Contents

Manufacturing Insight: China Aerospace Precision Machining

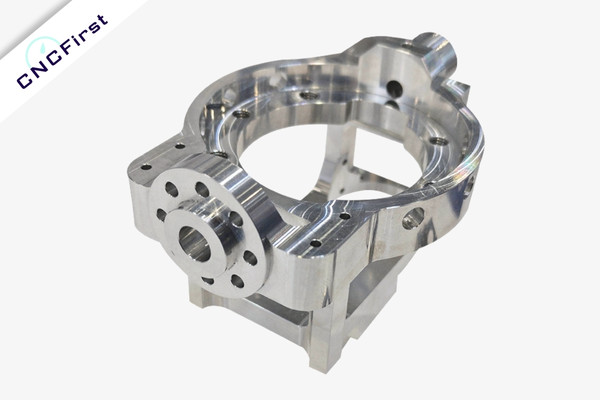

Precision Machining Excellence for China’s Aerospace Sector

Honyo Prototype delivers mission-critical CNC machining services engineered to meet the uncompromising demands of China’s aerospace industry. Our AS9100-certified manufacturing ecosystem combines advanced multi-axis milling, turning, and grinding capabilities with rigorous process controls to achieve micron-level tolerances (±0.0002″) on complex geometries in high-performance alloys including Inconel, titanium, and aluminum aerospace grades. Every component undergoes stringent NADCAP-accredited inspection protocols, ensuring dimensional integrity and material compliance across flight-critical systems from turbine blades to structural airframe assemblies.

We address aerospace supply chain challenges through integrated digital workflows that accelerate time-to-prototype without sacrificing quality. Our in-house technical team collaborates directly with engineering stakeholders to resolve DFM constraints early, while real-time SPC monitoring maintains Cpk >1.67 across production runs. This commitment to precision repeatability positions Honyo as a trusted partner for Tier 1 aerospace OEMs and defense contractors navigating China’s evolving regulatory landscape.

Accelerate your development cycle with our Online Instant Quote platform. Upload CAD files to receive AS9100-compliant production-ready pricing and lead time estimates within 2 hours—validated by our engineering team against aerospace-specific material, tolerance, and surface finish requirements. Experience how Honyo Prototype transforms precision machining from a supply chain vulnerability into your competitive advantage.

Technical Capabilities

Honyo Prototype delivers high-precision machining services meeting stringent aerospace standards, with technical capabilities centered on multi-axis CNC milling and turning for mission-critical components. Our 3-axis, 4-axis, and 5-axis CNC machining platforms are optimized for complex geometries, tight tolerances, and repeatable accuracy required in aerospace applications. We specialize in machining a range of materials including aluminum alloys (e.g., 6061-T6, 7075-T6), alloy steels (e.g., 4140, 17-4 PH), and high-performance polymers such as ABS and nylon (e.g., PA6, PA66), ensuring compatibility with both structural and non-metallic aerospace requirements.

The following table outlines the key technical specifications for our aerospace precision machining services:

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Maximum Work Envelope | 1000 x 600 x 500 mm | 800 x 500 x 400 mm | 600 x 400 x 400 mm | Ø300 x 500 mm length |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.003 mm | ±0.005 mm |

| Repeatability | ±0.003 mm | ±0.003 mm | ±0.002 mm | ±0.003 mm |

| Standard Tolerance | ±0.010 mm | ±0.010 mm | ±0.008 mm | ±0.010 mm |

| Tight Tolerance Capability | ±0.005 mm | ±0.005 mm | ±0.003 mm | ±0.005 mm |

| Surface Finish (Ra) | 0.8 – 3.2 µm | 0.8 – 3.2 µm | 0.4 – 1.6 µm | 0.8 – 3.2 µm |

| Spindle Speed (Milling) | Up to 24,000 rpm | Up to 20,000 rpm | Up to 20,000 rpm | N/A |

| Spindle Speed (Turning) | N/A | N/A | N/A | Up to 5,000 rpm |

| Tool Changer Capacity | 24–30 tools | 24 tools | 24 tools | 12–16 tools |

| Materials Supported | Aluminum, Steel, ABS, Nylon, Titanium, Inconel | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon |

All processes adhere to ISO 9001 and AS9100 quality management standards. Materials are certified and traceable, with full inspection reporting (FAI/PPAP available). 5-axis machining enables single-setup production of complex contours and deep cavities, reducing cumulative error and improving geometric accuracy. Tight tolerance capabilities are maintained through thermal compensation, in-process probing, and post-machining CMM verification using Zeiss or Hexagon metrology systems.

For polymer components such as ABS and nylon, we apply optimized cutting strategies, low-stress fixturing, and environmental controls to minimize deformation and ensure dimensional stability.

From CAD to Part: The Process

Honyo Prototype delivers China-based aerospace precision machining through a rigorously controlled workflow designed for mission-critical components. Our process integrates advanced technology with deep domain expertise to ensure compliance, quality, and on-time delivery for demanding aerospace applications.

Upload CAD

Clients initiate the process by securely uploading native or neutral CAD files (STEP, IGES, Parasolid) via our encrypted portal. For aerospace projects, we specifically request associated GD&T callouts, material specifications per AMS/ASTM standards, and any applicable drawing notes referencing ASME Y14.5 or aerospace-specific standards. Our system automatically checks file integrity and geometry complexity, flagging potential issues like non-manufacturable features before proceeding.

AI-Powered Quoting

Our proprietary AI engine analyzes the CAD geometry, material requirements, and tolerance stack-ups to generate an initial quote within 24 hours. The AI cross-references real-time data on titanium alloys (e.g., Ti-6Al-4V), Inconel 718, and aluminum aerospace grades, incorporating current raw material costs from certified Chinese mills. Crucially, the AI identifies high-risk features requiring specialized tooling or inspection—such as deep cavities with ±0.005mm tolerances—and factors in NADCAP-accredited process costs. A Senior Manufacturing Engineer validates all AI outputs, adding notes on feasible lead time reductions or critical process controls.

DFM Analysis

Honyo’s aerospace-dedicated DFM team conducts a 72-hour deep dive using Siemens NX CAM. We focus on aerospace-specific optimizations:

Material waste reduction for expensive alloys while maintaining forging grain flow orientation

Machining sequence validation for thin-walled structures to prevent distortion

Critical feature accessibility assessment for 5-axis milling of complex contours

Surface finish and residual stress mitigation strategies for fatigue-critical parts

The DFM report includes actionable recommendations with tolerance relaxation options per AS9100 clause 8.5.1, always preserving functional requirements. Clients receive a collaborative review session with our NADCAP-certified process engineers.

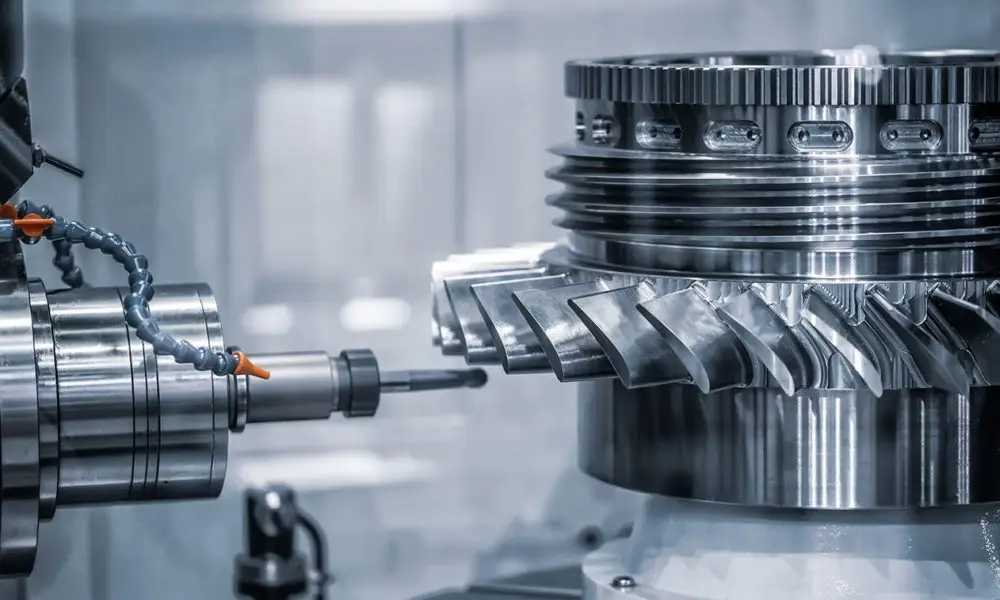

Production Execution

Manufacturing occurs in our ISO 14644 Class 7 cleanroom facility in Chengdu, featuring:

5-axis DMG MORI machines with integrated Renishaw probing for in-process verification

Vacuum induction melting (VIM) sourced materials with full material test reports (MTRs)

Real-time SPC monitoring of critical dimensions using Zeiss Calypso CMMs

Every operation follows documented work instructions aligned with AS9100 Rev D. For titanium components, we implement strict oxygen-level controls during machining to prevent contamination. First-article inspections include full FAI per AS9102 with 3D scan overlays against nominal CAD.

Delivery and Documentation

Final delivery includes the components in ESD-safe packaging with traceability tags linking to:

| Document Type | Aerospace Requirement | Honyo Implementation |

|————————-|———————————————–|——————————————|

| Material Certification | AMS 4928, AMS 5662 | Full MTR with heat number traceability |

| Inspection Report | AS9102 FAI Level 3 | CMM + optical comparator data |

| Process Certification | NADCAP AC7108 (Chemical) / AC7102 (NDT) | Valid certs for anodizing/penetrant test |

| Compliance Statement | ITAR/EAR, China Export Controls | Dual-checked export classification |

All aerospace shipments include a digital quality package via secure link, with physical documentation meeting FAA EASA Part 21 requirements. Typical delivery timelines range from 15–30 days for complex assemblies, with expedited options for urgent airframe or engine programs. Honyo maintains full component traceability from raw bar stock to end-of-life for 10+ years per aerospace industry mandates.

Start Your Project

For precision machining solutions in China’s aerospace sector, partner with Honyo Prototype. Our Shenzhen-based factory delivers high-accuracy components meeting strict aerospace standards. From complex geometries to tight-tolerance requirements, our advanced CNC capabilities ensure consistent quality and on-time delivery.

Contact Susan Leo for technical specifications, capacity details, or project quotations.

Email: [email protected]

Leverage our expertise in aerospace-grade materials, in-process inspection, and full traceability to support your mission-critical applications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.