Contents

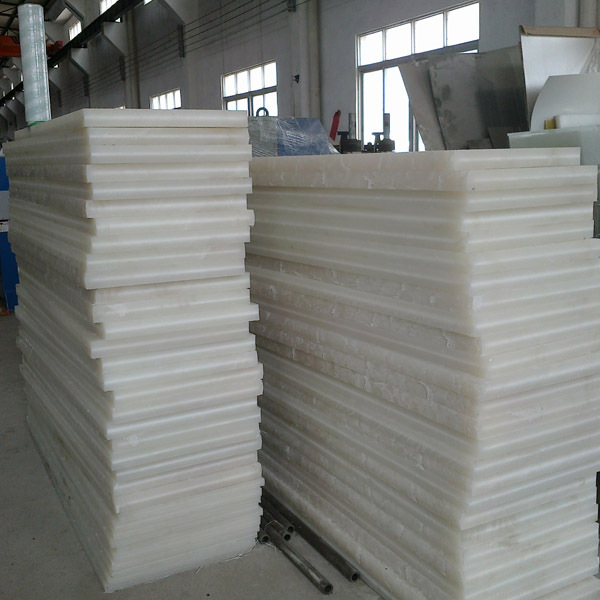

Manufacturing Insight: Chopping Board Plastic Sheets

Material Clarification and Service Alignment

Honyo Prototype specializes in precision sheet metal fabrication, not plastic sheet production. While chopping boards typically utilize food-grade polymers like HDPE or bamboo composites, our core expertise lies in metal-based manufacturing solutions for industrial and commercial applications.

Precision Sheet Metal Fabrication for Industrial Applications

For B2B manufacturing partners requiring robust, hygienic, and durable components—such as stainless steel work surfaces, support frames, or integrated hardware for commercial food preparation systems—Honyo delivers end-to-end sheet metal fabrication. Our processes include laser cutting, CNC bending, welding, and finishing for materials like 304/316 stainless steel, aluminum, and cold-rolled steel, meeting stringent industry standards for sanitation and structural integrity.

Streamlined Project Initiation

Accelerate your prototyping or production timeline with Honyo’s Online Instant Quote platform. Upload CAD files (STEP, DWG, DXF) to receive real-time cost estimates, lead time projections, and manufacturability feedback within minutes—eliminating traditional quotation delays while ensuring technical feasibility for complex metal fabrications.

Technical Differentiation

Unlike plastic sheet suppliers, we engineer metal solutions where thermal stability, load-bearing capacity, and regulatory compliance (e.g., NSF/ANSI 2) are critical. This includes components for food processing equipment, cleanroom fixtures, and heavy-duty commercial surfaces where polymer alternatives may compromise performance. Partner with Honyo to transform metal sheet requirements into certified, production-ready assemblies.

Technical Capabilities

Technical specifications for chopping board plastic sheets are critical when considering fabrication processes such as laser cutting, bending, and welding. While traditional chopping boards are typically made from wood or food-grade plastics, industrial or prototype versions may use engineered thermoplastics or metals with appropriate surface treatments for hygiene and durability. Below is a comparison of suitable materials—Aluminum, Steel, ABS, and Nylon—relative to these fabrication techniques and their applicability to chopping board sheet production.

| Material | Thickness Range (mm) | Laser Cutting Compatibility | Bending Capability | Welding / Joining Method | Thermal Resistance (°C) | Food Contact Compliant | Notes |

|---|---|---|---|---|---|---|---|

| ABS (Acrylonitrile Butadiene Styrene) | 2 – 10 | Excellent – clean cuts with CO₂ lasers; minimal charring with proper settings | Good – can be thermoformed; requires heated bending | Solvent welding or ultrasonic welding | 80 – 100 | Yes (food-grade versions available) | Easy to machine, impact-resistant; avoid high-temp environments |

| Nylon (Polyamide, e.g., PA6 or PA66) | 3 – 15 | Good – possible with CO₂ laser but prone to melting; requires controlled settings | Moderate – limited cold bending; best formed thermally | Hot plate welding or mechanical fastening | 120 – 150 | Yes (specific food-grade grades) | High wear and chemical resistance; hygroscopic (absorbs moisture) |

| Aluminum (e.g., 5052 or 6061-T6) | 1 – 6 | Excellent – fiber laser cutting recommended; reflective to CO₂ lasers | Excellent – high ductility; easily bent with press brakes | TIG or MIG welding; adhesive bonding for clean joints | Up to 200+ | Yes (with proper anodizing or coating) | Lightweight, hygienic, corrosion-resistant; requires edge finishing for safety |

| Stainless Steel (e.g., 304 or 316) | 1 – 8 | Excellent – fiber laser cutting ideal; clean, precise edges | Good – bendable with industrial equipment; springback must be compensated | TIG welding or laser welding | Up to 800+ | Yes (standard in food processing) | Highly durable and sanitary; heavier and more expensive |

Notes on Fabrication:

Laser cutting is highly effective for all listed materials when the correct laser type and parameters are used. CO₂ lasers work well for ABS and Nylon, while fiber lasers are preferred for Aluminum and Steel due to their reflectivity and conductivity.

Bending is most straightforward with metals using press brakes, whereas thermoplastics like ABS and Nylon require heat-assisted forming to avoid cracking.

Welding techniques vary significantly: thermoplastics use solvent, ultrasonic, or hot plate methods, while metals require fusion welding (TIG/MIG) or advanced laser welding for seamless joints.

For food-safe chopping boards, all materials must meet FDA or EU 10/2011 standards for food contact. Surface finish, edge smoothness, and joint integrity are critical to prevent bacterial ingress.

From CAD to Part: The Process

Honyo Prototype’s Chopping Board Plastic Sheet Manufacturing Process

Honyo Prototype delivers precision-manufactured chopping board plastic sheets through a streamlined, technology-driven workflow designed for speed, accuracy, and compliance with food-grade standards. Our process begins when a client uploads their CAD file to our secure portal. We accept industry-standard formats including STEP, IGES, and native SOLIDWORKS files. Upon upload, our system performs an initial validation to confirm file integrity, geometric completeness, and adherence to minimum manufacturable feature sizes for plastic sheet fabrication. This step ensures the design is viable for downstream processing and identifies critical parameters such as material thickness, dimensions, and tolerance requirements specific to chopping board applications.

The validated CAD data triggers our proprietary AI-powered quoting engine. This system analyzes geometric complexity, material selection (e.g., FDA-compliant HDPE, PP, or ABS), sheet dimensions, and finishing requirements to generate a preliminary cost and lead time estimate within two hours. The AI cross-references historical production data, real-time machine availability, and material costs while accounting for chopping board-specific factors like edge sealing, non-porous surface requirements, and NSF certification needs. Clients receive a transparent digital quote detailing material costs, machining time, finishing operations, and compliance documentation fees.

Following quote acceptance, the design enters our expert-led Design for Manufacturability (DFM) review. Honyo’s senior manufacturing engineers conduct a thorough analysis focused on food-safe plastic fabrication. We evaluate draft angles for CNC routing, optimize kerf compensation for laser cutting, verify flatness tolerances to prevent warpage in large sheets, and ensure seamless edge finishing to eliminate bacterial harborage points. For chopping boards, we specifically validate material suitability against FDA 21 CFR 177.1520 for indirect food contact, recommend optimal grain orientation to minimize moisture absorption, and suggest modifications to enhance structural integrity during use. Clients receive a detailed DFM report with actionable recommendations, typically within 24 business hours.

Approved designs move directly to production in our climate-controlled facility. Chopping board sheets are fabricated using precision CNC routers or CO2 lasers for cutouts and engravings, followed by automated edge rounding and sanding to achieve smooth, splinter-free surfaces. All operations occur in a dedicated food-grade zone with HEPA filtration to prevent contamination. Material batches are traceable via lot numbers, and critical dimensions undergo in-process CMM verification. Post-processing includes antimicrobial surface treatment (if specified) and thorough cleaning with NSF-certified sanitizers. Each sheet is individually inspected against ASME Y14.5 tolerances and food safety standards before packaging.

Final delivery includes comprehensive documentation: material certification (including FDA/NSF compliance paperwork), first-article inspection reports, and batch-specific test data. Chopping boards are vacuum-sealed in anti-static polyethylene and shipped via tracked carriers with climate-controlled options for temperature-sensitive materials. Standard lead time from DFM approval to delivery is 5–7 business days for quantities under 100 units, with real-time shipment tracking provided through our client portal.

Material and Compliance Reference Table

| Parameter | Standard Specification | Chopping Board Requirement |

|——————–|——————————|———————————|

| Material Grade | FDA 21 CFR 177.1520 | FDA-compliant HDPE/PP mandatory |

| Flatness Tolerance | ±0.5 mm per 300 mm | ±0.3 mm enforced for stability |

| Edge Finish | Ra ≤ 1.6 µm | Ra ≤ 0.8 µm for food safety |

| Documentation | Cert of Conformance (CoC) | Includes NSF audit trail |

This integrated process ensures Honyo delivers chopping board plastic sheets that meet rigorous food safety standards while minimizing time-to-market for our clients. Every phase incorporates closed-loop quality checks, with full traceability from CAD file to packaged shipment.

Start Your Project

Looking for high-quality plastic sheets for chopping board production? Source directly from our Shenzhen-based manufacturing facility for competitive pricing and reliable lead times.

Contact Susan Leo today at [email protected] to discuss your material specifications, volume requirements, and custom processing options.

We support OEM/ODM orders with precision cutting, surface finishing, and material certification for food-safe applications.

Let Honyo Prototype be your trusted partner for durable, compliant plastic sheet solutions. Reach out now to request samples or a quotation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.