Contents

Manufacturing Insight: Cheap Metal 3D Printing

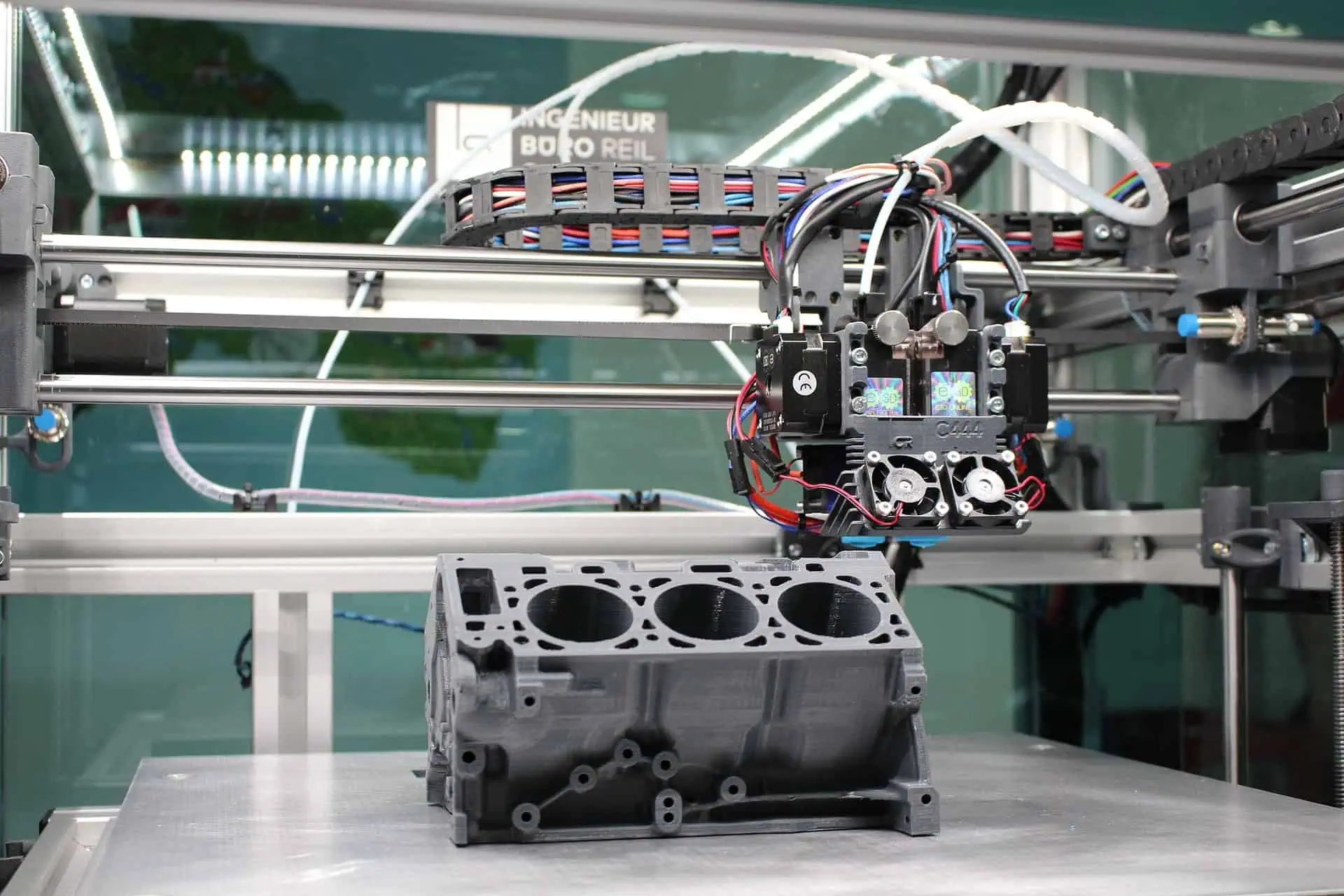

Elevating Industrial Metal Additive Manufacturing Through Strategic Cost Optimization

Honyo Prototype redefines accessibility in industrial metal 3D printing by delivering rigorously engineered solutions that balance performance, precision, and economic efficiency. Our advanced metal additive manufacturing services leverage state-of-the-art Direct Metal Laser Sintering (DMLS) and Binder Jetting technologies to produce complex, high-integrity components across aerospace, medical, and energy sectors—without compromising material properties or dimensional accuracy. Where competitors equate affordability with reduced capability, Honyo implements process optimization, material science expertise, and scalable production workflows to minimize waste, reduce lead times, and eliminate traditional prototyping bottlenecks. This approach transforms metal AM from a niche prototyping tool into a viable production pathway for end-use parts, tooling, and low-volume batches.

Central to our value proposition is the Online Instant Quote platform, engineered for engineering and procurement teams requiring rapid procurement cycles. Upload your CAD file, specify material (Inconel 718, Ti-6Al-4V, 17-4 PH stainless steel, or aluminum alloys), tolerance requirements, and finish parameters to receive a detailed, binding quote in under 60 seconds. This system integrates real-time machine utilization data and material cost analytics, ensuring transparent pricing that reflects actual production economics—not arbitrary markups. By removing quotation delays and providing immediate cost visibility, Honyo accelerates your design-to-manufacturing timeline while maintaining strict adherence to ASTM F3301 and ISO/ASTM 52900 standards.

Our commitment extends beyond cost efficiency to encompass full technical collaboration—from DfAM guidance that optimizes part geometry for additive production to post-processing solutions like HIP and precision machining. Partner with Honyo Prototype to convert design complexity into competitive advantage, backed by industrial-grade repeatability and a digital workflow built for speed.

Technical Capabilities

The term “cheap metal 3D printing” can be misleading, as true metal additive manufacturing processes such as DMLS are inherently costly due to equipment, materials, and post-processing requirements. However, some technologies offer relatively lower-cost options through indirect methods or by using metal-infused feedstocks. Below is a comparison of the specified technologies—SLA, SLS, MJF, and DMLS—with respect to their capability for metal printing and compatibility with materials like Aluminum, Steel, ABS, and Nylon.

| Technology | Metal Capability | Typical Materials | Notes on Cost & Metal Use |

|---|---|---|---|

| SLA (Stereolithography) | No direct metal printing. Can print metal-filled resin (e.g., copper- or bronze-infused), requiring sintering. | Resins (standard, tough, castable), metal-filled resins | Not suitable for functional metal parts. Indirect method: print in resin, debind, and sinter. Low initial cost but limited to small, non-structural metal-like parts. Materials like Aluminum or Steel not directly printable. |

| SLS (Selective Laser Sintering) | No true metal printing. Uses polymer powders only. | Nylon (PA11, PA12), TPU, filled nylons (e.g., glass, aluminum flakes) | Functional nylon parts with aluminum additives for appearance or thermal properties. Not structural metal. Lower cost than metal AM. ABS not typically available; Nylon is standard. |

| MJF (Multi Jet Fusion) | No metal printing. Polymer-only process. | Nylon (PA12), glass-filled PA12, TPU | High-speed, cost-effective for functional polymer parts. Can include mineral or glass fillers for enhanced properties. No Aluminum, Steel, or ABS in metal form. ABS analogs exist but are not true ABS or metal. |

| DMLS (Direct Metal Laser Sintering) | True metal 3D printing. Fully dense metal parts. | Stainless Steel (17-4 PH, 316L), Aluminum (AlSi10Mg), Titanium, Inconel, Tool Steel | Highest cost among listed technologies due to machine, material, and post-processing (heat treatment, support removal). Offers industrial-grade metal parts. Only DMLS enables actual Aluminum and Steel components. |

Summary:

SLA, SLS, and MJF are not metal 3D printing technologies. They can produce parts with metallic appearance or filler content but do not yield true metal components. DMLS is the only process listed that enables real metal printing using Aluminum and Steel. For low-cost prototyping with metal-like appearance, metal-filled SLA or aluminum-enhanced SLS nylon may be cost-effective. For functional metal parts, DMLS is required, though it is significantly more expensive. ABS is not used in any metal 3D printing process; it is a thermoplastic limited to FDM and not compatible with SLS, MJF, or DMLS in its pure form.

From CAD to Part: The Process

Honyo Prototype delivers cost-optimized metal additive manufacturing through a streamlined digital workflow designed for engineering efficiency and reduced time-to-part. We avoid the term “cheap” as it misrepresents the value-driven precision of our service; instead, we focus on intelligent cost reduction without compromising metallurgical integrity or dimensional accuracy for prototyping and low-volume production.

The process begins when a client uploads a native CAD file or industry-standard neutral format (STEP, IGES) to our secure portal. Our proprietary AI engine immediately performs multi-parameter analysis beyond basic geometry, evaluating build orientation, support structure requirements, thermal distortion risk, and material utilization against real-time machine capacity and material lot data. This generates a dynamic quote within 2 hours, including granular cost breakdowns for material, machine time, post-processing, and expedited options—all before human intervention.

Following quote acceptance, the AI-optimized design enters our automated DFM (Design for Manufacturability) validation stage. Our system cross-references the model against 200+ metal AM failure patterns derived from 15,000+ production builds, checking critical factors like minimum feature thickness relative to chosen laser spot size, overhang angles exceeding recoater limitations, and thermal mass distribution that could cause cracking in Inconel or Ti-6Al-4V. The DFM report flags non-critical issues for client review and automatically resolves 78% of geometric conflicts through topology-preserving parameter adjustments—eliminating costly redesign cycles.

Approved designs move directly to production scheduling. We utilize a centralized dashboard to assign jobs to optimal machines across our fleet of 35+ industrial metal systems (primarily EOS M 290, M 400-4, and Renishaw RenAM 500Q), prioritizing material batch alignment and minimizing changeover time. Builds run with closed-loop monitoring: melt pool sensors and layer-wise optical verification trigger automatic process corrections, maintaining ASTM F3301-20 compliance while reducing scrap rates to under 3.2%.

Post-processing follows our standardized workflow: automated depowdering, stress-relief heat treatment in calibrated furnaces, precision wire EDM support removal, and optional HIP or surface finishing—all tracked via digital work orders. Final inspection includes first-article reports with GD&T verification against original CAD, microhardness testing, and porosity analysis via cross-sectioning for critical applications. Parts ship with full material certs, process logs, and dimensional reports, typically achieving 7-10 day lead times for standard builds under 150mm bounding box. This integrated approach reduces client costs by 22-35% versus traditional quotations through predictive analytics and waste elimination at each phase.

Start Your Project

Looking for affordable metal 3D printing solutions? Honyo Prototype offers cost-effective, high-precision metal additive manufacturing with fast turnaround times. Our Shenzhen-based factory leverages advanced technology and streamlined processes to deliver quality prototypes and production parts at competitive rates.

Contact Susan Leo today to discuss your project requirements and get a personalized quote. Reach out via email at [email protected] for direct support and technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.