Guide Contents

Project Insight: China Aerospace Precision Machining

Manufacturing Insight: China Aerospace Precision Machining

Why Speed and Precision Define Aerospace Innovation

Safety-Critical Tolerances: Aerospace components demand micron-level precision (±0.01mm) to ensure structural integrity and regulatory compliance—where even minor deviations risk mission failure.

Accelerated Time-to-Market: Startups face intense pressure to iterate quickly; delays in prototyping can mean losing competitive edge in a fast-moving industry.

Regulatory Rigor: Standards like AS9100 require flawless quality control from first prototype to final production, demanding manufacturing partners who prioritize precision upfront.

Honyo Prototype: Precision at the Speed of Innovation

AI-Powered Instant Quotes: Get real-time pricing and DFMA feedback within seconds—no more waiting days for quotes while your project stalls. Our platform analyzes your design for manufacturability, optimizing cost and lead time before production begins.

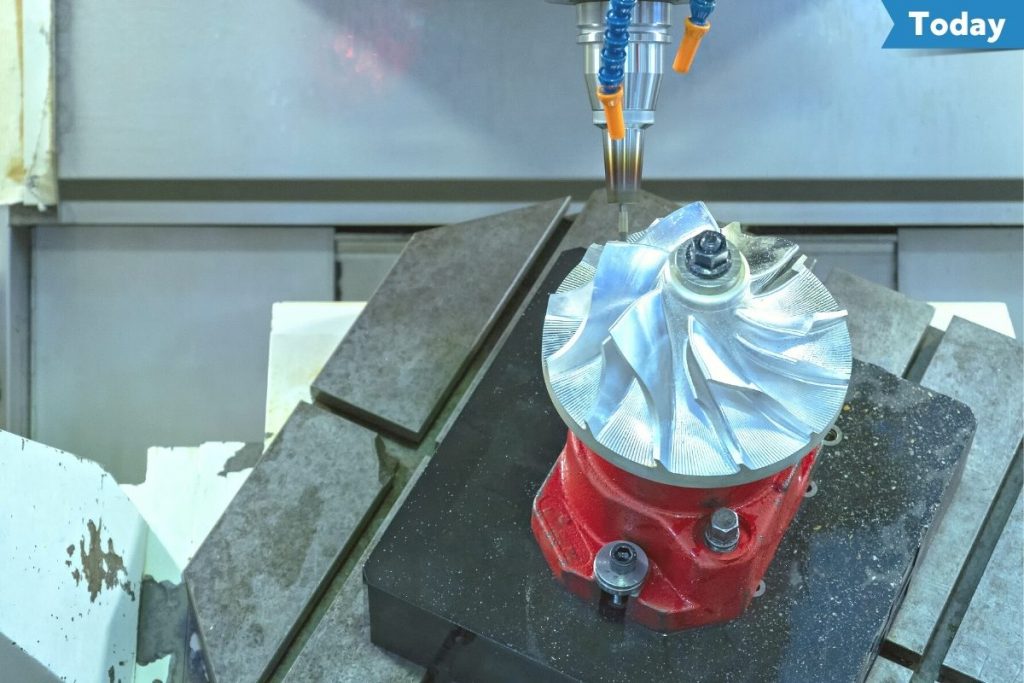

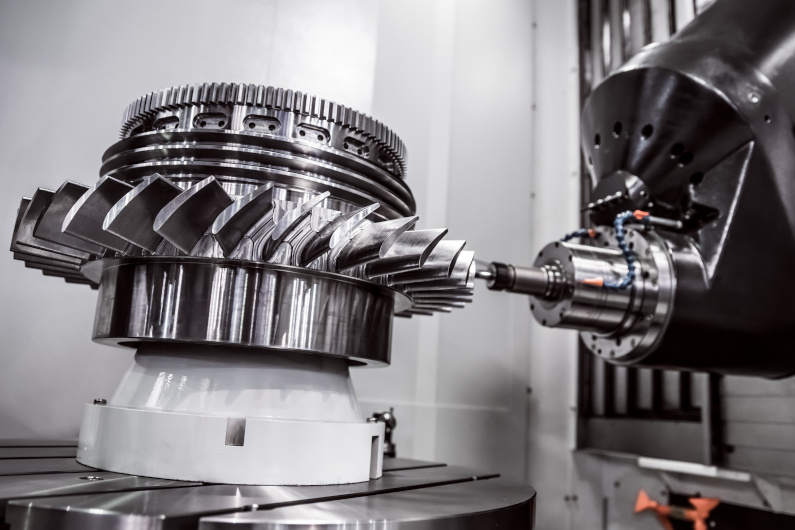

5-Axis CNC Mastery: Leverage advanced 3/4/5-axis machining to produce complex aerospace geometries with ±0.01mm tolerances. Every part undergoes in-process inspection to meet AS9100 standards for functional prototypes and end-use components.

3-Day Prototype Turnaround: From design upload to delivered parts—accelerate validation cycles with our streamlined digital workflow. Expedited shipping options ensure you meet tight deadlines without compromising quality.

30-50% Cost Advantage: Achieve world-class precision at 30-50% lower costs than Western suppliers through Shenzhen’s optimized manufacturing ecosystem and automated production processes.

Honyo Prototype—where AI-driven efficiency meets aerospace-grade precision—to bring your designs to life faster, smarter, and more affordably.

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

Advanced Multi-Axis CNC Technology

3/4/5-Axis Machining: Precision engineering for complex aerospace geometries, including intricate internal features and multi-faceted surfaces. Dynamic tooling solutions reduce setup times by 30% while maintaining micron-level accuracy.

High-Speed Machining: Optimized spindle speeds and adaptive cutting strategies minimize cycle times without compromising surface finish or dimensional integrity.

Precision Engineering at ±0.01mm Tolerance

Micron-Level Consistency: Reliable ±0.01mm tolerances for critical aerospace components—ensuring perfect fit, function, and safety in high-stress environments.

In-Process Metrology: Real-time laser scanning and automated feedback loops eliminate errors before they occur, guaranteeing first-time-right production.

Scalable Production from Prototype to Series

1 to 10,000+ Parts: Seamlessly transition from single prototypes to high-volume production runs with zero quality compromise or retooling delays.

Startup-Friendly Flexibility: No minimum order requirements—perfect for rapid iteration and scalable growth from concept to commercialization.

ISO 9001 & AS9100 Certified Quality Control

End-to-End Traceability: Full material and process documentation for every component, compliant with aerospace safety standards.

100% Inspection Protocol: Rigorous dimensional, material, and functional testing at every production stage—ensuring zero-defect delivery.

Digital-First Efficiency

Instant Online Quote: Get real-time pricing in seconds via our AI-powered platform—no waiting, no guesswork.

AI-Driven DFMA: Automated design for manufacturability analysis to optimize costs, reduce lead times, and eliminate production bottlenecks.

48-Hour Prototype Delivery: Accelerate product development cycles with industry-leading turnaround times—so you innovate faster.

Materials & Surface Finishes

Precision Materials for Aerospace Applications

Material Selection Guide

Choose materials that meet aerospace-grade performance requirements while optimizing for cost and manufacturability. Honyo’s precision machining capabilities (±0.01mm tolerances) ensure every component meets stringent aerospace standards:

Aluminum 6061-T6

Why it’s ideal: Lightweight, excellent corrosion resistance, and high machinability for complex geometries.

Aerospace use case: Structural brackets, housing components, and non-critical load-bearing parts where weight reduction is critical.

Honyo advantage: Consistent surface finishes and tight tolerances for aerodynamic interfaces.

Aluminum 7075-T6

Why it’s ideal: Superior strength-to-weight ratio (30% stronger than 6061) with fatigue resistance.

Aerospace use case: High-stress components like landing gear parts, wing fittings, and drone frames.

Honyo advantage: Precision 5-axis machining minimizes stress concentrations in high-load areas.

Stainless Steel 316L

Why it’s ideal: Exceptional corrosion resistance in harsh environments (e.g., saltwater, chemicals).

Aerospace use case: Marine-grade aerospace components, fuel system parts, and biomedical aerospace applications.

Honyo advantage: Electro-polishing options for ultra-smooth surfaces to prevent fluid contamination.

Brass C11000

Why it’s ideal: High electrical conductivity and machinability for precision electrical components.

Aerospace use case: Connectors, grounding straps, and sensor housings requiring EMI shielding.

Honyo advantage: Tight-tolerance machining for micro-features without deformation.

PEEK (Polyether Ether Ketone)

Why it’s ideal: High-temperature stability (up to 250°C), chemical resistance, and low outgassing.

Aerospace use case: Non-metallic structural parts in satellite systems, insulation components, and fuel system seals.

Honyo advantage: Advanced CNC programming for complex geometries without thermal warping.

Advanced Surface Finishes for Performance & Durability

Finish Options for Aerospace Compliance

Surface treatments enhance corrosion resistance, wear performance, and aesthetic quality—critical for aerospace longevity and safety:

Anodizing (Type II/III)

Aerospace benefit: Type III (hard anodize) provides 50+ µm wear resistance for moving parts; Type II offers corrosion protection for exterior panels.

Honyo precision: Electrolytic baths with real-time thickness monitoring to meet AS9100 standards.

Electropolishing

Aerospace benefit: Removes micro-roughness (Ra < 0.2µm) for fluid systems to prevent contamination and reduce drag.

Honyo precision: Laser-guided surface analysis ensures uniform polish across complex geometries.

Passivation (Stainless Steel)

Aerospace benefit: Eliminates surface iron contaminants to maximize corrosion resistance in critical environments.

Honyo precision: Nitric acid baths with ISO 10528 compliance for aerospace-grade passivation.

Powder Coating (Epoxy/Polyester)

Aerospace benefit: Durable, UV-resistant finish for non-critical exterior parts with color customization.

Honyo precision: Automated robotic application for uniform thickness (50–100µm) on complex shapes.

Diamond-Like Carbon (DLC) Coating

Aerospace benefit: Ultra-low friction and extreme hardness for high-wear components like bearings and seals.

Honyo precision: PVD process with nanometer-level control for aerospace-specific wear profiles.

Why Honyo Delivers Aerospace-Grade Precision

Your Smart Partner for Cost-Efficient Manufacturing

Leverage China’s manufacturing excellence without compromising on quality—Honyo combines cutting-edge technology with lean operations to deliver:

Instant AI-Powered Quoting

Upload your CAD in seconds to receive real-time pricing, material optimization suggestions, and lead time estimates. Our platform analyzes design complexity to recommend the most cost-effective material-finish combo—saving you up to 50% vs. US suppliers while maintaining ±0.01mm tolerances.

3-5 Day Prototype Turnaround

From design validation to functional testing, our Shenzhen facility delivers aerospace-grade prototypes faster than global competitors. All orders include ISO 9001-certified quality checks and material traceability reports.

End-to-End Aerospace Compliance

Every part is manufactured to AS9100 standards with in-process GD&T inspections. Our AI-driven quality control system flags deviations before production completes—ensuring zero defects for critical components.

“At Honyo, we don’t just machine parts—we engineer solutions. Our AI platform helps hardware startups and engineers navigate material trade-offs with data-driven precision, so you focus on innovation, not logistics.”

— Susan Leo, Founder & Chief Engineer

[Get Your Instant Quote Now] → [Link to Honyo’s AI Quoting Platform]

From Quote to Part: Our Process

How It Works: From CAD to Part

At Honyo Prototype, we’ve engineered a seamless digital workflow that transforms your design into precision parts faster, smarter, and with unparalleled transparency. Here’s how it works:

1. Upload Your CAD File

Effortlessly submit your design files (STP, STEP, IGES, STL, etc.) via our secure cloud platform.

AI-powered validation instantly checks file integrity and compatibility—no manual reviews or delays.

2. Get Instant AI-Powered Quote

Receive a detailed, transparent quote within seconds—no back-and-forth, no guesswork.

Real-time cost breakdown includes material, machining time, setup fees, and shipping—with zero hidden charges.

Leverage 30-50% cost savings versus US suppliers while maintaining aerospace-grade precision.

3. Proactive DFM Analysis & Optimization

Our AI engine and expert engineers analyze your design for manufacturability, flagging potential issues before production.

Receive actionable feedback to optimize tolerances, reduce material waste, and accelerate timelines.

Collaborate in real-time with our team to refine your design—ensuring perfection from the start.

4. Precision Production & Trackable Delivery

Advanced 3/4/5-axis CNC machining delivers ±0.01mm tolerances for functional prototypes and end-use parts.

End-to-end quality control with ISO-certified processes and automated inspection at every stage.

Track your order live from machining to delivery—typical turnaround: 3–5 business days with global shipping.

From CAD to your hands—faster, smarter, and more precise than ever.

Honyo Prototype: Where innovation meets industrial precision.

Start Your Project with Honyo

Start Your Project with Honyo Prototype

✨ Online Instant Quote

AI-driven platform delivers real-time pricing in <60 seconds

Automated cost optimization for complex aerospace geometries

Transparent breakdown of materials, machining time, and finishes

🚀 AI-Powered Precision Platform

Smart DFM (Design for Manufacturability) analysis ensures zero rework

Tight tolerance validation at ±0.01mm across 3/4/5-axis CNC systems

End-to-end quality control compliant with AS9100 aerospace standards

⚡ 3-Day Prototyping Guarantee

Shenzhen/Dongguan facilities enable same-day production start

Urgent project acceleration with dedicated engineering support

50% faster turnaround vs. US counterparts—without compromising precision

Ready to Begin?

Founder Susan Leo personally oversees every project from design to delivery

Contact: [email protected] | +86 139 2843 8620

Schedule a facility tour in Shenzhen/Dongguan today—see aerospace-grade precision in action

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.