Contents

Manufacturing Insight: China Precision Milling

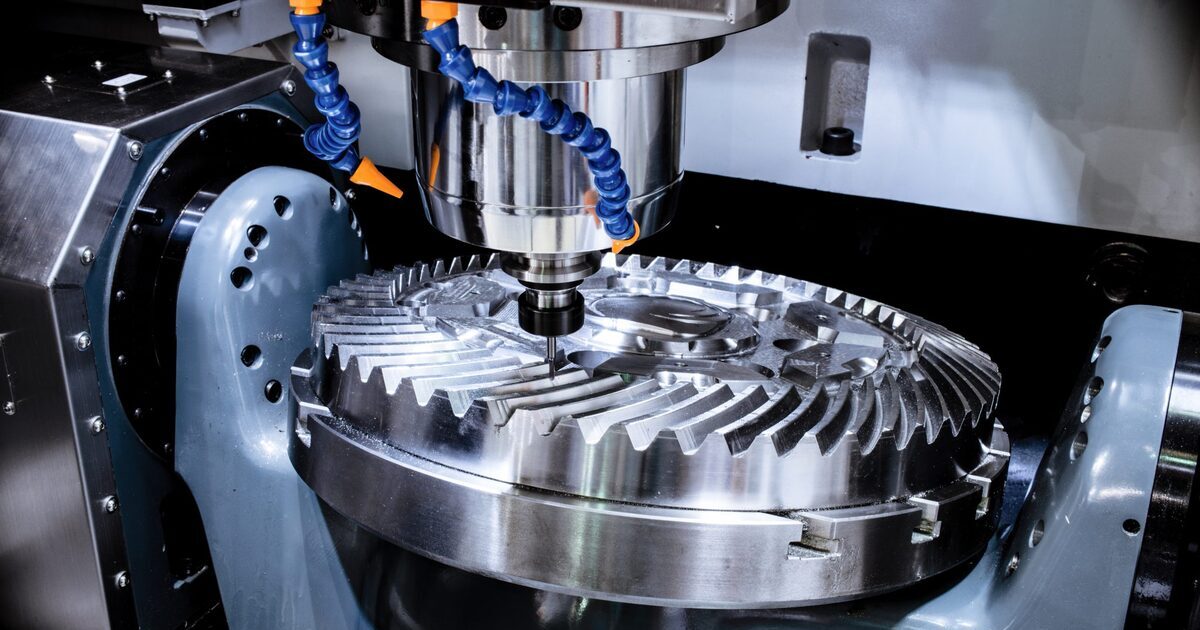

Precision Milling Excellence from China: Engineered for Your Demanding Applications

In today’s competitive manufacturing landscape, achieving micron-level accuracy in complex components is non-negotiable. Honyo Prototype delivers world-class China precision milling services through advanced 3-, 4-, and 5-axis CNC machining centers, engineered to meet the strictest aerospace, medical, and industrial tolerances down to ±0.005mm. Our facility operates under rigorous process controls, utilizing high-speed spindles, in-process probing, and calibrated metrology equipment to ensure repeatability across materials including titanium, aluminum alloys, stainless steel, and engineering plastics. Every component undergoes stringent first-article inspection and final quality verification against AS9100 and ISO 9001 standards, guaranteeing performance-critical parts that exceed expectations.

Streamline Your Sourcing with Real-Time Quoting

Accelerate your prototyping and production timelines with Honyo’s Online Instant Quote system. Upload your STEP or IGES files to receive a comprehensive, transparent cost analysis within hours—not days—including detailed manufacturability feedback and lead time estimates. This digital workflow eliminates traditional quotation bottlenecks while maintaining the engineering rigor our global clients rely on for mission-critical components. Partner with Honyo Prototype where Chinese manufacturing expertise meets uncompromising precision and responsive service.

Technical Capabilities

Honyo Prototype provides advanced precision CNC milling and turning services in China, specializing in high-accuracy machining for demanding industrial applications. Our capabilities include 3-axis, 4-axis, and 5-axis milling along with multi-axis turning, enabling complex geometries and tight tolerance control across a range of engineering materials.

We maintain tight tolerances down to ±0.005 mm (±0.0002″) depending on part geometry and material, with routine production held within ±0.01 mm (±0.0004″). Our ISO-compliant processes ensure repeatable quality for prototyping and low-to-mid volume production runs.

| Feature | Specification |

|---|---|

| Milling Capabilities | 3-Axis, 4-Axis, and 5-Axis CNC Milling |

| Turning Capabilities | CNC Turning (2-axis and multi-axis), Live Tooling for Mill-Turn |

| Positioning Accuracy (Milling) | ±0.005 mm (X/Y/Z axes) |

| Repeatability (Milling) | ±0.003 mm |

| Standard Tolerances | ±0.01 mm (machining), ±0.05 mm (general) |

| Tight Tolerance Capability | Down to ±0.005 mm with process validation |

| Surface Finish (Typical) | Ra 0.8 µm (32 µin) default; achievable down to Ra 0.2 µm (8 µin) with polishing |

| Maximum Work Envelope (Milling) | 1200 mm × 600 mm × 500 mm (X×Y×Z) |

| Maximum Turning Diameter | Ø300 mm |

| Maximum Turning Length | 500 mm |

| Spindle Speed (Milling) | Up to 24,000 RPM |

| Tooling System | CAT 40 / HSK-A63; Automatic Tool Changer (ATC) |

| Control Systems | Fanuc, Siemens, and Heidenhain |

Material Compatibility:

| Material | Machinability | Typical Applications |

|---|---|---|

| Aluminum (6061, 7075, 2024) | Excellent | Aerospace components, heat sinks, enclosures, prototypes |

| Stainless Steel (303, 304, 316, 17-4 PH) | Good to Moderate | Medical devices, valves, high-strength parts |

| Carbon & Alloy Steel (4140, 1018) | Moderate | Industrial machinery, tooling, structural parts |

| ABS | Excellent | Prototypes, housings, jigs, and fixtures |

| Nylon (PA6, PA66, GF-filled) | Good | Low-friction wear parts, insulators, gears |

All parts undergo in-process and final inspection using calibrated CMMs, optical comparators, and surface roughness testers. First Article Inspection (FAI) and PPAP documentation are available upon request. Our facility in Dongguan, China, supports rapid turnaround with full traceability and material certification.

From CAD to Part: The Process

Honyo Prototype Precision Milling Process Overview

Honyo Prototype executes China-based precision milling through a rigorously structured workflow designed for technical accuracy, cost transparency, and accelerated time-to-market. This integrated process leverages advanced automation while maintaining critical human engineering oversight at each phase.

CAD Upload and Initial Processing

Clients initiate the workflow by uploading native or neutral CAD formats including STEP, IGES, or Parasolid via Honyo’s secure customer portal. The system performs immediate geometric validation to confirm file integrity and manufacturability baseline. Non-conforming files trigger automated notifications detailing required corrections, ensuring only production-ready geometry advances to quoting.

AI-Powered Quoting with Engineering Validation

Uploaded geometry enters Honyo’s proprietary AI quoting engine, which analyzes 200+ technical parameters including material utilization, feature complexity, tolerance density, and machine time estimates. The AI generates a preliminary cost model within 90 minutes, but this output undergoes mandatory review by our Shenzhen-based manufacturing engineers. Engineers validate AI assumptions against real-time machine availability, tooling constraints, and material market fluctuations, adjusting quotes for technical feasibility before client delivery.

Collaborative DFM Analysis

Upon quote acceptance, Honyo’s DFM phase begins as a structured engineering dialogue rather than a unilateral review. Our team conducts tolerance stack analysis, identifies high-cost micro-features (e.g., internal radii <0.5mm), and evaluates fixturing challenges using NX CAM simulations. Clients receive a formal DFM report within 24 hours detailing actionable recommendations such as suggested tolerance relaxations or feature modifications that typically reduce costs by 18–35% without compromising function. This phase requires explicit client sign-off before production release.

Precision Production Execution

All milling occurs in Honyo’s ISO 9001:2015-certified Shenzhen facility using Makino V56 5-axis centers with sub-micron linear encoders. Production follows a documented control plan:

First-article inspection validates critical dimensions via Zeiss CONTURA CMM before batch commencement.

In-process checks at 25% and 75% completion monitor thermal drift and tool wear using Renishaw probes.

Final inspection certifies all features against ASME Y14.5 GD&T standards, with full FAIR documentation provided.

Global Delivery Management

Completed parts undergo vacuum desiccant packaging with humidity indicators for moisture-sensitive components. Honyo manages end-to-end logistics under DDP (Delivered Duty Paid) terms, providing clients with real-time shipment tracking via integrated DHL/FedEx APIs. Typical lead times range from 7–12 business days for 1–100 units depending on complexity, with expedited options available. All deliveries include digital quality dossiers containing CMM reports, material certs, and process validation records accessible through the client portal.

This closed-loop methodology ensures dimensional repeatability to ±0.005mm while maintaining audit-ready traceability from CAD file to delivered product, addressing core B2B requirements for quality governance and supply chain transparency in precision manufacturing.

Start Your Project

Looking for high-precision CNC milling services in China? Honyo Prototype delivers tight-tolerance, high-quality milled components with fast turnaround. Our state-of-the-art facility in Shenzhen is equipped to handle complex geometries and demanding specifications for industries including aerospace, medical, and industrial equipment.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Location: Shenzhen, China

Leverage our expertise in China-based precision milling for reliable, repeatable results—every time.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.