Introduction: Navigating the Global Market for chrome plating equipment for sale

The global market for chrome plating equipment is characterized by its complexity and diversity, presenting unique challenges for international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe. Sourcing chrome plating equipment for sale requires a nuanced understanding of various technical specifications, supplier capabilities, and regional compliance standards. As industries increasingly prioritize durability and aesthetic appeal in their products, the demand for high-quality chrome plating solutions has surged, making it essential for buyers to navigate this landscape with confidence.

This comprehensive guide delves into the multifaceted world of chrome plating equipment, exploring different types and applications—from hard chrome plating machines to portable plating kits. We provide actionable insights into supplier vetting processes, cost considerations, and the latest technological advancements in the field. With a focus on empowering informed purchasing decisions, this guide serves as a crucial resource for B2B buyers seeking to optimize their sourcing strategies and enhance their operational efficiency.

By addressing the unique needs and challenges faced by buyers in various markets, particularly in regions like Saudi Arabia and Germany, this guide equips you with the knowledge to make strategic investments. Whether you’re looking to upgrade existing equipment or explore new suppliers, understanding the nuances of chrome plating technology will be key to your success in this competitive landscape.

Understanding chrome plating equipment for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hard Chrome Plating Equipment | High hardness plating layer, fast deposition speed, strong bonding force | Mechanical components, automotive parts, molds | Pros: Durable, efficient; Cons: Higher initial cost |

| Decorative Chrome Plating Kits | Aesthetic finish, typically lower thickness, user-friendly for small-scale operations | Automotive trim, home decor, consumer goods | Pros: Cost-effective, versatile; Cons: Less durable |

| Brush Chrome Plating Systems | Portable, suitable for on-site applications, easy to switch between plating modes | Automotive repairs, custom parts | Pros: Flexible, convenient; Cons: Limited to small areas |

| Barrel Chrome Plating Machines | Automated, continuous plating for bulk items, suitable for small parts | Mass production, fasteners, electronic components | Pros: High efficiency, consistent results; Cons: Initial setup complexity |

| Rack Chrome Plating Systems | Customizable for various part sizes, ideal for larger items, manual or semi-automated | Aerospace, heavy machinery, industrial equipment | Pros: Versatile, high-quality finish; Cons: Slower than automated systems |

What Are the Key Characteristics of Hard Chrome Plating Equipment?

Hard chrome plating equipment is designed to apply a thick layer of chrome, typically over 20 microns, to enhance the hardness and wear resistance of components. This equipment is widely used in industries such as automotive and manufacturing, where durability is crucial. When purchasing, buyers should consider the equipment’s current efficiency, ease of operation, and compatibility with the desired substrate materials.

How Do Decorative Chrome Plating Kits Differ from Other Types?

Decorative chrome plating kits focus on aesthetics rather than industrial durability. These kits are often user-friendly and ideal for small-scale operations, making them popular among businesses involved in automotive trim and home decor. Buyers should evaluate the cost-effectiveness and the finish quality, keeping in mind that while these kits provide a beautiful appearance, they may not offer the same longevity as hard chrome options.

What Advantages Do Brush Chrome Plating Systems Offer?

Brush chrome plating systems are portable and allow for on-site applications, making them suitable for repairs and custom projects. They are particularly useful in automotive industries where quick turnaround is needed. Buyers should consider the flexibility and convenience these systems provide, though they may be limited to smaller surface areas compared to other plating methods.

What Are the Benefits of Using Barrel Chrome Plating Machines?

Barrel chrome plating machines are designed for high-volume production, allowing for continuous plating of small parts. This equipment is ideal for industries requiring mass production, such as fasteners and electronic components. While these machines offer efficiency and consistency, buyers must be prepared for the initial complexity of setup and maintenance.

How Do Rack Chrome Plating Systems Cater to Larger Components?

Rack chrome plating systems are versatile and can be customized to accommodate various part sizes, making them suitable for larger industrial components. Common applications include aerospace and heavy machinery. Buyers should consider the quality of the finish and the operational speed, as these systems tend to be slower than fully automated options but can deliver superior results for specific applications.

Key Industrial Applications of chrome plating equipment for sale

| Industry/Sector | Specific Application of chrome plating equipment for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Plating of vehicle parts such as bumpers and wheels | Enhances aesthetic appeal and corrosion resistance | Compliance with local regulations and quality standards |

| Aerospace | Coating of engine components and landing gear | Increases durability and performance under extreme conditions | High precision and strict quality assurance measures |

| Manufacturing | Surface finishing of molds and tools | Improves wear resistance and extends tool life | Equipment capacity and compatibility with existing systems |

| Electronics | Plating of connectors and circuit boards | Ensures conductivity and improves product reliability | Sourcing of eco-friendly plating solutions |

| Oil & Gas | Coating of valves and pumps | Enhances resistance to harsh environments and extends equipment life | Consideration of chemical resistance and operational conditions |

How is Chrome Plating Equipment Used in the Automotive Industry?

In the automotive sector, chrome plating equipment is vital for enhancing the appearance and longevity of vehicle parts, including bumpers, wheels, and trim. The chrome layer provides a shiny finish that is not only aesthetically pleasing but also offers significant corrosion resistance. For international buyers, particularly in regions like Africa and the Middle East, sourcing equipment that complies with local environmental regulations is essential. Additionally, understanding the specific requirements for automotive standards in their region can influence the selection of chrome plating technology.

What Role Does Chrome Plating Equipment Play in Aerospace Applications?

Aerospace applications leverage chrome plating equipment to coat critical components such as engine parts and landing gear. The chrome layer significantly improves the durability and performance of these components, allowing them to withstand extreme temperatures and stress. Buyers in this sector must prioritize equipment that meets stringent aerospace standards for quality and reliability. International buyers should also consider the logistics of sourcing parts that are compliant with both local and international aerospace regulations.

How Does Chrome Plating Benefit the Manufacturing Sector?

In manufacturing, chrome plating is extensively used for surface finishing of molds and tools, enhancing their wear resistance and overall performance. This process is critical in extending the life of tooling equipment, thereby reducing operational costs. For B2B buyers, particularly in South America and Europe, evaluating the capacity of chrome plating equipment and its compatibility with existing manufacturing systems is crucial. Moreover, understanding the maintenance and operational efficiency of the equipment can lead to better long-term investments.

What is the Importance of Chrome Plating in Electronics?

In the electronics industry, chrome plating equipment is employed to coat connectors and circuit boards, ensuring excellent conductivity and reliability. The chrome layer helps to protect against oxidation, which is vital for maintaining the performance of electronic components. International buyers must consider sourcing eco-friendly plating solutions that align with global sustainability trends. Additionally, ensuring that the plating process meets the specific electrical standards required in their market is essential for product success.

How Does Chrome Plating Equipment Enhance Oil & Gas Operations?

Chrome plating equipment is crucial in the oil and gas industry for coating valves, pumps, and other components exposed to harsh environments. The chrome layer enhances resistance to corrosion and wear, significantly extending the lifespan of equipment. Buyers in this sector should focus on sourcing equipment that can withstand the specific chemical and operational conditions typical of oil and gas applications. Understanding the local market needs and regulations is also vital for successful procurement.

3 Common User Pain Points for ‘chrome plating equipment for sale’ & Their Solutions

Scenario 1: High Initial Investment Costs in Chrome Plating Equipment

The Problem: Many B2B buyers are deterred by the high initial costs associated with purchasing chrome plating equipment. Companies in regions like Africa and South America may have budget constraints that make it challenging to invest in advanced machinery, which can lead to a lack of competitiveness in the market. Buyers often fear that the return on investment (ROI) may not justify the expenditure, especially when considering ongoing maintenance and operational costs.

The Solution: To mitigate the burden of initial costs, buyers should consider exploring financing options or leasing arrangements for chrome plating equipment. This approach allows companies to spread the costs over time, making it easier to manage cash flow. Additionally, conducting a comprehensive cost-benefit analysis can help buyers identify the long-term savings and efficiencies gained through higher-quality plating processes. They should also investigate equipment suppliers that offer tiered pricing or financing solutions tailored to emerging markets. Prioritizing suppliers with strong service agreements can further protect the investment by ensuring ongoing support and maintenance, ultimately leading to a more sustainable operational model.

Scenario 2: Ensuring Consistent Quality and Performance in Chrome Plating

The Problem: Achieving consistent quality in chrome plating can be a significant challenge for manufacturers. Variability in the plating process can lead to defects such as poor adhesion, uneven thickness, or a dull finish, which may result in customer complaints and returns. B2B buyers often struggle to find equipment that delivers reliable performance across different materials and production scales, particularly in industries with strict quality standards.

The Solution: To ensure quality and performance, buyers should prioritize purchasing chrome plating equipment that includes advanced features such as automated monitoring systems and adjustable parameters for different plating conditions. Investing in equipment with robust quality control mechanisms—like real-time feedback loops and data logging—can help identify issues early in the process. Buyers should also engage with suppliers who provide thorough training and ongoing technical support, enabling their teams to better understand the intricacies of the equipment. Regular maintenance and calibration of the machines are essential to uphold quality standards, and establishing a standard operating procedure (SOP) can help maintain consistency in production.

Scenario 3: Navigating Regulatory Compliance and Environmental Concerns

The Problem: B2B buyers face increasing pressure to comply with environmental regulations related to chrome plating processes, particularly in regions like Europe and the Middle East, where standards are stringent. The use of hazardous materials in chrome plating can pose risks not only to the environment but also to the company’s reputation. Buyers are often uncertain about how to select equipment that meets these regulations while still providing effective results.

The Solution: Buyers should conduct thorough research on local and international regulatory requirements before purchasing chrome plating equipment. Opting for machinery that utilizes trivalent chromium instead of hexavalent chromium can significantly reduce environmental impact and regulatory scrutiny. Additionally, buyers should seek suppliers who demonstrate a commitment to sustainability and compliance by providing documentation and certifications for their equipment. Investing in advanced filtration and waste management systems can also help ensure compliance with environmental regulations. Establishing a partnership with a supplier who has expertise in regulatory matters can facilitate smoother integration of compliance measures into the plating process, ultimately enhancing the company’s credibility and market position.

Strategic Material Selection Guide for chrome plating equipment for sale

What Are the Common Materials Used in Chrome Plating Equipment?

When selecting chrome plating equipment, the choice of materials is crucial for ensuring optimal performance and durability. Here, we analyze four common materials used in chrome plating equipment, focusing on their properties, advantages and disadvantages, and implications for international B2B buyers.

1. Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand elevated temperatures. It typically has a temperature rating up to 800°F (427°C) and can handle moderate pressure.

Pros & Cons: The durability of stainless steel makes it ideal for long-term use in chrome plating applications. However, it can be more expensive than other materials, which may impact initial investment costs. Manufacturing complexity can also be higher due to the need for specialized welding techniques.

Impact on Application: Stainless steel’s corrosion resistance makes it suitable for environments with aggressive chemicals, ensuring longevity and reduced maintenance costs.

Considerations for International Buyers: Compliance with standards such as ASTM A240 is essential. Buyers from regions like Europe may prefer stainless steel due to its reliability in stringent quality regulations.

2. Polypropylene

Key Properties: Polypropylene is a thermoplastic polymer known for its chemical resistance and lightweight nature. It can handle temperatures up to 200°F (93°C) and is resistant to many acids and bases.

Pros & Cons: The primary advantage of polypropylene is its cost-effectiveness and ease of manufacturing, making it suitable for large-scale production. However, its lower temperature tolerance limits its use in high-heat applications, and it may not be as durable as metals.

Impact on Application: Polypropylene is ideal for components that require chemical resistance but are not subjected to high temperatures, such as tanks and piping in chrome plating setups.

Considerations for International Buyers: Buyers should ensure that the polypropylene used meets specific international standards, such as ISO 9001, to guarantee quality and performance.

3. Titanium

Key Properties: Titanium is renowned for its exceptional strength-to-weight ratio and outstanding corrosion resistance, particularly in acidic environments. It can withstand temperatures exceeding 1,600°F (871°C).

Pros & Cons: Titanium’s durability and resistance to corrosion make it ideal for high-performance applications. However, it is significantly more expensive than stainless steel and requires specialized manufacturing techniques, which can complicate production.

Impact on Application: Its high strength and resistance make titanium suitable for components exposed to harsh environments, ensuring longevity and reliability.

Considerations for International Buyers: Compliance with ASTM B348 is critical for titanium products. Buyers in regions like the Middle East may prioritize titanium for its performance in high-temperature applications.

4. Glass-Filled Nylon

Key Properties: Glass-filled nylon is a composite material that combines nylon with glass fibers to enhance strength and rigidity. It can operate in temperatures up to 300°F (149°C) and offers good chemical resistance.

Pros & Cons: This material is lightweight and cost-effective, making it suitable for various components in chrome plating equipment. However, it may not be as durable as metals and can be susceptible to wear over time.

Impact on Application: Glass-filled nylon is often used in non-structural components where weight savings and cost are crucial, such as in brackets and housings.

Considerations for International Buyers: Buyers should verify that the glass-filled nylon complies with relevant standards, such as ASTM D4066, to ensure quality and performance.

Summary Table of Material Selection for Chrome Plating Equipment

| Material | Typical Use Case for chrome plating equipment for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Tanks, pipes, and structural components | Excellent corrosion resistance and durability | Higher initial cost and manufacturing complexity | High |

| Polypropylene | Tanks and piping | Cost-effective and easy to manufacture | Limited temperature tolerance and durability | Low |

| Titanium | High-performance components in harsh environments | Outstanding strength and corrosion resistance | Very high cost and complex manufacturing | High |

| Glass-Filled Nylon | Non-structural components like brackets and housings | Lightweight and cost-effective | Less durable compared to metals | Medium |

This guide provides a comprehensive overview of material selection for chrome plating equipment, enabling international B2B buyers to make informed decisions tailored to their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for chrome plating equipment for sale

What Are the Key Stages in the Manufacturing Process of Chrome Plating Equipment?

The manufacturing process for chrome plating equipment involves several critical stages to ensure high performance and durability. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: The initial step involves sourcing high-quality raw materials, such as stainless steel and specialized alloys. These materials must meet specific standards to ensure corrosion resistance and structural integrity. Suppliers often conduct thorough inspections to verify the quality of materials before they enter the production line.

-

Forming: The forming stage includes cutting, bending, and shaping the materials into the desired components for the plating equipment. Advanced techniques such as CNC machining and laser cutting are commonly employed to achieve precise dimensions and tolerances. This stage is crucial, as the accuracy of the formed parts directly influences the overall efficiency of the chrome plating process.

-

Assembly: Once the individual components are prepared, they are assembled into the final product. Skilled technicians follow detailed assembly instructions to ensure that each unit operates as intended. This stage may involve integrating various subsystems, such as power supplies, plating tanks, and control panels, which require careful calibration and alignment.

-

Finishing: The finishing stage typically includes surface treatments, such as polishing and anodizing, to enhance the aesthetic appeal and functionality of the equipment. This may also involve applying protective coatings to prevent corrosion and wear during operation. Quality checks during this stage ensure that the equipment meets both aesthetic and operational standards.

How Is Quality Assurance Implemented in Chrome Plating Equipment Manufacturing?

Quality assurance (QA) in the manufacturing of chrome plating equipment is vital for ensuring that the final products meet international standards and customer expectations. The QA process involves several key components:

-

Adherence to International Standards: Manufacturers often seek certification to international quality management standards, such as ISO 9001. This certification indicates that a company has established a systematic approach to managing quality, which can significantly enhance buyer confidence. Additionally, specific certifications like CE mark for European markets or API for petroleum-related applications may be required.

-

Quality Control Checkpoints: Effective quality control (QC) systems integrate multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This step involves inspecting raw materials and components upon arrival to ensure they meet specified requirements.

– In-Process Quality Control (IPQC): During the manufacturing stages, regular inspections are conducted to monitor the production process and identify any deviations from quality standards.

– Final Quality Control (FQC): Before shipping, the final product undergoes comprehensive testing to verify its functionality, safety, and compliance with quality standards. -

Common Testing Methods: Various testing methods are employed, including dimensional inspections, pressure tests, and electroplating thickness assessments. These tests help verify that the equipment performs as expected and meets specified tolerances.

How Can B2B Buyers Verify Quality Control Processes of Suppliers?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to mitigate risks and ensure product reliability. Here are some actionable steps buyers can take:

-

Conduct Supplier Audits: Performing on-site audits allows buyers to evaluate the supplier’s production facilities, quality control procedures, and adherence to international standards. This firsthand observation can provide valuable insights into the supplier’s operational capabilities.

-

Request Quality Assurance Documentation: Buyers should request comprehensive documentation, including quality management system manuals, inspection reports, and certification copies. This documentation serves as proof of the supplier’s commitment to quality.

-

Engage Third-Party Inspection Services: Utilizing third-party inspection services can add an extra layer of assurance. These independent entities can conduct inspections and tests to verify that the equipment meets specified requirements before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must be aware of specific nuances related to quality control when dealing with suppliers in different regions. These nuances can include:

-

Regulatory Compliance Variances: Different countries have varying regulatory requirements for manufacturing and quality assurance. Buyers should familiarize themselves with the specific compliance standards applicable in their region, such as environmental regulations or safety standards.

-

Cultural Differences in Quality Standards: Quality perception can vary significantly across cultures. Understanding these differences is essential for establishing effective communication with suppliers and ensuring mutual expectations regarding quality.

-

Logistical Challenges: International logistics can complicate quality assurance efforts. Buyers should consider how transportation and customs processes may affect the condition of the equipment upon arrival and ensure that suppliers are aware of the importance of maintaining quality during shipping.

Conclusion

The manufacturing processes and quality assurance measures for chrome plating equipment are critical elements that B2B buyers must understand to make informed purchasing decisions. By familiarizing themselves with the stages of manufacturing, the importance of quality control, and the verification processes, buyers can significantly enhance their procurement strategies and ensure they receive reliable, high-quality equipment tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘chrome plating equipment for sale’

Introduction

This guide serves as a practical checklist for B2B buyers interested in sourcing chrome plating equipment. Given the complexity of chrome plating technology and the diversity of available equipment, following a structured approach can help ensure you make informed purchasing decisions that align with your operational needs and business goals.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for your chrome plating process. Consider factors such as the type of chrome plating (hard chrome vs. decorative), the size of parts to be plated, and the desired thickness of the chrome layer. This clarity will enable you to identify equipment that meets your specific operational needs.

- Key Considerations:

- Thickness requirements (e.g., 20μm or more for hard chrome).

- Material compatibility (e.g., steel, aluminum).

- Desired production capacity.

Step 2: Research Different Types of Equipment

Familiarize yourself with the various types of chrome plating equipment available in the market. Options range from small kits for decorative applications to large industrial setups for hard chrome plating. Understanding the differences can help you determine which type best suits your production scale and objectives.

- Types to Explore:

- Hard Chrome Plating Machines: Ideal for wear resistance and durability.

- Decorative Chrome Kits: Suitable for aesthetic applications in automotive or consumer products.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly assess potential suppliers. This step is crucial to ensure reliability and quality in your sourcing process. Request detailed company profiles, technical documentation, and case studies to gain insights into their capabilities.

- What to Look For:

- Supplier certifications (ISO, CE).

- Customer references, especially from similar industries or regions.

- After-sales support and warranty terms.

Step 4: Request Quotes and Compare Pricing

Once you have a shortlist of potential suppliers, request quotes for the equipment that meets your specifications. Ensure that the quotes include all associated costs, such as shipping, installation, and training. Comparing these factors will help you identify the best value for your investment.

- Price Comparison Criteria:

- Base price of the equipment.

- Additional costs (installation, training).

- Payment terms and financing options.

Step 5: Review Compliance and Regulatory Requirements

Ensure that the chrome plating equipment complies with local and international regulations. This includes environmental standards for waste disposal and safety standards for operation. Non-compliance can lead to costly fines and operational delays.

- Regulatory Aspects to Check:

- Environmental impact assessments.

- Safety certifications and operational guidelines.

- Local regulations regarding chemical handling and waste management.

Step 6: Assess Training and Support Services

Inquire about the training and support services offered by the supplier. Proper training is essential for your team to operate the equipment efficiently and safely. Additionally, robust support services can minimize downtime and enhance productivity.

- Support Services to Consider:

- On-site training for operators.

- Technical support availability (phone, email, on-site).

- Access to spare parts and maintenance services.

Step 7: Finalize Your Purchase Agreement

After completing the above steps, it’s time to finalize your purchase agreement. Ensure that all terms discussed are clearly documented, including delivery timelines, installation responsibilities, and warranty coverage. A well-drafted agreement protects both parties and ensures a smooth transaction.

- Contractual Elements to Include:

- Delivery and installation timelines.

- Warranty terms and conditions.

- Payment milestones and penalties for non-compliance.

By following this checklist, you can navigate the complexities of sourcing chrome plating equipment effectively, ensuring that your investment aligns with your operational needs and business objectives.

Comprehensive Cost and Pricing Analysis for chrome plating equipment for sale Sourcing

What are the Key Cost Components in Chrome Plating Equipment Manufacturing?

When evaluating the costs associated with chrome plating equipment, several critical components come into play:

-

Materials: The primary materials include high-quality stainless steel, chromium compounds, and various chemicals used in the plating process. The choice of materials significantly impacts the durability and performance of the equipment, which in turn affects the overall cost.

-

Labor: Labor costs encompass the wages of skilled workers involved in the design, manufacturing, and assembly of the equipment. In regions with higher labor costs, such as Europe, the overall pricing may reflect these expenses more prominently.

-

Manufacturing Overhead: This includes utilities, rent for production facilities, and other indirect costs associated with running a manufacturing operation. Efficient management of these overheads can help suppliers offer more competitive pricing.

-

Tooling: The costs associated with molds, dies, and specialized tools necessary for production can be substantial. These upfront costs are often amortized over the production volume, influencing the price per unit.

-

Quality Control (QC): To ensure that equipment meets industry standards, significant investment in quality assurance processes is essential. This includes testing and certification, which adds to the overall cost but is critical for maintaining reliability and safety standards.

-

Logistics: Transportation costs, including shipping and handling, can vary widely depending on the destination and mode of transport. International buyers, particularly in Africa and South America, should factor in potential tariffs and customs fees.

-

Margin: Manufacturers typically add a profit margin to their costs, which can vary significantly based on their market position and competitiveness.

How Do Price Influencers Impact Chrome Plating Equipment Costs?

Several factors can influence the pricing of chrome plating equipment:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to economies of scale, reducing the per-unit cost. Buyers should negotiate MOQs to ensure they are getting the best pricing based on their needs.

-

Specifications and Customization: Custom equipment tailored to specific applications can incur additional costs. Buyers should clearly outline their specifications to avoid unexpected expenses.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO standards) can increase costs but are vital for ensuring longevity and compliance with industry regulations.

-

Supplier Factors: The reputation and reliability of the supplier can significantly impact pricing. Established suppliers may charge a premium for their products due to their track record of quality and service.

-

Incoterms: The chosen Incoterms (International Commercial Terms) will affect shipping costs and responsibilities, influencing the total landed cost of the equipment.

What Buyer Tips Can Help Secure Better Pricing for Chrome Plating Equipment?

To navigate the complexities of sourcing chrome plating equipment effectively, international B2B buyers should consider the following strategies:

-

Negotiation: Engage in discussions with suppliers to negotiate terms, including price, payment conditions, and delivery timelines. Leverage the potential for bulk purchases to secure discounts.

-

Cost-Efficiency Analysis: Evaluate the Total Cost of Ownership (TCO), which includes initial purchase price, maintenance, operational costs, and potential downtime. A lower upfront cost may lead to higher long-term expenses if the equipment is not durable.

-

Understand Pricing Nuances: Be aware that pricing can vary by region due to differing labor costs, material availability, and market demand. Buyers from regions like Saudi Arabia and Germany should conduct market research to benchmark prices effectively.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and service. Regular communication can help in negotiating favorable terms and receiving timely updates on new equipment or technologies.

-

Request Detailed Quotes: When seeking quotations, request detailed breakdowns of costs to understand where expenses are allocated. This transparency can facilitate more informed decision-making.

Disclaimer for Indicative Prices

Pricing for chrome plating equipment can vary widely based on the aforementioned factors and should be considered indicative only. Buyers are encouraged to obtain multiple quotes and conduct thorough due diligence to ensure they are making well-informed purchasing decisions.

Alternatives Analysis: Comparing chrome plating equipment for sale With Other Solutions

Exploring Viable Alternatives to Chrome Plating Equipment

In the realm of surface finishing, chrome plating equipment is a popular choice due to its durability and aesthetic appeal. However, several alternative solutions exist that may better suit specific operational needs, budget constraints, or environmental considerations. This section compares chrome plating equipment for sale with other viable methods, providing B2B buyers with actionable insights to guide their purchasing decisions.

| Comparison Aspect | Chrome Plating Equipment For Sale | Electroless Nickel Plating | Powder Coating |

|---|---|---|---|

| Performance | High wear resistance, smooth finish | Excellent corrosion resistance, uniform coating | Durable finish, impact-resistant |

| Cost | Moderate to high initial investment | Moderate initial investment, lower long-term costs | Low to moderate initial investment |

| Ease of Implementation | Requires skilled operators and safety measures | Easier to implement, less skill required | Relatively simple, minimal training needed |

| Maintenance | Regular maintenance of equipment and chemicals | Lower maintenance; less chemical handling | Low maintenance, generally self-cleaning |

| Best Use Case | Automotive, aerospace, and decorative parts | Electronics, plumbing, and automotive components | Industrial applications, furniture, and appliances |

Detailed Breakdown of Alternatives

Electroless Nickel Plating: A Viable Alternative

Electroless nickel plating is a chemical process that deposits nickel-phosphorus alloy onto a substrate without the need for electrical current. This method provides excellent corrosion resistance and uniform coating, making it suitable for complex geometries and intricate parts. While the initial investment is moderate, the long-term costs can be lower due to reduced chemical handling and waste. However, the process requires careful control of bath chemistry, which may necessitate some level of operator training.

Powder Coating: A Cost-Effective Solution

Powder coating is a dry finishing process that involves applying a powdered paint to a surface, which is then cured under heat to form a hard layer. This method is known for its durability and resistance to chipping, scratching, and fading, making it ideal for industrial applications and outdoor furniture. The initial investment for powder coating equipment can be lower than chrome plating, and the process is generally easier to implement, requiring minimal training. However, the finish may not achieve the same aesthetic appeal as chrome plating, which could be a consideration for decorative applications.

Conclusion: Choosing the Right Solution for Your Needs

When evaluating chrome plating equipment for sale against alternatives like electroless nickel plating and powder coating, B2B buyers should consider their specific application requirements, budget, and operational capabilities. Chrome plating offers unmatched durability and aesthetic qualities but comes with higher costs and maintenance. In contrast, electroless nickel plating provides a great balance of performance and ease of implementation, while powder coating stands out as a cost-effective solution for industrial needs. By carefully assessing these factors, businesses can select the most appropriate surface finishing technology to enhance their product offerings and operational efficiency.

Essential Technical Properties and Trade Terminology for chrome plating equipment for sale

What Are the Essential Technical Properties of Chrome Plating Equipment?

When evaluating chrome plating equipment for sale, it is crucial to consider several technical specifications that directly influence performance, durability, and suitability for specific applications. Here are key properties to keep in mind:

-

Cathode Current Efficiency

This specification typically ranges from 50% to 65% in modern hard chrome plating equipment. High cathode current efficiency indicates a better use of electrical energy during the electroplating process, resulting in faster deposition rates and lower operating costs. This property is essential for businesses aiming to maximize productivity and minimize waste. -

Plating Thickness

The thickness of the chrome layer is usually above 20 micrometers (μm) for effective wear resistance and durability. A thicker chrome layer enhances the component’s hardness (ranging from 900 to 1200 HV) and improves its resistance to corrosion and wear. Buyers should assess the required thickness for their specific applications to ensure optimal performance. -

Bonding Strength

The bond between the chrome plating layer and the substrate material should be robust to prevent peeling or flaking during use. Equipment that allows for proper pre-treatment and uniform deposition will achieve a strong bond, essential for parts subjected to high stress or friction. This property is particularly critical in industries such as automotive and aerospace. -

Operating Temperature Range

Chrome plating solutions typically operate at temperatures between 50°C and 55°C. Maintaining the correct temperature is vital for achieving consistent quality in the plating process. Equipment that includes precise temperature controls can improve production efficiency and reduce defects. -

Plating Solution Composition

Key components like Chromium Trioxide (CrO3) and sulfate ions (SO42-) in the plating solution must be carefully controlled. For example, CrO3 concentrations usually range from 220 to 250 grams per liter. Understanding the chemical composition is crucial for ensuring compliance with environmental regulations and achieving desired plating characteristics. -

Maintenance Requirements

Regular maintenance is necessary to ensure long-term reliability and performance of chrome plating equipment. Features such as easy access to components for cleaning and inspection can significantly reduce downtime. Buyers should consider equipment with user-friendly maintenance protocols to enhance operational efficiency.

What Are Common Trade Terms in the Chrome Plating Industry?

Understanding industry terminology is crucial for effective communication and negotiation when purchasing chrome plating equipment. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the chrome plating industry, OEMs may provide specialized equipment tailored to specific applications, making it essential for buyers to verify compatibility with their needs. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. This term is important for B2B buyers as it affects inventory costs and production planning. Understanding MOQ helps in budgeting and ensuring that the supplier can meet production demands without excess inventory. -

RFQ (Request for Quotation)

An RFQ is a standard business process to invite suppliers to submit price proposals for specific products or services. For chrome plating equipment, issuing an RFQ allows buyers to compare prices, specifications, and terms from multiple suppliers, enabling informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce (ICC) that outline the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for understanding shipping costs, insurance, and risk management when importing chrome plating equipment. -

Lead Time

This refers to the time taken from placing an order to receiving the product. In the context of chrome plating equipment, lead time can significantly impact production schedules. Buyers should inquire about lead times to plan their projects effectively. -

Turnkey Solution

A turnkey solution refers to a complete package provided by a supplier that includes equipment, installation, and training. This term is relevant for buyers seeking a hassle-free setup process for their chrome plating operations, ensuring they can start production quickly and efficiently.

By understanding these technical properties and trade terminologies, international B2B buyers can make more informed decisions when purchasing chrome plating equipment, leading to successful procurement and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the chrome plating equipment for sale Sector

What Are the Current Market Dynamics and Key Trends in Chrome Plating Equipment for Sale?

The chrome plating equipment market is experiencing significant growth driven by several global factors. Increased demand for high-performance materials in industries such as automotive, aerospace, and electronics is propelling the need for advanced chrome plating solutions. Emerging economies in Africa and South America are particularly witnessing a surge in manufacturing activities, leading to a higher demand for chrome-plated components. Additionally, technological advancements are facilitating the adoption of automated and semi-automated plating systems, which enhance efficiency and reduce labor costs.

International B2B buyers are also becoming more attuned to sourcing trends that emphasize flexibility and customization. The rise of Industry 4.0 is leading to a demand for integrated solutions that combine chrome plating with other processes, such as anodizing and electroless plating. This trend is particularly relevant in regions like the Middle East and Europe, where manufacturers are seeking to streamline operations and reduce lead times. Furthermore, the shift towards online procurement platforms is transforming how businesses source chrome plating equipment, providing access to a wider range of suppliers and facilitating competitive pricing.

How Is Sustainability Influencing Sourcing Trends in Chrome Plating Equipment?

Sustainability has become a crucial factor in the sourcing of chrome plating equipment. The environmental impact of traditional plating methods, which often involve hazardous chemicals, has led to increased scrutiny from regulatory bodies and consumers alike. As a result, B2B buyers are prioritizing suppliers that demonstrate a commitment to sustainable practices. This includes using eco-friendly plating solutions that minimize harmful emissions and waste.

Moreover, ethical sourcing is gaining traction among international buyers. Companies are increasingly seeking partners who adhere to fair labor practices and transparent supply chains. Certifications such as ISO 14001, which focuses on effective environmental management systems, are becoming essential for suppliers aiming to capture the growing market of environmentally conscious buyers. By selecting chrome plating equipment that aligns with sustainability goals, businesses not only comply with regulations but also enhance their brand reputation in an increasingly competitive marketplace.

What Is the Historical Evolution of Chrome Plating Equipment and Its Impact on B2B?

The history of chrome plating equipment dates back to the early 20th century when it was primarily used for decorative purposes in the automotive industry. Over the decades, the technology has evolved significantly, transitioning from manual processes to sophisticated automated systems. The introduction of hard chrome plating in the mid-20th century revolutionized the industry by providing enhanced wear resistance and corrosion protection for industrial applications.

This evolution has had a profound impact on B2B dynamics, particularly in how manufacturers approach quality and efficiency. The development of advanced plating techniques, such as trivalent chromium processes, has not only improved the performance of chrome plating but has also addressed environmental concerns associated with hexavalent chromium. Today, the market continues to innovate, with a focus on integrating digital technologies that offer real-time monitoring and data analytics, thus enhancing operational efficiency and product quality.

In conclusion, understanding the current market dynamics, sustainability considerations, and historical context is essential for B2B buyers navigating the chrome plating equipment sector. By leveraging these insights, businesses can make informed decisions that align with their operational needs and ethical commitments.

Frequently Asked Questions (FAQs) for B2B Buyers of chrome plating equipment for sale

-

How do I choose the right chrome plating equipment for my business?

Choosing the right chrome plating equipment involves assessing your production needs, budget, and the specific applications you intend to serve. Consider factors such as the size of the parts you will be plating, the desired thickness of the chrome layer, and the materials being plated. Additionally, evaluate the equipment’s efficiency, ease of operation, and maintenance requirements. Consulting with manufacturers or suppliers can provide insights into the best options available for your specific industry, whether it be automotive, aerospace, or machinery. -

What is the best type of chrome plating equipment for small-scale operations?

For small-scale operations, portable chrome plating kits or brush plating systems are ideal. These systems are cost-effective and easy to use, making them suitable for businesses that may not require large volumes of production. Look for kits that include essential components such as power supplies and various applicators. Ensure that the equipment allows for versatility in plating different parts and materials while still achieving high-quality finishes. -

What are the key factors to consider when sourcing chrome plating equipment internationally?

When sourcing chrome plating equipment internationally, consider factors such as supplier reputation, compliance with international quality standards, and shipping logistics. It’s vital to verify the supplier’s experience and client references to assess reliability. Additionally, consider the total landed cost, including shipping, customs duties, and potential tariffs. Engaging a local expert familiar with regulations in your region can help navigate the complexities of international trade. -

What customization options are available for chrome plating equipment?

Many manufacturers offer customization options for chrome plating equipment to meet specific business needs. Customization can include adjustments in the size of the plating tank, modifications to the plating process for different materials, or enhancements in automation features. Discussing your requirements with the supplier can lead to tailored solutions that improve efficiency and output. Ensure that any custom features still adhere to industry standards for quality and safety. -

What are typical minimum order quantities (MOQs) for chrome plating equipment?

Minimum order quantities for chrome plating equipment can vary significantly based on the supplier and the type of equipment. Generally, larger manufacturers may have higher MOQs due to the cost of production, while smaller suppliers might offer more flexible options. It’s advisable to inquire directly with suppliers about their MOQs and negotiate based on your business needs and potential for future orders. -

What payment terms should I expect when purchasing chrome plating equipment?

Payment terms for chrome plating equipment purchases can vary based on the supplier’s policies and the transaction size. Common terms include a deposit upon order confirmation, with the balance due before shipment or upon delivery. Some suppliers may offer financing options or extended payment terms for larger orders. It’s essential to clarify these terms upfront to avoid any misunderstandings and to ensure that the terms align with your cash flow capabilities. -

How can I ensure quality assurance (QA) for chrome plating equipment?

To ensure quality assurance for chrome plating equipment, request detailed specifications and performance standards from the supplier. Conducting factory visits or audits can provide firsthand insight into their manufacturing processes. Additionally, inquire about certifications such as ISO compliance and any warranty or after-sales support they offer. Implementing a robust QA process within your own operations, including regular equipment maintenance and testing, will further enhance product quality. -

What logistics considerations should I keep in mind when importing chrome plating equipment?

When importing chrome plating equipment, logistics considerations include shipping methods, transit times, and customs clearance processes. Evaluate whether air freight or sea freight is more suitable based on urgency and cost. Additionally, familiarize yourself with import regulations in your country, including any necessary permits or documentation required for chemicals used in chrome plating. Working with experienced logistics partners can streamline the import process and help mitigate potential delays.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Chrome Plating Equipment For Sale Manufacturers & Suppliers List

1. Black Chrome Electroplating Kit – 24K Gold Plating Machine

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: – Black Chrome Electroplating kit, Gold/Chrome/Rhodium/Plating Machine kit: Brand New, $269.00 or Best Offer, Free delivery, Located in United States, 38 watchers

– 24k Gold/Chrome Plating Machine, 24K Gold Plating Kit: Includes Gold solution, Brand New, $239.99 or Best Offer, Free delivery, Located in United States, 66 sold

– Gold Plating Kit, Gold plating machine for plating car parts: Brand New…

2. Electroplating Machines – RST-DDG-001

Domain: electroplatingmachines.com

Registered: 2022 (3 years)

Introduction: {‘Model No.’: ‘RST-DDG-001’, ‘Price’: ‘US$6,000-US$200,000’, ‘Min. order quantity’: ‘1 Set’, ‘Capacity’: ‘5 Sets / Month’, ‘Country of origin’: ‘Hebei, China’, ‘Trade terms’: ‘FOB, CFR, CIF’, ‘Payment terms’: ‘L/C, T/T’, ‘Raw material’: ‘New Polypropylene(NPP), PVC, Stainless Steel, Copper’, ‘Size’: ‘Customized’, ‘Features’: [‘Anti-corrosion & Anti-oxidation’, ‘Supply conductive & insulating coati…

3. Eastwood – Electroplating Solution

Domain: eastwood.com

Registered: 1995 (30 years)

Introduction: Eastwood Electroplating is a process that allows users to create a durable, corrosion-resistant finish on metal surfaces. The product is designed for DIY enthusiasts and professionals looking to restore or enhance metal parts. It features a simple application process, requiring minimal equipment. The electroplating solution is suitable for various metals and provides a shiny, attractive finish. It…

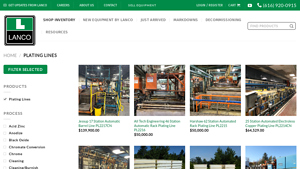

4. Lanco Corporation – Plating Lines

Domain: lanco-corp.com

Registered: 1997 (28 years)

Introduction: Plating Lines offered by Lanco Corporation include various models such as: 1. Jessup 17 Station Automatic Barrel Line PL2217CN – $139,900.00 2. All Tech Engineering 46 Station Automatic Rack Plating Line PL2216 – $50,000.00 3. Harshaw 62 Station Automated Rack Plating Line PL2215 – $50,000.00 4. 25 Station Automated Electroless Copper Plating Line PL2214CN – $64,529.00 5. 19 Station Automated Iron…

5. SPROCKET – Chrome Plated IDLE SPROCKET DRCS40-17-17

Domain: machinio.com

Registered: 2013 (12 years)

Introduction: {“products”:[{“name”:”Chrome plated IDLE SPROCKET DRCS40-17-17 / 6203Z BEARING”,”condition”:”new”,”manufacturer”:”SPROCKET”,”price”:”$40 USD”,”location”:”Muskegon, MI”},{“name”:”Star Ultra-Max 24 Inch Chrome Plated Propane Thermostatic Griddle”,”condition”:”used”,”price”:”$3,299 USD”,”location”:”Grand Rapids, MI”},{“name”:”Glycon GL17840 Feed Screw For Injection Molding Machine”,”condition”:”used”…

6. Hard Chrome Systems – Chromic Acid Purifiers & Plating Equipment

Domain: hard-chromesystems.com

Registered: 1998 (27 years)

Introduction: Porous pot, chromic-acid purifiers for removing dissolved iron, copper, nickel contaminants and reoxidized trivalent chrome; hard chrome plating equipment and supplies; two bus bar, reversible plating racks; plating fixtures and conforming lead mat anodes; tank ventilation equipment meeting EPA standards; fume scrubbers and exhaust hoods; lead-lined chrome plating tanks; plating rectifiers; lead m…

7. Walmart – Jewelry Gold Plating Kit

Domain: walmart.com

Registered: 1995 (30 years)

Introduction: This company, Walmart – Jewelry Gold Plating Kit, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for chrome plating equipment for sale

In conclusion, effective strategic sourcing of chrome plating equipment is crucial for enhancing operational efficiency and product quality across diverse industries. Buyers should prioritize equipment that offers high cathode current efficiency, fast deposition speeds, and strong bonding forces to ensure superior plating outcomes. Additionally, understanding the technical specifications and operational guidelines, such as the optimal plating solution parameters and maintenance practices, can significantly impact the longevity and performance of the equipment.

As international markets, especially in Africa, South America, the Middle East, and Europe, continue to evolve, there is a growing demand for reliable chrome plating solutions that meet both industry standards and sustainability criteria. By leveraging strategic sourcing practices, businesses can not only reduce costs but also enhance their competitive edge in the global marketplace.

Looking forward, we encourage B2B buyers to engage with reputable suppliers and manufacturers who can provide tailored solutions to meet their specific needs. The future of chrome plating equipment is promising, and those who act decisively will position themselves advantageously in their respective markets. Explore your options today and invest in the technology that will drive your business forward.