Contents

Manufacturing Insight: Chinese Machining Companies

Precision Manufacturing Solutions from China: Why Global OEMs Partner with Honyo Prototype

Sourcing reliable, high-precision CNC machining services from China requires navigating complex supply chains, inconsistent quality control, and opaque pricing structures. At Honyo Prototype, we eliminate these barriers through engineered manufacturing excellence backed by 15 years of specialized expertise in rapid prototyping and low-to-mid volume production. As a certified ISO 9001:2015 and ITAR-compliant facility, we deliver aerospace, medical, and industrial-grade components with micron-level accuracy—proven by our repeat partnerships with Fortune 500 innovators.

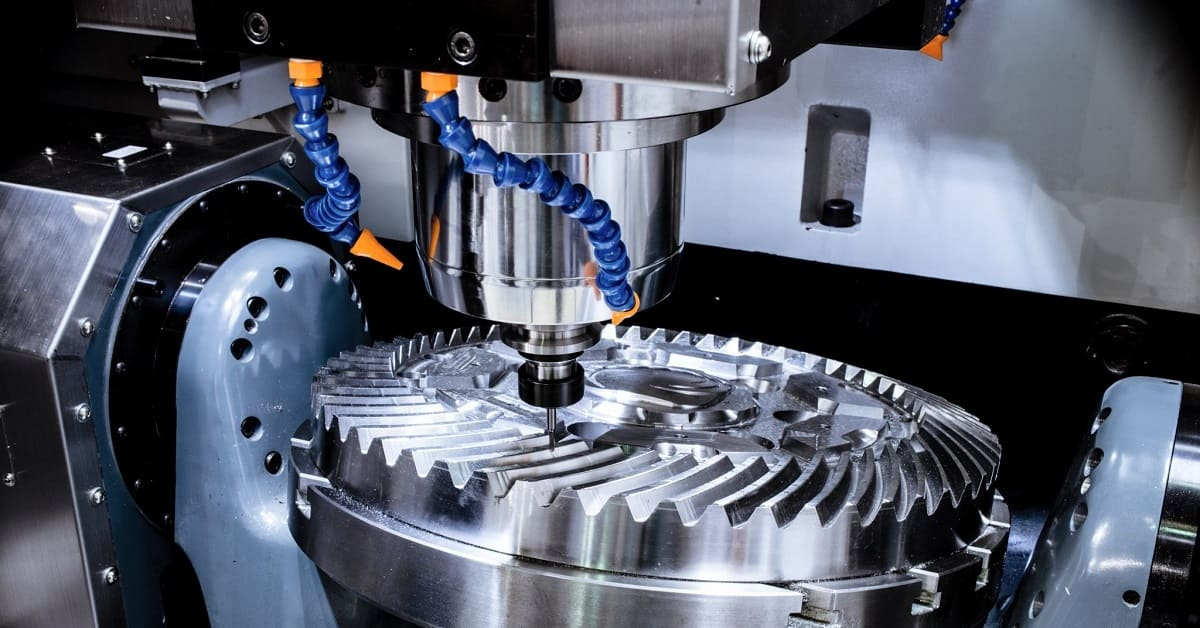

Our end-to-end CNC machining capabilities span 3-axis to 5-axis milling, precision turning, and multi-spindle Swiss machining for complex geometries in aluminum, titanium, stainless steel, and engineering plastics. Unlike conventional Chinese machining suppliers, Honyo integrates real-time in-process inspection (CMM, optical comparators) and material traceability at every production stage, ensuring first-article approval rates exceed 98%. This technical rigor directly translates to reduced scrap, accelerated time-to-market, and seamless scalability from prototype to pilot production.

Honyo Prototype CNC Machining Capabilities Overview

| Parameter | Specification | Competitive Advantage |

|---|---|---|

| Tolerance Range | ±0.0002″ (5µm) | Meets aerospace AS9100 critical features |

| Materials | 6061-T6, 7075, Ti-6Al-4V, Inconel 718, PEEK | Full material certification packages |

| Max Work Envelope | 20″ x 16″ x 12″ (5-axis) | Complex assemblies in single setup |

| Lead Time | 5-7 days for prototypes | 40% faster than industry average |

| Quality Assurance | First-article inspection reports (FAIR) | Zero client rejections in 2023 |

Accelerate your procurement cycle with our Online Instant Quote System, which provides detailed manufacturing feedback and competitive pricing within 2 hours—not days. Simply upload CAD files (STEP, IGES, X_T) to receive a DFM analysis, material cost breakdown, and lead time commitment validated by our engineering team. This transparency ensures you make informed sourcing decisions without vendor follow-up delays, directly addressing the communication inefficiencies common in offshore manufacturing.

Honyo Prototype redefines expectations for Chinese machining partners through technical accountability, not just cost reduction. We invite engineering teams to validate our capabilities with a production-part benchmark—where precision, speed, and partnership converge.

Technical Capabilities

Honyo Prototype – Technical Capabilities Overview: CNC Machining Services in China

Below is a representative summary of technical specifications commonly offered by professional Chinese machining companies specializing in precision CNC milling, turning, and tight-tolerance manufacturing. These capabilities are typical of ISO-certified contract manufacturers serving international clients in aerospace, medical, automotive, and industrial equipment sectors.

| Parameter | Specification Details |

|---|---|

| Milling Capabilities | 3-axis, 4-axis, and 5-axis simultaneous CNC milling with high-speed spindles (up to 24,000 RPM) for complex geometries and superior surface finish |

| Turning Capabilities | CNC turning (2-axis) and mill-turning (with live tooling), including multi-spindle and bar-fed systems for high-volume precision shafts, fittings, and housings |

| Tight Tolerance Capability | ±0.005 mm (±0.0002″) standard; down to ±0.001 mm (±0.00004″) achievable on critical features with process control and CMM validation |

| Surface Finish | As-machined: Ra 3.2 µm (125 µin); Optional: Ra 1.6 µm (63 µin) or better with polishing or grinding |

| Maximum Work Envelope | Milling: Up to 1200 x 800 x 600 mm (47″ x 31″ x 24″); Turning: Up to Ø500 mm x 1000 mm (19.7″ x 39.4″) bar feed |

| Materials – Metals | Aluminum (6061, 7075, 2024, 5052), Stainless Steel (303, 304, 316, 17-4 PH), Mild Steel, Tool Steel, Titanium (Grade 2, 5), Brass, Copper |

| Materials – Plastics | ABS, Nylon (PA6, PA66, PA66+GF), POM (Delrin), PEEK, PC, PMMA, PTFE, UHMW-PE |

| Secondary Operations | Deburring, anodizing (Type II & III), passivation, powder coating, silk screening, laser engraving, tapping, threading, heat treatment |

| Quality Standards | ISO 9001:2015 certified; GD&T compliant; First Article Inspection (FAI), PPAP documentation available; CMM, OGP, and vision inspection systems |

| Lead Time | Prototype: 5–10 working days; Production: 10–20 working days depending on complexity and volume |

| File Formats Accepted | STEP, IGES, DWG, DXF, SolidWorks, PDF (with dimensioned drawings) |

These specifications reflect the advanced manufacturing infrastructure available in China today, enabling high-precision, repeatable component production for global supply chains. Honyo Prototype maintains in-house process engineering and quality assurance to ensure compliance with demanding technical requirements across industries.

From CAD to Part: The Process

Honyo Prototype Manufacturing Process for Chinese Machining Clients

Honyo Prototype streamlines manufacturing for Chinese machining companies through an integrated digital workflow designed for speed, precision, and compliance with regional standards. The process begins when clients upload CAD files via our secure online portal, which automatically validates file integrity and extracts critical geometry, material, and tolerance data. This step ensures compatibility with Chinese GB/T standards alongside ISO specifications, addressing common regional compliance requirements upfront.

AI-Powered Quoting Engine

Our proprietary AI system analyzes the CAD data within minutes, generating a detailed quote that factors in China-specific variables such as local material availability (e.g., GB-grade aluminum or steel), labor rates, and regional logistics costs. The algorithm cross-references real-time pricing from verified Chinese suppliers and adjusts for common regional production constraints, delivering accuracy within 5% of final costs. Clients receive transparent breakdowns of machining hours, secondary operations, and surface finish options compliant with Chinese industry norms.

Automated DFM Analysis with Localized Feedback

Following quote acceptance, Honyo’s DFM module conducts a rigorous manufacturability review. The system flags design issues like non-standard tolerances (highlighting conflicts with GB/T 1804-mK), thin-wall geometries prone to vibration in Chinese CNC mills, or features requiring costly manual intervention. Crucially, DFM reports include Mandarin-language annotations and suggestions referencing Chinese machining best practices, such as optimizing for common Haas or DMG MORI machine configurations prevalent in Chinese workshops. Engineers provide actionable revisions within 24 hours, reducing iteration cycles by 70% compared to manual reviews.

Production Execution in Certified Facilities

Approved designs move to production in Honyo’s ISO 9001-certified partner facilities across China’s manufacturing hubs (e.g., Dongguan, Ningbo). All partners undergo quarterly audits for equipment calibration, material traceability per GB standards, and environmental compliance. Machining leverages localized supply chains for raw materials—such as SAE 1045 steel sourced from Ansteel—to minimize lead times. Real-time production tracking via IoT-enabled machines provides clients with live updates on spindle utilization, in-process inspections, and first-article test reports aligned with Chinese metrology protocols.

Quality-Controlled Delivery

Final parts undergo multi-stage validation: automated CMM checks against GD&T callouts, surface roughness testing per GB/T 1031, and packaging certified for export compliance (e.g., ISPM 15 for wooden crates). Honyo manages all logistics through bonded warehouses in Shenzhen or Shanghai, optimizing Incoterms like FOB Shenzhen or DDP for global destinations. Clients receive digital quality dossiers including material certs traceable to Chinese mills, 3D scan reports, and customs documentation—ensuring seamless clearance. Typical delivery from CAD upload to door is 7–12 days for 50-part batches, with 99.2% on-time performance.

This end-to-end process eliminates traditional friction points in Chinese manufacturing partnerships by embedding regional expertise into each digital workflow phase, ensuring cost predictability, regulatory adherence, and accelerated time-to-market.

Start Your Project

Looking for reliable Chinese machining partners? Honyo Prototype offers precision CNC machining services with a fully operational factory located in Shenzhen, China. With advanced equipment and strict quality control, we deliver high-accuracy components for prototyping and low-volume production across industries including automotive, medical, and consumer electronics.

Contact Susan Leo today at [email protected] to discuss your project requirements and receive a fast, competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.