Introduction: Navigating the Global Market for chrome bumper cleaner

In the fast-paced world of automotive maintenance, sourcing effective chrome bumper cleaner can pose significant challenges for international B2B buyers. The need to restore and maintain the appearance of chrome surfaces is paramount, especially in regions like Africa, South America, the Middle East, and Europe, where environmental factors can accelerate tarnishing and corrosion. This guide is designed to equip businesses with the knowledge necessary to navigate the complexities of the chrome cleaner market.

We will delve into various types of chrome cleaners, including heavy-duty and light-duty formulations, highlighting their specific applications and benefits. Additionally, we will address supplier vetting processes, ensuring buyers can identify reputable manufacturers and distributors. Understanding the cost structures associated with chrome bumper cleaners is also vital, as it enables businesses to budget effectively while maximizing value.

By providing comprehensive insights into product specifications, market trends, and procurement strategies, this guide empowers B2B buyers to make informed purchasing decisions. Whether you’re operating in Nigeria, Saudi Arabia, or any other global market, having the right chrome bumper cleaner can significantly enhance the longevity and aesthetic appeal of automotive chrome surfaces, ultimately contributing to customer satisfaction and brand reputation.

Understanding chrome bumper cleaner Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Heavy Metal Polish | Contains larger abrasive particles for deep cleaning | Restoration of heavily oxidized chrome | Pros: Effective on severe tarnish; quick results. Cons: Can be harsh on delicate surfaces. |

| Light Metal Polish | Uses finer abrasives for routine maintenance | Regular upkeep of chrome surfaces | Pros: Gentle on metal; ideal for light tarnish. Cons: May not remove deep stains effectively. |

| Chrome Polish & Rust Remover | Combines cleaning and protective sealing properties | Restoration and protection of chrome parts | Pros: Long-lasting protection; easy application. Cons: May require multiple applications for best results. |

| Ceramic Chrome Coating | Advanced protection with a ceramic layer for durability | High-end vehicle detailing | Pros: Exceptional shine; resistant to contaminants. Cons: Higher cost; requires professional application. |

| All-in-One Cleaner | Multi-functional products that clean, polish, and protect | General maintenance for fleets | Pros: Saves time and effort; versatile. Cons: May not specialize in heavy-duty cleaning. |

What Are the Characteristics of Heavy Metal Polish?

Heavy metal polish is designed for intensive cleaning and restoration of severely oxidized chrome surfaces. Its formulation includes larger abrasive particles that effectively tackle rust, tarnish, and deep stains. This type of cleaner is particularly suitable for B2B applications in industries where vehicles or equipment endure harsh conditions, such as transportation or construction. Buyers should consider the balance between its aggressive cleaning capabilities and potential damage to delicate finishes.

How Does Light Metal Polish Differ from Other Types?

Light metal polish features finer abrasives, making it ideal for routine maintenance of chrome surfaces that have only light tarnish or oxidation. This product is suitable for businesses that focus on regular upkeep, such as car detailers or fleet management services. It allows for quick polishing without the risk of damaging the underlying surface. B2B buyers should weigh the benefits of maintaining shine against the limitations in removing heavier stains.

Why Choose Chrome Polish & Rust Remover?

Chrome polish and rust remover products combine the cleaning power of abrasives with protective sealants that help maintain the chrome’s luster over time. They are particularly effective for restoring chrome bumpers and wheels in automotive applications. B2B buyers will find this type advantageous for both immediate restoration and long-term protection. However, it may require multiple applications for optimal results, which could impact labor costs.

What Advantages Do Ceramic Chrome Coatings Offer?

Ceramic chrome coatings provide an advanced level of protection by forming a durable layer over chrome surfaces. This type is best suited for high-end vehicles or luxury fleets that demand exceptional shine and resistance to environmental contaminants. While the upfront cost can be higher, the long-lasting effects and reduced frequency of maintenance may justify the investment for B2B buyers focused on premium services.

What Makes All-in-One Cleaners a Practical Choice?

All-in-one cleaners are versatile products that simplify the cleaning, polishing, and protecting processes into a single application. They are particularly beneficial for businesses managing fleets or offering comprehensive detailing services. While they save time and can be effective for general maintenance, B2B buyers should consider whether their performance meets the specific needs of heavily tarnished chrome surfaces.

Key Industrial Applications of chrome bumper cleaner

| Industry/Sector | Specific Application of chrome bumper cleaner | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Used in assembly lines for polishing chrome components | Enhances product quality and customer satisfaction | Consistency in supply, compliance with safety standards |

| Vehicle Repair and Restoration | Essential for detailing and restoring vintage and luxury cars | Increases service offerings and customer retention | Availability of bulk orders, compatibility with various surfaces |

| Fleet Management | Regular maintenance of fleet vehicles’ chrome fixtures | Reduces long-term maintenance costs and downtime | Cost-effectiveness, ease of use, and rapid application |

| Retail Automotive Accessories | Cleaning and polishing chrome parts for resale | Improves product appeal and marketability | Supplier reliability, product effectiveness, and packaging options |

| Heavy-Duty Equipment | Maintenance of chrome bumpers and parts on trucks and machinery | Extends equipment lifespan and enhances performance | Product durability, resistance to harsh environments, and bulk pricing |

How is Chrome Bumper Cleaner Used in Automotive Manufacturing?

In the automotive manufacturing sector, chrome bumper cleaner is crucial for maintaining the aesthetic appeal of vehicles during the assembly process. It is used to polish chrome components, ensuring they are free from oxidation and scratches before the final product is presented to customers. This not only enhances the overall quality of the vehicle but also elevates customer satisfaction, leading to repeat business. International buyers, particularly from regions like Africa and the Middle East, should prioritize sourcing cleaners that comply with local regulations and offer consistent performance across different climates.

What Role Does Chrome Bumper Cleaner Play in Vehicle Repair and Restoration?

For vehicle repair and restoration businesses, chrome bumper cleaner is an essential tool for detailing vintage and luxury cars. It effectively removes tarnish and oxidation, restoring chrome parts to their original luster. This service can significantly increase customer retention, as clients are often willing to invest in premium detailing for their prized vehicles. Buyers in South America and Europe should consider the cleaner’s compatibility with various chrome finishes and the availability of bulk purchasing options to ensure they can meet demand efficiently.

Why is Chrome Bumper Cleaner Important for Fleet Management?

In fleet management, regular maintenance of vehicles is vital to minimize downtime and extend the lifespan of assets. Chrome bumper cleaner is used to maintain the chrome fixtures on fleet vehicles, preventing rust and deterioration. This proactive approach can lead to substantial long-term savings on maintenance costs. Businesses in Africa and the Middle East should focus on sourcing cost-effective cleaning solutions that allow for easy application, as well as those that are effective in diverse environmental conditions.

How Does Chrome Bumper Cleaner Enhance Retail Automotive Accessories?

Retailers of automotive accessories utilize chrome bumper cleaner to enhance the appearance of chrome parts before sale. By ensuring products are polished and free of imperfections, retailers can significantly improve their marketability and appeal to consumers. Suppliers should ensure their products are reliable and effective, with packaging that meets the demands of retail environments. International buyers, especially from Europe and South America, should look for cleaners that offer competitive pricing and efficient delivery options.

What Benefits Does Chrome Bumper Cleaner Offer for Heavy-Duty Equipment Maintenance?

Heavy-duty equipment, such as trucks and machinery, often features chrome components that require regular maintenance to prevent wear and tear. Chrome bumper cleaner helps to maintain the appearance and functionality of these parts, extending their operational lifespan and enhancing performance. For businesses in the Middle East and Africa, sourcing durable cleaning solutions that can withstand harsh working environments is crucial. Buyers should prioritize products that offer bulk pricing and are designed for heavy-duty applications to optimize their maintenance processes.

3 Common User Pain Points for ‘chrome bumper cleaner’ & Their Solutions

Scenario 1: The Challenge of Oxidation and Stains on Chrome Bumpers

The Problem: B2B buyers in the automotive industry often face the issue of heavily oxidized and stained chrome bumpers, particularly in regions with harsh environmental conditions, such as high humidity or pollution. Over time, these conditions lead to a dull appearance and can even result in surface corrosion. This not only affects the aesthetic appeal of vehicles but can also diminish their resale value. For businesses that rely on maintaining a fleet or reselling vehicles, this becomes a critical pain point, as it necessitates frequent and costly detailing services.

The Solution: To effectively combat oxidation and stains, B2B buyers should source a heavy-duty chrome bumper cleaner that contains fine abrasives and protective sealants. Products that incorporate advanced formulations, such as those found in Chemical Guys’ or Turtle Wax’s offerings, can efficiently restore chrome surfaces while providing a protective barrier against future damage. Buyers should look for cleaners that are easy to apply and remove, allowing for quick turnaround times. Regular maintenance using a light metal polish can also help sustain the shine and prevent the buildup of grime, ultimately extending the lifespan of chrome components.

Scenario 2: Difficulty in Achieving a Mirror-Like Finish

The Problem: Many B2B buyers struggle with the application process of chrome bumper cleaners, often failing to achieve a desired mirror-like finish. This challenge can arise from using the wrong type of cleaner or improper application techniques. The inability to produce a high-quality finish can lead to customer dissatisfaction, especially in businesses focused on aesthetics, such as car dealerships or detailing services.

The Solution: To address this issue, B2B buyers should invest in training their staff on the proper techniques for applying chrome bumper cleaners. Utilizing products specifically designed for chrome, such as those with acrylic sealants, can enhance the overall appearance and longevity of the finish. It is also advisable to conduct test applications on less visible areas before full application to ensure compatibility and desired results. Additionally, adopting a two-step process—first cleaning with a specialized cleaner followed by a polish—can significantly improve the final appearance. Providing staff with clear, step-by-step guides can further enhance their skills and confidence in achieving that showroom-quality finish.

Scenario 3: The Environmental Impact of Chrome Cleaning Products

The Problem: In today’s market, B2B buyers are increasingly concerned about the environmental impact of the products they use. Many chrome bumper cleaners contain harsh chemicals that can be harmful to both the environment and the personnel applying them. This concern is especially relevant for businesses operating in regions where regulations regarding chemical use are strict, and sustainability is a key value proposition.

The Solution: Buyers should seek out eco-friendly chrome bumper cleaners that utilize biodegradable ingredients and sustainable packaging. Brands that prioritize environmental responsibility, such as Turtle Wax, often provide formulations that are effective yet safe for both users and the planet. Additionally, conducting thorough research on suppliers can help businesses identify products that align with their sustainability goals. Implementing proper disposal practices for used products and promoting the use of environmentally friendly cleaners within the organization can also enhance a company’s reputation and appeal to eco-conscious consumers. Training staff on the benefits and applications of these sustainable options can foster a culture of environmental responsibility while maintaining high standards of vehicle care.

Strategic Material Selection Guide for chrome bumper cleaner

What Are the Key Materials Used in Chrome Bumper Cleaners?

When selecting chrome bumper cleaners, it’s essential to consider the materials used in their formulation. The effectiveness and safety of these products can vary significantly based on their chemical composition. Here, we analyze four common materials used in chrome bumper cleaners, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Aluminum Oxide

Key Properties:

Aluminum oxide is a highly durable abrasive material known for its hardness and resistance to corrosion. It can withstand high temperatures and is effective in polishing chrome surfaces without causing damage.

Pros & Cons:

Aluminum oxide is cost-effective and widely available, making it a popular choice among manufacturers. However, its abrasive nature can lead to surface scratching if not used properly, which may require additional polishing steps.

Impact on Application:

This material is compatible with various cleaning media, including liquid and paste formulations. Its effectiveness in removing oxidation and tarnish makes it suitable for heavy-duty applications.

Considerations for International Buyers:

Buyers should ensure compliance with local regulations regarding abrasive materials. Standards such as ASTM and DIN may dictate acceptable levels of abrasiveness and safety.

2. Citric Acid

Key Properties:

Citric acid is a natural organic acid that serves as an effective cleaning agent. It is biodegradable and has a low environmental impact, making it suitable for eco-friendly formulations.

Pros & Cons:

The primary advantage of citric acid is its ability to dissolve rust and tarnish without harsh chemicals, making it safer for users and the environment. However, it may require longer application times to achieve desired results compared to stronger chemical cleaners.

Impact on Application:

Citric acid is effective in both liquid and gel forms, allowing for versatile application methods. It works best on lightly tarnished surfaces and may not be effective against severe oxidation.

Considerations for International Buyers:

B2B buyers should verify that citric acid formulations comply with local environmental regulations. In regions like Europe, adherence to REACH regulations is crucial for chemical safety.

3. Sodium Bicarbonate (Baking Soda)

Key Properties:

Sodium bicarbonate is a mild abrasive that is non-toxic and safe for various surfaces. It has excellent cleaning properties and is effective in neutralizing odors and stains.

Pros & Cons:

The advantages of sodium bicarbonate include its low cost and availability. However, it may not be as effective on heavy tarnish or rust compared to stronger chemical agents, limiting its use in more severe applications.

Impact on Application:

This material is best used in paste or powder form, often combined with water to create a cleaning solution. Its gentle nature makes it suitable for regular maintenance of chrome surfaces.

Considerations for International Buyers:

Sodium bicarbonate is generally accepted worldwide, but buyers should confirm that formulations meet local safety standards. Its use in food-grade applications may also require compliance with specific regulations in certain regions.

4. Polymeric Compounds

Key Properties:

Polymeric compounds, such as acrylics and silicones, provide a protective layer on chrome surfaces. They enhance shine and offer resistance against environmental factors like moisture and UV rays.

Pros & Cons:

The key advantage of polymeric compounds is their ability to provide long-lasting protection and shine. However, they can be more expensive to produce and may require specific application techniques to ensure even coverage.

Impact on Application:

These compounds are typically used in liquid formulations and are compatible with various cleaning agents. Their protective qualities make them ideal for high-end chrome finishes.

Considerations for International Buyers:

Buyers should ensure that polymeric formulations comply with local regulations regarding chemical usage. In regions like the Middle East and Africa, understanding local preferences for protective coatings can also influence purchasing decisions.

Summary Table of Material Selection for Chrome Bumper Cleaners

| Material | Typical Use Case for chrome bumper cleaner | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Oxide | Heavy-duty polishing | Durable and effective for oxidation removal | Can scratch surfaces if misused | Medium |

| Citric Acid | Eco-friendly cleaning | Biodegradable and safe for users | Longer application time for severe tarnish | Low |

| Sodium Bicarbonate | Regular maintenance | Non-toxic and cost-effective | Less effective on heavy rust | Low |

| Polymeric Compounds | Protective coating | Provides long-lasting shine and protection | Higher production cost and specific application needed | High |

This strategic material selection guide provides B2B buyers with insights into the various materials used in chrome bumper cleaners, allowing for informed purchasing decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for chrome bumper cleaner

What Are the Main Stages of Manufacturing Chrome Bumper Cleaner?

The manufacturing process for chrome bumper cleaners typically involves several key stages: material preparation, formulation, filling and packaging, and quality assurance.

-

Material Preparation: This initial stage involves sourcing high-quality raw materials, including surfactants, solvents, and polishing agents. Suppliers often conduct rigorous supplier audits to ensure the materials meet the necessary specifications. For chrome cleaners, it’s crucial to utilize materials that not only clean but also protect against oxidation and corrosion.

-

Formulation: In this phase, manufacturers blend the raw materials to create the cleaning solution. Advanced techniques such as emulsification and homogenization are employed to ensure uniform distribution of ingredients. This stage may also involve the addition of proprietary compounds that enhance the cleaner’s effectiveness against tarnish and rust, crucial for restoring chrome surfaces to their original shine.

-

Filling and Packaging: Once the formulation is complete, the product is filled into containers, which can range from spray bottles to bulk containers depending on the target market. Automated filling lines often ensure consistency and reduce contamination risks. Packaging is designed not only for functionality but also for marketing appeal, featuring labels that communicate the product’s benefits and usage instructions.

-

Quality Assurance: This is an ongoing process that starts from material receipt and continues through to the final product. Manufacturers often implement strict quality control measures at every stage, ensuring that the final product meets both regulatory and customer expectations.

How Is Quality Assurance Implemented in Chrome Bumper Cleaner Manufacturing?

Quality assurance (QA) in the production of chrome bumper cleaners is vital for maintaining product integrity and customer satisfaction. Several international standards and industry-specific regulations guide this process.

-

International Standards: Many manufacturers adhere to ISO 9001, which outlines the criteria for a quality management system. This standard emphasizes customer satisfaction and continuous improvement, ensuring that products consistently meet quality requirements.

-

Industry-Specific Certifications: Depending on the target markets, other certifications may be relevant. For example, CE marking is important for products sold in the European market, indicating compliance with health, safety, and environmental protection standards. In some cases, products may also need to meet local regulations, such as those enforced by the Saudi Standards, Metrology and Quality Organization (SASO) in Saudi Arabia.

-

Quality Control Checkpoints: Manufacturers typically implement several checkpoints throughout the production process:

– Incoming Quality Control (IQC): At this stage, raw materials are inspected upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During production, samples are taken to monitor the formulation and ensure that it adheres to the required specifications.

– Final Quality Control (FQC): Before packaging, the final product undergoes rigorous testing to verify its effectiveness, safety, and compliance with labeling regulations.

What Common Testing Methods Are Used for Chrome Bumper Cleaners?

To ensure the effectiveness and safety of chrome bumper cleaners, manufacturers utilize various testing methods:

-

Performance Testing: This involves laboratory tests to assess the cleaner’s ability to remove oxidation, rust, and grime. Common metrics include shine level, tarnish removal effectiveness, and longevity of the protective barrier created by the product.

-

Stability Testing: Products are subjected to extreme conditions (heat, cold, humidity) to evaluate their stability over time. This testing helps ensure that the product remains effective and safe throughout its shelf life.

-

Toxicity and Safety Testing: Manufacturers often conduct toxicity tests to ensure that the product is safe for consumers and complies with relevant health regulations. This includes assessments for skin irritation and inhalation toxicity.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial for ensuring product quality and compliance. Here are several strategies to consider:

-

Supplier Audits: Conducting an audit of the supplier’s facilities can provide insight into their manufacturing processes and quality control measures. This includes reviewing their adherence to international standards like ISO 9001.

-

Quality Control Reports: Requesting documentation of quality control tests and results can help buyers assess the reliability of the product. This includes performance testing outcomes and stability reports.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality assurance processes. These inspections often include audits of production practices and product testing.

What Are the Quality Control Nuances for International B2B Buyers?

When engaging in international trade, B2B buyers must be aware of specific quality control nuances that can impact their purchasing decisions:

-

Regulatory Compliance: Different countries have varying regulations concerning chemical products. Buyers should ensure that their suppliers comply with local regulations in their target markets, including any necessary certifications.

-

Cultural and Regional Considerations: Understanding the specific needs and preferences of regional markets can influence product formulation. For example, buyers in humid climates may prioritize rust prevention features more than those in arid regions.

-

Communication and Documentation: Clear communication regarding quality expectations and documentation is essential. B2B buyers should ensure that suppliers provide comprehensive product data sheets and safety data sheets (SDS) to facilitate compliance and understanding.

By focusing on these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing chrome bumper cleaners, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘chrome bumper cleaner’

In the competitive landscape of automotive care, sourcing the right chrome bumper cleaner is essential for maintaining the aesthetic and longevity of chrome surfaces. This guide provides a systematic checklist for B2B buyers to ensure they make informed decisions while procuring chrome bumper cleaners suitable for various markets, including Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in sourcing chrome bumper cleaners. Consider factors such as the product’s formulation (e.g., abrasive level, pH balance), intended use (heavy-duty vs. light maintenance), and compatibility with other car care products. This clarity helps narrow down options and ensures the chosen product meets your operational needs.

Step 2: Research Market Demand and Trends

Understanding market demand is crucial for making strategic sourcing decisions. Investigate current trends in chrome care products, including popular formulations and features that resonate with consumers in your target regions. This information can help you identify which products are likely to perform well and align with buyer preferences.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Look for suppliers with proven track records in the automotive care industry. Request company profiles, case studies, and references from businesses in similar markets to assess their reliability and product quality. This due diligence can prevent future issues related to product quality and delivery.

Step 4: Verify Certifications and Compliance

It is essential to ensure that the chrome bumper cleaner meets local regulations and international standards. Verify if the products have certifications such as ISO, REACH, or other relevant industry standards. Compliance with regulations not only ensures safety but also enhances your credibility with customers.

Step 5: Request Product Samples for Testing

Before placing a bulk order, request samples from shortlisted suppliers. Testing these samples allows you to evaluate their effectiveness, ease of application, and compatibility with different chrome surfaces. This hands-on approach ensures that the product meets your quality expectations and performance standards.

Step 6: Assess Packaging and Branding Options

Packaging plays a significant role in product appeal and usability. Consider the design, size, and labeling of the chrome bumper cleaner. Effective packaging not only protects the product but also communicates brand values and usage instructions clearly to end-users.

Step 7: Negotiate Terms and Establish Long-term Relationships

Once you’ve selected a supplier, focus on negotiating favorable terms that benefit both parties. Discuss pricing, payment terms, minimum order quantities, and delivery schedules. Building a long-term relationship with a reliable supplier can lead to better pricing, priority service, and collaborative opportunities in product development.

By following this checklist, B2B buyers can confidently source high-quality chrome bumper cleaners that meet market demands and enhance customer satisfaction.

Comprehensive Cost and Pricing Analysis for chrome bumper cleaner Sourcing

What Are the Key Cost Components for Chrome Bumper Cleaner Production?

Understanding the cost structure of chrome bumper cleaners is essential for international B2B buyers aiming to source these products efficiently. The primary cost components include:

-

Materials: The formulation of chrome bumper cleaners typically involves high-quality abrasives, solvents, and protective agents. The choice of raw materials directly impacts the performance and pricing of the final product. Premium ingredients can significantly increase costs, but they often provide better results.

-

Labor: Labor costs vary based on the region of production. In countries with higher wages, such as those in Western Europe, labor can account for a larger portion of the total cost. Conversely, sourcing from regions with lower labor costs can provide savings, but may come with trade-offs in quality control.

-

Manufacturing Overhead: This encompasses expenses related to facility maintenance, utilities, and equipment depreciation. Efficient production processes can help minimize these costs, contributing to a more competitive pricing strategy.

-

Tooling: Initial costs for tooling can be substantial, especially if custom formulations or packaging designs are required. Buyers should consider these costs when evaluating suppliers, as they can be spread over larger order quantities (MOQs) to achieve better pricing.

-

Quality Control (QC): Investing in robust quality control systems ensures that products meet international standards and certifications. While this adds to the cost, it is crucial for maintaining brand reputation and customer satisfaction.

-

Logistics: Transportation costs can vary widely based on the shipping method and distance. For international buyers, understanding Incoterms is critical to managing logistics costs effectively.

-

Margin: Suppliers typically add a margin to cover their costs and earn a profit. This can vary based on market conditions, competition, and perceived value.

How Do Price Influencers Impact the Cost of Chrome Bumper Cleaners?

Several factors influence the pricing of chrome bumper cleaners, which B2B buyers should consider:

-

Volume/MOQ: Larger orders often lead to lower per-unit costs. Suppliers are usually willing to negotiate better rates for bulk purchases, allowing buyers to optimize their spending.

-

Specifications and Customization: Custom formulations tailored to specific market needs can result in higher costs. Buyers should assess whether standard products can meet their requirements to avoid unnecessary expenses.

-

Material Quality and Certifications: Products made with higher-quality materials or those that are certified for environmental safety may command premium pricing. However, these investments can lead to lower Total Cost of Ownership (TCO) due to reduced rework and longer product lifespan.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to their track record, while newer entrants might offer competitive rates to gain market share.

-

Incoterms: The choice of Incoterms affects shipping and insurance costs. Understanding these terms can help buyers manage their total costs more effectively.

What Negotiation and Cost-Efficiency Tips Should International Buyers Consider?

International B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, should implement strategic approaches to sourcing chrome bumper cleaners:

-

Leverage Volume Discounts: Buyers should aim to consolidate orders to meet MOQ thresholds. This not only reduces unit costs but can also strengthen relationships with suppliers.

-

Request Samples: Before committing to large orders, request samples to evaluate product performance. This mitigates the risk of poor-quality purchases that could lead to higher costs in the long run.

-

Evaluate Total Cost of Ownership (TCO): Consider all costs associated with sourcing and using chrome bumper cleaners, including shipping, storage, and disposal costs. A higher initial price may be justified if the product offers superior performance and longevity.

-

Stay Informed About Market Trends: Understanding global trends in the chemical and automotive industries can help buyers anticipate price fluctuations and make informed purchasing decisions.

-

Build Long-Term Relationships: Establishing long-term partnerships with reliable suppliers can lead to better terms, pricing, and responsiveness to changing needs.

Disclaimer on Pricing

The prices for chrome bumper cleaners can vary significantly based on the factors outlined above. Buyers should conduct thorough market research and engage directly with suppliers to obtain the most accurate and current pricing information tailored to their specific sourcing needs.

Alternatives Analysis: Comparing chrome bumper cleaner With Other Solutions

Exploring Alternatives to Chrome Bumper Cleaner

In the automotive maintenance sector, chrome bumper cleaners are essential for restoring the shine and protecting chrome surfaces. However, various alternatives exist that can achieve similar results, catering to diverse needs and preferences. This analysis will compare chrome bumper cleaners with two viable alternatives: metal polishes and rust removers. Understanding these options will help international B2B buyers make informed decisions based on performance, cost, and ease of use.

| Comparison Aspect | Chrome Bumper Cleaner | Metal Polish | Rust Remover |

|---|---|---|---|

| Performance | Highly effective on chrome surfaces | Excellent for tarnished metals | Best for removing rust and oxidation |

| Cost | Moderate ($10-$30) | Varies ($10-$50) | Generally lower ($5-$15) |

| Ease of Implementation | Simple application, often spray-based | Requires more effort to buff | Easy to apply, but may need scrubbing |

| Maintenance | Regular use needed for best results | Requires periodic reapplication | May need follow-up protection |

| Best Use Case | Ideal for regular detailing of chrome | Best for restoring heavily tarnished surfaces | Effective for initial rust removal |

What Are the Advantages and Disadvantages of Using Metal Polish?

Metal polish is a popular alternative to chrome bumper cleaners. It is designed to restore the shine of various metal surfaces, including chrome. The primary advantage of metal polish is its ability to tackle heavy oxidation and tarnish, providing a mirror-like finish. However, it often requires more effort during application, as users need to buff the surface to achieve optimal results. Additionally, metal polish can be more expensive, especially for high-quality products, making it less suitable for budget-conscious businesses.

How Does Rust Remover Compare to Chrome Bumper Cleaners?

Rust removers are specifically formulated to address rust and oxidation, making them effective for initial cleaning. They can be particularly beneficial for vehicles exposed to harsh environments where rust formation is a concern. The ease of application is another advantage, as many rust removers come in spray form and require minimal scrubbing. However, while they excel at rust removal, they may not provide the same protective layer that chrome bumper cleaners offer, necessitating additional products for long-term maintenance.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Selecting the right chrome bumper maintenance solution involves understanding the specific needs of your business. If your focus is on regular maintenance and protection, chrome bumper cleaners are likely the best choice due to their protective properties. However, if you are dealing with severely tarnished surfaces, metal polish might offer the restoration needed, albeit with more effort. For businesses primarily concerned with rust, rust removers provide a quick fix but should be complemented with protective products. Ultimately, evaluating performance, cost, and ease of use will guide B2B buyers in making the most suitable choice for their automotive care requirements.

Essential Technical Properties and Trade Terminology for chrome bumper cleaner

What Are the Key Technical Properties of Chrome Bumper Cleaners?

When sourcing chrome bumper cleaners for your business, understanding the essential technical properties is crucial for ensuring product efficacy and compatibility. Below are the key specifications to consider:

-

Active Ingredients

The effectiveness of a chrome bumper cleaner largely depends on its active ingredients. Common components include abrasives, acids, and surfactants. Abrasives help remove oxidation and tarnish, while acids can dissolve rust and grime. Surfactants improve the spreadability and penetration of the cleaner. B2B buyers should ensure that these ingredients are suitable for their specific applications, especially in regions with varying environmental conditions. -

pH Level

The pH level of a chrome bumper cleaner can significantly influence its effectiveness and safety. Most chrome cleaners are formulated to be either acidic or neutral. Acidic cleaners are effective against rust but can be harsh on sensitive surfaces. Neutral pH cleaners are gentler and less likely to cause damage. Understanding the pH balance is essential for businesses to prevent surface degradation and ensure long-lasting results. -

Abrasiveness

Abrasiveness is a measure of how much material can be removed from the surface being cleaned. Chrome bumper cleaners can be classified as light or heavy-duty based on their abrasiveness. Light abrasives are suitable for regular maintenance, while heavy-duty options are necessary for heavily tarnished or neglected surfaces. Businesses should choose the appropriate level of abrasiveness based on their cleaning needs and the condition of the chrome surfaces. -

Application Method

Chrome bumper cleaners can be available in various application formats, such as liquid, paste, or spray. The choice of application method affects ease of use and efficiency. For example, spray cleaners may offer quicker application but require more careful handling to avoid overspray. Understanding the preferred application method can help businesses streamline their cleaning processes. -

Protective Coatings

Many chrome cleaners include protective agents that create a barrier against future tarnishing and oxidation. These coatings can prolong the shine and integrity of chrome surfaces. For B2B buyers, selecting products with protective properties can reduce the frequency of cleaning and maintenance, ultimately saving time and costs.

What Are Common Trade Terms in the Chrome Bumper Cleaner Industry?

Familiarity with industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are sold under another company’s brand name. In the context of chrome bumper cleaners, businesses may seek OEM products that meet specific quality and performance standards set by vehicle manufacturers. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for businesses to ensure they can meet their inventory needs without overcommitting financially. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. It is crucial for buyers to use RFQs to compare options and negotiate favorable terms. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce. They define the responsibilities of buyers and sellers in international transactions, including shipping and insurance responsibilities. Knowledge of Incoterms can help businesses avoid misunderstandings and ensure smoother logistics. -

Shelf Life

Shelf life refers to the length of time a product remains usable or effective when stored under recommended conditions. For chrome bumper cleaners, understanding shelf life is important for inventory management and ensuring product efficacy at the time of use. -

Compatibility

Compatibility indicates how well a cleaner can be used on various chrome surfaces without causing damage. It is crucial for businesses to verify product compatibility to avoid costly mistakes and ensure customer satisfaction.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing chrome bumper cleaners, ensuring they select products that meet their specific needs and regulatory requirements.

Navigating Market Dynamics and Sourcing Trends in the chrome bumper cleaner Sector

What Are the Key Trends Influencing the Chrome Bumper Cleaner Market?

The chrome bumper cleaner market is experiencing significant shifts driven by various global factors. Key drivers include the increasing demand for vehicle aesthetics, particularly in regions like Africa, South America, and the Middle East, where vehicle ownership is on the rise. Additionally, as consumers become more aware of the importance of vehicle maintenance, there is a growing preference for high-quality cleaning solutions that not only restore shine but also offer protective features against environmental damage.

Emerging B2B tech trends are reshaping sourcing strategies in this sector. Digital platforms for procurement are becoming more prevalent, allowing international buyers to access a wider range of products and suppliers. Companies are leveraging data analytics to forecast demand and optimize inventory, ensuring they can meet the needs of their customers more efficiently. Furthermore, the integration of e-commerce solutions is simplifying the purchasing process, particularly for buyers in remote regions.

Market dynamics are also influenced by competitive pricing and product innovation. As manufacturers introduce advanced formulas that enhance cleaning efficacy and provide long-lasting protection, B2B buyers are increasingly prioritizing products that deliver both performance and value. In regions like Saudi Arabia and Nigeria, where climatic conditions can accelerate vehicle wear, there is a heightened focus on sourcing cleaners that offer durable solutions to combat rust and oxidation.

How Important Is Sustainability and Ethical Sourcing in the Chrome Bumper Cleaner Industry?

Sustainability has emerged as a critical consideration for B2B buyers in the chrome bumper cleaner market. The environmental impact of chemical cleaners is under scrutiny, prompting manufacturers to adopt greener practices. This includes the use of biodegradable ingredients and eco-friendly packaging, which not only appeal to environmentally conscious consumers but also comply with increasing regulatory pressures in various markets.

Ethical sourcing practices are equally important, as buyers seek suppliers who prioritize transparency and social responsibility. This includes ensuring that raw materials are sourced from suppliers who adhere to ethical labor practices and environmental standards. Certifications such as EcoLogo or Green Seal are becoming essential for products in this sector, providing assurance to buyers regarding the sustainability of their purchases.

Moreover, the demand for ‘green’ certifications is influencing product development, with many manufacturers reformulating their products to meet these standards. As consumers increasingly prefer eco-friendly options, B2B buyers can leverage this trend to enhance their brand reputation and meet the expectations of their customers.

What Has Been the Evolution of Chrome Bumper Cleaners?

The history of chrome bumper cleaners reflects broader changes in automotive care. Initially, basic cleaning agents were used, but as vehicles became more sophisticated, so did the products designed to maintain them. The introduction of specialized chrome polishes marked a turning point, with formulations evolving to include advanced abrasives and protective agents.

In recent years, the focus has shifted towards multifunctional products that not only clean but also protect surfaces from corrosion and oxidation. This evolution has been driven by technological advancements in chemical formulations and a growing understanding of the environmental impact of automotive care products. Today, the market is characterized by a diverse range of offerings, catering to both professional detailers and everyday consumers, with a strong emphasis on quality, performance, and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of chrome bumper cleaner

-

How do I solve oxidation and tarnishing on chrome bumpers?

To effectively address oxidation and tarnishing on chrome bumpers, use a dedicated chrome bumper cleaner that contains both abrasive and protective elements. Products with fine abrasives can safely remove light oxidation, while those with heavier abrasives are suitable for more severe tarnishing. Always follow the manufacturer’s instructions for application, and consider using a sealant afterward to protect the surface from future damage. Regular maintenance and cleaning will prolong the shine and life of chrome surfaces. -

What is the best chrome bumper cleaner for international shipping?

When sourcing chrome bumper cleaners for international shipping, look for products that are non-toxic, biodegradable, and compliant with international shipping regulations. Brands that offer concentrated formulas are also preferable, as they reduce shipping costs and storage space. Always verify that the product packaging is robust to withstand the rigors of international transport. Additionally, consider suppliers who provide detailed shipping documentation and have a solid logistics plan for your region. -

How can I vet suppliers of chrome bumper cleaners effectively?

To vet suppliers of chrome bumper cleaners, start by checking their industry reputation and customer reviews. Request samples to assess product quality firsthand and inquire about their manufacturing processes and quality control measures. Verify their certifications and compliance with international standards, especially for chemical products. Establishing communication with previous clients can also provide insights into reliability and service quality. -

What are typical minimum order quantities (MOQ) for chrome bumper cleaners?

Minimum order quantities for chrome bumper cleaners can vary significantly based on the supplier and product type. Typically, MOQs range from 100 to 1,000 units. It’s advisable to negotiate MOQs based on your business needs, especially if you are a smaller buyer. Some suppliers may offer flexibility for first-time orders or trial runs to establish a relationship before committing to larger quantities. -

What payment terms should I expect when sourcing chrome bumper cleaners?

Payment terms can vary widely among suppliers, but common practices include 30% upfront payment and 70% upon shipment. Some suppliers may offer net 30 or net 60 terms for established customers. Always clarify payment methods accepted, such as wire transfer or letters of credit, and ensure that all terms are documented in a formal agreement. Consider using escrow services for large orders to protect both parties. -

How do I ensure quality assurance for chrome bumper cleaners?

To ensure quality assurance for chrome bumper cleaners, request detailed product specifications and safety data sheets from your supplier. Establish a quality control process, which may include third-party inspections before shipment. It’s also beneficial to conduct your own testing with samples to verify performance and safety. Building a good relationship with your supplier can facilitate better communication regarding quality issues. -

What should I know about the logistics of importing chrome bumper cleaners?

When importing chrome bumper cleaners, be aware of customs regulations and potential tariffs in your country. Ensure that your supplier provides all necessary documentation, including bills of lading and customs declarations. Work with a reliable freight forwarder who understands the specifics of shipping chemical products. Additionally, consider the lead time for shipping and customs clearance to avoid delays in inventory replenishment. -

Are there customization options available for chrome bumper cleaners?

Many suppliers offer customization options for chrome bumper cleaners, including formulation adjustments, packaging sizes, and private labeling. If you have specific requirements, such as eco-friendly ingredients or unique branding, communicate these to your potential supplier early in the negotiation process. Customization can enhance your product’s market appeal, especially in regions where consumers prioritize sustainability or specific performance characteristics.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Chrome Bumper Cleaner Manufacturers & Suppliers List

1. Chemical Guys – Metal & Chrome Polish

Domain: chemicalguys.com

Registered: 2003 (22 years)

Introduction: Metal & Chrome Polish by Chemical Guys restores a brilliant shine to severely oxidized, stained, and tarnished metal surfaces. It reverses the effects of oxygen, sulfur, and toxins in the air while protecting metal from future issues. The product achieves a mirror-like finish on chrome and metal components, restoring the appearance of tarnished or corroded surfaces by removing oxidation and rust. …

2. Turtle Wax – Chrome Polish & Rust Remover

Domain: turtlewax.com

Registered: 1995 (30 years)

Introduction: Product Name: Turtle Wax Chrome Polish & Rust Remover

Size: 10.0 fl oz

Price: $3.75 (was $5.00)

Key Features:

– Quick and easy application and removal

– Superior cleaning power removes surface rust & grime to like-new condition

– Transforms rusty, tarnished chrome to an original, gleaming luster

– Provides a brilliant, mirror-like shine

– Contains acrylic sealant to prolong rust-free appearance on…

3. Reddit – Chrome Care Essentials

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Chrome polish is not needed for new chrome as it can add swirls to the finish. Recommended treatments include a clay treatment and good waxing periodically. CG Jetseal is suggested for metal protection, with a lifespan of several months, requiring two treatments a year for optimal safety.

4. MG – Original Chrome Bumpers for 1969 MGB MkII

Domain: mgexp.com

Registered: 2011 (14 years)

Introduction: Original chrome bumpers for 1969 MG MGB MkII; condition: good with light swirl marks from improper polishing; replacement for aftermarket reproductions; suggestions for polishing include using Meguiars Chrome Polish, heavy cutting compound, light compound, and sealer or wax; caution against aggressive polishing to avoid damaging chrome layer; alternatives discussed include professional chrome plat…

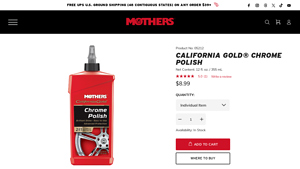

5. Mothers® – California Gold® Chrome Polish

Domain: mothers.com

Registered: 1995 (30 years)

Introduction: Product Name: California Gold® Chrome Polish

Brand: Mothers®

Product Number: 05212

Net Content: 12 fl. oz. / 355 mL

Price: $8.99

Availability: In stock

Description: Thick, rich, and easy-to-use polish that deep cleans and brightens automotive chrome bumpers, wheels, trim, and accessories. Contains advanced polymers for protection against fingerprints, spotting, rust, and corrosion. Safely cleans a…

6. WikiHow – Chrome Cleaning Essentials

Domain: wikihow.life

Registered: 2014 (11 years)

Introduction: 1. Chrome Polish: Any polish labeled for chrome use, often containing a cleaner and sealant. 2. Dish Soap: Used to create a gentle cleaning solution for chrome bumpers. 3. White Vinegar: A mild cleaner for tough stains and rust. 4. Microfiber Cloths: Non-abrasive cloths for cleaning and polishing. 5. Painter’s Tape: Optional for protecting adjacent plastic trim. 6. Applicator Pad: For applying the…

Strategic Sourcing Conclusion and Outlook for chrome bumper cleaner

In conclusion, strategic sourcing for chrome bumper cleaners is essential for international B2B buyers aiming to enhance the longevity and appearance of chrome surfaces in automotive applications. By prioritizing high-quality products that effectively remove oxidation and provide protective barriers, businesses can ensure their chrome components maintain a showroom shine while resisting future damage. Understanding the differences between heavy and light metal polishes allows buyers to make informed decisions tailored to their specific needs, whether for routine maintenance or restoration of heavily tarnished surfaces.

As markets evolve, particularly in regions like Africa, South America, the Middle East, and Europe, the demand for effective chrome cleaners is on the rise. By partnering with reputable suppliers and leveraging innovative formulations, companies can differentiate themselves in a competitive landscape.

Looking forward, it is crucial for B2B buyers to remain proactive in sourcing chrome bumper cleaning solutions that align with their operational goals. Invest in products that not only deliver immediate results but also promise long-term protection and enhancement. Seize the opportunity to elevate your chrome care offerings and establish a strong foothold in your market today.