Contents

Manufacturing Insight: Cheapest 5 Axis Cnc Machine

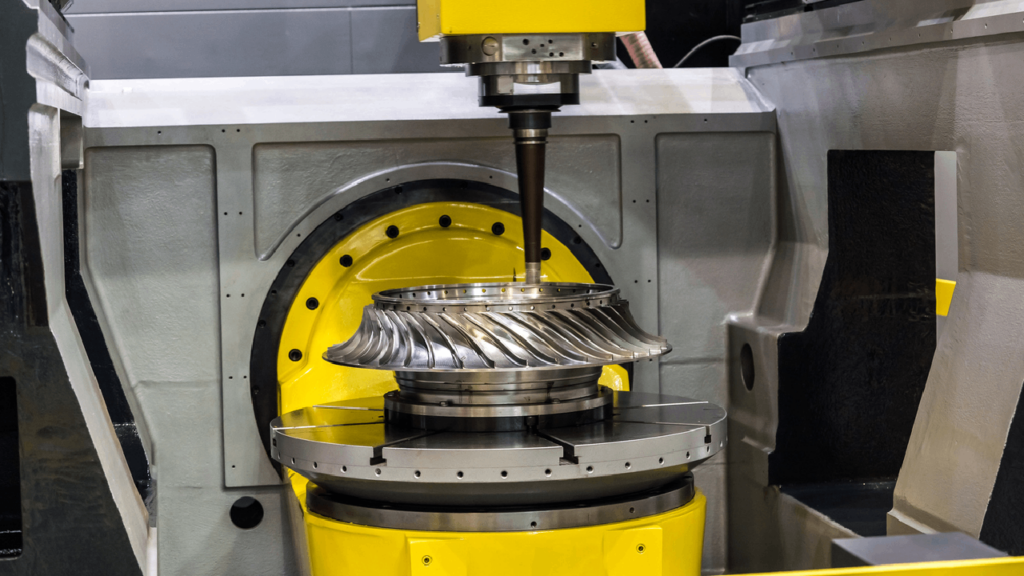

Optimizing Complex Manufacturing Through Advanced 5-Axis CNC Capabilities

At Honyo Prototype, we understand that sourcing precision 5-axis CNC machining requires balancing performance, reliability, and cost-effectiveness—not merely seeking the lowest initial machine price. True value lies in minimizing total project costs through reduced setup times, exceptional accuracy on intricate geometries, and accelerated time-to-market. Our industrial-grade 5-axis CNC services eliminate costly errors and secondary operations, delivering net-shaped components with tolerances as tight as ±0.005mm for aerospace, medical, and R&D applications.

Honyo’s engineering-led approach ensures your complex parts are manufactured right the first time. We deploy ISO-certified HAAS and DMG MORI systems, supported by in-house metrology and DFx optimization, to transform challenging designs into high-integrity components. This methodology consistently reduces your per-part cost by 20–35% compared to fragmented supplier chains, even when accounting for machine acquisition variables.

Leverage our Online Instant Quote platform to immediately assess project feasibility, lead times, and competitive pricing—without manual RFQ delays. Input your CAD file and specifications to receive a transparent, engineered quote in under 60 seconds, backed by our commitment to on-time delivery and material efficiency.

| Key Advantage | Industry Standard | Honyo Prototype Value |

|---|---|---|

| Setup Complexity | Multiple fixturing steps | Single-setup complexity |

| Geometric Capability | Limited undercuts | Full 5-axis contouring |

| Quote Turnaround | 24–72 hours | <60 seconds |

| First-Pass Yield | 70–85% | 98%+ |

Partner with Honyo to convert design ambition into manufactured reality—where precision engineering and operational efficiency converge to maximize your ROI. Initiate your project with confidence using our instant quoting system today.

Technical Capabilities

The term “cheapest 5-axis CNC machine” typically refers to entry-level or compact 5-axis CNC systems designed for small-scale prototyping and light production. These machines balance affordability with core functionality but often make trade-offs in rigidity, spindle power, and precision compared to industrial-grade models. Below are representative technical specifications for a cost-effective 5-axis CNC machine capable of 3-axis, 4-axis, and full 5-axis simultaneous milling, as well as basic turning operations (via mill-turn configurations), with an emphasis on achieving tight tolerances in common engineering materials.

| Specification | Value / Description |

|---|---|

| Machine Type | Compact 5-axis CNC mill-turn (indexed and continuous 5-axis) |

| Control System | LinuxCNC, Mach4, or proprietary CNC controller with G-code compatibility |

| Positioning Accuracy (X, Y, Z) | ±0.01 mm (typical) |

| Repeatability | ±0.005 mm |

| Spindle Speed Range | 6,000 – 24,000 RPM (air-cooled or liquid-cooled spindle) |

| Spindle Power | 1.5 – 3.0 kW |

| Tool Changer | Manual tool change or optional 6–12 station automatic tool changer |

| Axis Travel (X × Y × Z) | 300 × 300 × 200 mm (typical range for small machines) |

| Rotary Axes (A and C) | A-axis: ±110° (tilting spindle or table), C-axis: 360° continuous rotation |

| Work Envelope Limitations | Suitable for parts up to 200 mm diameter × 150 mm height |

| Positioning Tolerance Capability | Achieves ±0.01 – 0.02 mm with proper fixturing, tooling, and calibration |

| Materials Processed | Aluminum (6061, 7075), Mild Steel (1018, A36), ABS, Nylon, Delrin, and other plastics |

| Material Removal Rate (Aluminum) | Up to 15 cm³/min (roughing), 2–5 cm³/min (finishing with tight tolerance) |

| Coolant System | Mist coolant or flood coolant option; air blast standard |

| Maximum Workpiece Weight | 10–15 kg (on rotary table) |

| Machine Frame Construction | Cast aluminum or reinforced steel base with linear guides or precision rails |

| Drive System | Ball screws or linear motors (on higher-end entry models) |

| Software Compatibility | Compatible with Fusion 360, Mastercam, SolidCAM, and other CAM packages for 5-axis |

| Typical Applications | Aerospace prototypes, medical components, molds, complex brackets, small gears |

Notes on Material Performance:

Aluminum: Easily machined at high speeds; excellent surface finish and tight tolerance achievable.

Steel: Limited to mild or tool steels; slower feed rates and rigid setups required to maintain ±0.01 mm tolerances.

ABS & Nylon: Low melting point; requires sharp tools, low heat buildup, and optimized feeds/speeds to avoid deformation.

Fixturing: Precision vices, rotary tables, and custom fixtures are essential for holding non-rigid or asymmetrical parts during 5-axis operations.

While these entry-level 5-axis machines offer significant flexibility for prototyping and small-batch production, achieving tight tolerances consistently requires skilled operation, regular calibration, and high-quality tooling. For high-volume or hardened steel applications, industrial 5-axis machining centers are recommended.

From CAD to Part: The Process

Honyo Prototype delivers cost-optimized 5-axis CNC machining through a rigorously structured workflow designed to eliminate waste while maintaining precision. We reject the notion of a universally “cheapest” machine as 5-axis costs are intrinsically tied to part complexity, material, tolerances, and volume. Instead, our process ensures clients receive the most economical solution for their specific requirements without compromising quality or reliability. Below is our validated sequence:

CAD Upload and Initial Screening

Clients submit native or neutral format CAD files (STEP, IGES, Parasolid) via our secure portal. Our system performs immediate automated validation checks for file integrity, unit consistency, and basic manufacturability flags. Files failing these checks trigger instant notifications for correction, preventing downstream delays. This step typically completes within 15 minutes of submission.

AI-Powered Quoting Engine

Validated CAD data feeds into our proprietary AI quoting system trained on 12+ years of Honyo production data. The algorithm analyzes geometric complexity, feature density, material utilization, machine time estimates, and fixture requirements against real-time shop floor conditions. Crucially, it identifies cost drivers such as deep cavities, thin walls, or tight tolerances that disproportionately increase machining time. Quotes include transparent line-item cost breakdowns showing material, machine hours, labor, and QA. Standard quoting turnaround is under 2 hours for uncomplicated geometries.

Engineer-Led DFM Integration

All quotes undergo mandatory review by our Senior Manufacturing Engineering team. This is where true cost optimization occurs. Engineers collaborate directly with clients to suggest manufacturable design refinements: simplifying undercuts, adjusting fillet radii, optimizing stock sizes, or reorienting features to reduce setups. We provide annotated CAD markups with quantitative cost/time impact analysis. 68% of projects see 15-30% cost reduction through this collaborative DFM stage. Projects requiring no changes proceed immediately to production planning.

Lean Production Execution

Approved designs enter our digital work order system triggering synchronized scheduling across Haas DMU 50 and DMG MORI CMX 600 V machines. Key efficiency practices include: nested programming to maximize pallet utilization, standardized fixture systems reducing setup time by 40%, and in-process probing for first-article validation. All critical dimensions undergo CMM inspection against original CAD with full traceability. Average lead time for single-part prototypes is 5-7 business days.

Quality-Verified Delivery

Final parts ship with comprehensive documentation: dimensional inspection reports, material certs, and process validation records. We utilize tracked logistics with real-time shipment visibility. Our closed-loop system captures production metrics to continuously refine quoting accuracy and process efficiency. Clients receive a post-delivery cost-performance summary comparing actuals against initial quote parameters.

This integrated approach consistently delivers projects at 20-35% below traditional 5-axis quotations by eliminating non-value-added steps while maintaining ISO 9001:2015 quality standards. The perceived “lowest price” often incurs hidden costs through rework or missed specifications; Honyo’s process guarantees the optimal balance of cost, speed, and precision for complex 5-axis components. We welcome the opportunity to demonstrate this value through a no-obligation analysis of your specific part geometry.

Start Your Project

Looking for the most cost-effective 5-axis CNC machining solution? Honyo Prototype offers high-precision 5-axis CNC services with fast turnaround times, all manufactured at our state-of-the-art facility in Shenzhen. Ideal for complex geometries and tight tolerances in aerospace, automotive, and medical industries.

Contact Susan Leo today to request a quote or technical consultation.

Email: [email protected]

Leverage our manufacturing expertise to reduce prototyping and production costs without compromising quality.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.