Introduction: Navigating the Global Market for chrome stripping service

In today’s rapidly evolving global market, sourcing reliable chrome stripping services can be a significant challenge for B2B buyers. Companies in diverse industries—from automotive to aerospace—often require effective de-plating solutions to refurbish components and extend their lifespan. This guide aims to demystify the chrome stripping process, providing essential insights into various techniques, applications, and the nuances of selecting the right service provider.

As you navigate this comprehensive resource, you will discover a wealth of information on the different types of chrome stripping methods available, including chemical, mechanical, and environmentally friendly solutions. We will also explore critical applications across industries, ensuring you understand when and why each method is appropriate. Additionally, this guide includes practical advice on supplier vetting, enabling you to identify credible partners who can meet your quality and compliance standards.

Furthermore, we will break down cost considerations, helping you make informed decisions that align with your budgetary constraints. By equipping international B2B buyers—especially those from Africa, South America, the Middle East, and Europe, including markets like Saudi Arabia and Brazil—with actionable knowledge, this guide empowers you to optimize your sourcing strategy and enhance operational efficiency. Whether you are looking to streamline production processes or ensure quality in refurbishment projects, understanding the nuances of chrome stripping services is crucial for your success.

Understanding chrome stripping service Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electrolytic Deplating | Uses electrical current to reverse plating, effective for metals. | Automotive parts, industrial machinery | Pros: Precise, minimizes base metal damage. Cons: Requires expertise, can be slow for thick layers. |

| Chemical Stripping | Utilizes chemical solutions to dissolve chrome, quick and efficient. | Electronics, decorative items, automotive | Pros: Fast, effective for complex shapes. Cons: May require safety precautions, potential environmental impact. |

| Mechanical Stripping | Involves abrasive methods like sanding or blasting. | Heavy machinery, tools, and equipment | Pros: Immediate results, effective for thick coatings. Cons: Risk of damaging underlying surfaces. |

| Plastic Chrome Deletion | Specialized for plastic surfaces, preserves base material. | Automotive trims, consumer goods | Pros: Non-damaging, quick preparation for painting. Cons: Limited to specific applications, may require multiple applications. |

| Acid Dipping | Submerges parts in acid solutions to remove chrome. | Aerospace components, high-precision parts | Pros: Thorough removal, ideal for complex geometries. Cons: Requires handling precautions, may affect surface finish. |

What are the Characteristics and Suitability of Electrolytic Deplating?

Electrolytic deplating is a highly specialized method that employs electrical currents to reverse the electroplating process. This technique is particularly suitable for metal components where precision is paramount, such as automotive and industrial machinery parts. B2B buyers should consider the expertise required for this method, as improper execution can damage the base metal. However, its ability to selectively strip plating without harming the substrate makes it an attractive option for high-value components.

How Does Chemical Stripping Compare for Industrial Applications?

Chemical stripping utilizes specially formulated solutions to dissolve chrome plating effectively. This method is favored in industries like electronics and automotive, where intricate shapes and designs are common. Buyers should weigh the speed and efficiency of this process against the potential environmental implications and safety measures necessary when handling chemicals. While it offers rapid results, it may necessitate additional steps to ensure compliance with environmental regulations.

When is Mechanical Stripping the Best Choice?

Mechanical stripping employs abrasive techniques such as sanding, blasting, or grinding to remove chrome coatings. This method is particularly effective for heavy-duty applications, including tools and machinery, where quick and aggressive removal is needed. B2B purchasers must consider the potential for surface damage, as this method can affect the integrity of the underlying material. However, its immediate results make it suitable for projects requiring rapid turnaround.

What are the Advantages of Plastic Chrome Deletion?

Plastic chrome deletion is a specialized service designed for chrome removal from plastic surfaces without damaging the underlying material. This method is ideal for automotive trims and consumer goods, where aesthetics and surface integrity are essential. Buyers should appreciate its efficiency and the readiness it provides for subsequent painting processes. However, it is limited to specific applications and may require multiple treatments for complete removal.

How Effective is Acid Dipping for Complex Geometries?

Acid dipping involves submerging parts in corrosive solutions to remove chrome plating thoroughly. This method is particularly effective for complex geometries found in aerospace and high-precision components. While it offers comprehensive removal, buyers must be aware of the necessary safety precautions and the potential impact on the surface finish. Its thoroughness makes it a preferred choice for detailed applications, albeit with considerations for handling and post-treatment finishing.

Key Industrial Applications of chrome stripping service

| Industry/Sector | Specific Application of chrome stripping service | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Restoration of chrome-plated components | Enhances vehicle aesthetics and extends component life | Quality of stripping process, turnaround time, environmental compliance |

| Aerospace | Maintenance of aircraft parts | Ensures safety and compliance with aviation standards | Certifications, precision in stripping, and damage prevention |

| Electronics | Refurbishment of electronic casings | Improves performance and appearance of electronic devices | Compatibility with sensitive materials, eco-friendly solutions |

| Manufacturing & Heavy Machinery | Repair of worn-out machinery parts | Reduces operational downtime and costs | Expertise in handling various metal types, scalability of service |

| Furniture & Home Decor | Restoration of chrome-plated furniture | Revives aesthetics and increases product lifespan | Customization options, handling of delicate designs |

How is Chrome Stripping Service Applied in the Automotive Industry?

In the automotive sector, chrome stripping services are essential for restoring chrome-plated components such as bumpers, wheels, and trim. This process not only enhances the vehicle’s aesthetics but also extends the life of these components by allowing for repairs and refinishing. B2B buyers must ensure the service provider maintains high-quality standards to prevent damage to underlying materials. Additionally, turnaround times are critical, especially in markets like Brazil and South Africa, where vehicle restoration can be time-sensitive.

What Role Does Chrome Stripping Play in Aerospace Maintenance?

The aerospace industry relies on chrome stripping services for the maintenance of aircraft parts, where chrome plating is common for its corrosion resistance. Stripping these components is crucial for inspections, repairs, and re-coating to ensure compliance with stringent aviation safety standards. Buyers in this sector should prioritize suppliers with relevant certifications and experience in handling aerospace materials, ensuring that the stripping process does not compromise the integrity of the parts.

How is Chrome Stripping Used in Electronics Refurbishment?

In electronics, chrome stripping is applied to refurbish electronic casings that may have chrome finishes. This service improves both the performance and appearance of devices by preparing surfaces for new coatings. International buyers should seek providers that specialize in eco-friendly stripping solutions, as many electronic components are sensitive to harsh chemicals. Additionally, understanding the compatibility of stripping processes with various materials is vital for successful outcomes.

What Benefits Does Chrome Stripping Offer to Manufacturing & Heavy Machinery?

For the manufacturing and heavy machinery sectors, chrome stripping services are vital for repairing worn-out parts, such as hydraulic cylinders and pumps. This process reduces operational downtime and maintenance costs by allowing for the effective restoration of components. B2B buyers should consider suppliers that can handle a variety of metal types and offer scalable services to meet production demands, particularly in regions with growing industrial bases like the Middle East.

How Can Chrome Stripping Revitalize Furniture and Home Decor?

In the furniture and home decor industry, chrome stripping is used to restore chrome-plated furniture pieces, giving them a new lease on life. This service not only enhances the visual appeal but also increases the lifespan of products, making them more attractive to consumers. Buyers should look for customization options and ensure that the service provider is skilled in handling delicate designs, particularly in markets across Europe where design quality is paramount.

3 Common User Pain Points for ‘chrome stripping service’ & Their Solutions

Scenario 1: Inconsistent Quality in Chrome Stripping Results

The Problem: B2B buyers often encounter inconsistent quality when sourcing chrome stripping services. This inconsistency may arise from varying levels of expertise among service providers or differences in stripping methods and chemicals used. For companies that rely on precise specifications, such as automotive manufacturers or restoration specialists, uneven results can lead to costly rework, delays, and dissatisfaction from end clients. A product that emerges with uneven surfaces or residual chrome can compromise the integrity of subsequent coatings or finishes.

The Solution: To ensure consistent quality in chrome stripping, buyers should prioritize service providers with a proven track record and established industry standards. Begin by requesting detailed case studies or examples of previous work to gauge their expertise. It’s beneficial to look for companies that utilize advanced stripping technologies, such as environmentally friendly chemical solutions that minimize damage to the substrate. Furthermore, buyers should specify their requirements clearly, including desired surface finish and any particular considerations regarding the base material. Regular quality checks and open communication during the stripping process can also help mitigate inconsistencies.

Scenario 2: Environmental Compliance and Safety Concerns

The Problem: Many B2B buyers are increasingly concerned about the environmental impact and safety of chrome stripping processes, especially given the stringent regulations in regions such as Europe and North America. Traditional stripping methods often involve hazardous chemicals that can pose risks to workers and the environment, leading to potential legal liabilities and increased scrutiny from regulatory bodies. Buyers may struggle to find suppliers who adhere to sustainable practices while still delivering effective results.

The Solution: To address these concerns, buyers should focus on sourcing chrome stripping services that prioritize eco-friendly practices. Look for providers that utilize non-toxic, biodegradable stripping agents that comply with international safety standards. Request information about their waste disposal methods and any certifications they may hold regarding environmental management. Additionally, consider implementing a vendor evaluation process that includes an assessment of sustainability practices. Engaging in partnerships with companies committed to reducing their environmental footprint not only aligns with corporate social responsibility goals but can also enhance brand reputation.

Scenario 3: Turnaround Time and Project Delays

The Problem: Timeliness is critical for many B2B projects, particularly in industries like automotive or aerospace, where delays can cascade through the supply chain. Buyers often face challenges with chrome stripping services that do not meet expected turnaround times, which can result in stalled production schedules and financial losses. Unforeseen issues during the stripping process, such as complex geometries or unexpected thickness of plating, can further complicate and prolong timelines.

The Solution: To mitigate delays, buyers should establish clear timelines and expectations with their chosen chrome stripping service provider. Before initiating a project, conduct a thorough assessment of the components needing treatment, and communicate any complexities upfront. Service providers should be encouraged to share their process timelines and any potential risks involved. Furthermore, consider selecting partners who offer expedited services or have a flexible capacity to handle urgent requests. Building a strong relationship with the service provider can facilitate quicker resolution of issues and ensure that both parties remain aligned on project milestones.

Strategic Material Selection Guide for chrome stripping service

What Are the Key Materials Used in Chrome Stripping Services?

When selecting materials for chrome stripping services, it’s essential to consider their properties, advantages, disadvantages, and compatibility with various applications. Below is an analysis of four common materials used in the chrome stripping process, focusing on their relevance to B2B buyers across different regions, including Africa, South America, the Middle East, and Europe.

1. Acids (e.g., Sulfuric Acid)

Key Properties:

Acids like sulfuric acid are highly effective for chrome stripping due to their strong corrosive nature. They operate efficiently at elevated temperatures, enhancing their stripping capabilities.

Pros & Cons:

Acids are generally low-cost and provide quick results. However, their handling requires strict safety measures due to their corrosive nature, which can lead to significant manufacturing complexity and safety compliance issues.

Impact on Application:

Acids can effectively strip chrome from various metal substrates. However, they may not be suitable for sensitive materials that could be damaged by aggressive chemical exposure.

Considerations for International Buyers:

International buyers must ensure compliance with local environmental regulations regarding acid disposal. Standards such as ASTM and DIN may dictate the acceptable concentrations and handling procedures for acids in different countries.

2. Alkaline Solutions

Key Properties:

Alkaline solutions, often containing sodium hydroxide, are less aggressive than acids but still effective for chrome removal. They typically operate at lower temperatures and are less hazardous.

Pros & Cons:

These solutions are safer to handle compared to acids, reducing the risk of chemical burns. However, they may take longer to achieve the desired results and can be more expensive than acidic alternatives.

Impact on Application:

Alkaline solutions are suitable for stripping chrome from sensitive substrates, making them ideal for applications involving delicate components.

Considerations for International Buyers:

Buyers should verify the compatibility of alkaline solutions with local regulations and standards, particularly in regions with stringent environmental laws.

3. Mechanical Stripping (e.g., Abrasive Blasting)

Key Properties:

Mechanical stripping involves the physical removal of chrome using abrasive materials. This method is effective for various substrates and does not rely on chemicals.

Pros & Cons:

Mechanical stripping is environmentally friendly and avoids chemical hazards. However, it can lead to surface damage if not performed carefully and may require specialized equipment.

Impact on Application:

This method is particularly effective for large or robust components but may not be suitable for intricate parts where precision is critical.

Considerations for International Buyers:

Buyers should consider the availability of equipment and skilled labor for mechanical stripping in their regions, as well as compliance with occupational safety standards.

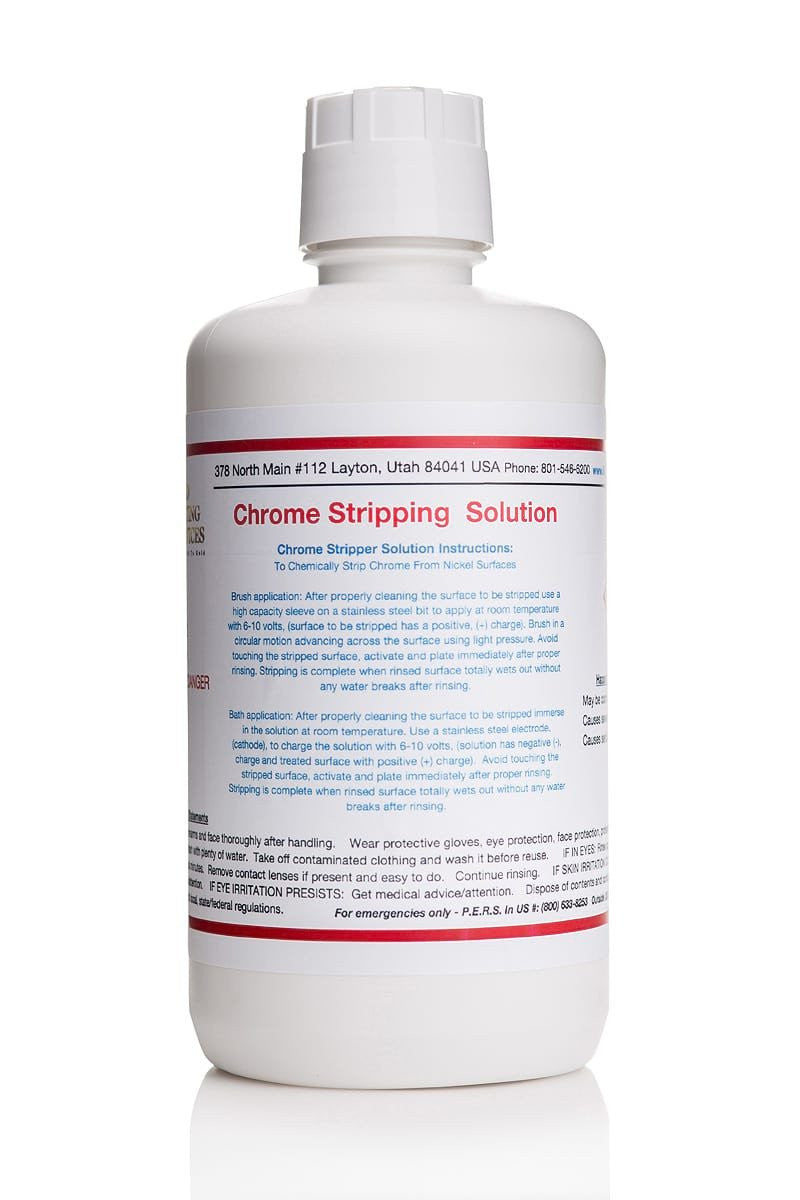

4. Chrome Stripper Solutions

Key Properties:

Specialized chrome stripper solutions are designed to dissolve chrome without damaging the underlying substrate. These formulations often feature environmentally friendly components.

Pros & Cons:

These solutions are efficient and can minimize damage to the base material. However, they may come at a higher cost compared to traditional methods and may require specific application techniques.

Impact on Application:

Chrome strippers are versatile and can be used on a variety of surfaces, including plastics and metals, making them suitable for diverse applications.

Considerations for International Buyers:

Buyers should ensure that chrome stripper products comply with local environmental regulations and standards, especially in regions with strict chemical usage guidelines.

Summary Table of Material Selection for Chrome Stripping Services

| Material | Typical Use Case for chrome stripping service | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Acids (e.g., Sulfuric Acid) | Stripping chrome from metal parts | Quick and effective removal | Highly corrosive; safety concerns | Low |

| Alkaline Solutions | Stripping chrome from sensitive components | Safer to handle; less hazardous | Slower process; potentially higher cost | Medium |

| Mechanical Stripping | Stripping chrome from large components | Environmentally friendly; no chemicals | Risk of surface damage; equipment needed | Medium |

| Chrome Stripper Solutions | Versatile stripping for various surfaces | Minimal damage to substrate | Higher cost; specific application needed | High |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions when sourcing chrome stripping services tailored to their specific needs.

In-depth Look: Manufacturing Processes and Quality Assurance for chrome stripping service

What Are the Main Stages of the Chrome Stripping Manufacturing Process?

The manufacturing process for chrome stripping services typically involves several crucial stages, ensuring that the components are prepared for effective and safe de-plating. These stages include material preparation, forming, assembly, and finishing. Each stage plays a vital role in maintaining the integrity of the base material while ensuring that the chrome and other coatings are removed efficiently.

Material Preparation: How Is the Initial Assessment Conducted?

Before any stripping begins, an initial assessment of the materials is essential. This involves inspecting the components for type, thickness, and the condition of the existing coatings. The assessment helps determine the most suitable stripping method—whether chemical, mechanical, or electrochemical—based on the material’s properties and the desired outcome.

The preparation may also include cleaning the parts to remove any contaminants that could interfere with the stripping process. This step is critical, especially in industries where precision is paramount, such as aerospace or automotive sectors.

What Techniques Are Employed in the Chrome Stripping Process?

The choice of technique is pivotal in achieving optimal results without damaging the base material. Common techniques include:

-

Chemical Stripping: This method uses specialized chemical agents to dissolve chrome and other coatings. It is particularly effective for intricate shapes and surfaces, ensuring a uniform removal without harming the underlying substrate.

-

Mechanical Stripping: Techniques such as shot blasting or sanding are employed to physically remove the chrome layer. This method is typically used when the coating is thick or when there is a need for surface roughening before re-coating.

-

Electrochemical Stripping: This advanced method reverses the electroplating process to strip chrome from the component. It involves applying a current to the part in a controlled environment, allowing for precise removal of the coating. This method is beneficial for preserving the integrity of complex geometries.

How Is Quality Assurance Implemented in Chrome Stripping Services?

Quality assurance (QA) in chrome stripping services is vital to ensure that the de-plating process meets international and industry-specific standards. Adhering to these standards not only ensures the safety and efficacy of the service but also builds trust with B2B clients, particularly in diverse markets such as Africa, South America, the Middle East, and Europe.

Which International Standards Are Relevant to Chrome Stripping Services?

Many international standards guide the QA processes in chrome stripping services. Among these, ISO 9001 is the most recognized, focusing on quality management systems. Compliance with ISO 9001 ensures that the service provider consistently meets customer and regulatory requirements.

Other standards may be relevant depending on the industry served, such as CE marking for products sold within the European Economic Area (EEA) or API standards for oil and gas applications. It is crucial for B2B buyers to ensure that their suppliers adhere to these standards, as they often dictate the quality and safety of the end products.

What Are the Key Quality Control Checkpoints in the Stripping Process?

Quality Control (QC) involves several checkpoints throughout the chrome stripping process to ensure that standards are met. These include:

-

Incoming Quality Control (IQC): This stage involves inspecting incoming materials and components to ensure they meet predefined specifications before they undergo the stripping process.

-

In-Process Quality Control (IPQC): Regular checks during the stripping process help identify any deviations from the required standards, allowing for immediate corrective actions. This is especially important in processes like electrochemical stripping, where variations in current can affect the outcome.

-

Final Quality Control (FQC): After the stripping process, a thorough inspection is conducted to ensure that all chrome and other coatings have been effectively removed and that the base material is intact. This may involve visual inspections, measurements, and even surface testing.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s QC practices is essential. Here are some effective strategies:

What Audit Processes Should Be Considered?

Conducting audits is one of the most effective ways to assess a supplier’s quality management system. This can involve both internal audits by the supplier and external audits by third-party organizations. Buyers can request audit reports to gain insights into the supplier’s adherence to quality standards.

How Can Third-Party Inspections Enhance Trust?

Engaging third-party inspection services adds an extra layer of assurance. These independent entities can evaluate the supplier’s processes, compliance with industry standards, and overall quality management practices. This is particularly beneficial for buyers concerned about quality consistency across borders.

What Documentation Should Be Requested from Suppliers?

B2B buyers should request relevant documentation, such as quality control reports, compliance certificates, and material safety data sheets (MSDS). This documentation serves as proof of the supplier’s commitment to quality and safety standards.

What Are the Common Testing Methods Employed in Quality Assurance?

Testing is a fundamental aspect of quality assurance in chrome stripping services. Common testing methods include:

- Adhesion Testing: Ensures that any subsequent coatings will adhere properly to the stripped surface.

- Surface Roughness Measurements: Evaluates the texture of the stripped surface, which can impact coating performance.

- Visual Inspections: Identifies any visible defects or areas where chrome may not have been adequately removed.

How Do Quality Control Nuances Vary for International Buyers?

Quality control nuances can vary significantly across different regions. For example, buyers from Europe may have stricter regulatory compliance requirements than those in other regions. Understanding these regional differences is crucial for B2B buyers to ensure that their suppliers meet local standards.

In conclusion, the manufacturing processes and quality assurance practices involved in chrome stripping services are intricate and highly specialized. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers, ensuring that their needs are met with the highest standards of quality and efficiency.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘chrome stripping service’

To assist B2B buyers in procuring chrome stripping services effectively, this guide provides a structured checklist that outlines essential steps to ensure a successful sourcing process. Understanding the nuances of chrome stripping can enhance your procurement strategy and lead to better supplier relationships.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for communicating your needs to potential suppliers. Consider the types of materials you need stripped (e.g., chrome, nickel, copper) and the dimensions of the parts. This clarity helps suppliers assess their capabilities and ensures they can meet your requirements.

- Material Types: Identify the base materials (e.g., aluminum, steel) to avoid damage during the stripping process.

- Size and Complexity: Specify the dimensions and geometrical features of the parts, as complex shapes may require specialized techniques.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to create a list of potential suppliers that offer chrome stripping services. Utilize industry directories, trade shows, and online resources to find reputable companies.

- Industry Experience: Look for suppliers with a proven track record in chrome stripping, particularly in your industry.

- Geographic Considerations: Choose suppliers located near your operations to reduce shipping costs and lead times.

Step 3: Evaluate Supplier Certifications and Compliance

Before engaging with suppliers, verify their certifications and compliance with industry standards. This step is vital for ensuring quality and safety in the stripping process.

- ISO Certifications: Suppliers with ISO certifications demonstrate adherence to quality management standards.

- Environmental Compliance: Ensure that suppliers follow environmental regulations, particularly regarding the disposal of hazardous materials.

Step 4: Request Detailed Quotes

Once you have shortlisted potential suppliers, request detailed quotes that break down costs for the services you need. This transparency will help you make informed decisions.

- Cost Breakdown: Look for itemized pricing that includes labor, materials, and any additional fees.

- Minimum Order Requirements: Be aware of any minimum order quantities that could impact your procurement budget.

Step 5: Assess Supplier Capabilities and Technology

Evaluate the capabilities and technologies employed by each supplier. Understanding their methods can provide insight into the quality and efficiency of their services.

- Stripping Techniques: Inquire about the specific techniques used (e.g., chemical stripping, electrolysis) and their effectiveness on different materials.

- Equipment and Facilities: Consider whether the supplier has modern equipment that can handle your specific needs.

Step 6: Check References and Reviews

Before finalizing your supplier choice, check references and online reviews. This step can provide valuable insights into the supplier’s reliability and service quality.

- Customer Testimonials: Reach out to past clients to gather feedback on their experiences.

- Industry Reputation: Research the supplier’s reputation within the industry to gauge their reliability and service consistency.

Step 7: Negotiate Terms and Finalize Contracts

After selecting a supplier, negotiate the terms of service and finalize contracts. Ensure that all agreements are documented to avoid misunderstandings.

- Service Level Agreements (SLAs): Establish clear expectations for turnaround times and quality standards.

- Payment Terms: Agree on payment schedules and methods that suit both parties.

By following this structured checklist, B2B buyers can navigate the procurement process for chrome stripping services with confidence, ensuring they select the right suppliers to meet their needs efficiently and effectively.

Comprehensive Cost and Pricing Analysis for chrome stripping service Sourcing

What Are the Key Cost Components in Chrome Stripping Services?

When sourcing chrome stripping services, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The chemical solutions used for chrome stripping, such as acid dips and specialized strippers, significantly impact costs. Environmentally friendly options may carry a premium but can save on disposal fees and regulatory compliance.

-

Labor: Skilled technicians are required for effective chrome stripping, especially for intricate parts. Labor costs can vary widely based on regional wage standards and the complexity of the job.

-

Manufacturing Overhead: This includes facility costs, utilities, and other indirect expenses that support production. High-quality facilities equipped for chrome stripping may command higher prices but ensure better quality outcomes.

-

Tooling: Specialized equipment for stripping chrome can be capital-intensive. Providers often amortize these costs over multiple projects, which can affect pricing.

-

Quality Control: Ensuring that the stripping process does not damage underlying materials is critical. Comprehensive QC procedures may add to costs but are essential for maintaining product integrity.

-

Logistics: Shipping parts to and from the service provider can incur significant costs, especially for international shipments. Buyers should consider the total logistics costs, including potential customs duties.

-

Margin: Suppliers typically add a profit margin to cover operational risks and provide return on investment. This margin can vary depending on market competition and service demand.

What Factors Influence Pricing for Chrome Stripping Services?

Several factors can influence the pricing of chrome stripping services, particularly for international buyers from regions such as Africa, South America, the Middle East, and Europe.

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for volume discounts. Buyers should negotiate based on anticipated future orders to secure better rates.

-

Specifications and Customization: Custom parts may require unique stripping processes, which can lead to increased costs. Clear communication of specifications can help avoid unexpected charges.

-

Material Type: The base material of the part being stripped (e.g., aluminum, steel, plastic) can affect the stripping process and, consequently, the pricing.

-

Quality and Certifications: Suppliers with industry certifications or a proven track record may charge more, but this often translates into higher quality and reliability.

-

Supplier Factors: The supplier’s location, reputation, and operational capacity can also affect pricing. Suppliers in regions with higher living costs may charge more than those in lower-cost areas.

-

Incoterms: The chosen Incoterms can significantly impact overall costs, especially regarding transportation and insurance. Buyers should be clear about responsibilities for shipping and handling.

What Are Essential Tips for Buyers to Negotiate Chrome Stripping Service Costs?

To achieve cost efficiency in sourcing chrome stripping services, international buyers can employ several strategies:

-

Negotiation: Always be prepared to negotiate terms and pricing. Building a long-term relationship with suppliers can lead to better pricing and service options.

-

Total Cost of Ownership (TCO): Assess the total cost, including logistics, quality, and after-service support. A lower upfront price may not always be the best deal if it leads to higher TCO.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and taxes that can impact the final cost. Understanding these factors can help in budget planning.

-

Request for Quotes: Solicit quotes from multiple suppliers to compare pricing structures and services. This can also provide leverage in negotiations.

-

Explore Alternative Solutions: In some cases, alternative methods like chemical strippers or in-house processing may offer cost savings compared to outsourcing.

Disclaimer Regarding Indicative Prices

Prices for chrome stripping services can vary widely based on the aforementioned factors and should be considered indicative. Buyers are encouraged to obtain specific quotes based on their unique requirements and service needs to ensure accurate budgeting and procurement planning.

Alternatives Analysis: Comparing chrome stripping service With Other Solutions

Introduction to Alternatives in Chrome Stripping

In the realm of surface treatment and restoration, chrome stripping services offer a specialized solution for removing chrome plating from various substrates. However, businesses may find themselves exploring alternative methods that can deliver similar results with varying degrees of efficiency, cost, and ease of implementation. Understanding these alternatives is crucial for B2B buyers aiming to make informed decisions based on their specific operational needs.

Comparison Table

| Comparison Aspect | Chrome Stripping Service | Chemical Chrome Stripper | Chrome Delete for Plastic |

|---|---|---|---|

| Performance | High efficiency, minimal damage to base metal | Fast-acting, may require multiple applications | Effective on plastic, quick setup |

| Cost | Typically ranges from $75 to $175 per wheel | Priced between $25 and $36 per application | Approximately $125 per gallon |

| Ease of Implementation | Requires professional handling and equipment | User-friendly for DIY applications | Simple application, no special equipment needed |

| Maintenance | Regular service may be necessary to maintain quality | Minimal maintenance; store chemicals properly | Minimal maintenance; clean surfaces after use |

| Best Use Case | Ideal for metal parts needing restoration | Suitable for small-scale projects or DIY | Best for plastic parts in automotive or decorative applications |

Detailed Breakdown of Alternatives

Chemical Chrome Stripper

Chemical chrome strippers are solutions designed to effectively dissolve chrome plating from various surfaces. They are particularly advantageous for smaller projects or DIY applications, as they can be used without professional assistance. However, while they are generally efficient, the performance can vary based on the thickness of the chrome and the underlying material. Additionally, users must handle these chemicals with care, as they can be hazardous if not used properly. Their lower cost makes them appealing, but the requirement for multiple applications can increase overall expenses.

Chrome Delete for Plastic

Chrome Delete is a specialized coating that allows for the removal of chrome plating from plastic components. It offers a fast and efficient solution, especially for businesses in the automotive sector looking to prepare parts for painting. The major benefit of this method is its non-destructive nature; it does not damage the underlying plastic, creating a ready-to-paint surface. However, it is important to note that this solution is primarily limited to plastic parts and may not be suitable for metal components. The ease of application makes it an attractive option for shops that frequently handle plastic parts.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate solution for chrome stripping, B2B buyers should carefully consider their specific requirements, including the type of material being treated, project scale, and budget constraints. Chrome stripping services offer high efficiency for larger or more complex projects, while chemical strippers provide flexibility for smaller tasks. Alternatively, Chrome Delete is ideal for businesses focused on plastic parts. By assessing these factors, companies can make informed decisions that align with their operational goals and enhance their service offerings.

Essential Technical Properties and Trade Terminology for chrome stripping service

What Are the Key Technical Properties of Chrome Stripping Services?

Understanding the technical properties of chrome stripping services is essential for B2B buyers, especially when sourcing suppliers or evaluating service quality. Here are some critical specifications to consider:

-

Material Compatibility

Chrome stripping can involve various substrates, including steel, aluminum, and plastic. Knowing the material compatibility is crucial, as some stripping methods may damage the base material. This knowledge helps buyers select the right service provider that can handle their specific components without compromising integrity. -

Thickness of Plating Removal

The thickness of the chrome layer being removed can vary significantly. It is important for buyers to understand the tolerances required for their parts. This is vital in applications where base metal exposure must be uniform to ensure proper adhesion of subsequent coatings. Mismanagement in this area can lead to product failures or increased rework costs. -

Stripping Methodology

Various methodologies exist for chrome stripping, such as chemical stripping, abrasive blasting, and electrochemical processes. Each method has its advantages and drawbacks, affecting factors like turnaround time, cost, and environmental impact. Buyers should consider the method’s suitability for their specific needs and the environmental regulations in their region. -

Surface Finish Quality

After chrome stripping, the surface finish of the base material can impact subsequent processes like painting or powder coating. Buyers should inquire about the expected surface finish quality to ensure compatibility with their production processes. A smoother finish can improve adhesion and overall aesthetics in final products. -

Turnaround Time

The time required to complete the chrome stripping process can vary based on the complexity of the job and the service provider’s capabilities. Understanding the expected turnaround time is crucial for project planning and inventory management. Delays can lead to increased costs and impact supply chain efficiency. -

Environmental Compliance

Many regions have strict regulations regarding the chemicals used in chrome stripping processes. Buyers must ensure that their chosen service provider complies with local and international environmental standards. This consideration not only protects the environment but also mitigates potential legal liabilities.

What Are Common Trade Terms Used in Chrome Stripping Services?

Familiarity with industry jargon can enhance communication with service providers and streamline the procurement process. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM standards is vital for buyers looking to maintain compatibility and quality in their chrome stripping services. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. For chrome stripping services, knowing the MOQ helps buyers plan their orders effectively and avoid unnecessary costs. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit pricing and terms from suppliers. For chrome stripping services, issuing an RFQ can help buyers compare different service providers based on price, capabilities, and timelines, ensuring they make informed decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers engaging in cross-border chrome stripping services, as they clarify who is responsible for shipping, insurance, and tariffs. -

Lead Time

This term refers to the time it takes from placing an order to its fulfillment. In the context of chrome stripping services, understanding lead times is crucial for planning and ensuring timely project completion. -

Sustainability Practices

This term encompasses the methods and processes that minimize environmental impact. Buyers should inquire about the sustainability practices of their chrome stripping service providers, as this can influence both brand reputation and compliance with regulations.

Being knowledgeable about these technical properties and trade terminology can significantly enhance your ability to engage effectively with chrome stripping service providers, ensuring that your procurement process is efficient and aligned with your business needs.

Navigating Market Dynamics and Sourcing Trends in the chrome stripping service Sector

What Are the Key Trends Driving the Chrome Stripping Service Market?

The chrome stripping service market is currently experiencing a robust evolution, driven by several global factors. A significant driver is the growing demand for refurbishment in industries such as automotive, aerospace, and manufacturing, where chrome plating is prevalent. As businesses seek to maintain equipment and vehicles, the need for effective and efficient chrome stripping solutions has surged. Emerging technologies such as automated stripping processes and advanced chemical formulations are also shaping the market, improving efficiency and reducing turnaround times.

Additionally, international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly prioritizing suppliers who leverage digital platforms for sourcing. The rise of e-commerce in industrial services allows companies to easily compare prices, quality, and service offerings from various providers, streamlining the procurement process. Furthermore, the trend towards customization in chrome stripping services, where businesses seek tailored solutions for specific projects, is becoming more prevalent. This shift emphasizes the importance of supplier flexibility and responsiveness to client needs.

How Is Sustainability Influencing Sourcing Trends in Chrome Stripping Services?

Sustainability is becoming a cornerstone of sourcing decisions within the chrome stripping service sector. The environmental impact of traditional stripping methods, which often involve hazardous chemicals, is prompting buyers to seek more sustainable alternatives. Companies are now more than ever focused on ethical supply chains and environmentally friendly practices, leading to the adoption of ‘green’ certifications and materials. For instance, suppliers that utilize eco-friendly chrome stripping solutions, which minimize harmful waste and emissions, are gaining a competitive edge.

Moreover, the industry is seeing a rise in demand for services that not only strip chrome but also prepare surfaces for recycling and reuse. This trend aligns with broader global initiatives aimed at reducing waste and promoting circular economy principles. B2B buyers are increasingly looking for partners who can demonstrate a commitment to sustainability, not just through their product offerings but also in their operational practices. This focus on ethical sourcing is likely to shape long-term partnerships and influence buyer loyalty.

What Is the Historical Context of Chrome Stripping Services?

The chrome stripping service industry has its roots in the early 20th century, when chrome plating became popular for its aesthetic appeal and corrosion resistance. Initially, stripping methods were rudimentary, often involving harsh chemicals that posed significant environmental risks. Over the decades, as environmental regulations tightened and the demand for sustainable practices grew, the industry underwent substantial transformation.

Advancements in technology have led to the development of more effective and less harmful stripping methods, including the use of electrochemical processes and biodegradable solutions. This evolution has not only improved the efficiency of chrome stripping but has also aligned the industry with contemporary sustainability goals. Today, chrome stripping services are recognized as essential components of maintenance and refurbishment processes across various sectors, reflecting the ongoing need for innovation and adaptation in response to market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of chrome stripping service

-

How do I ensure quality in chrome stripping services?

To ensure quality in chrome stripping services, start by vetting potential suppliers thoroughly. Look for certifications, customer reviews, and case studies that demonstrate their expertise in the process. Request samples of their work or references from previous clients, especially those in your industry. Additionally, inquire about their quality assurance processes, such as the use of advanced stripping technologies and adherence to safety standards, which can significantly impact the final result. -

What is the typical turnaround time for chrome stripping services?

The turnaround time for chrome stripping services can vary based on the complexity of the project and the supplier’s workload. Generally, expect a timeframe of 5 to 14 business days for standard orders. However, for large-scale projects or urgent requests, some suppliers may offer expedited services. Always discuss timelines upfront and consider including penalties for delays in your contract to safeguard your interests. -

Are there minimum order quantities (MOQ) for chrome stripping services?

Many chrome stripping service providers implement a minimum order quantity (MOQ) to ensure efficiency and cost-effectiveness. This can range from a single item to several units, depending on the supplier. When sourcing a service, clarify the MOQ and explore whether they offer flexibility for smaller projects. Some companies may accommodate lower quantities at a higher price point or provide customized solutions that meet your specific needs. -

What payment terms should I expect when sourcing chrome stripping services?

Payment terms for chrome stripping services can vary widely among suppliers. Common arrangements include net 30, net 60, or upfront payments, especially for first-time customers. Some suppliers may offer discounts for early payments or bulk orders. Always negotiate terms that align with your cash flow and ensure they are clearly documented in your contract to avoid misunderstandings later on. -

How can I assess the environmental impact of chrome stripping services?

Evaluating the environmental impact of chrome stripping services is crucial for sustainable business practices. Inquire about the chemicals and processes used by potential suppliers, focusing on eco-friendly methods that minimize hazardous waste. Look for certifications indicating compliance with environmental regulations. Additionally, consider suppliers who utilize advanced technologies, which can enhance efficiency and reduce environmental footprints. -

What customization options are available for chrome stripping services?

Many chrome stripping service providers offer customization options to cater to specific industry needs. This may include tailored stripping methods for different materials, varying levels of finish, or specialized processes for intricate parts. When discussing your project, clearly outline your requirements and expectations. A responsive supplier will work with you to develop a customized solution that meets your specifications. -

How do I handle logistics and shipping for chrome stripping services?

When sourcing chrome stripping services internationally, logistics and shipping are critical factors. Discuss shipping options with your supplier, including costs, delivery times, and insurance for your items during transit. Ensure they have experience handling international shipments and can comply with customs regulations in your country. Consider using freight forwarders for complex logistics to streamline the process and mitigate potential delays. -

What are the common challenges in chrome stripping services, and how can they be mitigated?

Common challenges in chrome stripping include inconsistent stripping quality, damage to base materials, and delays due to equipment issues. To mitigate these risks, choose suppliers with proven track records and advanced stripping technologies. Discuss potential issues upfront and establish clear quality benchmarks and communication protocols. Regularly monitor the progress of your orders and maintain an open line of communication to address any concerns promptly.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Chrome Stripping Service Manufacturers & Suppliers List

1. Gold Plating – Chrome Stripping Solution

Domain: goldplating.com

Registered: 1996 (29 years)

Introduction: Chrome Stripping Solution – Available in the Continental US & Canada only. Sizes: 500 mL (16 oz) – $25.00, 1 Liter – $45.00, 2 Liters – $75.00, 3 Liters – $105.00, 4 Liters – $130.00, 5 Liters – $160.00, 6 Liters – $189.00. Designed to electrochemically remove chrome plating without damaging the underlying nickel plate. Recommended for preparing chrome surfaces for plating with other metals. Requi…

2. U.S. Chrome – Industrial Plating Services

Domain: uschrome.com

Registered: 1999 (26 years)

Introduction: U.S. Chrome offers a range of industrial plating services including Hard Chrome, Flash Chrome, Thin Dense Chrome, Electroless Nickel, Electrolytic Nickel, and Cerakote Alternative Coatings. They serve various industries such as Aerospace, Agriculture, Alternative Energy, Defense, Medical, and Oil & Gas. The company has been in operation since 1940 and is known for its quality and precision in hard…

3. BuyScorpion – Chrome Delete Vinyl Wrap

Domain: buyscorpion.com

Registered: 2020 (5 years)

Introduction: Chrome Delete is a vinyl wrap that allows you to remove or cover chrome accents on your vehicle. It is designed for easy application and removal, providing a sleek, modern look. The product is available in various finishes and colors to match your vehicle’s aesthetic. It is durable, weather-resistant, and protects the underlying surface from scratches and UV damage.

4. HCS Plating – Hard Chrome Plating & Electroless Nickel

Domain: hcsplating.com

Registered: 2005 (20 years)

Introduction: This company, HCS Plating – Hard Chrome Plating & Electroless Nickel, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. J&B Chrome Plating – Chrome Plating & Metal Polishing Services

Domain: jbchrome.com

Registered: 2017 (8 years)

Introduction: J&B Chrome Plating offers chrome plating and metal polishing services in Fort Worth, TX, with over 8 years of experience. They provide affordable prices and a pick-up and delivery service to accommodate clients’ schedules. The business is known for its quality workmanship, as evidenced by positive customer reviews. Their operational hours are Monday to Friday from 7:00 am to 5:30 pm and Saturday f…

6. JR Smith – Decorative Chrome Plating & Polishing Services

Domain: jrsmith.com

Registered: 1996 (29 years)

Introduction: Decorative Chrome Plating & Polishing Services

Strategic Sourcing Conclusion and Outlook for chrome stripping service

As international B2B buyers evaluate chrome stripping services, strategic sourcing emerges as a critical factor in achieving operational efficiency and cost-effectiveness. Key takeaways include the importance of selecting suppliers with a proven track record in both quality and environmental compliance, particularly in regions such as Africa, South America, the Middle East, and Europe. Understanding the variety of stripping techniques—ranging from chemical solutions to mechanical processes—enables buyers to make informed decisions that align with their specific needs.

Moreover, fostering relationships with suppliers who offer tailored services can lead to significant savings and enhanced product longevity. As industries increasingly prioritize sustainability, engaging with providers who utilize eco-friendly methods will not only meet regulatory demands but also resonate with environmentally conscious consumers.

Looking ahead, the chrome stripping service sector is poised for growth, driven by advancements in technology and an expanding global market. B2B buyers are encouraged to explore new partnerships and innovations in this space to enhance their competitive edge. Now is the opportune moment to act; streamline your sourcing strategy and position your business for success in an evolving marketplace.