Contents

Manufacturing Insight: Chrome Removal Service

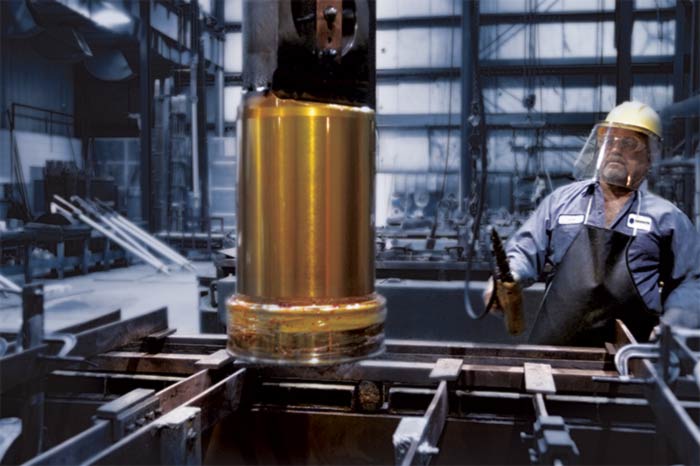

Precision Chrome Removal for High-Value Components

Chrome plating provides critical surface properties like wear resistance and corrosion protection, but legacy components often require precise chrome removal for repair, rework, or recycling. Traditional methods such as chemical stripping or abrasive blasting risk substrate damage, dimensional inaccuracy, and inconsistent results—particularly problematic for mission-critical aerospace, medical, and industrial parts. At Honyo Prototype, we address this challenge through advanced CNC machining services engineered for controlled, non-destructive chrome layer elimination.

Our proprietary CNC milling and turning processes remove chrome plating with micron-level precision, maintaining strict tolerances (±0.005 mm) while preserving the integrity of underlying substrates including stainless steel, aluminum, and exotic alloys. Unlike manual techniques, our computer-guided approach ensures uniform material removal across complex geometries, eliminating pitting, hydrogen embrittlement, and dimensional drift. This capability streamlines workflows for clients managing high-value asset lifecycles, reducing scrap rates and enabling cost-effective component refurbishment.

Engineers leverage our integrated manufacturing ecosystem to transition seamlessly from chrome removal to secondary operations like re-machining, re-plating, or final finishing—all under one roof with stringent AS9100-compliant quality control. For immediate project assessment, access our Online Instant Quote system to upload CAD files and receive a detailed technical feasibility analysis and competitive pricing within minutes, accelerating your prototyping and production timelines.

Technical Capabilities

Technical Specifications for Chrome Removal Service

Honyo Prototype offers precision chrome removal services tailored for components requiring high accuracy and surface integrity, particularly in applications where post-plating machining is necessary. Our capabilities include selective chrome layer removal using 3, 4, and 5-axis CNC milling and precision turning, ensuring tight tolerances and excellent dimensional control across a range of substrates.

This service is ideal for restoring functional surfaces of chrome-plated parts that have experienced wear, damage, or require rework due to dimensional inaccuracies. By removing chrome selectively, we enable precise re-machining, preparation for re-plating, or inspection of the base material.

Supported Materials:

Aluminum (e.g., 6061-T6, 7075-T6)

Steel (e.g., 4140, 1018, Stainless 304/316)

ABS (Acrylonitrile Butadiene Styrene)

Nylon (Polyamide, including glass-filled variants)

Our process ensures minimal impact on the underlying substrate while maintaining geometric accuracy and surface finish requirements.

| Parameter | Specification |

|---|---|

| Machining Axes | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning (2-axis and live tooling) |

| Tolerance Capability | ±0.0002″ (5 µm) for critical dimensions; typical ±0.001″ (25 µm) |

| Surface Finish (Ra) | 32–125 µin (0.8–3.2 µm) typical; down to 16 µin (0.4 µm) with fine finishing |

| Minimum Feature Size | 0.020″ (0.5 mm) using micro-milling tools |

| Material Compatibility | Aluminum, Steel, ABS, Nylon (all standard grades and common alloys) |

| Chrome Layer Removal Depth | 0.001″ – 0.010″ (25–250 µm), controllable per zone |

| Work Envelope (Max) | Milling: 24″ x 36″ x 20″; Turning: Ø16″ x 24″ max part length |

| Tooling | Carbide and diamond-coated end mills; specialized turning inserts |

| Quality Control | CMM, optical comparators, surface profilometry, go/no-go gauging |

| Applications | Aerospace components, hydraulic shafts, molds, prototypes, rework of tooling |

Note: Chrome removal is performed prior to final dimensional finishing. For re-plating readiness, surface preparation (e.g., polishing, etching) can be included as an additional step. All operations are documented and traceable per AS9100 and ISO 9001 standards.

From CAD to Part: The Process

Chrome Removal Service Process Overview

Honyo Prototype executes chrome removal as a precision surface treatment process for decorative or functional chrome plating on metal substrates (e.g., brass, steel, aluminum). Our workflow ensures dimensional integrity, substrate protection, and regulatory compliance, structured into five integrated phases:

CAD Upload and Material Specification

Clients initiate the process by uploading 3D CAD files (STEP, IGES, or native formats) via our secure portal. Critical metadata must accompany the upload: substrate material type, chrome layer thickness (if known), part geometry constraints, and target surface finish post-removal. This data feeds our AI-driven analysis engine, eliminating manual interpretation delays.

AI-Powered Quoting and Feasibility Assessment

Our proprietary AI engine analyzes the CAD geometry and material inputs to generate an instant technical quote. The system evaluates plating thickness distribution, complex feature accessibility (e.g., internal bores, sharp radii), and potential stripping-induced stress points. Quotes include cost, lead time (typically within 72 hours), and preliminary notes on substrate vulnerability. Human engineers validate all AI outputs for edge cases involving multi-layer coatings or heat-treated substrates.

DFM Analysis for Chrome Removal

Design for Manufacturability (DFM) focuses exclusively on process survivability. Engineers assess:

Risk of substrate pitting or etching from chemical stripping agents

Thermal distortion potential during mechanical stripping of thin-walled sections

Masking requirements for selective removal areas

Compatibility of residual stresses with post-removal finishing (e.g., powder coating)

DFM reports detail actionable modifications, such as recommending localized grit blasting over chemical stripping for nickel-underplate layers to prevent hydrogen embrittlement.

Controlled Production Execution

Removal occurs via a hybrid methodology selected during DFM:

Chemical Stripping: For uniform decorative chrome, using pH-stabilized alkaline solutions with real-time concentration monitoring. Substrates undergo immediate neutralization and passivation.

Abrasive Techniques: Precision glass bead or plastic media blasting for hard chrome or complex geometries, with automated pressure/angle controls to maintain ±0.002″ dimensional tolerance.

All processes adhere to ISO 14644-1 Class 7 cleanroom standards. Waste streams are treated onsite per EPA 40 CFR 266 regulations, with hazardous byproducts documented in chain-of-custody logs.

Validation and Delivery Protocol

Post-removal, parts undergo three-stage verification:

1. Adhesion Testing: ASTM D3359 cross-hatch evaluation to confirm zero residual chrome lift

2. Surface Metrology: Profilometer scans (Ra, Rz) against client-specified roughness parameters

3. Dimensional Certification: CMM inspection of critical features, with GD&T compliance reports

Final packaging uses VCI paper and humidity-controlled containers. Delivery includes full process documentation: stripping method logs, waste disposal certificates, and QC test data. Standard lead time from CAD upload to shipment is 5–7 business days for batches under 50 units.

This end-to-end process minimizes rework through proactive DFM intervention and closed-loop environmental controls, ensuring chrome-free substrates meet downstream finishing requirements without compromising structural integrity.

Start Your Project

Looking for a reliable chrome removal service for your prototyping or production needs? Honyo Prototype offers precision chrome removal with fast turnaround times, supported by our in-house factory in Shenzhen.

Contact Susan Leo today at [email protected] to discuss your project requirements and receive a customized quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.