Introduction: Navigating the Global Market for cheapest 5 axis cnc

In today’s competitive manufacturing landscape, sourcing the cheapest 5-axis CNC machines is a critical challenge for international B2B buyers. Many companies face the dilemma of balancing budget constraints with the need for high precision and versatility in machining. This guide is designed to equip buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Brazil and Nigeria—with the insights needed to navigate this complex purchasing process effectively.

Throughout this comprehensive guide, we will explore various types of 5-axis CNC machines, their diverse applications—from aerospace to medical manufacturing—and the importance of supplier vetting to ensure quality and reliability. Understanding the nuances of pricing and what factors contribute to the cost of these advanced machines will empower buyers to make informed decisions that align with their operational needs and financial goals.

By addressing key considerations in sourcing, such as machine specifications, supplier reputation, and after-sales support, this guide serves as an essential resource for B2B buyers looking to invest wisely in 5-axis CNC technology. With the right knowledge, businesses can not only enhance their manufacturing capabilities but also achieve significant cost savings, positioning themselves for success in the global market.

Understanding cheapest 5 axis cnc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Benchtop 5-Axis CNC Mill | Compact design, high-speed spindle (5,000-30,000 RPM), automatic tool changer | Micro-machining, jewelry, medical | Pros: Space-efficient, affordable; Cons: Limited work envelope compared to larger models. |

| Trunnion Table 5-Axis CNC | 4th and 5th axis integration, high rotational accuracy, suitable for complex geometries | Aerospace, automotive, mold making | Pros: Enhanced accuracy for complex parts; Cons: Higher initial investment than basic models. |

| Used 5-Axis CNC Mill | Cost-effective, previously owned machines, diverse brands available | General machining, prototyping | Pros: Significant cost savings; Cons: Potential for wear and limited warranty options. |

| Vertical 5-Axis CNC Machining Center | Vertical spindle orientation, large work envelopes, versatile tooling options | Heavy-duty machining, large components | Pros: Greater rigidity for heavy cuts; Cons: Requires more floor space and power. |

| Hybrid 5-Axis CNC Systems | Combines additive and subtractive manufacturing, multi-material capability | Aerospace, automotive, custom parts | Pros: Versatile production capabilities; Cons: More complex operation and maintenance requirements. |

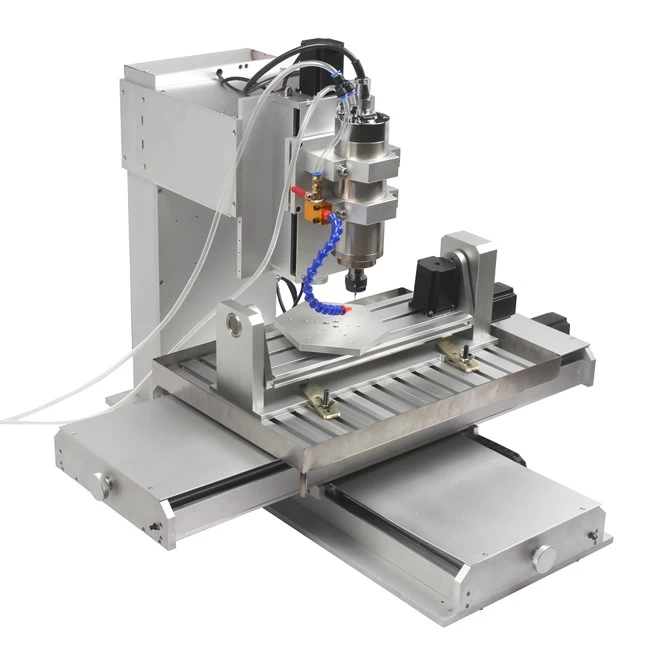

What Are the Key Characteristics of Benchtop 5-Axis CNC Mills?

Benchtop 5-axis CNC mills are designed for precision in compact environments. They typically feature high-speed spindles that can operate between 5,000 to 30,000 RPM, making them ideal for micro-machining applications. This type of machine is particularly suitable for industries like jewelry making and medical device manufacturing, where intricate designs are essential. When purchasing, buyers should consider the machine’s footprint, spindle capabilities, and whether it includes features such as an automatic tool changer, which can enhance operational efficiency.

How Do Trunnion Table 5-Axis CNC Machines Stand Out?

Trunnion table 5-axis CNC machines are recognized for their ability to handle complex geometries with high precision. They integrate 4th and 5th axes, allowing for simultaneous machining operations that can significantly reduce production time for intricate components. Common applications include aerospace and automotive parts, where precision is critical. Buyers should evaluate factors such as rotational accuracy and the machine’s ability to support various tooling options, which can influence production flexibility.

What Advantages Do Used 5-Axis CNC Mills Offer?

Used 5-axis CNC mills present an attractive option for companies looking to minimize capital expenditure. These machines come from various reputable brands and can provide substantial savings compared to new models. They are often suitable for general machining and prototyping tasks. However, potential buyers should assess the machine’s condition, warranty status, and any history of maintenance, as these factors can impact long-term reliability and performance.

What Are the Benefits of Vertical 5-Axis CNC Machining Centers?

Vertical 5-axis CNC machining centers are characterized by their vertical spindle orientation, which offers excellent rigidity and stability for heavy-duty machining. These machines are ideal for large components and can accommodate a wide range of tooling options. In industries requiring robust machining capabilities, such as heavy equipment manufacturing, these machines excel. Buyers should consider the machine’s size, power requirements, and tooling versatility when making a purchase decision.

Why Consider Hybrid 5-Axis CNC Systems?

Hybrid 5-axis CNC systems combine both additive and subtractive manufacturing processes, allowing for the creation of complex parts with multi-material capabilities. This versatility makes them suitable for advanced applications in aerospace and automotive sectors. However, they may require more sophisticated operation and maintenance due to their dual functionality. When purchasing, it’s crucial to evaluate the system’s compatibility with existing workflows and the potential return on investment through enhanced production capabilities.

Key Industrial Applications of cheapest 5 axis cnc

| Industry/Sector | Specific Application of cheapest 5 axis cnc | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision part manufacturing for aircraft components | Enhanced accuracy and reduced production time | Ensure high rotational accuracy and material compatibility |

| Medical Devices | Custom prosthetics and implants manufacturing | Improved patient outcomes and customization options | Compliance with medical standards and material certifications |

| Jewelry | Intricate designs for custom jewelry pieces | High-quality finishes and unique product offerings | Look for machines with fine spindle control and detail capabilities |

| Automotive | Production of complex engine components | Streamlined production and lower operational costs | Focus on machines that can handle diverse materials and geometries |

| Electronics | Manufacturing of enclosures and circuit boards | Increased efficiency and reduced waste | Consider sourcing machines with advanced software integration for design adaptability |

How is ‘cheapest 5 axis CNC’ utilized in the Aerospace Sector?

In the aerospace industry, the cheapest 5 axis CNC machines are pivotal for manufacturing precision parts such as turbine blades, brackets, and other intricate components. These machines facilitate the creation of complex geometries that traditional machining cannot achieve, significantly enhancing accuracy and speed. For international buyers, particularly in regions like Africa and South America, sourcing machines that comply with aerospace standards and offer high rotational accuracy (e.g., +/-0.002mm) is crucial to meet stringent quality requirements.

What role does ‘cheapest 5 axis CNC’ play in Medical Device Manufacturing?

The medical device sector employs cheapest 5 axis CNC technology for producing custom prosthetics and implants tailored to individual patient needs. This application allows for intricate designs that enhance patient comfort and effectiveness. Buyers must prioritize machines that adhere to medical manufacturing standards, ensuring that materials used are biocompatible and that the machines can operate within strict tolerances. Compliance with certifications like ISO 13485 is essential for international buyers in this field.

How does ‘cheapest 5 axis CNC’ enhance Jewelry Manufacturing?

In jewelry manufacturing, the cheapest 5 axis CNC machines are utilized to create intricate designs and detailed engravings on various materials. This capability allows jewelers to offer unique, customized pieces that stand out in a competitive market. Buyers should focus on machines that provide excellent spindle control to achieve fine detailing, as well as those that can handle a variety of materials, including precious metals and stones, to maximize their product offerings.

How is ‘cheapest 5 axis CNC’ beneficial for Automotive Production?

The automotive industry benefits from the cheapest 5 axis CNC machines by producing complex engine components and parts that require high precision. These machines streamline production processes, reduce operational costs, and improve overall manufacturing efficiency. International buyers should consider sourcing machines that can handle diverse materials and geometries, ensuring adaptability to various automotive applications, from prototyping to full-scale production runs.

What advantages does ‘cheapest 5 axis CNC’ provide in Electronics Manufacturing?

In the electronics sector, cheapest 5 axis CNC machines are crucial for the production of enclosures and circuit boards, allowing for intricate designs that optimize space and performance. The use of these machines leads to increased efficiency and reduced waste during manufacturing. Buyers should look for machines with advanced software integration capabilities, enabling seamless design adaptations and quick turnaround times, which are particularly important in fast-paced electronics markets.

3 Common User Pain Points for ‘cheapest 5 axis cnc’ & Their Solutions

Scenario 1: Balancing Cost and Quality in 5-Axis CNC Machines

The Problem:

B2B buyers often face a significant dilemma when searching for the cheapest 5-axis CNC machines: balancing cost with quality. Many manufacturers, particularly in regions like Africa and South America, may find themselves tempted by low-priced options that promise advanced features. However, these machines frequently lack the reliability and precision required for complex projects. This can lead to increased downtime, higher maintenance costs, and ultimately, a negative impact on production schedules and profit margins.

The Solution:

To mitigate this challenge, buyers should prioritize thorough research and evaluation of potential vendors. Start by identifying reputable manufacturers or distributors known for offering budget-friendly 5-axis CNC machines without compromising on quality. Request detailed specifications and customer reviews to gauge performance and reliability. Additionally, consider investing slightly more upfront in a machine with better durability and support services, as this can result in lower total cost of ownership over time. Engaging in direct communication with manufacturers about warranty and service agreements can also provide peace of mind and security in your investment.

Scenario 2: Complexity in Machine Operation and Programming

The Problem:

Another prevalent issue for businesses purchasing the cheapest 5-axis CNC machines is the complexity of operation and programming. Many affordable models come with limited user-friendly interfaces, making it challenging for operators who may not have extensive technical training. This complexity can lead to increased errors, longer setup times, and a steep learning curve for new staff, which can disrupt workflows and reduce productivity.

The Solution:

To address this pain point, buyers should prioritize machines that come with intuitive software and comprehensive training resources. Look for CNC systems that utilize industry-standard G-code and provide robust control software that can simplify programming tasks. Additionally, consider vendors that offer on-site training or online support to help operators become proficient in using the machine efficiently. Investing in supplementary training for existing staff can also enhance operational efficiency. This proactive approach not only streamlines the learning process but also ensures that the machine is utilized to its full potential, maximizing productivity.

Scenario 3: Limited Technical Support and After-Sales Service

The Problem:

Buyers of the cheapest 5-axis CNC machines often encounter a lack of technical support and after-sales service, which can be particularly detrimental for businesses in emerging markets. Many budget options come from manufacturers that do not provide adequate customer service or technical assistance, leaving operators stranded when issues arise. This lack of support can lead to prolonged downtimes and production losses, causing frustration and financial strain.

The Solution:

To overcome this issue, prospective buyers should conduct due diligence on the support services offered by manufacturers before making a purchase. Evaluate the availability of local service representatives and the responsiveness of customer support teams. Choosing machines from well-established brands that have a track record of providing excellent after-sales support can significantly reduce risks. Additionally, consider investing in a maintenance plan that includes regular check-ups and immediate support for troubleshooting. This foresight can help ensure that your machine remains operational and that any potential issues are resolved swiftly, thereby protecting your investment and maintaining productivity.

Strategic Material Selection Guide for cheapest 5 axis cnc

What Materials Are Commonly Used in the Cheapest 5 Axis CNC Machines?

When selecting materials for the cheapest 5-axis CNC machines, it’s essential to understand how different materials can affect performance, cost, and suitability for specific applications. Below are analyses of four common materials used in the manufacturing of these CNC machines.

Aluminum: A Lightweight and Versatile Choice

Key Properties: Aluminum is known for its lightweight nature, excellent thermal conductivity, and resistance to corrosion. It can withstand moderate temperatures and pressures, making it suitable for various machining applications.

Pros & Cons: The primary advantage of aluminum is its ease of machining, which reduces manufacturing complexity and costs. However, while aluminum is durable, it may not be suitable for high-stress applications where strength is critical. Additionally, its lower density can lead to vibrations during high-speed machining.

Impact on Application: Aluminum is compatible with a variety of machining processes, making it ideal for applications in aerospace, automotive, and consumer products. Its corrosion resistance is beneficial in environments where exposure to moisture is a concern.

Considerations for International Buyers: Compliance with standards such as ASTM for aluminum alloys is crucial. Buyers in regions like Africa and South America should consider local suppliers who can provide materials that meet international specifications, ensuring quality and performance.

Steel: Strength and Durability for Heavy-Duty Applications

Key Properties: Steel is renowned for its high tensile strength and durability. It can withstand high temperatures and pressures, making it suitable for heavy-duty machining tasks.

Pros & Cons: The major advantage of steel is its robustness, which allows for the machining of complex parts without deformation. However, steel is heavier and more expensive than aluminum, which can increase shipping costs and complicate machine design. Additionally, machining steel requires more advanced tools and longer processing times.

Impact on Application: Steel is often used in industries requiring high precision and strength, such as oil and gas, construction, and heavy machinery. It is particularly suitable for components that will undergo significant wear and tear.

Considerations for International Buyers: Buyers should be aware of the varying grades of steel and their corresponding standards (e.g., DIN, JIS). Understanding the specific requirements for their applications will help in selecting the appropriate steel grade.

Composite Materials: Innovative Solutions for Lightweight Applications

Key Properties: Composites, such as carbon fiber reinforced plastics, offer excellent strength-to-weight ratios and corrosion resistance. They can withstand a range of temperatures and are often tailored for specific applications.

Pros & Cons: The key advantage of composites is their lightweight nature, which can significantly reduce machine weight and improve efficiency. However, they can be more expensive than metals and may require specialized machining techniques, leading to increased manufacturing complexity.

Impact on Application: Composites are ideal for applications in aerospace and automotive industries where weight reduction is critical. They are also suitable for creating intricate designs that would be difficult to achieve with traditional materials.

Considerations for International Buyers: International buyers should ensure that composite materials comply with relevant standards, as these can vary significantly between regions. Understanding local regulations regarding material safety and environmental impact is also essential.

Titanium: The Premium Choice for High-Performance Applications

Key Properties: Titanium is known for its exceptional strength, lightweight, and corrosion resistance. It can withstand extreme temperatures and is highly biocompatible, making it suitable for medical applications.

Pros & Cons: The primary advantage of titanium is its strength-to-weight ratio, which allows for the creation of strong yet lightweight components. However, titanium is one of the more expensive materials, and its machining can be challenging, requiring specialized tools and techniques.

Impact on Application: Titanium is commonly used in aerospace, medical devices, and high-performance automotive applications where strength and weight are critical. Its corrosion resistance makes it suitable for harsh environments.

Considerations for International Buyers: Buyers should be mindful of the high cost associated with titanium and its specific machining requirements. Compliance with international standards for titanium alloys is also crucial, particularly in regulated industries.

Summary Table of Material Selection for Cheapest 5 Axis CNC

| Material | Typical Use Case for cheapest 5 axis cnc | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace, automotive, consumer products | Lightweight and easy to machine | Lower strength than steel | Low |

| Steel | Heavy machinery, oil & gas | High strength and durability | Heavier and more expensive | Med |

| Composite | Aerospace, automotive | Excellent strength-to-weight ratio | Higher cost and machining complexity | High |

| Titanium | Aerospace, medical devices | Exceptional strength and corrosion resistance | Expensive and challenging to machine | High |

This guide provides a comprehensive overview of material selection for the cheapest 5-axis CNC machines, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for cheapest 5 axis cnc

What Are the Main Stages in the Manufacturing Process of Cheap 5 Axis CNC Machines?

The manufacturing process for the cheapest 5-axis CNC machines involves several critical stages, each contributing to the machine’s overall performance and reliability.

-

Material Preparation

The process begins with the selection of high-quality materials, typically aluminum or steel, which are chosen for their strength and machinability. Raw materials undergo rigorous inspections to ensure they meet specified standards. This may involve checking for defects, composition analysis, and dimensional tolerances. Suppliers must maintain a detailed record of material certifications, which is crucial for B2B buyers. -

Forming

Once materials are prepared, they are cut, shaped, or forged into required components. Techniques such as laser cutting, water jet cutting, or CNC machining are commonly employed to achieve precise geometries. The use of CNC technology in this stage ensures high accuracy and repeatability. B2B buyers should inquire about the forming techniques used and whether they align with modern standards for efficiency and precision. -

Assembly

The assembly phase involves the integration of various components, including the spindle, motors, and control systems. Precision is paramount here, as even minor misalignments can affect the machine’s performance. Automated assembly tools may be used to enhance efficiency. Buyers should assess the assembly protocols and whether they involve strict adherence to manufacturer guidelines to ensure the longevity and reliability of the CNC machines. -

Finishing

The final stage involves surface treatment and finishing processes such as anodizing, painting, or coating to enhance durability and aesthetics. This stage is crucial for protecting against corrosion and wear, particularly for machines operating in harsh environments. Buyers should understand the types of finishing processes employed and their implications for maintenance and longevity.

How Is Quality Assurance Ensured in the Manufacturing of Cheap 5 Axis CNC Machines?

Quality assurance (QA) is vital for ensuring that the final product meets industry standards and customer expectations.

-

What International Standards Are Relevant for 5 Axis CNC Manufacturing?

Adhering to international standards such as ISO 9001 is essential for manufacturers. This standard focuses on quality management systems and continuous improvement. Additionally, certifications such as CE and API may be relevant, depending on the specific applications of the CNC machines. B2B buyers should verify that suppliers possess these certifications, as they demonstrate a commitment to quality and safety. -

What Are the Key Quality Control Checkpoints?

Quality control (QC) is integrated into various stages of the manufacturing process. Common checkpoints include:

– Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specifications.

– In-Process Quality Control (IPQC): Ongoing assessments during the manufacturing process to catch defects early.

– Final Quality Control (FQC): A comprehensive review of the finished product, including functional testing and dimensional checks. -

What Testing Methods Are Commonly Used?

Various testing methods are employed to ensure the quality and functionality of 5-axis CNC machines. These include:

– Functional Testing: Evaluating machine performance under operational conditions.

– Dimensional Inspection: Using tools such as calipers and coordinate measuring machines (CMM) to verify that components meet specified tolerances.

– Stress Testing: Assessing machine durability under extreme conditions to ensure reliability.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding and verifying supplier QC processes is crucial.

-

What Are the Best Practices for Auditing Suppliers?

Conducting audits is one of the most effective ways for buyers to ensure that suppliers adhere to quality standards. This may involve onsite visits to evaluate manufacturing processes, QC protocols, and overall facility conditions. Buyers should develop a checklist to guide their audits, focusing on areas such as compliance with international standards, employee training, and equipment calibration. -

How Can Buyers Request Quality Reports?

Suppliers should be willing to provide quality reports that detail their QC processes, results from testing, and certifications. These documents can provide insights into the supplier’s commitment to quality and consistency. Buyers should not hesitate to request these reports as part of their due diligence. -

What Role Do Third-Party Inspections Play?

Engaging third-party inspection agencies can offer an unbiased assessment of the supplier’s quality control. These agencies can perform inspections at various stages of production and provide reports that help buyers make informed decisions. This is particularly important for international buyers who may not have the ability to conduct onsite inspections themselves.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

When sourcing 5-axis CNC machines internationally, buyers must navigate specific QC and certification nuances.

-

Understanding Regional Certification Requirements

Different regions may have varying certification requirements. For instance, CE marking is essential for products sold within the European market, while other regions may prioritize different standards. B2B buyers should familiarize themselves with the necessary certifications for their target markets to ensure compliance. -

Recognizing the Importance of Traceability

Traceability is crucial in quality assurance, allowing buyers to track the origin of materials and the manufacturing processes used. Suppliers should maintain detailed records of production batches and testing results, which can be invaluable during audits or in the event of a product recall. -

Evaluating Post-Sale Support and Warranty Policies

Quality assurance does not end with the purchase. Buyers should assess the supplier’s post-sale support, including warranty policies, maintenance services, and availability of spare parts. A robust support system can significantly impact the machine’s long-term performance and reliability.

In conclusion, understanding the manufacturing processes and quality assurance mechanisms for the cheapest 5-axis CNC machines is essential for B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring they invest in reliable machinery that meets their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cheapest 5 axis cnc’

Introduction

This sourcing guide is designed to assist international B2B buyers in procuring the most cost-effective 5-axis CNC milling machines. By following this structured checklist, you can ensure that you make informed decisions, optimize your procurement process, and ultimately find a machine that meets your operational needs and budget.

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical requirements for the 5-axis CNC machine you need. Consider factors such as:

– Travel Dimensions: Ensure the machine can accommodate the size of the parts you intend to manufacture.

– Spindle Speed and Power: Higher RPM and torque are essential for complex machining tasks.

– Precision Requirements: Identify the necessary accuracy levels for your applications, such as micro-machining or aerospace components.

Step 2: Research Available Models

Conduct thorough research on various 5-axis CNC models available in the market. Focus on:

– Brand Reputation: Consider well-established brands known for quality and service, such as Haas and Mazak.

– Machine Capabilities: Look for machines that can perform both simultaneous 5-axis machining and 3+2 indexing, enhancing versatility.

– User Reviews: Explore online forums or product review sites to gather feedback from existing users regarding performance and reliability.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to vet suppliers thoroughly.

– Request Documentation: Ask for company profiles, certifications, and case studies that demonstrate their experience in your industry.

– Seek References: Contact previous buyers from similar regions to gain insights into the supplier’s reliability and service quality.

– Assess Local Support: Ensure the supplier can provide local support or service, which is vital for maintenance and troubleshooting.

Step 4: Verify Supplier Certifications

Confirm that your potential suppliers hold the necessary certifications to ensure quality and compliance.

– ISO Standards: Look for ISO 9001 certification as a mark of quality management.

– Product Safety Certifications: Ensure the machinery complies with safety regulations relevant to your region, which is crucial for operational safety and liability.

Step 5: Request Detailed Quotations

Once you have narrowed down your options, request detailed quotations from the shortlisted suppliers.

– Breakdown of Costs: Ensure the quote includes not just the machine price but also shipping, installation, and any additional accessories.

– Warranty and Service Agreements: Look for clarity on warranty terms and post-purchase support, which can save costs in the long run.

Step 6: Conduct a Cost-Benefit Analysis

Before finalizing your decision, perform a cost-benefit analysis to assess the overall value of the machine.

– Total Cost of Ownership: Consider not just the initial purchase price but also maintenance, operational costs, and potential downtimes.

– Return on Investment (ROI): Estimate how quickly the machine will pay for itself based on your production needs and potential efficiencies.

Step 7: Finalize Purchase and Arrange Logistics

Once you have selected the best machine, finalize the purchase and arrange for logistics.

– Payment Terms: Ensure that the payment terms are clear and favorable for your cash flow.

– Shipping and Installation: Coordinate shipping schedules and installation timelines to minimize downtime when the machine arrives.

By following these steps, you will be well-equipped to make an informed purchase decision that aligns with your operational goals and budget constraints.

Comprehensive Cost and Pricing Analysis for cheapest 5 axis cnc Sourcing

What Are the Key Cost Components of Sourcing the Cheapest 5 Axis CNC Machines?

When evaluating the costs associated with sourcing the cheapest 5-axis CNC machines, several components come into play. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materials: The type of materials used in the construction of the CNC machine significantly affects pricing. High-quality metals, electronics, and components will naturally increase costs. Buyers should inquire about material specifications and their impact on the machine’s durability and performance.

Labor and Manufacturing Overhead: Labor costs can vary greatly by region, influencing the final price. For instance, sourcing from countries with lower labor costs, such as some regions in Africa or South America, may provide initial savings. However, manufacturers with higher labor costs may offer superior craftsmanship and reliability, potentially reducing long-term expenses.

Tooling and QC: Tooling costs involve the equipment required for production, which can be substantial depending on the complexity of the machine. Quality control measures are essential to ensure that the machines meet industry standards, which can also add to the overall cost. Buyers should evaluate the supplier’s QC processes to understand how they affect pricing.

Logistics and Margin: Logistics encompass shipping, handling, and any tariffs or duties applicable to international transactions. These costs can fluctuate based on the shipping method, distance, and volume of machines ordered. Additionally, suppliers typically include a profit margin, which can vary based on their market position and demand.

How Do Price Influencers Affect the Cost of 5 Axis CNC Machines?

Several factors influence the pricing of 5-axis CNC machines, particularly in international markets.

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for bulk purchases. Understanding the MOQ can help buyers negotiate better pricing, particularly for large projects or ongoing needs.

Specifications and Customization: Custom features or specifications tailored to specific applications can raise costs. Buyers should clearly define their requirements to avoid unnecessary expenses.

Quality and Certifications: Machines that comply with international quality standards or certifications (e.g., ISO, CE) may carry a higher price tag. Buyers should consider whether these certifications are essential for their operations.

Supplier Factors and Incoterms: The choice of supplier can greatly influence price. Established suppliers might charge a premium for their reputation and reliability. Additionally, understanding Incoterms is crucial for international transactions, as they define responsibilities regarding shipping, risk, and costs.

What Are the Best Buyer Tips for Cost-Efficient Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, there are several strategies to enhance cost-efficiency.

Negotiate Wisely: Leverage your purchasing power by negotiating prices based on volume and long-term commitments. Suppliers may be willing to offer better terms for consistent orders.

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance, operational costs, and potential downtime. A cheaper machine may incur higher long-term expenses due to inferior quality or limited support.

Research Pricing Nuances: Understand local market conditions and economic factors that may affect pricing. For instance, currency fluctuations and import tariffs can significantly impact the final cost of machines sourced internationally.

Seek Multiple Quotes: Obtaining quotes from various suppliers allows for comparison and better negotiation leverage. It also provides insights into standard pricing in the market.

Disclaimer on Indicative Prices

It is essential to note that prices for 5-axis CNC machines can vary widely based on the factors discussed. The figures provided in this analysis are indicative and should be verified with suppliers for accuracy and relevance to specific sourcing needs.

Alternatives Analysis: Comparing cheapest 5 axis cnc With Other Solutions

Introduction: Exploring Alternative Solutions to the Cheapest 5 Axis CNC

In the competitive landscape of manufacturing, businesses often seek cost-effective solutions that still deliver high performance. When evaluating the cheapest 5-axis CNC machines, it’s essential to consider various alternatives that could meet similar needs. These alternatives may provide different advantages in terms of cost, performance, and application suitability. Understanding these options will help B2B buyers make informed decisions tailored to their operational requirements.

Comparison Table

| Comparison Aspect | Cheapest 5 Axis CNC | Used 5 Axis CNC Mill | 3-Axis CNC Machine |

|---|---|---|---|

| Performance | High precision (0.002mm) | Variable, depending on condition | Moderate precision (0.01mm) |

| Cost | Low initial investment | Moderate, varies with age | Low to moderate |

| Ease of Implementation | Simple setup with turn-key solution | May require refurbishing | Straightforward setup |

| Maintenance | Low, with available support | Potentially higher due to age | Generally low |

| Best Use Case | Micro-machining and aerospace | General machining applications | Basic machining tasks |

Detailed Breakdown of Alternatives

Used 5 Axis CNC Mill

Investing in a used 5-axis CNC mill can be a viable alternative for companies looking for advanced capabilities at a lower price point. These machines often come from reputable brands and can offer superior performance compared to entry-level options. However, the condition of the machine is critical; potential buyers should assess wear and tear, parts availability, and the cost of potential refurbishments. While the upfront cost may be moderate, maintenance and the need for parts can add to the overall expense.

3-Axis CNC Machine

For businesses with simpler machining needs, a 3-axis CNC machine may suffice. These machines are generally less expensive and easier to operate than their 5-axis counterparts. They are well-suited for straightforward milling tasks and are often easier to maintain due to their simpler mechanics. However, the limitation of only three axes means that they are not ideal for complex geometries or intricate designs. Buyers should weigh the trade-off between cost savings and the need for advanced capabilities when considering this option.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right CNC solution requires a careful analysis of your specific operational demands and budget constraints. While the cheapest 5-axis CNC offers an attractive blend of performance and affordability for high-precision applications, alternatives like used 5-axis mills and 3-axis CNC machines present unique benefits and challenges. Buyers should consider factors such as the complexity of their projects, required precision, and total cost of ownership, including maintenance and operational expenses. By thoroughly evaluating these aspects, businesses can make informed decisions that align with their manufacturing goals and financial strategies.

Essential Technical Properties and Trade Terminology for cheapest 5 axis cnc

What Are the Key Technical Specifications for the Cheapest 5 Axis CNC Machines?

When evaluating the cheapest 5-axis CNC machines, several technical specifications are critical to ensure optimal performance and suitability for specific applications. Here are some essential properties to consider:

-

Spindle Speed (RPM)

The spindle speed, typically ranging from 5,000 to 30,000 RPM, is crucial for determining the machining capabilities of the CNC mill. Higher spindle speeds allow for faster material removal rates and the ability to work with harder materials, making it essential for industries like aerospace and medical manufacturing. For B2B buyers, understanding spindle speed can inform decisions about machine compatibility with specific applications. -

Rotational Accuracy

This specification indicates how precisely the machine can rotate its cutting tool. A rotational accuracy of ±0.002 mm (0.00008 inches) is standard for high-precision tasks. In sectors like micro-machining and jewelry manufacturing, where detail is paramount, this property can significantly impact product quality and production efficiency. -

Table Travel (XYZ)

The travel distance of the table in the X, Y, and Z axes (e.g., 500mm, 200mm, and 280mm) defines the maximum size of the workpiece that can be accommodated. This is particularly important for B2B buyers who need to ensure that the CNC mill can handle the dimensions of their components. Inadequate travel can lead to the need for additional setups, increasing production time and costs. -

Tool Changer Capacity

An automatic tool changer with multiple positions (e.g., 8-position) enhances productivity by reducing downtime during tool swaps. This feature is vital for operations requiring frequent changes in tooling, such as in batch production scenarios. Buyers should assess tool changer capacity based on their production volume and complexity. -

Material Grade

The construction material of the CNC machine affects its durability, stability, and machining precision. Machines made from high-grade steel or aluminum alloys can withstand heavier workloads and vibrations, ensuring longevity and consistent performance. B2B buyers should consider the material grade to evaluate the machine’s suitability for their operational demands. -

Power Requirements

Power specifications, such as 230VAC single-phase or optional 110VAC, are essential for ensuring that the machine can be integrated into existing electrical systems without the need for expensive modifications. Understanding power requirements helps buyers plan installation logistics and operational costs effectively.

What Are Common Trade Terminology and Jargon Used in the 5 Axis CNC Market?

Familiarizing yourself with industry jargon can enhance communication and streamline procurement processes. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the CNC industry, this term is crucial for understanding sourcing and compatibility of replacement parts and accessories. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps businesses manage inventory and budgetary constraints, especially when negotiating bulk purchases of CNC machines or components. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price proposals for specific products or services. In the CNC sector, submitting an RFQ can lead to competitive pricing and better understanding of the market landscape. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for B2B buyers to manage shipping, insurance, and logistics effectively when purchasing CNC machines from overseas. -

CNC (Computer Numerical Control)

CNC refers to the automated control of machining tools by means of a computer. This term is foundational in the industry, emphasizing the technology’s role in enhancing precision and efficiency in manufacturing processes. -

Tolerance

Tolerance indicates the permissible limit of variation in a physical dimension. In CNC machining, tighter tolerances are often required for high-precision applications, making it an important consideration for B2B buyers focused on quality assurance.

By understanding these specifications and trade terminologies, B2B buyers can make informed decisions when sourcing the cheapest 5-axis CNC machines, ensuring they meet their operational needs and budget constraints effectively.

Navigating Market Dynamics and Sourcing Trends in the cheapest 5 axis cnc Sector

What Are the Current Market Dynamics and Key Trends in the Cheapest 5 Axis CNC Sector?

The global market for the cheapest 5 axis CNC machines is witnessing significant growth driven by increasing demand for precision engineering across various industries such as aerospace, medical, and automotive. B2B buyers from regions like Africa, South America, the Middle East, and Europe are particularly focused on cost-effective solutions that do not compromise on quality. One of the notable trends is the rising adoption of automation and smart manufacturing technologies. These innovations enhance operational efficiency, reduce labor costs, and improve product quality, making them attractive to international buyers.

Additionally, the market is experiencing a shift towards more compact and versatile CNC machines, such as benchtop models that offer high precision in smaller footprints. This trend is particularly relevant for small and medium-sized enterprises (SMEs) in emerging markets, where space and budget constraints often dictate purchasing decisions. Furthermore, there is a growing emphasis on sourcing used or refurbished machines, which can provide significant cost savings while still meeting operational needs.

Another critical factor influencing sourcing decisions is the increasing availability of online marketplaces and platforms that facilitate direct connections between buyers and manufacturers. This trend not only enhances transparency but also allows buyers to compare prices and features across a wider range of products, thereby making informed purchasing decisions.

How Important Is Sustainability and Ethical Sourcing in the Cheapest 5 Axis CNC Sector?

Sustainability and ethical sourcing are becoming increasingly vital considerations for B2B buyers in the cheapest 5 axis CNC sector. As environmental concerns escalate globally, manufacturers are under pressure to adopt sustainable practices. This includes utilizing eco-friendly materials and processes, minimizing waste, and reducing energy consumption during manufacturing. Buyers are now prioritizing suppliers who demonstrate a commitment to sustainability, as this can directly impact their own corporate social responsibility (CSR) initiatives.

Moreover, ethical supply chains that ensure fair labor practices and compliance with environmental regulations are essential for building trust and long-term partnerships. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) can serve as indicators of a manufacturer’s commitment to sustainability and ethical practices. By sourcing from certified suppliers, buyers not only mitigate risks associated with unethical practices but also enhance their brand reputation in the market.

In the context of the cheapest 5 axis CNC machines, adopting sustainable practices can also lead to cost savings in the long run. For instance, machines that are designed for energy efficiency can significantly lower operational costs, making them more appealing to cost-conscious buyers.

What Is the Brief Evolution and History of 5 Axis CNC Technology?

The evolution of 5 axis CNC technology can be traced back to the mid-20th century when CNC (Computer Numerical Control) machines were first introduced. Initially limited to 2D operations, the technology gradually advanced to include 3D capabilities, allowing for more complex machining tasks. The introduction of 4 axis CNC machines marked a significant milestone, enabling manufacturers to rotate parts on an additional axis, thus enhancing precision and versatility.

The real breakthrough came with the development of 5 axis CNC machines, which allow for simultaneous movement across all five axes. This capability revolutionized manufacturing, particularly in sectors requiring intricate designs and high precision, such as aerospace and medical device production. Over the years, technological advancements have led to more compact, affordable, and user-friendly models, making 5 axis machining accessible to a broader range of businesses, including SMEs in developing regions. Today, the focus is on integrating smart technologies and automation, further driving the evolution of 5 axis CNC machining in the global market.

Frequently Asked Questions (FAQs) for B2B Buyers of cheapest 5 axis cnc

-

1. How do I ensure the quality of a 5-axis CNC machine before purchasing?

To ensure the quality of a 5-axis CNC machine, request detailed specifications, performance metrics, and operational history from the supplier. Look for certifications such as ISO or CE, indicating compliance with international standards. Ask for references from previous customers to gauge their satisfaction. Additionally, consider arranging a factory visit or requesting a demonstration to assess the machine’s performance firsthand. Quality assurance protocols, such as pre-shipment inspections, can also provide peace of mind regarding the machine’s condition before delivery. -

2. What is the best way to compare prices for 5-axis CNC machines?

To effectively compare prices for 5-axis CNC machines, create a standardized list of specifications that are important to your operations, such as spindle speed, accuracy, and size. Utilize online platforms to gather quotes from multiple suppliers, ensuring you account for additional costs like shipping, customs duties, and installation. Engage with industry forums or trade shows to gain insights on pricing trends and competitor offerings. Finally, consider the total cost of ownership, including maintenance and operational costs, to make a more informed decision. -

3. How do I vet suppliers of 5-axis CNC machines?

Vetting suppliers involves a thorough assessment of their reputation, experience, and financial stability. Check for customer reviews and testimonials, and consider their years of operation in the CNC industry. Request information on their production capabilities, quality control processes, and after-sales support. It may also be beneficial to conduct a background check or visit their facility if possible. Establishing clear communication about expectations and standards can further ensure a successful partnership. -

4. Can I customize a 5-axis CNC machine to meet specific requirements?

Yes, many manufacturers offer customization options for 5-axis CNC machines. When discussing your needs with potential suppliers, clearly outline your specifications, such as modifications in spindle type, table size, or software compatibility. Customizations may involve additional costs and longer lead times, so it’s essential to confirm these details upfront. Ensure that the supplier has a proven track record in delivering customized solutions, as this can significantly impact your operational efficiency. -

5. What are the typical minimum order quantities (MOQs) for 5-axis CNC machines?

Minimum order quantities for 5-axis CNC machines can vary significantly depending on the supplier and the type of machine. Some manufacturers may have no MOQ for standard models, while others may require orders of multiple units for customized machines or bulk pricing. Always clarify the MOQ when requesting quotes, and consider discussing your purchasing plans with suppliers to negotiate favorable terms, especially if you are a smaller business or a first-time buyer. -

6. What payment terms should I expect when buying a 5-axis CNC machine?

Payment terms can differ among suppliers, but common practices include a deposit upfront (typically 20-30%) with the balance due upon delivery or installation. Some suppliers may offer financing options or payment plans, which can be beneficial for larger purchases. Always review the terms in detail, including any penalties for late payment or discounts for early settlement. It’s also advisable to use secure payment methods to protect your investment. -

7. How do I handle logistics when importing a 5-axis CNC machine?

Handling logistics for importing a 5-axis CNC machine involves coordinating with freight forwarders and customs brokers to ensure a smooth shipping process. Verify the shipping method (air or sea) based on cost and urgency, and check the supplier’s shipping capabilities. Prepare all necessary documentation, including commercial invoices, packing lists, and import licenses. Familiarize yourself with local import regulations and taxes to avoid unexpected costs and delays. -

8. What post-purchase support should I expect for a 5-axis CNC machine?

Post-purchase support typically includes installation assistance, training for operators, and ongoing technical support from the supplier. Ensure that the supplier provides a comprehensive warranty covering parts and service for a specified duration. Ask about available maintenance services and whether the supplier offers spare parts. A good relationship with the supplier can enhance support, so maintain open lines of communication for troubleshooting and future upgrades.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Cheapest 5 Axis Cnc Manufacturers & Suppliers List

1. CNC Mills – Entry Level 5-Axis Options

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Entry level 5-axis CNC mill; capable of machining steel and other ferrous metals; able to work on parts around 15″ in one or two axes; price range discussed is under $100k; examples mentioned include DMC Shariff and Hurco VMX30U (purchased for $40k); user emphasizes the need for a machine that can create various shapes with few limitations.

2. MDA Precision – High Precision 5-Axis CNC Mill

Domain: mdaprecision.com

Registered: 2003 (22 years)

Introduction: This company, MDA Precision – High Precision 5-Axis CNC Mill, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. CNC Machines – 5 Axis Mills

Domain: cncmachines.com

Registered: 1997 (28 years)

Introduction: 5 Axis CNC Mill, 50% Off Used 5 Axis Mill For Sale, rotates on A and B axis, moves across X, Y, Z in linear direction, capable of milling complex parts, brands include Haas, Mazak, Hurco, DMS, SCM, various models and categories available, options include chip conveyor, probe, coolant thru spindle, programmable coolant, 360 deg. indexing table, delivery options, year range, price filters, condition…

4. Hermle – C250 with HS Flex Hybrid

Domain: practicalmachinist.com

Registered: 2000 (25 years)

Introduction: 1. Hermle C250 – Automation option: HS Flex Hybrid

2. DN Solutions DVF 4000 or 5000 – Automation option: AWC Pallet pool

3. DMG MORI DMU 40 Pro – Automation option: PH 150 or Robo2go

4. Brother U500Xd1 – Noted for dual-contact spindle, suitable for parts with 5-8 lbs of metal removal, budget-friendly, and footprint considerations.

5. CNC Machines – 5-Axis Milling, Routers & More

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: 5-axis CNC machines available on eBay include various types such as milling machines, routers, and machining centers. Key brands include Acer, Bridgeport, Brother, DMG MORI, Haas, and Mazak. The machines are offered in new and used conditions, with voltage options ranging from 110V to 480V. Prices range from under $25 to over $50,000. Listings include specific models like the 5 Axis CNC 6040 Route…

6. Haas – Universal Machining Centers

Domain: haascnc.com

Registered: 1996 (29 years)

Introduction: This company, Haas – Universal Machining Centers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. STYLECNC – STM1325-5A

Domain: stylecnc.com

Registered: 2015 (10 years)

Introduction: {“Brand”:”STYLECNC”,”Model”:”STM1325-5A”,”Working Area”:”1300*2500*950mm”,”Travelling C axis”:”±210°”,”A axis”:”±120°”,”Double Pendulum Head Type”:”HS655″,”Output Power of Spindle”:”10KW”,”Spindle Speed”:”22000rpm/min”,”Servo System”:”YASKAWA”,”Inverter”:”Delta”,”Material of Table”:”T-slot & Vacuum combined table”,”Tool Magazine”:”Rotary tool magazine (12 positions)”,”Cutter Specifications”:”HSK63…

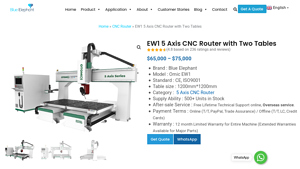

8. Blue Elephant – Omic EW1 5 Axis CNC Router

Domain: elephant-cnc.com

Registered: 2013 (12 years)

Introduction: {“Model”:”Omic EW1″,”Price”:”$65,000–$75,000″,”Brand”:”Blue Elephant”,”Standard”:”CE, ISO9001″,”Table Size”:”1200mm*1200mm”,”Category”:”5 Axis CNC Router”,”Supply Ability”:”500+ Units in Stock”,”After-sale Service”:”Free Lifetime Technical Support online, Overseas service”,”Payment Terms”:”Online (T/T, PayPal, Trade Assurance) / Offline (T/T, LC, Credit Cards)”,”Warranty”:”12 month Limited Warrant…

Strategic Sourcing Conclusion and Outlook for cheapest 5 axis cnc

In the dynamic landscape of CNC machining, the pursuit of cost-effective solutions without compromising quality is paramount for international buyers. The exploration of affordable 5-axis CNC machines reveals significant opportunities to enhance manufacturing capabilities across diverse industries, from aerospace to medical applications. Key takeaways include the importance of evaluating machine specifications—such as spindle power, accuracy, and versatility—as these factors directly influence operational efficiency and product quality.

Strategic sourcing plays a critical role in this process, enabling buyers to identify reliable suppliers that offer competitive pricing and robust support. As industries across Africa, South America, the Middle East, and Europe continue to evolve, the demand for precision machining will only increase.

Investing in the right 5-axis CNC technology not only streamlines production but also fosters innovation. International buyers are encouraged to leverage global networks and explore partnerships that can facilitate access to the best deals in the market. Embrace the opportunity to enhance your manufacturing prowess—begin your journey towards strategic sourcing today and secure a competitive edge in your industry.