establish a clear and detailed tolerance guide, including visual aids and measurement examples, specifically for circularity and cylindricity. Regular communication with suppliers through virtual meetings can help clarify expectations and promote understanding. Furthermore, implementing a vendor certification program that assesses alignment with GD&T standards would enhance the overall quality of supplied components. Encouraging suppliers to invest in both training and measurement technologies will also ensure adherence to the specified tolerances, ultimately fostering a more reliable supply chain partnership.

Scenario 3: Difficulty in Handling Complex Assembly Processes

The Problem: An industrial equipment manufacturer in Africa faces assembly issues due to inconsistent circularity and cylindricity in component parts, like gears and bearings. This inconsistency leads to difficulties in achieving the proper fit between mating components. Workers report increased assembly time and a growing backlog due to repeated attempts to correct misalignments, hindering production efficiency.

The Solution: The manufacturer should consider revising its design and engineering standards to explicitly incorporate tolerances for both circularity and cylindricity earlier in the design process. Using design software that integrates GD&T principles will allow for better visualization of tolerance requirements. It’s also essential to adopt a Design for Manufacturability (DFM) approach, which involves collaborating with suppliers during the design phase to ensure manufacturability and performance. Additionally, providing training for assembly line workers on understanding GD&T and its implications for fit and function can empower them to identify potential issues early. Implementing these strategies will not only enhance the quality of the components but also improve overall assembly efficiency and product reliability.

Strategic Material Selection Guide for circularity vs cylindricity

What Materials Are Best for Ensuring Circularity and Cylindricity in Manufacturing?

In the pursuit of achieving precise circularity and cylindricity in engineered components, the choice of material plays a pivotal role. Below is a comparative analysis of four commonly employed materials, evaluated from a B2B perspective, considering key properties, advantages, disadvantages, and impacts specific to international buyers from regions such as Africa, South America, the Middle East, and Europe.

1. Steel (Carbon and Alloy)

Key Properties:

Steel possesses excellent strength and can be heat-treated to enhance hardness. It also offers good dimensional stability, which is crucial for maintaining circularity and cylindricity during machining.

Pros & Cons:

Steel is highly durable and resistant to wear, making it suitable for high-stress applications. However, it can be susceptible to corrosion unless treated. The manufacturing complexity can be higher due to the need for precise machining to meet tight tolerances.

Impact on Application:

Steel can handle high temperature and pressure, making it ideal for automotive and aerospace applications. However, its compatibility with certain corrosive environments might require stainless steel or additional surface treatments.

International Buyer Considerations:

B2B buyers from regions with specific compliance requirements (like ASTM for the U.S. or DIN for Europe) need to ensure that the steel grades meet local standards. Understanding the implications of alloy compositions on machinability is also vital for efficient production.

2. Aluminum

Key Properties:

Aluminum is lightweight and offers good corrosion resistance. It can be easily machined and is available in various grades, each suitable for different applications.

Pros & Cons:

The advantages of aluminum include its low weight and excellent thermal conductivity, which can enhance operational efficiency in many applications. However, it has lower strength than steel and is less suitable for high-stress environments without appropriate alloys.

Impact on Application:

Aluminum is often used in applications where weight reduction is critical, such as in the aerospace industry. Its corrosion resistance makes it suitable for marine environments, though considerations must be taken for potential galvanic corrosion.

International Buyer Considerations:

When sourcing aluminum, compliance with international standards (such as JIS in Japan or EN in Europe) is crucial for quality assurance. Knowledge of local processing capabilities can also inform material selection to meet specific tolerances.

3. Polycarbonate

Key Properties:

Polycarbonate is a thermoplastic with high impact resistance and transparency. It exhibits good dimensional stability and can be machined to achieve precise tolerances.

Pros & Cons:

The main advantage of polycarbonate is its lightweight and shatter-resistant nature. However, it is prone to scratching and can degrade under prolonged UV exposure unless treated.

Impact on Application:

This material is commonly used in applications like safety glasses and machine guards, where impact resistance and transparency are valued. The temperature limit may restrict its use in high-heat environments.

International Buyer Considerations:

Polycarbonate must meet specific standards, particularly in safety-critical applications. Buyers should assess the implications of regulatory compliance for plastic materials, especially regarding environmental impacts and recycling.

4. Bronze

Key Properties:

Bronze offers exceptional corrosion resistance and is ideal for applications in maritime environments. It has good wear resistance and self-lubricating properties.

Pros & Cons:

While bronze is durable and fantastic for protecting against wear, it is typically more expensive than aluminum or steel. The manufacturing methods for bronze parts can also be more complex due to its melting point and casting requirements.

Impact on Application:

Bronze is widely used in bearing applications, where friction reduction is paramount. Its ability to resist saltwater corrosion makes it ideal for naval applications.

International Buyer Considerations:

Understanding the specific grade of bronze chosen is important for compliance with international standards. B2B buyers should also consider procurement logistics and costs associated with sourcing bronze from different regions.

Summary Table

| Material | Typical Use Case for circularity vs cylindricity | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Automotive and aerospace components | High strength and durability | Susceptible to corrosion | High |

| Aluminum | Aerospace and transportation applications | Lightweight and corrosion resistant | Lower strength compared to steel | Medium |

| Polycarbonate | Safety glasses and machine guards | Impact resistance | Scratches easily | Low |

| Bronze | Marine bearings and components | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

The detailed overview of materials above equips international buyers with actionable insights necessary for making informed decisions when balancing performance and cost in maintaining circularity and cylindricity in their engineering applications.

In-depth Look: Manufacturing Processes and Quality Assurance for circularity vs cylindricity

What are the Key Manufacturing Processes Involved in Achieving Circularity and Cylindricity?

The manufacturing processes that ensure precision in achieving circularity and cylindricity differ in complexity and technique, depending on the final product’s specifications. An understanding of these processes is essential for B2B buyers who want to ensure that suppliers meet stringent tolerances.

Material Preparation: How does it Impact Circularity and Cylindricity?

The journey to achieving circularity and cylindricity begins with proper material selection and preparation. This stage often involves:

-

Material Selection: Choosing the right materials is crucial as metals, plastics, or composites exhibit different machinability and thermal properties. Stainless steel, for instance, is commonly used for parts that require high resistance to wear but may be more challenging to machine accurately.

-

Cutting and Shaping: Techniques like turning, milling, and grinding help shape material into a rough form close to the desired circular profile. For instance, turning is used to create cylindrical shapes, while grinding can refine these shapes to meet strict tolerances.

-

Heat Treatment: Often, materials undergo heat treatment processes to enhance their hardness and durability. This process can also influence dimensions; thus, understanding how it affects the final shape is essential.

What Forming Techniques Ensure the Desired Specifications?

Once prepared, the forming stage employs various techniques to mold the material into its final shape.

-

Turning: This machining process rotates the workpiece while a cutting tool shapes it into a cylindrical form. It is particularly effective for achieving excellent cylindrical features.

-

Extrusion and Injection Molding: For non-metallic components, these techniques can be utilized. Extrusion pushes material through a die to create long shapes, while injection molding forces molten material into a mold.

-

Precision Grinding: To meet stringent cylindrical specifications, precision grinding is often used as a finishing step. This method allows for a high degree of accuracy and surface finish.

How are Assembly Processes Incorporated in Circularity and Cylindricity?

In assembly, ensuring circularity and cylindricity can be critical when parts interact mechanically.

-

Fixtures and Jigs: Using precision fixtures helps in maintaining the positions of parts during assembly, ensuring that cylindrical components fit together without issues.

-

Dynamic Balancing: For rotating parts such as shafts, dynamic balancing is essential to minimize vibration and wear, thus maintaining their function and longevity.

What are the Key Quality Assurance Measures for Circularity and Cylindricity?

Quality assurance processes must align with international and industry standards to guarantee that the manufacturing meets specified tolerances for circularity and cylindricity.

Which International Standards Should B2B Buyers Consider?

International standards act as benchmarks for ensuring quality and consistency. Buyers should pay attention to:

-

ISO 9001: This standard specifies requirements for a quality management system, emphasizing consistent quality. Implementing ISO 9001 can assure buyers of the reliability in the manufacturing processes.

-

Industry-Specific Standards: Beyond ISO, buyers should consider specific certifications like CE for European manufacturers or API for oil and gas components, which can indicate adherence to industry-specific quality measures.

How Do Quality Control Checkpoints Function in Manufacturing?

Quality control (QC) is integral in every stage of manufacturing. Here are essential checkpoints:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components to ensure they meet the required specifications before entering production.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing measurements and inspections ascertain that tolerances concerning circularity and cylindricity are maintained throughout the production process. This may include real-time data collection and monitoring systems.

-

Final Quality Control (FQC): After production, components undergo final inspections to verify all attributes, including their cylindrical form. Measurement tools or gauges may be used to confirm compliance prior to shipping.

What Testing Methods Are Commonly Used to Ensure Compliance with Circularity and Cylindricity?

Testing methods for circularity and cylindricity can vary, but several tools and techniques are considered industry best practices:

-

Coordinate Measuring Machines (CMM): These high-precision instruments measure the physical geometrical characteristics of an object. They can determine circularity and cylindricity accurately across a 3D space.

-

Laser Scanning: Utilizing laser technology, manufacturers can assess the shape of components and collect data that represent their form, highlighting deviations from the intended shape.

-

Roundness Testers: Designed specifically for measuring circularity, these devices rotate parts against a fixed probe to assess deviations from perfect roundness.

How Can B2B Buyers Verify the Quality Control of Their Suppliers?

B2B buyers must take proactive steps to ensure the quality claims of suppliers. Consider the following strategies:

-

Supplier Audits: Conducting audits allows buyers to verify suppliers’ adherence to manufacturing and quality standards. These audits should include reviews of records related to IQC, IPQC, and FQC processes.

-

Requesting Quality Reports: Regular quality reports provide insights into previous production runs, revealing trends and compliance with circularity and cylindricity tolerances.

-

Third-Party Inspections: Engaging independent inspection services can help validate the quality of a supplier’s processes and outputs, especially for international transactions where regulations may differ.

What Unique QC Considerations Are Important for International B2B Buyers?

International clients, particularly those from diverse markets such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances:

-

Regulatory Compliance: Different regions might have distinct regulations affecting manufacturing standards. It’s critical for buyers to ensure that products meet local regulations, especially for industries like automotive or aerospace.

-

Cross-Cultural Communication: Clear communication regarding specifications and quality expectations can mitigate misunderstandings. Utilizing local representatives who understand cultural nuances can enhance supplier relationships.

-

Documentation and Certification: Ensure that suppliers provide complete documentation, including material certificates, testing results, and compliance certifications, to verify the integrity of the manufacturing process.

Conclusion

Ensuring circularity and cylindricity in manufactured products involves a complex interplay of meticulous manufacturing processes and stringent quality assurance measures. By understanding these elements, B2B buyers can make informed decisions, secure reliable suppliers, and ensure that their procurement aligns with their operational needs and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘circularity vs cylindricity’

To effectively source components that meet the requirements for circularity and cylindricity, it’s essential to follow a systematic approach. This step-by-step checklist is designed to guide international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, through the procurement process, ensuring that the components meet quality and specification needs.

Step 1: Define Your Technical Specifications

Clearly articulate your product requirements regarding circularity and cylindricity. This includes tolerances, the dimensions of the cylindrical parts, and how these specifications relate to the function of the final product. Make sure to reference applicable industry standards to provide context for local suppliers.

- Example Specifications: Clearly note if a specific cylindricity tolerance is needed (e.g., 0.004mm for a shaft).

- Application Context: Identify how deviations might affect product performance, such as in rotating machinery.

Step 2: Research Potential Suppliers

Conduct comprehensive research to identify suppliers with experience in producing components that meet circularity and cylindricity standards. Focus on their industry reputation, certification status, and previous projects.

- Supplier Reputation: Look for reviews, testimonials, or feedback from other B2B buyers.

- Certifications: Ensure suppliers have relevant certifications like ISO 9001 for quality management systems.

Step 3: Evaluate Supplier Capabilities

Assess whether potential suppliers possess the technology and equipment necessary to achieve the required tolerances. Capabilities in precision manufacturing, measurement, and quality control are critical.

- Technology Check: Investigate if the supplier uses advanced measurement techniques like coordinate measuring machines (CMM) for quality assurance.

- Capacity and Scalability: Confirm that the supplier can handle your volume requirements and any potential adjustments in order size.

Step 4: Request Test Samples

Before placing a bulk order, request samples of the components to evaluate their conformity to your specifications. This offers a practical insight into the supplier’s precision and how their products perform in real scenarios.

- Sample Evaluation: Analyze the samples for both circularity and cylindricity using appropriate measurement tools.

- Feedback Mechanism: Provide feedback to the supplier on the samples, discussing any discrepancies with tolerances.

Step 5: Verify Supplier Quality Management Practices

Inquire about the quality assurance processes that suppliers implement for continuous improvement. This ensures that they maintain consistency in producing components that meet your specified tolerances.

- Quality Control Procedures: Check for established QC protocols and traceability in their manufacturing processes.

- Regular Audits: Understand how frequently they conduct internal audits and their response to quality issues.

Step 6: Engage in Open Communication

Maintain ongoing dialogue with your suppliers during the sourcing process. Clear communication can help resolve any misunderstandings regarding specifications or expectations right from the start.

- Clarification of Terms: Discuss the definitions and implications of terms like circularity and cylindricity to ensure both parties are aligned.

- Collaboration on Adjustments: Be open to collaborating on feasible changes to specifications if necessary.

Step 7: Review Contracts Carefully

Before finalizing your purchase, review contracts meticulously. Ensure that they clearly specify the tolerances for circularity and cylindricity, delivery timelines, payment terms, and dispute resolution mechanisms.

- Detail Orientation: Check that the expressed tolerances are measurable and realistic.

- Legal Safeguards: Include terms that protect your interests in cases of non-compliance with the specified tolerances.

Following these steps will enhance the efficiency of sourcing processes and ensure that the components you procure meet the stringent requirements of circularity and cylindricity crucial for product performance.

Comprehensive Cost and Pricing Analysis for circularity vs cylindricity Sourcing

When sourcing components that require precision tolerances such as circularity and cylindricity, understanding the comprehensive cost structure and influencing pricing factors is crucial for B2B buyers. This intersection of engineering design and procurement requires careful consideration of various elements within the pricing framework.

What are the primary cost components for circularity vs. cylindricity sourcing?

The costs incurred can be categorized into several components:

-

Materials: The choice of materials greatly impacts pricing. For components that require high circularity or cylindricity, metals or specialized polymers are often more expensive. Understanding the implications of material selection can lead to more competitive pricing.

-

Labor: Skilled labor is needed for the precise manufacturing of parts. The complexity of achieving tight tolerances can lead to higher labor costs, especially when manual intervention is required in quality checks or adjustments during machining.

-

Manufacturing Overhead: This includes costs associated with utilities, maintenance, and facility management. For processes requiring higher precision, the overhead can be a significant contributor to overall costs.

-

Tooling: High-quality tooling is essential for maintaining tolerances. Although initial setups may incur higher costs, efficient and precise tooling can reduce production time and waste, thus, potentially lowering per-unit costs in larger volume orders.

-

Quality Control (QC): Implementing rigorous QC processes is indispensable when tolerances such as circularity and cylindricity are critical to component function. The costs associated with measuring equipment and personnel for quality inspections add to the total expenditure.

-

Logistics: International shipping, especially between regions like Africa, South America, and Europe, can introduce substantial logistics costs, varying significantly based on the destination, mode of transport, and Incoterms chosen.

-

Margin: Supplier margins vary based on capabilities, reputation, and quality guarantees. Suppliers with extensive experience in achieving difficult tolerances may justify higher markup to reflect their added value.

What factors influence the pricing of circularity vs. cylindricity components?

Pricing is not solely dictated by the above cost components; numerous factors can influence final costs:

-

Volume/MOQ: Suppliers often offer tiered pricing based on order volume. Higher volumes usually lead to a lower cost per unit due to economies of scale, whereas small orders might incur setup charges that inflate unit costs.

-

Specifications and Customization: Custom designs that require unique tolerances can lead to increased costs. Buyers should clarify specifications upfront to avoid unexpected charges later in the production process.

-

Quality and Certifications: Certification to international quality standards, such as ISO or AS9100, can influence both the cost and supplier selection. Buyers should weigh the benefits of certified suppliers against their budgets.

-

Supplier Factors: The supplier’s geographic location, technological prowess, and logistics capabilities can substantially affect pricing. Establishing a relationship with local suppliers may reduce shipping times and tariffs, particularly for regional markets.

-

Incoterms: The choice of Incoterms directly impacts logistics and responsibility across the supply chain. Terms such as CIF or DDP can shift the costs associated with transport and insurance, impacting the overall price.

How can B2B buyers negotiate for better pricing?

Effective negotiation strategies can significantly enhance cost-efficiency:

-

Understand Total Cost of Ownership (TCO): Buyers should consider not just the purchase price but also long-term operational costs. Components with higher precision may reduce maintenance and operational failures, warranting a higher upfront investment.

-

Leverage volume: By projecting future needs and consolidating orders, buyers can create a strong case for competitive pricing.

-

Engage in multi-year contracts: Suppliers may offer favorable terms for long-term commitments, translating to lower costs over time.

-

Benchmark against market rates: Having a clear understanding of prevailing market prices facilitates more informed negotiation discussions.

By considering these factors and strategies, international B2B buyers can navigate the complexities of sourcing components that adhere to circularity and cylindricity tolerances, ensuring both competitive pricing and adherence to quality standards. Buyers should keep in mind that indicative prices can fluctuate based on current market conditions, material availability, and specific supplier circumstances.

Alternatives Analysis: Comparing circularity vs cylindricity With Other Solutions

Introduction: Understanding Alternatives in Circularity and Cylindricity

When evaluating features like circularity and cylindricity in manufacturing processes, it is essential to consider alternative solutions that deliver similar results. These alternatives not only expand the capacity to achieve high-quality tolerances but also provide diverse approaches tailored to specific operational needs. Here, we compare circularity and cylindricity with two viable alternatives: runout measurement and profile tolerance, highlighting their unique attributes and applications.

| Comparison Aspect | Circularity Vs Cylindricity | Runout Measurement | Profile Tolerance |

|---|---|---|---|

| Performance | High for roundness and axis | Good for positional accuracy | Excellent for complex shapes |

| Cost | Moderate | Low to moderate | Higher due to complexity |

| Ease of Implementation | Moderate | Easy | Complex |

| Maintenance | Low | Low | Moderate |

| Best Use Case | Critical cylindrical features | Rotating elements (e.g., shafts) | Irregular shapes needing form control |

How Does Runout Measurement Differ from Circularity and Cylindricity?

Runout measurement evaluates the total variation of a surface as it rotates around an axis. It combines attributes of circularity and straightness, making it ideal for assessing the integrity of parts like shafts and rotors in automotive and aerospace applications.

Pros:

– Cost-effective and straightforward to implement.

– Provides a comprehensive picture of a cylindrical part by measuring both circularity and deviation.

Cons:

– Less stringent than circularity and cylindricity; may overlook finer details needed for critical parts.

– Primarily focused on rotation, limiting its applicability in non-rotational contexts.

In What Scenarios is Profile Tolerance More Effective than Circularity or Cylindricity?

Profile tolerance offers a versatile way to control the shape of a feature across three dimensions. This method is useful in applications requiring complex geometries, such as molds or intricate body structures in automotive manufacturing.

Pros:

– Accommodates irregular shapes and offers design flexibility.

– Can control multiple dimensions simultaneously, enhancing quality across different features.

Cons:

– Often more costly due to complex setups and measurements.

– May require more advanced measuring equipment and skilled personnel to interpret results accurately.

Conclusion: Which Solution Should a B2B Buyer Choose for Their Needs?

Selecting the right solution between circularity, cylindricity, and their alternatives largely depends on the specific application and technical requirements of the component being manufactured. For high-precision cylindrical parts, circularity and cylindricity provide rigorous standards that ensure functionality and performance. In contrast, runout measurement simplifies the complexity of checking cylindrical features while profile tolerance is key for parts with intricate outlines. B2B buyers should assess their unique production capabilities, budget, and intended end-use of components when making a decision, ensuring the selected approach aligns with quality standards and operational efficiency.

Essential Technical Properties and Trade Terminology for circularity vs cylindricity

What Are the Key Technical Properties of Circularity and Cylindricity?

1. Tolerance Levels

Tolerance is a crucial specification that indicates the permissible limit of variation in a manufactured part. For circularity, this is expressed as a two-dimensional tolerance zone between two concentric circles, while for cylindricity, it is a three-dimensional zone between two concentric cylinders. Understanding and applying the appropriate tolerance levels ensures parts fit together smoothly, which is essential for functionality, reducing wear and failure risks, especially in applications such as bearings, shafts, and pins.

2. Material Grade

The material grade of components significantly impacts their performance against geometric tolerances like circularity and cylindricity. High-grade materials often exhibit superior dimensional stability, enabling them to better maintain their intended form despite manufacturing processes. Selecting the right material grade can enhance a product’s durability and longevity, important factors for B2B buyers concerned with quality and reliability.

3. Measurement Methods

Accurate measurement is integral to achieving circularity and cylindricity. Techniques such as rotating a part on a turntable with a gauge probe are standard methods for verifying circularity. In contrast, cylindricity requires measuring along the entire length of a cylindrical part. Familiarity with these measurement methods allows B2B companies to specify their quality assurance processes effectively, ensuring adherence to industry standards.

4. Functional Requirements

In B2B settings, understanding how circularity and cylindricity influence functional requirements is crucial. For example, in components like fuel injector nozzles or hydraulic cylinders, precision in geometry directly correlates to performance. Manufacturers must clearly specify transactional requirements to prevent cost overruns or performance failures, significantly impacting operational efficiency.

5. Cost Implications

The degree of circularity or cylindricity required can influence production costs. Higher precision often leads to more expensive manufacturing processes. As B2B buyers negotiate prices, they must weigh the need for perfection in shape against their budget constraints, ensuring that the product’s performance justifies the expenditure.

What Are Common Trade Terms Relevant to Circularity and Cylindricity?

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for B2B buyers, as it affects supply chain reliability and product compatibility.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest amount of a product that a supplier is willing to sell. Knowing the MOQ is important for procurement strategies, as it can dictate inventory costs and affect project budgets.

3. RFQ (Request for Quotation)

A request for quotation is a document sent to suppliers to solicit pricing and availability for products or services. B2B buyers utilize RFQs to secure competitive pricing, helping streamline purchasing decisions particularly when specifying parts with geometric tolerances like circularity and cylindricity.

4. Incoterms

These are international commercial terms that define the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms ensures clarity in logistics, pricing, and liabilities in global transactions involving cylindrical parts, which may be subject to stringent transport regulations.

5. CAD (Computer-Aided Design)

CAD software is essential in the design phase for parts that necessitate specific geometric tolerances. Understanding how to use CAD tools effectively allows B2B buyers to ensure that designs comply with circular and cylindrical specifications before manufacturing commences.

6. Tolerance Stack-Up Analysis

This process assesses the cumulative effect of individual tolerances on overall assembly fit and function. For B2B buyers, mastering this analysis is critical for ensuring that series of components, particularly those utilizing circularity and cylindricity tolerances, will function harmoniously when assembled.

Navigating Market Dynamics and Sourcing Trends in the circularity vs cylindricity Sector

Understanding the Market Dynamics in Circularity vs. Cylindricity

What Are the Global Drivers and Key Trends Affecting B2B Buyers?

In the ever-evolving landscape of manufacturing and engineering, the distinction between circularity and cylindricity is becoming a focal point for companies committed to precision and quality. Global drivers such as increasing automation, advancements in manufacturing technology, and a rising demand for high-quality components are reshaping the sourcing dynamics. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, evaluate sourcing strategies, a notable trend is the push for enhanced product specifications that blend both circular and cylindrical characteristics. Technologies like Artificial Intelligence and IoT are facilitating real-time monitoring and quality assessments, ensuring manufacturers achieve those stringent tolerances more consistently.

Another emerging trend is the integration of virtual simulation and digital twin technologies. These innovations allow companies to design and test components virtually, significantly reducing waste and enhancing the overall efficiency of production cycles. Furthermore, geopolitical factors and supply chain disruptions are prompting buyers to reconsider their procurement strategies, focusing on establishing local partnerships or diversifying suppliers to mitigate risks. This trend aligns well with the requirement for flexibility in production processes, a key aspect in balancing circularity and cylindricity in engineering design.

How Important Is Sustainability and Ethical Sourcing in Today’s B2B Environment?

Sustainability is no longer just a buzzword; it is a fundamental component influencing sourcing decisions across industries. In the context of circularity and cylindricity, the environmental impact of manufacturing processes has spurred a demand for ethical supply chains. Buyers are increasingly scrutinizing the sources of their raw materials and opting for suppliers who demonstrate a commitment to sustainable practices and materials. This includes the use of recycled metals and certified green materials, which contribute to lower carbon footprints and reduced waste in production.

The importance of ‘green’ certifications is another critical aspect of this trend. B2B buyers are placing significant value on certifications such as ISO 14001, which reflect a company’s commitment to environmental management. Furthermore, companies adopting circular economy principles are viewed favorably, as these practices focus on maximizing resource efficiency and minimizing ecological impact throughout the product lifecycle. By prioritizing these sustainability metrics, buyers not only enhance the ecological integrity of their operations but also align themselves with increasingly discerning consumers who value responsible production.

What Is the Brief Evolution and Historical Context of Circularity and Cylindricity in B2B?

The concepts of circularity and cylindricity have evolved significantly over the decades, largely driven by advances in manufacturing capabilities and heightened quality expectations. Historically, circularity pertains specifically to the roundness of a part, often relevant in industries where precise fit is crucial, such as in components for automotive or aerospace applications. Cylindricity, which incorporates both the roundness and straightness of a cylindrical feature, emerged as manufacturing processes advanced to ensure comprehensive control over the geometric form of a part.

In the B2B context, the historical reliance on traditional inspection methods has evolved toward sophisticated technology-driven alternatives, which provide vastly improved accuracy and efficiency. The integration of geometric dimensioning and tolerancing (GD&T) into design processes has enabled more stringent controls, which are vital for ensuring parts meet performance standards. Today, companies are continuously adjusting their design and manufacturing protocols, recognizing the critical need for precision in an increasingly competitive marketplace. This evolution not only supports enhanced product performance but also drives innovation within supply chains, as businesses strive for optimal balance between performance metrics and sustainable practices.

Frequently Asked Questions (FAQs) for B2B Buyers of circularity vs cylindricity

-

How do I ensure the right tolerances for my cylindrical parts?

To ensure the correct tolerances for cylindrical parts, you first need to clearly define your functional requirements. Assess whether circularity or cylindricity is needed based on the part’s application; use circularity for roundness and cylindricity for both roundness and straightness along an axis. Collaborate with your engineering team to set appropriate GD&T callouts. Consider the manufacturing process when setting tolerances, as tighter tolerances often increase costs. Partner with suppliers who understand these requirements and can provide compliant parts consistently. -

What is the best way to measure circularity or cylindricity in my products?

The best method to measure circularity is through a coordinate measuring machine (CMM) that rotates the part to record surface variations across multiple cross-sections. For cylindricity, use a similar approach but focus on measuring the entire length of the cylindrical feature, ensuring all surface points fall within the specified tolerance zone defined by two concentric cylinders. Depending on your budget and volume needs, opt for either high-resolution metrology equipment or simpler gauge setups, considering the trade-offs in cost and accuracy. -

What considerations should I have when sourcing suppliers for circularity and cylindricity tolerances?

When sourcing suppliers, verify their capability to meet your specified tolerances consistently. Look for manufacturers with experience in your industry, as they can better anticipate challenges related to tolerances. Ask for case studies or testimonials from buyers in similar regions like Africa, South America, or Europe. Request samples and run small batch tests to assess quality firsthand. Ensure that they provide clear documentation of quality assurance practices, including the measurement processes for circularity and cylindricity. -

Can I customize the tolerances for circularity and cylindricity in my order?

Yes, most reputable manufacturers offer customization of tolerances based on your project specifications. When placing an order, provide detailed engineering drawings and clearly define the desired tolerances for both circularity and cylindricity. Discuss with suppliers the feasibility of your customizations, as certain manufacturing processes may limit achievable tolerances. Ensure these details are included in your contract to avoid misunderstandings and verify that suppliers can consistently deliver according to your specifications. -

What are typical minimum order quantities (MOQs) for parts with circularity and cylindricity specifications?

Minimum order quantities vary widely depending on the supplier and part complexity. Generally, MOQs may range from 100 to 1,000 pieces for standard components; however, more complex parts requiring high tolerances may have higher MOQs. When negotiating, communicate your forecasted volume and any flexibility you may have to minimize costs. Suppliers may also offer tiered pricing based on order quantity, which can be advantageous. It’s important to secure your requirements early to align production schedules. -

How can I negotiate better payment terms with my suppliers?

To negotiate favorable payment terms, establish a strong relationship with your supplier, backed by a history of transparent communication. Propose terms that align with your cash flow cycles, such as net 30 or net 60 days. Offer to make down payments for large orders to mitigate supplier risk. Additionally, consider discussing discounts for early payments or larger bundles. Ensure that these terms are documented clearly in your purchase agreements to avoid any misunderstandings. -

What quality assurance practices should I look for in suppliers working with circularity and cylindricity?

Look for suppliers that implement robust quality assurance measures, such as ISO certification and documented inspection processes. They should have a clear methodology for measuring and verifying tolerances related to circularity and cylindricity. Ask if they use calibrated measuring equipment and provide traceability for measurement standards, as well as inspection reports for every batch. Strong QA practices not only ensure compliance with your specifications but also reduce the risk of defects that could lead to higher costs and production delays. -

How does logistics impact the procurement of cylindrical parts with specific tolerances?

Logistics plays a crucial role in the procurement of cylindrical parts with specific tolerances. Delays can arise from complex supply chains, especially when transporting goods internationally. Consider transport times, customs regulations, and potential fees when choosing suppliers. To mitigate risks, work with suppliers located closer to your operation or employ reliable logistics partners that can offer real-time tracking. Additionally, maintaining a safety stock can help buffer against delays and ensure that production schedules aren’t disrupted.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Circularity Vs Cylindricity Manufacturers & Suppliers List

1. GD&T Basics – Cylindricity Tolerance

Domain: gdandtbasics.com

Registered: 2014 (11 years)

Introduction: Cylindricity Symbol: Indicates how closely an object conforms to a true cylinder. It is a 3-Dimensional tolerance controlling the overall form of a cylindrical feature, ensuring it is round and straight along its axis. Independent of any datum feature, tolerance must be less than the diameter dimensional tolerance of the part. It encompasses two concentric cylinders that run the entire length of t…

2. Fractory – Cylindricity Tolerance Solutions

Domain: fractory.com

Registered: 2000 (25 years)

Introduction: Cylindricity is a GD&T (Geometric Dimensioning and Tolerancing) tolerance that ensures a part’s cylindrical shape by controlling roundness and axis straightness. It defines a tolerance zone represented by two concentric cylinders, thereby constraining the entire surface of the part. Unlike circularity, which applies to single cross-sections, cylindricity applies to all cross-sections of the part, …

3. CrossCo – Essential Geometric Tolerances

Domain: crossco.com

Registered: 1997 (28 years)

Introduction: The article discusses various geometric tolerances including roundness, cylindricity, coaxiality, concentricity, runout, and total runout, which are essential for controlling radial deviations in parts with a round cross-section. It emphasizes the significance of these measurement parameters in engineering and precision manufacturing. Cross offers an experienced inspection team to assist with meas…

4. Reddit – Circularity & Cylindricity Explained

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – Circularity & Cylindricity Explained, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. RedLux – Cylindricity Measurement Solutions

Domain: redlux.net

Registered: 2005 (20 years)

Introduction: Cylindricity is a measure used in GD&T (Geometric Dimensioning and Tolerancing) to control the form of cylindrical shafts or holes, requiring that their form does not deviate from an ideal cylinder beyond a specified tolerance. The cylindricity symbol, found in the feature control frame on drawings or 3D CAD models, consists of a circle with two oblique lines on either side. It applies to the full…

6. eMachineShop – Cylindricity Tolerance Solutions

Domain: emachineshop.com

Registered: 1999 (26 years)

Introduction: Cylindricity tolerance is used for cylindrical part features requiring good circularity and straightness, such as pins or camshafts. Unlike circularity, which applies to cross sections, cylindricity applies to the entire surface, and does not need to be related to a datum. It is quantified by requiring that the surface lies between two concentric cylinders spaced a specified distance apart (e.g., …

7. Eng-Tips – Geometric Tolerances in Mechanical Engineering

Domain: eng-tips.com

Registered: 1997 (28 years)

Introduction: The discussion focuses on the effects of straightness on circularity and cylindricity, with specific mentions of maximum errors for circularity (0.4) and cylindricity (0.8). The thread is based on geometric tolerances in mechanical engineering, particularly on how these tolerances relate to each other in the context of manufacturing precision. Members discuss the implications of straightness contr…

8. Practical Machinist – Cylindricity Measurement Insights

Domain: practicalmachinist.com

Registered: 2000 (25 years)

Introduction: This company, Practical Machinist – Cylindricity Measurement Insights, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for circularity vs cylindricity

In navigating the complexities of circularity and cylindricity, international B2B buyers can glean critical insights for enhancing product quality and manufacturing efficiency. Circularity, focusing on the roundness of individual features, is vital for components such as bearings where precision is crucial to prevent wear and tear. Meanwhile, cylindricity governs the overall form of cylindrical parts, ensuring both straightness and roundness, ultimately supporting better fit and function in assemblies.

For businesses sourcing components, understanding these tolerances empowers strategic decision-making, leading to optimized designs, reduced scrap rates, and improved supply chain efficiency. By integrating these geometric dimensioning and tolerancing (GD&T) principles into sourcing strategies, companies can gain a competitive edge, particularly in regions like Africa, South America, the Middle East, and Europe, where manufacturing technologies continue to evolve rapidly.

Looking ahead, it is imperative for B2B buyers to engage with suppliers offering expertise in technology and materials that ensure compliance with stringent circularity and cylindricity standards. This collaboration will not only maximize the reliability of products but also facilitate sustainable practices within the manufacturing ecosystem. Embrace this opportunity to elevate your sourcing strategy—invest in quality today for a more resilient tomorrow.