Contents

Manufacturing Insight: Chrome Stripping Service

Precision Chrome Stripping for High-Value Machined Components

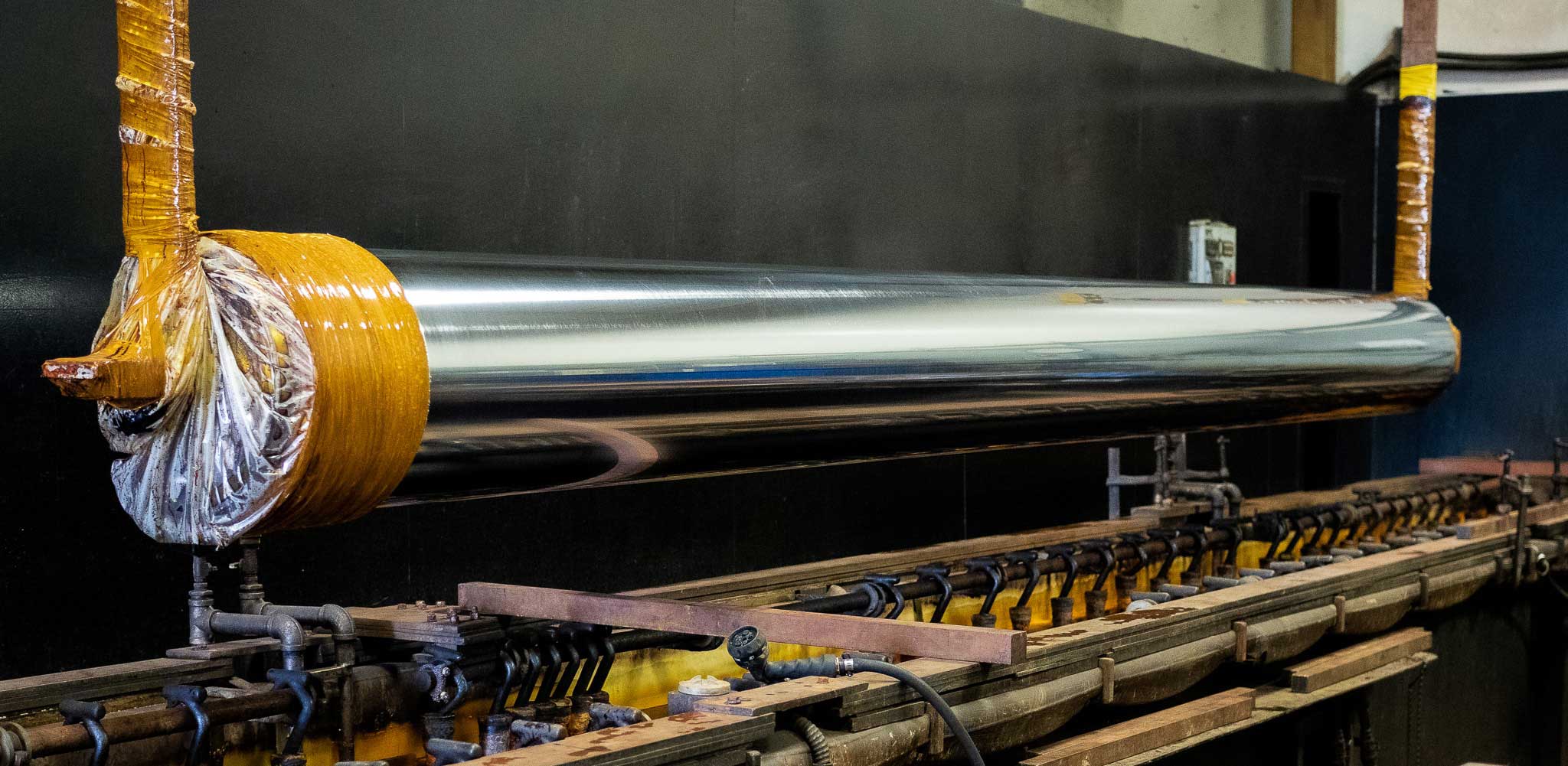

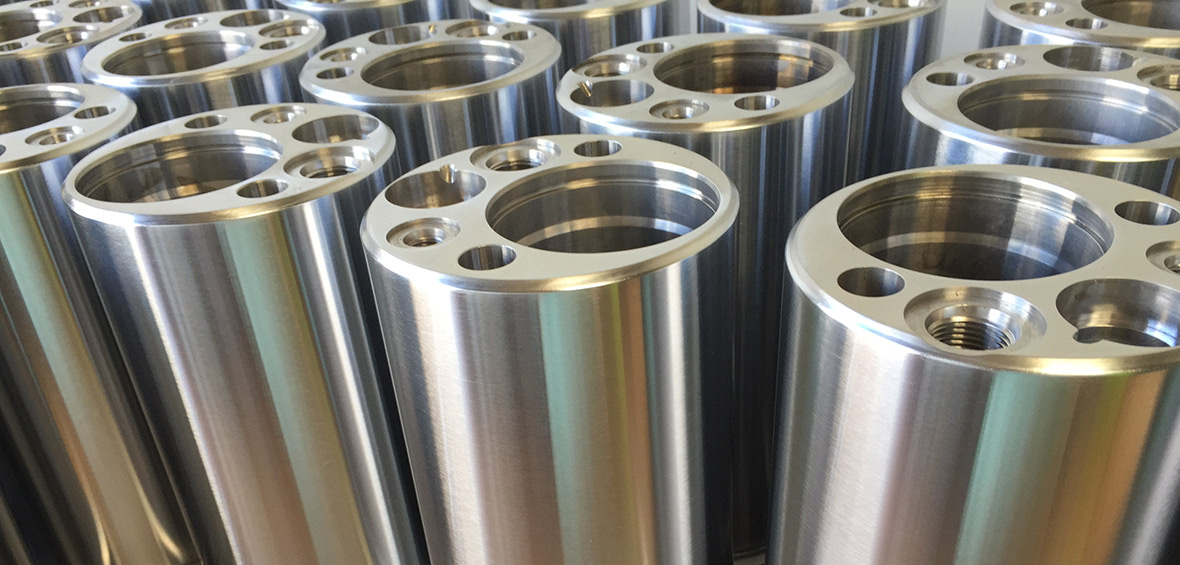

Honyo Prototype delivers integrated surface preparation solutions essential for advanced CNC machining workflows, including expert chrome stripping services. This critical capability enables the precise re-machining, modification, or re-coating of high-value components originally finished with hard chrome plating. Unlike generic stripping processes, our engineered approach prioritizes substrate integrity and dimensional stability, ensuring base materials—particularly aerospace-grade alloys and hardened tool steels common in precision CNC applications—remain unaffected for subsequent high-tolerance operations.

This service directly supports our core CNC machining expertise by removing chrome deposits without compromising critical geometries or surface finishes required for tight-tolerance part fabrication. Whether preparing legacy tooling for redesign, restoring worn components, or enabling complex modifications to plated prototypes, our stripping process is calibrated to meet the exacting standards demanded by medical, aerospace, and industrial OEMs.

Leverage Honyo’s end-to-end manufacturing capability: strip chrome to access the base material, then seamlessly transition to our CNC milling, turning, or multi-axis machining services—all under one quality-controlled roof. Eliminate supply chain fragmentation and reduce lead times by consolidating these interdependent processes with a single trusted partner.

Obtain immediate cost and timeline visibility for both chrome stripping and CNC machining through our Online Instant Quote platform. Input your part specifications and material requirements to receive a validated engineering assessment and competitive pricing within minutes, accelerating your prototyping or production schedule from inquiry to delivery.

Technical Capabilities

Chrome stripping service is a specialized process used to remove chrome plating from precision-machined components prior to rework, inspection, or re-coating. This service supports parts produced via 3-axis, 4-axis, and 5-axis milling, as well as CNC turning operations, particularly those requiring tight tolerances. The process ensures dimensional integrity is maintained post-stripping, especially critical for high-precision components used in aerospace, medical, and industrial applications.

The service accommodates a variety of base materials including Aluminum (e.g., 6061, 7075), Steel (e.g., 4140, 17-4 PH), ABS, and Nylon. Each material requires tailored stripping parameters to avoid substrate degradation while completely removing the chrome layer. Non-destructive chemical or electrolytic methods are typically employed, with post-process cleaning and inspection to verify surface quality and dimensional accuracy.

Below are the technical specifications for the chrome stripping service in relation to high-precision machined components:

| Parameter | Specification |

|---|---|

| Compatible Machining Methods | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning |

| Tolerance Capability | ±0.0002″ (5 µm) maintained post-stripping for critical features |

| Base Materials Supported | Aluminum alloys (6061, 7075), Steel (4140, 17-4 PH), ABS, Nylon |

| Chrome Layer Thickness Range | 0.0001″ – 0.003″ (2.5 – 76 µm) |

| Stripping Method | Controlled chemical bath or electrolytic process; non-etching formulations |

| Substrate Protection | Verified via profilometry and optical inspection; no pitting or corrosion |

| Post-Stripping Treatment | Deionized water rinse, passivation (for metals), drying, dimensional check |

| Max Part Size (Mill/Turn) | 24″ x 36″ x 20″ (610 x 914 x 508 mm) for milled parts; Ø24″ x 48″ for turned |

| Lead Time | 2–5 business days depending on volume and complexity |

| Quality Standards | ISO 9001:2015 compliant; first-article inspection available upon request |

This service is ideal for components requiring post-plating modifications, failure analysis, or re-manufacturing where preserving tight tolerance features is critical. Material-specific process validation ensures that even sensitive polymers like ABS and Nylon are stripped without deformation or surface damage.

From CAD to Part: The Process

Honyo Prototype executes chrome stripping services through a rigorously defined five-stage workflow designed for precision, efficiency, and material integrity. This process ensures optimal results while minimizing substrate damage and environmental impact. Below is the technical breakdown of each phase.

CAD Upload and Material Specification

Clients initiate the process by uploading detailed CAD files via our secure portal. We require explicit material composition data (e.g., ASTM A36 steel, 6061-T6 aluminum) and current plating specifications including chrome thickness (per ASTM B456), underplate layers (e.g., nickel duplex), and part geometry constraints. Incomplete submissions trigger automated validation checks, halting progression until specifications meet ISO 14687 surface preparation standards. This phase establishes the technical baseline for subsequent chemical and mechanical processing parameters.

AI-Powered Quotation and Feasibility Assessment

Our proprietary AI engine analyzes the CAD geometry, material data, and plating details against a database of 12,000+ historical stripping projects. The system calculates chemical consumption ratios, cycle times, and waste treatment requirements using ISO 14688 environmental compliance matrices. Crucially, human engineers validate all AI outputs within 4 business hours, assessing edge cases like blind holes or thin-walled sections where chemical entrapment could occur. The final quote includes NADCAP-accredited process validation costs and explicit tolerance allowances for potential substrate pitting.

DFM Analysis for Stripping Integrity

During Design for Manufacturability review, our team focuses on chrome stripping-specific failure modes. We simulate chemical diffusion paths using COMSOL Multiphysics to identify risk zones (e.g., crevices where chromic acid may pool). Critical checks include:

Substrate hardness verification to prevent hydrogen embrittlement (per AMS-H-81200)

Intergranular corrosion susceptibility in high-strength alloys

Dimensional stability thresholds for tight-tolerance features post-stripping

Clients receive a DFM report with actionable recommendations, such as adding vent holes or specifying alternative stripping chemistries for sensitive materials.

Controlled Production Execution

Stripping occurs in ISO 14689 certified wet benches with real-time process monitoring. Key operational parameters:

| Material Type | Chemistry System | Temp Range (°C) | Cycle Time (min) | Agitation Method |

|---|---|---|---|---|

| Carbon Steel | Chromic-Sulfuric | 55-65 | 8-15 | Ultrasonic 40kHz |

| Stainless Steel | Hydrochloric-Based | 70-80 | 12-20 | Mechanical |

| Aluminum | Alkaline Etch | 60-70 | 5-10 | Air Sparging |

All baths undergo hourly titration per ASTM D512, with spent solutions processed through our on-site reverse osmosis recovery system meeting EPA 40 CFR 266 standards. Parts move through inline DI water rinsing cascades (18.2 MΩ·cm purity) to prevent flash rusting.

Verification and Delivery Protocol

Post-stripping, parts undergo three-tier inspection:

1. Visual examination under 1000 lux lighting per ASTM E303 for residual plating or etching defects

2. Substrate roughness validation via profilometry (Ra ≤ 0.8 μm typical)

3. Adhesion testing per ASTM D3359 for subsequent re-plating readiness

Certified reports include before/after surface profilometry data and waste disposal manifests. Parts ship in VCI-protected packaging with humidity indicators, accompanied by full chain-of-custody documentation. Typical lead time from CAD upload to delivery is 7-10 business days for standard batches under 50 kg.

Start Your Project

Looking for a reliable chrome stripping service to prepare your parts for refinishing or inspection? Honyo Prototype offers professional chrome stripping with precision handling, ensuring surface integrity and consistent results. Our facility in Shenzhen is equipped for high-quality metal finishing services tailored to your manufacturing or prototyping needs.

Contact Susan Leo at [email protected] to discuss your project requirements and receive a customized quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.