Introduction: Navigating the Global Market for chrome removal service

In an increasingly interconnected world, sourcing reliable chrome removal services presents a significant challenge for international B2B buyers. As industries evolve and regulatory standards tighten, the demand for effective chrome stripping solutions that protect underlying metal surfaces while ensuring environmental compliance is paramount. This comprehensive guide delves into the intricacies of chrome removal services, offering insights into various methods, applications across different sectors, and essential supplier vetting criteria.

From automotive manufacturers in Germany to construction firms in South America, understanding the nuances of chrome stripping can empower businesses to make informed purchasing decisions. This guide will cover everything from the types of chrome removal techniques available, such as electrochemical stripping, to the cost implications and the importance of selecting suppliers who adhere to stringent quality and environmental standards.

By equipping B2B buyers with the necessary knowledge, this resource aims to facilitate smarter sourcing strategies, ultimately enhancing operational efficiency and compliance. Whether you are located in the Middle East or Africa, navigating the global market for chrome removal services has never been easier. Engage with this guide to unlock the potential for effective partnerships and superior product outcomes in your industry.

Understanding chrome removal service Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electrochemical Stripping | Utilizes an electric current to remove chrome without damaging the substrate. | Automotive parts, industrial machinery, and decorative items. | Pros: Preserves underlying materials; suitable for complex shapes. Cons: Requires specialized equipment; safety precautions necessary. |

| Chemical Stripping | Employs chemical solutions to dissolve chrome plating. | Restoration of vintage automotive parts, marine hardware. | Pros: Effective for large surfaces; less equipment-intensive. Cons: Potentially hazardous chemicals; may require thorough rinsing and disposal. |

| Mechanical Abrasion | Involves physical methods like sandblasting or grinding to remove chrome. | Heavy machinery, tools, and large-scale industrial components. | Pros: Quick removal; can achieve a rough surface for re-coating. Cons: Can damage underlying materials; less precise. |

| Thermal Stripping | Uses high temperatures to oxidize and remove chrome plating. | Aerospace components, high-performance automotive parts. | Pros: Effective for tough applications; can remove multiple layers. Cons: Risk of warping materials; requires specialized facilities. |

| Laser Stripping | Employs focused laser beams to precisely remove chrome. | High-precision applications like electronics and medical devices. | Pros: High accuracy; minimal thermal impact. Cons: High initial investment; requires skilled operators. |

What are the key characteristics of electrochemical stripping services?

Electrochemical stripping is a sophisticated method that uses electric currents to remove chrome plating while preserving the integrity of the underlying material. This technique is particularly suitable for intricate parts, as it can reach complex geometries without causing damage. B2B buyers should consider the need for specialized electroplating equipment and safety measures when opting for this service. It is ideal for industries focused on automotive parts and decorative items where surface quality is critical.

How does chemical stripping differ from other chrome removal methods?

Chemical stripping involves the application of specialized chemical solutions that dissolve chrome plating. This method is often used in the restoration of vintage automotive parts and marine hardware, as it effectively covers larger surface areas. While it requires fewer specialized tools than electrochemical methods, businesses must be cautious due to the potentially hazardous nature of the chemicals involved. Ensuring proper disposal and rinsing processes is essential for compliance with environmental regulations.

What are the advantages and disadvantages of mechanical abrasion?

Mechanical abrasion utilizes physical methods such as sandblasting or grinding to remove chrome plating. This method is favored for heavy machinery and tools due to its speed and ability to prepare surfaces for re-coating. However, it can inadvertently damage the underlying material, which makes it less suitable for delicate components. B2B buyers must weigh the need for quick service against the potential for additional repair work on affected parts.

When is thermal stripping the preferred choice for chrome removal?

Thermal stripping is an effective method that employs high temperatures to oxidize and remove chrome plating. This technique is best suited for aerospace components and high-performance automotive parts, where durability is crucial. While it can efficiently eliminate multiple layers of plating, it poses a risk of warping the underlying materials, necessitating the use of specialized facilities. Buyers should evaluate the thermal tolerance of their components before proceeding with this method.

What makes laser stripping a unique option for chrome removal?

Laser stripping is a cutting-edge method that uses focused laser beams to precisely remove chrome plating. This technique is especially beneficial for high-precision applications in electronics and medical devices, where minimal thermal impact is critical. Although it offers high accuracy and efficiency, the initial investment in laser equipment can be significant, and skilled operators are required to manage the process effectively. B2B buyers should consider their specific application needs and budget constraints when exploring this option.

Key Industrial Applications of chrome removal service

| Industry/Sector | Specific Application of chrome removal service | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Restoration of classic and vintage car parts | Enhances aesthetics and value of restored vehicles | Quality of chrome removal, environmental compliance, cost |

| Aerospace | Maintenance of aircraft components | Ensures safety and compliance with regulations | Certifications, precision of removal, turnaround time |

| Marine | Restoration of boat hardware and fittings | Increases longevity and performance in harsh conditions | Chemical safety, service speed, and surface integrity |

| Manufacturing | Preparing parts for re-plating or finishing | Reduces costs and improves product lifespan | Compatibility with existing processes, technical support |

| Consumer Goods | Chrome removal from decorative items and fixtures | Improves product appearance and customer satisfaction | Eco-friendliness, reliability, and scalability of service |

How is Chrome Removal Service Used in the Automotive Sector?

In the automotive industry, chrome removal services are vital for restoring classic and vintage car parts, which often suffer from wear and corrosion. By removing old chrome plating, businesses can prepare these components for re-plating or refinishing, enhancing the vehicle’s aesthetic appeal and market value. B2B buyers in this sector must consider the quality of the chrome removal process, ensuring it does not damage underlying materials, while also evaluating environmental compliance and cost-effectiveness.

What Role Does Chrome Removal Play in Aerospace Maintenance?

In aerospace, chrome removal is essential for maintaining aircraft components, where safety and regulatory compliance are paramount. The service allows for the thorough cleaning of parts before they undergo further treatment, ensuring they meet strict aviation standards. International buyers from this sector should prioritize suppliers with relevant certifications and expertise in precision removal techniques to guarantee the integrity and reliability of the components.

How is Chrome Removal Beneficial for Marine Applications?

The marine industry benefits significantly from chrome removal services, especially for boat hardware and fittings that are exposed to harsh marine environments. This service extends the lifespan of components by enabling effective cleaning and preparation for protective coatings. Buyers in this sector should focus on sourcing services that ensure chemical safety and can demonstrate a proven track record in maintaining surface integrity, as these factors are critical for long-term performance.

Why is Chrome Removal Important in Manufacturing?

Manufacturers often utilize chrome removal services to prepare parts for re-plating or finishing, which can significantly reduce production costs and enhance the longevity of products. This process is particularly important for components that require a high level of surface preparation to ensure adhesion of new coatings. B2B buyers should consider the compatibility of the chrome removal service with their existing processes, as well as the availability of technical support to address any challenges that may arise.

How Does Chrome Removal Enhance Consumer Goods?

In the consumer goods sector, chrome removal services are used to restore decorative items and fixtures, improving their appearance and increasing customer satisfaction. By effectively removing old chrome, businesses can apply new finishes that align with current design trends. Buyers in this industry should prioritize eco-friendly options and reliable service providers capable of scaling operations to meet fluctuating demand, ensuring a consistent supply of high-quality products.

3 Common User Pain Points for ‘chrome removal service’ & Their Solutions

Scenario 1: Difficulty in Preparing Surfaces for New Plating

The Problem: B2B buyers often face challenges when preparing chrome-plated surfaces for re-plating with other metals, such as gold or silver. The existing chrome layer can be stubborn and may not allow new plating to adhere properly, leading to subpar results. This issue is particularly critical in industries such as automotive manufacturing, where precision and aesthetics are paramount. Buyers may worry about damaging the underlying materials during the chrome removal process, which could result in costly repairs or replacements.

The Solution: To effectively prepare surfaces for new plating, sourcing a reliable chrome removal service is essential. Buyers should look for providers that specialize in electrochemical chrome stripping solutions, which can remove chrome without harming the underlying nickel plating. When selecting a service, inquire about their specific methodologies and safety protocols. It’s advisable to request case studies or testimonials from previous clients in similar industries. Additionally, ensure the service provider uses high-quality stripping solutions that comply with environmental regulations to mitigate any risk of harmful chemical exposure. Properly communicating the specific needs and expectations will help in achieving a flawless surface ready for re-plating.

Scenario 2: Environmental and Regulatory Compliance Concerns

The Problem: In regions such as Europe and the Middle East, strict environmental regulations govern the disposal of hazardous materials involved in chrome plating and removal. B2B buyers often find themselves navigating complex compliance requirements, which can lead to anxiety over potential legal repercussions. Failing to adhere to these regulations can result in hefty fines and damage to a company’s reputation, especially for manufacturers aiming to maintain high standards of corporate social responsibility.

The Solution: To alleviate concerns around compliance, buyers should prioritize partnering with chrome removal services that are well-versed in local and international environmental laws. This includes understanding the proper disposal methods for hazardous waste and the use of eco-friendly products in the chrome removal process. When evaluating potential partners, ask for certifications or proof of compliance with environmental standards, such as ISO certifications. Additionally, establishing a clear line of communication about your company’s sustainability goals can guide the service provider to tailor their methods accordingly, ensuring a partnership that aligns with your corporate values and legal obligations.

Scenario 3: Unexpected Downtime and Production Delays

The Problem: One of the significant pain points for B2B buyers utilizing chrome removal services is the potential for unexpected downtime. When chrome parts need to be stripped and re-plated, delays can occur due to unforeseen complications, such as the need for additional treatments or repairs after removal. This can disrupt production schedules and lead to financial losses, especially in industries with tight deadlines and high demands, like automotive and aerospace manufacturing.

The Solution: To minimize the risk of downtime, buyers should engage in thorough pre-planning and communication with their chrome removal service provider. Start by setting clear timelines and expectations for the project, including milestones for each phase of the removal and re-plating process. Request a detailed project plan that outlines potential risks and mitigation strategies. Additionally, consider opting for services that offer rapid turnaround times or have experience handling high-volume requests. It may also be beneficial to establish a long-term relationship with a service provider, allowing for streamlined processes and better preparedness for future projects. By ensuring that both parties are aligned on expectations, the likelihood of unexpected delays can be significantly reduced.

Strategic Material Selection Guide for chrome removal service

What Are the Key Materials Used in Chrome Removal Services?

In the chrome removal service industry, the choice of materials is critical for ensuring effective and efficient operations. Below, we analyze four common materials used in chrome removal processes, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Electrolytic Solutions

Key Properties: Electrolytic solutions, often alkaline or acidic, are designed to facilitate the electrochemical removal of chrome plating. These solutions typically operate effectively within a temperature range of 20-60°C and can withstand varying pressure levels depending on the application.

Pros & Cons: The primary advantage of electrolytic solutions is their ability to selectively remove chrome without damaging the underlying metal, which is crucial for preserving the integrity of components. However, they can be costly to produce and require precise control of operating conditions to ensure optimal performance.

Impact on Application: The compatibility of electrolytic solutions with specific media is vital. For instance, the solution must be tailored to the base material of the component being treated to avoid adverse reactions.

Considerations for International Buyers: Compliance with local environmental regulations is essential, particularly in regions like Europe where stringent standards (e.g., REACH) apply. Buyers should also verify that the solutions meet common standards such as ASTM or DIN.

2. Chemical Strippers

Key Properties: Chemical strippers are typically composed of solvents or acids that can dissolve chrome plating. They often have a high viscosity and can operate effectively at ambient temperatures.

Pros & Cons: The main advantage of chemical strippers is their ease of use and effectiveness on a wide range of substrates. However, they can be hazardous, requiring extensive safety measures and proper disposal methods, which can increase operational costs.

Impact on Application: Chemical strippers may not be suitable for all materials, particularly those sensitive to aggressive chemicals. Understanding the substrate is crucial to avoid damage during the stripping process.

Considerations for International Buyers: Buyers must consider the availability of safety equipment and compliance with chemical handling regulations in their respective countries, especially in regions with strict environmental laws like Germany.

3. Mechanical Abrasives

Key Properties: Mechanical abrasives, such as sandblasting media, are used to physically remove chrome plating. These materials vary in hardness and size, allowing for tailored applications based on the substrate.

Pros & Cons: The advantage of mechanical abrasives is their ability to remove chrome quickly and effectively without the need for chemicals. However, they can be less precise, potentially leading to substrate damage if not used correctly.

Impact on Application: The choice of abrasive material must align with the hardness of the substrate to prevent wear or damage. This compatibility is essential for achieving the desired finish.

Considerations for International Buyers: Buyers should ensure that the abrasives comply with local regulations regarding dust and waste management, particularly in regions like South America where environmental standards may vary.

4. Protective Coatings

Key Properties: After chrome removal, protective coatings are often applied to prevent corrosion. These coatings can be polymer-based or metallic, offering varying levels of durability and resistance to environmental factors.

Pros & Cons: The key advantage of protective coatings is their ability to enhance the longevity of the substrate after chrome removal. However, they can add to the overall cost and require additional processing time.

Impact on Application: The effectiveness of protective coatings depends on the surface preparation prior to application. Properly removing chrome is essential to ensure adhesion and performance.

Considerations for International Buyers: Buyers should evaluate the compatibility of protective coatings with their local climate and environmental conditions, particularly in the Middle East where high temperatures and humidity can impact performance.

Summary Table of Material Selection for Chrome Removal Services

| Material | Typical Use Case for chrome removal service | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Electrolytic Solutions | Electrochemical stripping of chrome plating | Selectively removes chrome without damage | High production cost and requires precision | Medium |

| Chemical Strippers | Dissolving chrome plating on various substrates | Easy to use and effective on many materials | Hazardous, requiring safety measures | High |

| Mechanical Abrasives | Physical removal of chrome via sandblasting | Fast removal without chemicals | Less precise; risk of substrate damage | Medium |

| Protective Coatings | Corrosion prevention post-chrome removal | Enhances substrate longevity | Adds cost and processing time | Medium |

This strategic material selection guide provides essential insights for international B2B buyers in the chrome removal service sector, facilitating informed decisions that align with operational needs and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for chrome removal service

What Are the Key Stages in the Chrome Removal Manufacturing Process?

The manufacturing process for chrome removal services typically involves several critical stages, each essential for ensuring the effectiveness and safety of the operation. Understanding these stages can help B2B buyers make informed decisions when selecting a service provider.

1. Material Preparation

The first step involves careful assessment and preparation of the materials to be stripped of chrome. This includes identifying the substrate material (such as steel, aluminum, or zinc die castings) and evaluating the existing chrome layer. Proper surface preparation is crucial as it determines the effectiveness of the chrome removal process. Depending on the substrate, pre-treatment might involve cleaning to remove contaminants, which can interfere with the stripping process.

2. Chrome Stripping Techniques

There are various techniques employed in chrome removal, each tailored to the specific requirements of the substrate and the type of chrome plating. The most commonly used methods include:

-

Electrochemical Stripping: This method employs an electrochemical solution that selectively removes chrome without damaging the underlying substrate. It requires specialized equipment, including power supplies and safety measures to protect operators from chemical exposure.

-

Chemical Stripping: Using strong acids or alkaline solutions, this method involves immersing parts in a stripping bath. While effective, it requires strict adherence to safety protocols and environmental regulations due to the hazardous nature of the chemicals involved.

-

Mechanical Stripping: In some cases, mechanical methods such as abrasive blasting may be used to remove chrome. However, this technique is less common due to the risk of damaging the underlying surface.

3. Finishing

After chrome removal, finishing processes are employed to prepare the substrate for subsequent treatments, such as re-plating or coating. Finishing may include polishing, buffing, or applying protective coatings to enhance the surface quality and prevent corrosion.

How Is Quality Assurance Implemented in Chrome Removal Services?

Quality assurance (QA) is a cornerstone of the chrome removal process, ensuring that services meet both industry standards and client expectations. For B2B buyers, understanding these QA measures is vital for selecting a reliable supplier.

International Standards and Certifications

Adhering to recognized international standards is crucial for chrome removal service providers. Key standards include:

-

ISO 9001: This standard outlines a framework for quality management systems and is widely recognized across various industries. Companies certified under ISO 9001 demonstrate a commitment to quality and continuous improvement.

-

CE Marking: Particularly relevant for suppliers in Europe, CE marking indicates that products meet European health, safety, and environmental protection standards. B2B buyers in Europe should prioritize suppliers with CE certification for compliance assurance.

-

API Standards: For buyers in the oil and gas sector, compliance with American Petroleum Institute (API) standards is essential. These standards ensure that chrome removal processes meet the rigorous requirements of this industry.

Key Quality Control Checkpoints

Quality control (QC) checkpoints are integral to maintaining high standards throughout the chrome removal process. Common QC stages include:

-

Incoming Quality Control (IQC): At this stage, raw materials and components are inspected upon arrival. This includes verifying the quality of stripping solutions and ensuring they meet specified standards.

-

In-Process Quality Control (IPQC): During the chrome removal process, continuous monitoring is conducted to ensure that the stripping is effective and that no damage occurs to the substrate. This includes regular checks on chemical concentrations and process parameters.

-

Final Quality Control (FQC): Once the chrome has been removed, a final inspection is conducted to assess the substrate’s condition. This may involve surface roughness testing, visual inspections, and adherence to thickness specifications.

What Testing Methods Are Commonly Used in Quality Control for Chrome Removal Services?

Various testing methods are employed to ensure the integrity of the chrome removal process and the quality of the finished substrate. Some common methods include:

-

Surface Roughness Testing: This method assesses the texture of the substrate after chrome removal, ensuring it meets the necessary specifications for further processing.

-

Adhesion Testing: If the substrate is to be re-plated, adhesion tests are performed to confirm that the new coating will bond effectively to the surface.

-

Chemical Analysis: Regular chemical analysis of stripping solutions is conducted to verify concentration levels and effectiveness.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s QC practices is essential to ensure reliability and compliance. Here are actionable steps to consider:

-

Supplier Audits: Conducting on-site audits can provide invaluable insights into a supplier’s QC processes. This allows buyers to assess their adherence to international standards and evaluate their operational capabilities.

-

Requesting Quality Reports: Suppliers should be willing to provide detailed reports on their quality control measures, including results from IQC, IPQC, and FQC processes.

-

Third-Party Inspections: Engaging independent third-party inspectors can offer an unbiased assessment of a supplier’s quality practices, ensuring compliance with relevant standards.

What Are the Unique Quality Control Considerations for International B2B Buyers?

International B2B buyers must navigate various nuances in QC practices that can differ by region. Some considerations include:

-

Regulatory Compliance: Understanding the specific regulatory requirements in the buyer’s region is crucial. For example, buyers in Europe may have stricter environmental regulations compared to those in other regions.

-

Cultural Differences: Cultural perceptions of quality and service can vary significantly. Buyers should consider these differences when assessing supplier capabilities and reliability.

-

Logistics and Supply Chain Risks: International shipping can introduce risks that affect product quality. B2B buyers should evaluate how suppliers manage logistics and what measures they have in place to ensure product integrity during transit.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance practices in chrome removal services equips B2B buyers with the knowledge needed to select reliable suppliers. By focusing on key stages in the manufacturing process, relevant quality standards, and verification methods, buyers can make informed decisions that align with their operational needs and compliance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘chrome removal service’

Introduction

This guide aims to provide B2B buyers with a comprehensive checklist for sourcing chrome removal services effectively. Chrome removal is a critical step in various industries, including automotive, aerospace, and manufacturing, where parts need to be refurbished or repurposed. By following this checklist, buyers can ensure they partner with reliable service providers who meet their specific needs.

Step 1: Define Your Technical Specifications

Before reaching out to potential suppliers, clearly outline your technical requirements. This includes the types of materials involved, the dimensions of the parts, and the desired finish after chrome removal.

– Key Considerations: Different materials may require specific removal methods to avoid damage, so knowing your specifications ensures compatibility with service offerings.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers specializing in chrome removal services. Look for companies with a strong reputation in the industry and experience with similar projects.

– Sources to Explore: Industry publications, online directories, and trade shows can provide valuable insights. Additionally, check reviews and testimonials from other B2B clients to gauge reliability.

Step 3: Evaluate Supplier Certifications and Compliance

Verify that potential suppliers hold necessary certifications and comply with industry regulations. This may include environmental compliance certifications, safety standards, and quality assurance certifications.

– Why This Matters: Compliance not only ensures that the supplier adheres to legal requirements but also reflects their commitment to quality and safety in operations.

Step 4: Request Detailed Proposals

Once you have shortlisted suppliers, request detailed proposals outlining their services, methodologies, timelines, and costs. A well-structured proposal should address your specific needs and provide transparency in pricing.

– What to Look For: Ensure the proposal includes a breakdown of costs, potential hidden fees, and timelines for each stage of the chrome removal process.

Step 5: Inquire About Equipment and Technology

Ask about the equipment and technology used by the suppliers for chrome removal. Advanced technologies can enhance the efficiency and quality of the service.

– Considerations: Suppliers using state-of-the-art equipment are likely to deliver better results and adhere to higher safety standards. Inquire about their process to ensure it aligns with your quality expectations.

Step 6: Assess Customer Support and Communication

Evaluate the level of customer support offered by each supplier. Effective communication is vital for a successful partnership, especially in addressing concerns or changes during the project.

– Important Factors: Look for suppliers who are responsive and willing to provide ongoing support throughout the project duration, ensuring that you are informed at every step.

Step 7: Check for Warranty and After-Sales Support

Before finalizing a partnership, inquire about warranties or guarantees on their chrome removal services. Understanding their after-sales support can also provide peace of mind regarding the longevity of the service.

– Why It Matters: A solid warranty indicates confidence in their service quality, while robust after-sales support can help resolve any issues that arise post-service, enhancing your overall experience.

By following this checklist, B2B buyers can make informed decisions when sourcing chrome removal services, ensuring they select a partner that meets their specific requirements and standards.

Comprehensive Cost and Pricing Analysis for chrome removal service Sourcing

What Are the Key Cost Components in Chrome Removal Services?

When evaluating the cost structure of chrome removal services, several key components come into play. Materials typically account for a significant portion of the costs. The primary material is the chrome stripping solution itself, which must be effective yet safe for the underlying metal. Additionally, other materials such as protective equipment for workers and any ancillary chemicals used in the process can contribute to overall expenses.

Labor costs are another critical factor, influenced by the complexity of the job and the expertise required. Skilled labor is necessary for effective chrome removal, which may involve electrochemical processes or mechanical methods. Therefore, labor rates may vary significantly based on the region, skill level, and labor laws.

Manufacturing overhead encompasses facility costs, utilities, and maintenance of equipment. These costs can fluctuate based on local economic conditions and operational efficiency. Moreover, tooling costs can arise from the need for specialized equipment, such as electroplating systems or safety apparatus.

Quality control (QC) is essential in the chrome removal process to ensure the integrity of the underlying surfaces. This involves testing and inspection, which adds to the cost but is crucial for maintaining service standards and customer satisfaction.

Finally, logistics costs are significant, especially for international shipments. Import duties, taxes, and freight charges can add substantial costs to the overall pricing structure.

What Influences Pricing in Chrome Removal Services?

Several factors can influence the pricing of chrome removal services, particularly for international buyers. Volume and minimum order quantities (MOQ) play a critical role; larger orders often lead to discounted rates. Custom specifications may also affect pricing, as highly customized jobs typically require additional labor and materials.

The choice of materials significantly impacts the cost. High-quality stripping solutions or environmentally friendly options may come at a premium but can enhance performance and safety. Quality certifications can also influence pricing, with suppliers who adhere to stringent standards often charging more due to their commitment to quality.

Supplier factors such as reputation, experience, and geographic location can also affect pricing. Established suppliers may command higher prices due to their proven track record and reliability. Additionally, the choice of Incoterms can influence costs, as they define responsibilities between buyers and sellers regarding shipping, insurance, and tariffs.

What Tips Can Help International Buyers Negotiate Better Prices?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider several strategies to enhance cost-efficiency. Negotiation is key; buyers should be prepared to discuss pricing openly and leverage volume commitments to secure better deals.

Understanding the total cost of ownership (TCO) is vital. Buyers should evaluate not just the initial costs but also the long-term implications, including maintenance and potential rework costs. Investing in higher-quality services may result in lower TCO over time.

Additionally, buyers should be aware of pricing nuances that vary by region. For instance, economic conditions, local labor costs, and regulations can significantly affect service pricing. Buyers from Europe may find different pricing structures compared to those in Africa or South America due to differing labor costs and market demand.

Lastly, conducting thorough market research on various suppliers can provide insights into competitive pricing and service offerings, allowing buyers to make informed decisions.

Disclaimer on Indicative Prices

Prices for chrome removal services can vary widely based on the factors discussed above. It is advisable for buyers to seek quotes from multiple suppliers and consider all cost components to arrive at a comprehensive understanding of the pricing landscape.

Alternatives Analysis: Comparing chrome removal service With Other Solutions

Understanding Alternatives to Chrome Removal Services

In the realm of metal finishing, chrome removal services are essential for preparing surfaces for new coatings, enhancing aesthetics, and preventing corrosion. However, various alternative methods exist that can achieve similar outcomes. This section will compare chrome removal services with two prominent alternatives: chemical stripping and abrasive blasting. Each method has its own set of advantages and limitations, making it crucial for B2B buyers to evaluate their options based on specific project needs.

Comparison Table

| Comparison Aspect | Chrome Removal Service | Chemical Stripping | Abrasive Blasting |

|---|---|---|---|

| Performance | High effectiveness in removing chrome without damaging underlying layers | Effective but may require multiple applications | Highly effective, but can damage underlying surfaces |

| Cost | Moderate to high, depending on service provider | Generally lower initial cost, but may add up with multiple applications | Varies widely based on media and equipment used |

| Ease of Implementation | Requires professional service, less DIY-friendly | Can be done in-house with proper equipment and training | Requires specialized equipment and trained personnel |

| Maintenance | Minimal maintenance needed post-service | Frequent monitoring for safety and effectiveness required | Equipment maintenance is necessary for optimal performance |

| Best Use Case | Ideal for intricate parts needing preservation of underlying layers | Suitable for flat surfaces and less intricate designs | Best for robust items that can withstand surface damage |

In-Depth Analysis of Alternatives

What is Chemical Stripping and How Does It Compare?

Chemical stripping utilizes solvent-based solutions to dissolve chrome plating. This method is particularly beneficial for flat surfaces and less intricate designs, where the risk of damaging underlying materials is lower. The initial costs for chemical stripping are generally lower than chrome removal services; however, multiple applications may be required for thorough removal, potentially increasing overall expenses. While this method allows for in-house execution, it mandates stringent safety measures due to the toxic nature of the chemicals involved.

What are the Advantages and Disadvantages of Abrasive Blasting?

Abrasive blasting, also known as sandblasting, involves propelling abrasive materials against a surface to remove coatings, including chrome. This method is highly effective for robust components, offering quick results and the ability to remove heavy buildup. However, it poses a risk of damaging the substrate, particularly with softer metals. The cost can vary significantly based on the type of abrasive media used and the scale of the operation. Like chemical stripping, it requires specialized equipment and trained personnel, adding to implementation complexity.

Conclusion: How Can B2B Buyers Choose the Right Solution?

Selecting the appropriate chrome removal solution hinges on specific project requirements, including the complexity of the parts, budget constraints, and desired outcomes. For delicate components where preserving the underlying finish is paramount, chrome removal services offer unmatched precision. In contrast, chemical stripping may be more suitable for simpler, flat surfaces, while abrasive blasting is ideal for heavy-duty applications. By carefully weighing the performance, cost, ease of implementation, and maintenance needs of each alternative, B2B buyers can make informed decisions that align with their operational goals and product specifications.

Essential Technical Properties and Trade Terminology for chrome removal service

What Are the Essential Technical Properties of Chrome Removal Services?

When engaging with chrome removal services, B2B buyers should be aware of several critical technical properties that can affect the quality and suitability of the service for their needs. Understanding these properties ensures that the selected service aligns with industry standards and specific project requirements.

-

Material Compatibility

Chrome removal processes must be compatible with the underlying materials, such as nickel, brass, or aluminum. Using the wrong method can damage the substrate, leading to costly repairs or replacements. B2B buyers should confirm that the service provider employs techniques that preserve the integrity of the base materials. -

Thickness Tolerance

The thickness of the chrome layer being removed is crucial. Services should specify their tolerance levels for thickness, as exceeding these can lead to surface damage. For manufacturers, ensuring that the chrome removal process adheres to precise thickness specifications can be critical for maintaining quality control in production runs. -

Surface Finish Quality

The desired surface finish after chrome removal can significantly impact the next steps in manufacturing or plating. Buyers should inquire about the surface finish quality achieved post-removal. A smooth finish may be necessary for subsequent processes like re-plating, while rough finishes may require additional processing. -

Chemical Composition of Stripping Solutions

The chemical solutions used for chrome stripping should be carefully evaluated. Buyers should look for eco-friendly options that comply with local regulations, especially in regions with stringent environmental laws. Understanding the chemical properties helps in assessing potential risks and safety measures needed during the chrome removal process. -

Processing Time

The time taken for chrome removal can affect production schedules. B2B buyers should clarify expected turnaround times to align their project timelines accordingly. Fast and efficient service can significantly reduce downtime and improve overall productivity. -

Environmental Compliance Standards

Chrome removal services must adhere to environmental regulations, particularly concerning waste management and chemical disposal. B2B buyers should ensure that their chosen service provider follows local and international environmental compliance standards to avoid legal issues and promote sustainability.

What Are Common Trade Terms Related to Chrome Removal Services?

Familiarity with industry-specific terminology is essential for effective communication and negotiation in the chrome removal service sector. Here are some common terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In chrome removal, understanding OEM specifications ensures that the services provided meet the quality and performance standards required by the original product designs. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest amount of product that a supplier is willing to sell. In the context of chrome removal services, knowing the MOQ can help buyers plan their budgets and production schedules effectively. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and service details for a specific project. Sending an RFQ allows buyers to compare offerings from different chrome removal services and select the best option based on cost and quality. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers engaged in cross-border chrome removal services, ensuring clarity on shipping, risks, and costs involved. -

Lead Time

Lead time refers to the time between placing an order and receiving the goods or services. For chrome removal services, understanding lead times helps businesses manage their production schedules and avoid delays. -

Surface Preparation

Surface preparation encompasses the processes involved in preparing a substrate for further treatment, such as plating. This term is vital as it directly relates to the effectiveness of chrome removal and the quality of the final finish.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when selecting chrome removal services, ensuring they meet their operational needs and compliance standards.

Navigating Market Dynamics and Sourcing Trends in the chrome removal service Sector

What Are the Current Market Dynamics and Key Trends in the Chrome Removal Service Sector?

The chrome removal service sector is experiencing significant growth driven by various global factors. One primary driver is the increasing demand for surface finishing in industries such as automotive, aerospace, and electronics. As manufacturers seek to enhance the durability and aesthetic appeal of their products, the need for effective chrome removal techniques becomes crucial. Moreover, the rise of international trade has expanded the market reach for chrome removal services, particularly in regions like Africa, South America, the Middle East, and Europe.

Emerging technologies are also reshaping the landscape of chrome removal services. Electrochemical stripping solutions are gaining popularity due to their efficiency and minimal environmental impact. This innovative approach allows for the removal of chrome plating without damaging the underlying substrate, making it an attractive option for businesses looking to repurpose or replate metal components. Additionally, advancements in automation and robotics are streamlining processes, reducing labor costs, and improving accuracy in chrome removal applications.

B2B buyers should stay informed about market trends such as the shift towards integrated service providers that offer comprehensive solutions, including chrome removal, plating, and finishing. Companies that can provide a one-stop-shop experience are increasingly preferred by manufacturers looking to simplify their supply chains and ensure consistent quality across processes.

How Does Sustainability and Ethical Sourcing Impact Chrome Removal Services?

Sustainability is becoming a pivotal concern in the chrome removal service sector. The environmental impact of chrome plating and its removal processes has prompted businesses to seek solutions that minimize harm to the ecosystem. The increasing scrutiny from regulatory bodies regarding hazardous waste disposal and the use of toxic chemicals is driving the adoption of safer, more sustainable practices.

Ethical sourcing is also gaining traction among B2B buyers who prioritize suppliers with robust environmental management systems. Companies are increasingly looking for partners that can demonstrate compliance with international standards, such as ISO 14001, and those that utilize ‘green’ certifications or materials in their operations. This trend not only mitigates risks associated with environmental regulations but also enhances brand reputation among eco-conscious consumers.

Furthermore, suppliers are encouraged to invest in technologies that recycle or repurpose waste generated during chrome removal processes. This not only aligns with sustainability goals but also can lead to cost savings and improved operational efficiency. B2B buyers should prioritize partnerships with service providers committed to ethical practices and sustainable solutions, ensuring a responsible approach to chrome removal and related services.

What Has Been the Historical Evolution of Chrome Removal Services?

The chrome removal service industry has evolved significantly over the decades. Initially, traditional methods such as abrasive blasting and chemical stripping were prevalent, but these techniques often posed risks to both workers and the environment. The advent of electrochemical stripping processes marked a turning point, allowing for more precise and safer removal of chrome plating.

As industries faced increasing regulatory pressures and environmental concerns, the demand for sustainable practices led to innovations in chemical formulations and application methods. Today, the sector is characterized by a focus on efficiency, safety, and environmental responsibility, with continuous advancements shaping the future of chrome removal services.

In summary, understanding these dynamics, sustainability imperatives, and historical context equips B2B buyers with the insights necessary to navigate the evolving landscape of chrome removal services effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of chrome removal service

-

1. How do I solve issues with chrome plating removal?

To address chrome plating removal effectively, you should engage a specialized service that utilizes electrochemical stripping solutions. These solutions are designed to remove chrome without damaging the underlying materials, such as nickel or other metals. It’s crucial to communicate your specific needs, including the type of substrate and the desired finish. Additionally, ensure that the service provider adheres to environmental regulations and safety standards, especially if you are operating in regions with strict compliance requirements. -

2. What is the best method for chrome removal from automotive parts?

The best method for chrome removal from automotive parts involves electrochemical stripping. This method minimizes damage to the underlying metal and prepares the surface for re-plating or refinishing. Look for a service that offers expertise in automotive applications, as they will understand the nuances of different metals and finishes. It’s also advisable to request samples or references to ensure their process meets your quality standards. -

3. How can I vet potential chrome removal service providers?

When vetting chrome removal service providers, consider their industry experience, certifications, and compliance with environmental regulations. Request case studies or references from previous clients, particularly in your sector. Evaluate their technology and methods to ensure they use advanced, safe practices. Additionally, assess their customer service responsiveness and willingness to customize services to fit your specific needs, as this can be indicative of their overall reliability. -

4. What customization options are available for chrome removal services?

Customization options for chrome removal services can include specific stripping techniques tailored to different metal substrates, finishing processes after chrome removal, and the ability to handle unique part shapes or sizes. Discuss your requirements with potential providers to see how they can adapt their services to meet your specifications. Many companies may also offer additional services, such as polishing or re-plating, which can be advantageous for a comprehensive solution. -

5. What are the typical minimum order quantities (MOQs) for chrome removal services?

Minimum order quantities for chrome removal services can vary widely based on the service provider and the complexity of the job. Some companies may accept small batches for prototyping or testing, while others may require larger orders for industrial applications. It’s essential to clarify the MOQ upfront and understand how it aligns with your production needs. Additionally, inquire about pricing structures, as larger orders may qualify for discounts. -

6. What payment terms should I expect when sourcing chrome removal services internationally?

When sourcing chrome removal services internationally, payment terms can differ significantly based on the provider’s policies and your negotiation. Common practices include upfront deposits, net 30 or net 60 payment terms, and the use of letters of credit for larger transactions. Ensure you fully understand the terms, including any additional fees for international transactions, currency conversion, or customs duties. Clear communication regarding payment terms can help prevent misunderstandings and foster a smoother transaction process. -

7. How do I ensure quality assurance in chrome removal services?

To ensure quality assurance in chrome removal services, request detailed documentation of their processes, including safety and environmental compliance measures. Look for ISO certifications or other industry standards that demonstrate their commitment to quality. Additionally, consider implementing a quality control agreement that specifies acceptable tolerances and inspection criteria. Regular communication with the service provider throughout the process can also help maintain quality and address any issues promptly. -

8. What logistics considerations should I keep in mind when sourcing chrome removal services?

Logistics considerations for sourcing chrome removal services include shipping arrangements for your parts, turnaround times, and potential customs challenges. Ensure the service provider has experience with international shipping and can handle the necessary documentation. Discuss lead times and potential delays, especially if you are working on a tight schedule. It’s also wise to evaluate the provider’s ability to accommodate urgent requests or fluctuations in demand, which can impact your overall project timeline.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Chrome Removal Service Manufacturers & Suppliers List

1. J&B Chrome – Local Chrome Plating Services

Domain: jbchrome.com

Registered: 2017 (8 years)

Introduction: This company, J&B Chrome – Local Chrome Plating Services, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

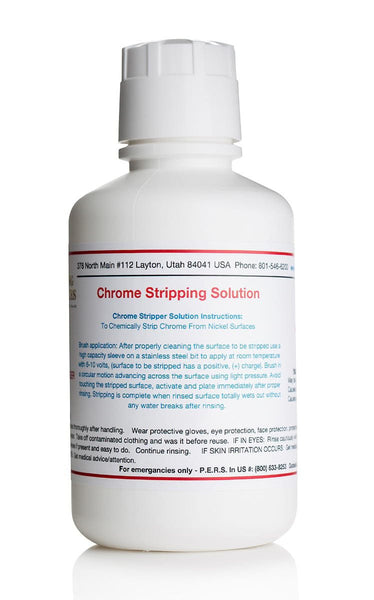

2. Gold Plating – Chrome Stripping Solution

Domain: goldplating.com

Registered: 1996 (29 years)

Introduction: Chrome Stripping Solution – Available in the Continental US & Canada only. Sizes: 500 mL (16 oz) – $25.00, 1 Liter – $45.00, 2 Liters – $75.00, 3 Liters – $105.00, 4 Liters – $130.00, 5 Liters – $160.00, 6 Liters – $189.00. Designed to electrochemically remove chrome plating without damaging the underlying nickel plate. Recommended for preparing chrome surfaces for plating with other metals. Requi…

3. Pulido Plating – Chrome, Nickel, Copper, and Gold Plating Services

Domain: pulidoplating.net

Registered: 2021 (4 years)

Introduction: Pulido Plating offers chrome, nickel, copper, and gold plating services since 1999. Key services include Bright Decorative Chrome, Triple Plating, Replating, Pot Metal, Household, Automotive, Marine, Motorcycle, and Custom Parts. They specialize in mirror polishing on aluminum wheels. Locations include Balch Springs, TX and Converse, TX.

4. Atlas Chrome – Stripping and De-plating Services

Domain: atlaschrome.com

Registered: 2000 (25 years)

Introduction: Stripping and De-plating Services:

– De-plating to bare metal for wheels:

– Up to 20″ wheel: $125 & up

– 21″-22″ wheel: $175+

– Paint Stripping:

– Up to 20″ wheel: $75 & up

– 21″-22″ wheel: $125+

– Parts shot blasting and acid dip cleaning: $75+

– Removing chrome and roughing nickel for paint/powder: $75 & up

Processes:

– Chrome, Nickel, Copper, Brass, Gold stripping without dam…

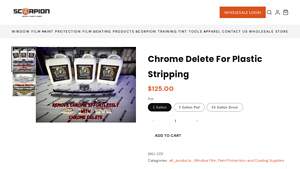

5. BuyScorpion – Chrome Delete For Plastic Stripping

Domain: buyscorpion.com

Registered: 2020 (5 years)

Introduction: {“product_name”: “Chrome Delete For Plastic Stripping”, “regular_price”: “$125.00”, “sizes_available”: [{“size”: “1 Gallon”, “price”: “$125.00”}, {“size”: “5 Gallon Pail”, “price”: “$595.00”}, {“size”: “55 Gallon Drum”, “price”: “$5,995.00”}], “features”: [“Effortlessly remove chrome plating from plastic parts”, “Does not damage the plastic underneath”, “Creates a perfect ready-for-paint surface”]…

6. North Texas Quality Chrome – Chrome Plating Services

Domain: aandwproductions.com

Registered: 2007 (18 years)

Introduction: North Texas Quality Chrome is a full service chrome plating and polishing company located in Gainesville, TX. The facility spans 20,000 square feet and features a state-of-the-art chrome plating shop. Key offerings include: Chrome Plating, Aluminum Plating, Nickel Plating, Copper Plating, Polishing, Re-chroming, De-plating, Stripping, and Repair Preparation. The company operates as a zero discharg…

7. Speed & Sport Chrome Plating – Chrome Plating Services

Domain: speedsportchrome.com

Registered: 2009 (16 years)

Introduction: Speed & Sport Chrome Plating specializes in chrome plating for various materials including pot metal, steel, cast iron, aluminum, stainless steel, and brass. They do not chrome mag wheels. The typical turnaround time for plating services is 15-20 working days, with rush service available. They ship worldwide and have been providing show quality work for 50 years. The company is located in Houston,…

8. Caswell Inc. – Plug N’ Strip Chrome Stripping Kit

Domain: caswellplating.com

Registered: 1997 (28 years)

Introduction: Plug N’ Strip Chrome Stripping Kit from Caswell Inc. is designed for effective chrome stripping. It is part of a larger range of plating kits and accessories offered by Caswell. The kit is suitable for various applications, including automotive and industrial uses. It provides a user-friendly solution for removing chrome plating, making it ideal for restoration projects. The product is backed by c…

Strategic Sourcing Conclusion and Outlook for chrome removal service

In today’s competitive landscape, the chrome removal service presents significant opportunities for B2B buyers aiming to enhance their operational efficiency and product quality. By strategically sourcing chrome removal solutions, businesses can ensure the integrity of their substrates while preparing for subsequent plating processes. This not only improves aesthetic appeal but also extends the longevity and performance of the finished products.

Key takeaways include the importance of selecting service providers with a proven track record in environmental compliance, quality assurance, and advanced technology. Understanding the nuances of chrome stripping methods—such as electrochemical processes—can also contribute to better decision-making, ensuring that the underlying materials are preserved and ready for further processing.

As international B2B buyers from Africa, South America, the Middle East, and Europe explore these services, it is essential to partner with reputable providers who prioritize quality and sustainability. The future of chrome removal is poised for growth, driven by innovation and rising demand for eco-friendly practices. Engage with industry leaders today to secure your competitive advantage and unlock the full potential of your chrome removal needs.