Introduction: Navigating the Global Market for cheap cnc machine for wood

Navigating the global market for cheap CNC machines for wood presents significant challenges for international B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. As industries increasingly shift towards automation and precision machining, sourcing affordable CNC solutions becomes essential for maintaining competitive advantage. This guide serves as a comprehensive resource, detailing various types of CNC machines, their applications in woodworking, and effective supplier vetting processes.

Understanding the nuances of cost structures, warranty offerings, and technical support options is crucial for making informed purchasing decisions. Buyers will discover how to assess the capabilities of machines suitable for different wood types, from basic routers to advanced multi-functional models. Additionally, insights into financing options and logistics for international shipping will empower businesses to optimize their investments in CNC technology.

By equipping international buyers with the knowledge needed to navigate this complex landscape, this guide aims to demystify the process of acquiring affordable CNC machines for woodworking applications. Whether you are a small business owner in Germany, a manufacturer in Saudi Arabia, or a hobbyist in South America, the actionable insights provided will enable you to make strategic decisions that enhance productivity and expand your operational capabilities.

Understanding cheap cnc machine for wood Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Entry-Level CNC Router | Compact design, user-friendly software, affordable pricing | Small-scale woodworking, hobbyist projects | Pros: Low cost, easy to use; Cons: Limited features, lower precision |

| 4×8 CNC Router | Large working area (4’ x 8’), versatile cutting capabilities | Furniture making, cabinetry, sign-making | Pros: Efficient for large projects; Cons: Requires more space, higher initial cost |

| Plasma CNC Machine | Designed for metal cutting, high precision | Metal fabrication, artistic metalwork | Pros: Versatile across materials; Cons: More expensive, specialized use |

| Hybrid CNC Machine | Combines routing and laser cutting, multi-functional | Prototyping, custom design, intricate carvings | Pros: Versatile applications; Cons: Complexity in operation, higher maintenance |

| Desktop CNC Machine | Small footprint, ideal for limited spaces | Prototyping, small crafts, educational purposes | Pros: Space-efficient, affordable; Cons: Limited working area, lower power |

What are the Characteristics of Entry-Level CNC Routers?

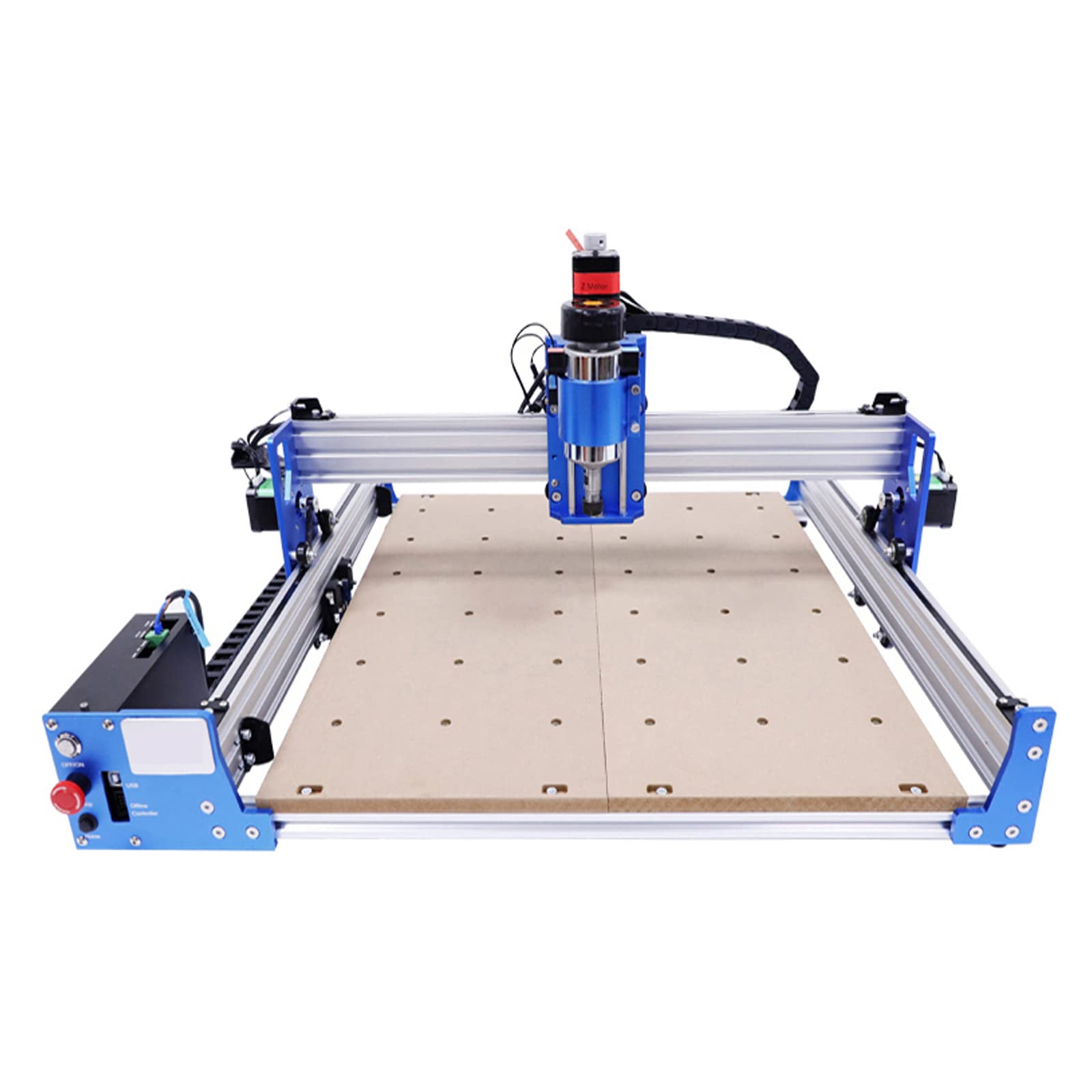

Entry-level CNC routers are designed for beginners and small businesses looking to introduce automation into their woodworking processes. These machines typically feature compact designs and user-friendly software, making them accessible for those new to CNC machining. They are ideal for small-scale woodworking projects, such as crafting furniture or decorative items. Buyers should consider the machine’s capabilities in terms of material types and size limitations, as these routers may not handle larger projects or more complex cuts effectively.

Why Choose a 4×8 CNC Router for Woodworking?

The 4×8 CNC router is a popular choice for professional woodworkers and small businesses due to its large working area, which allows for the processing of full-size plywood sheets without the need for cutting them down. This machine is versatile, capable of handling a wide range of applications from furniture making to cabinetry and intricate sign-making. When purchasing, businesses should evaluate the machine’s precision, speed, and compatibility with various materials to ensure it meets their specific project needs.

What Advantages Do Plasma CNC Machines Offer?

Plasma CNC machines are primarily designed for cutting metal but can also be adapted for various materials, including wood for artistic applications. They are known for their high precision and speed, making them suitable for metal fabrication and artistic projects that require intricate designs. However, these machines tend to be more expensive and are specialized, which may not be ideal for all woodworking businesses. Buyers should assess their specific needs and whether the investment aligns with their production capabilities.

How Do Hybrid CNC Machines Enhance Versatility?

Hybrid CNC machines combine the functionalities of routing and laser cutting, making them a valuable asset for businesses that require versatility in their operations. They are particularly useful for prototyping, custom designs, and intricate carvings, allowing users to switch between different cutting methods seamlessly. However, the complexity of operation and higher maintenance requirements may pose challenges for some users. Companies should consider their technical capabilities and the types of projects they intend to undertake when evaluating these machines.

What Makes Desktop CNC Machines Ideal for Small Spaces?

Desktop CNC machines are designed for users with limited space, making them perfect for small workshops, educational settings, or hobbyist environments. These machines offer a cost-effective entry point into CNC machining, allowing users to create prototypes and small crafts efficiently. However, their limited working area and lower power may restrict the types of projects that can be undertaken. Buyers should weigh the benefits of affordability and space efficiency against the potential limitations in project scope.

Key Industrial Applications of cheap cnc machine for wood

| Industry/Sector | Specific Application of cheap cnc machine for wood | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Cutting and shaping wood for furniture components | Enhanced precision and reduced waste in production | Supplier reliability, machine capabilities, and support |

| Signage and Graphics | Creating custom signs and decorative elements | Faster production times and customization options | Material compatibility, software integration, and training |

| Cabinet Making | Fabricating cabinet parts with intricate designs | Increased efficiency and design flexibility | Size of working area, warranty terms, and after-sales support |

| Educational Institutions | Teaching CNC machining and design principles | Hands-on learning experience for students | Availability of training resources and technical support |

| Hobbyist Projects | Crafting intricate wood designs and models | Cost-effective introduction to CNC technology | Ease of use, availability of accessories, and community support |

How Are Cheap CNC Machines Used in Furniture Manufacturing?

In the furniture manufacturing sector, cheap CNC machines are utilized to cut and shape various wood components with high precision. This technology addresses the common challenges of manual cutting, such as inconsistencies and waste. By automating the process, manufacturers can produce uniform parts, significantly reducing production time and material waste. International buyers should consider the machine’s capabilities for different wood types and the supplier’s reliability in providing ongoing support and maintenance.

What Role Do Cheap CNC Machines Play in Signage and Graphics?

Cheap CNC machines have become essential in the signage and graphics industry for crafting custom signs and decorative elements. These machines allow for rapid production of intricate designs, enhancing the ability to customize products for clients. The main advantage is the reduction in lead times and the ability to offer diverse design options. Buyers should prioritize sourcing machines that are compatible with various materials and can integrate easily with design software to streamline operations.

How Are Cheap CNC Machines Transforming Cabinet Making?

In cabinet making, cheap CNC machines are employed to fabricate parts with precise dimensions and intricate designs. This technology enables manufacturers to achieve a high level of detail while improving efficiency in production. The benefits include reduced labor costs and the ability to respond quickly to customer demands. Buyers in this sector should focus on the size of the working area to accommodate larger panels and the warranty terms to ensure long-term usability.

What Benefits Do Educational Institutions Gain from Cheap CNC Machines?

Educational institutions leverage cheap CNC machines to provide students with practical experience in CNC machining and design. These machines facilitate hands-on learning, allowing students to engage in real-world applications of engineering and design principles. The key benefit is the ability to foster creativity and technical skills among students. Institutions should consider the availability of training resources and ongoing technical support when sourcing these machines to maximize their educational impact.

How Are Hobbyists Utilizing Cheap CNC Machines for Their Projects?

Hobbyists are increasingly adopting cheap CNC machines to create intricate wood designs and models, making this technology accessible for personal projects. These machines enable users to explore their creativity while minimizing the cost associated with traditional woodworking methods. The primary advantage is the ease of use and the ability to achieve professional-quality results at home. Buyers should look for machines that come with user-friendly software and a supportive community to enhance their crafting experience.

3 Common User Pain Points for ‘cheap cnc machine for wood’ & Their Solutions

Scenario 1: Limited Budget Yet High Expectations in CNC Performance

The Problem: Many B2B buyers, particularly in emerging markets, face a significant challenge when trying to balance cost with performance. They often seek affordable CNC machines for wood but fear that lower prices will compromise the quality and capabilities of the equipment. This is especially critical for businesses in competitive sectors like furniture manufacturing, where precision and reliability are paramount. Buyers may worry that a cheap CNC machine will lead to increased downtime, poor product quality, or even higher operational costs due to inefficiencies.

The Solution: To navigate this dilemma, it’s essential to conduct thorough research on various models and manufacturers. Focus on reputable brands that offer a good balance between cost and quality, such as those providing detailed specifications, warranty information, and customer support. For instance, investing in a machine like the STM1325 can be a wise decision, as it offers a large working area and is designed for versatility, allowing for a range of woodworking applications. Additionally, consider seeking out user reviews and case studies that demonstrate the performance of these machines in real-world settings. This data can help validate your purchase decision and ensure that you choose a machine that meets your operational requirements without breaking the bank.

Scenario 2: Complexity of Setup and Operation

The Problem: A common pain point for B2B buyers is the perceived complexity involved in setting up and operating a CNC machine. Many users come from traditional woodworking backgrounds and may not be familiar with CNC technology, leading to anxiety about the learning curve. This is particularly true for businesses in regions with limited access to technical training resources. The fear of making costly mistakes during setup or operation can prevent buyers from fully embracing CNC technology, thereby stunting their growth potential.

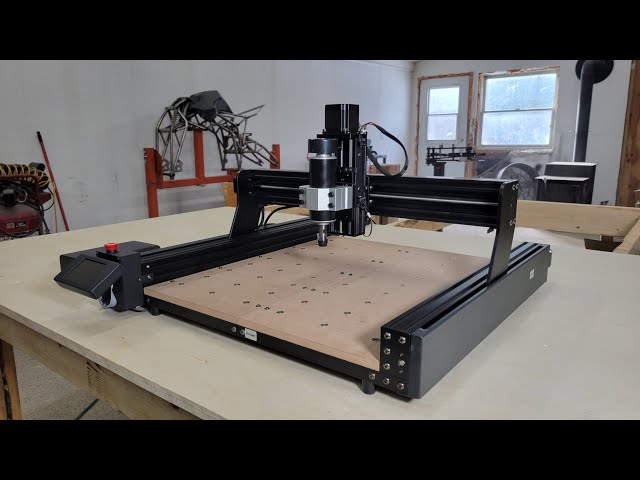

The Solution: To alleviate these concerns, it is crucial to select a CNC machine that comes with robust support and training resources. Look for manufacturers that offer comprehensive technical support, including online tutorials, user manuals, and responsive customer service. For example, choosing a machine like the MillRight CNC offers lifetime technical support, which can significantly ease the learning process. Additionally, invest time in training your team through workshops or online courses that focus on CNC operation and maintenance. This proactive approach will empower your workforce, reduce errors, and enhance overall productivity, making the transition to CNC technology smoother and more efficient.

Scenario 3: Concerns Over Maintenance and Longevity

The Problem: Another prevalent concern among B2B buyers of cheap CNC machines for wood is the long-term reliability and maintenance of the equipment. Many buyers fear that lower-priced machines may have shorter lifespans and higher maintenance costs, leading to a cycle of frequent repairs and replacements. This is particularly concerning for businesses that rely heavily on their CNC machines for daily operations, as unexpected downtime can lead to lost revenue and missed deadlines.

The Solution: To address these maintenance concerns, it’s essential to choose a CNC machine that offers a strong warranty and easy access to replacement parts. When evaluating options, look for machines that provide at least a one-year warranty and have a reputation for durability and reliability. Additionally, establish a regular maintenance schedule and invest in training for your team on basic troubleshooting and upkeep practices. For instance, opting for models that are designed with user-friendly maintenance features can make a significant difference in longevity. Engaging with manufacturers that provide detailed maintenance guidelines will also help ensure that your CNC machine remains in optimal condition, ultimately enhancing its lifespan and reducing total cost of ownership.

Strategic Material Selection Guide for cheap cnc machine for wood

What Are the Key Materials for CNC Machines Used in Woodworking?

When selecting a CNC machine for woodworking, the choice of materials significantly impacts the machine’s performance, durability, and suitability for various applications. Here we analyze four common materials used in the construction of affordable CNC machines, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

Wood: The Primary Material for CNC Machines

Key Properties: Wood is lightweight, easy to machine, and offers good vibration dampening. It is generally not susceptible to corrosion but can warp or swell with moisture.

Pros & Cons: Wood is cost-effective and readily available, making it an attractive choice for budget-conscious buyers. However, its durability is limited compared to metals, and it may require more frequent maintenance. Additionally, wood’s performance can vary significantly based on the type used (e.g., plywood vs. solid wood).

Impact on Application: Wood is ideal for applications such as furniture making, cabinetry, and decorative items. Its compatibility with various wood types allows for a broad range of designs and finishes.

Considerations for International Buyers: Compliance with local standards (e.g., ASTM for the U.S. or DIN for Germany) is essential, particularly regarding the sourcing of sustainable wood. Buyers should also consider the local availability of specific wood types to avoid delays.

Aluminum: A Lightweight Alternative

Key Properties: Aluminum is known for its excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity. It can withstand high temperatures and pressures, making it suitable for various machining processes.

Pros & Cons: The main advantage of aluminum is its durability and resistance to environmental factors, which enhances the longevity of CNC machines. However, it is more expensive than wood and may require specialized tooling for machining, increasing manufacturing complexity.

Impact on Application: Aluminum is often used in applications requiring precision and durability, such as in aerospace components or high-end furniture. Its lightweight nature makes it suitable for portable CNC machines.

Considerations for International Buyers: Buyers should ensure that aluminum components meet international quality standards (e.g., JIS in Japan) and consider the implications of import tariffs on aluminum products.

Steel: The Heavy-Duty Option

Key Properties: Steel offers high tensile strength, durability, and resistance to deformation under load. It can handle high-pressure applications and is often used in industrial settings.

Pros & Cons: The strength of steel makes it suitable for heavy-duty CNC machines that require stability and precision. However, it is heavier and more expensive than both wood and aluminum, and it may require additional maintenance to prevent rust.

Impact on Application: Steel is ideal for applications that involve heavy materials or require high precision, such as metalworking or large-scale woodworking projects.

Considerations for International Buyers: Compliance with safety and quality standards is crucial, especially in regions with stringent regulations. Buyers should also consider the logistics of transporting heavy steel components.

Composite Materials: The Versatile Choice

Key Properties: Composite materials combine different materials to achieve superior properties, such as enhanced strength, reduced weight, and improved resistance to environmental factors.

Pros & Cons: Composites can be tailored for specific applications, offering a balance between cost and performance. However, they can be more expensive to produce and may require specialized machining techniques.

Impact on Application: Composites are suitable for a wide range of applications, from intricate designs to structural components in woodworking.

Considerations for International Buyers: Buyers should verify the material specifications and certifications to ensure compliance with local standards. The availability of composite materials can vary significantly by region, impacting lead times.

Summary Table

| Material | Typical Use Case for cheap cnc machine for wood | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Furniture making, cabinetry | Cost-effective and readily available | Limited durability compared to metals | Low |

| Aluminum | Precision components, portable machines | Lightweight and corrosion-resistant | Higher cost and manufacturing complexity | Medium |

| Steel | Heavy-duty applications, industrial settings | High strength and durability | Heavier and prone to rust | High |

| Composite | Intricate designs, structural components | Tailored properties for specific needs | More expensive and requires special machining | Medium to High |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions when investing in CNC machines for woodworking applications. Understanding the properties and implications of each material helps optimize performance and cost-effectiveness in diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for cheap cnc machine for wood

What Are the Main Stages of Manufacturing Cheap CNC Machines for Wood?

The manufacturing process of cheap CNC machines for wood is typically segmented into several key stages: material preparation, forming, assembly, and finishing. Each stage plays a crucial role in ensuring the final product meets the desired specifications and quality standards.

How Is Material Prepared for CNC Machines?

Material preparation begins with selecting high-quality raw materials, such as aluminum or steel for structural components, and high-density plastic or MDF for non-structural parts. These materials are sourced from reliable suppliers to ensure consistency and durability.

Once the materials are chosen, they undergo cutting and machining to create the necessary components. Techniques like laser cutting or water jet cutting are often employed to achieve precise dimensions. Additionally, suppliers may utilize CNC machining at this stage to ensure that parts are manufactured to exact tolerances.

What Forming Techniques Are Used in CNC Machine Manufacturing?

Forming techniques vary depending on the design and functionality of the CNC machine. Common methods include:

- CNC Machining: This is a cornerstone of CNC machine manufacturing, where computer-controlled tools shape materials with precision.

- Welding: For metal components, welding is employed to join parts securely, ensuring structural integrity.

- Injection Molding: This technique is often used for creating plastic components, allowing for complex shapes and designs.

These forming techniques are integral to achieving the desired performance characteristics of the CNC machines, such as rigidity and accuracy.

How Is the Assembly Process Conducted for CNC Machines?

The assembly of CNC machines typically follows a systematic approach. Components are first organized and checked for quality before assembly. The assembly process involves:

- Sub-assembly: Smaller components are assembled first, such as the gantry, bed, and control system.

- Main Assembly: The sub-assemblies are then combined to create the complete machine. This stage often involves aligning parts and securing them using bolts and screws to maintain precision.

Special attention is paid to wiring and electronics during assembly, ensuring that all connections are secure and properly insulated.

What Finishing Processes Are Commonly Used for CNC Machines?

Finishing processes enhance the aesthetic and functional qualities of CNC machines. Common finishing techniques include:

- Surface Treatment: This may involve sanding, painting, or applying protective coatings to prevent corrosion and wear.

- Calibration: After assembly, machines undergo calibration to ensure that they operate within specified tolerances. This includes adjusting the axes, checking the spindle alignment, and confirming that the software is configured correctly.

Finishing not only improves the appearance of the machine but also contributes to its longevity and performance.

What Quality Assurance Measures Are Essential for CNC Machine Manufacturing?

Quality assurance (QA) is critical in the manufacturing of cheap CNC machines for wood, ensuring that each machine meets industry standards and customer expectations.

Which International Standards Should B2B Buyers Be Aware Of?

International standards play a vital role in quality assurance for CNC machines. Key standards include:

- ISO 9001: This is a widely recognized standard that outlines the criteria for a quality management system. Compliance indicates that a manufacturer consistently provides products that meet customer and regulatory requirements.

- CE Marking: For machines sold in Europe, CE marking indicates compliance with EU safety, health, and environmental protection standards.

Understanding these standards can help B2B buyers assess the credibility and reliability of potential suppliers.

What Are the Key Quality Control Checkpoints in CNC Machine Manufacturing?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to catch defects early. Common QC checkpoints include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, regular checks are performed to monitor the quality of components as they are being produced.

- Final Quality Control (FQC): Once the machine is assembled, it undergoes a comprehensive inspection to verify that it meets all specifications before shipping.

These checkpoints help in minimizing defects and ensuring that only high-quality machines reach the market.

What Common Testing Methods Are Used to Ensure Quality?

Testing methods vary but commonly include:

- Functional Testing: This involves running the machine to ensure it operates correctly under various conditions.

- Dimensional Testing: Precision measuring tools are used to verify that components meet required tolerances.

- Load Testing: Machines are subjected to stress tests to assess their performance under maximum load conditions.

These tests help ensure that machines are not only functional but also durable and reliable in real-world applications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control practices of suppliers. Here are some effective strategies:

What Steps Can Buyers Take to Conduct Supplier Audits?

Conducting supplier audits is an essential part of the vetting process. Buyers can:

- Request Documentation: Suppliers should provide documentation of their quality management systems, including ISO certifications and internal QC processes.

- Visit Manufacturing Facilities: If feasible, visiting the supplier’s manufacturing facility can provide insights into their operations and quality practices.

- Evaluate Past Performance: Analyzing previous orders and customer feedback can help gauge the reliability and quality of the supplier’s products.

How Can Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection services can further enhance quality assurance. These independent firms can provide:

- Impartial Evaluations: Third-party inspectors can offer unbiased assessments of the manufacturing processes and finished products.

- Verification of Compliance: They can confirm that the supplier adheres to relevant international standards and regulations.

This additional layer of scrutiny is particularly valuable for international buyers looking to mitigate risks associated with cross-border transactions.

What Are the Unique Quality Control Considerations for International Buyers?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, there are specific quality control nuances to consider:

- Regulatory Compliance: Different regions may have varying regulatory requirements, making it essential for buyers to understand local laws related to machinery and safety standards.

- Logistics and Shipping: Quality assurance doesn’t end at manufacturing; shipping conditions can impact the integrity of the product. Buyers should ensure that suppliers use reliable shipping methods and packaging materials to prevent damage during transit.

- Warranty and Support: Understanding warranty terms and post-sale support is crucial. Buyers should inquire about the extent of warranties and the availability of technical support, especially when sourcing from overseas.

By taking these factors into account, international buyers can make informed decisions and establish successful partnerships with suppliers of cheap CNC machines for wood.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cheap cnc machine for wood’

Introduction

This practical sourcing guide is designed to assist B2B buyers in procuring affordable CNC machines for woodworking. With the growing demand for precision and efficiency in woodworking, having a reliable CNC machine can significantly enhance productivity and quality. This checklist outlines essential steps to ensure you choose the right machine and supplier for your needs.

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical specifications required for your CNC machine. Consider factors such as working area size, material compatibility, and precision levels.

- Working Area: Ensure the machine can accommodate the dimensions of the materials you typically work with.

- Material Compatibility: Verify that the CNC machine can handle wood and any other materials you may use, like plastics or soft metals.

Step 2: Assess Your Budget

Determine a realistic budget for your CNC machine acquisition. This includes not only the purchase price but also potential additional costs such as shipping, installation, and maintenance.

- Total Cost of Ownership: Look beyond the initial price; consider long-term costs such as spare parts and technical support.

- Financing Options: Explore financing solutions offered by suppliers, which can help manage upfront expenses.

Step 3: Research Supplier Reputation

Investigate the reputation of potential suppliers in the market. A supplier’s credibility is crucial for ensuring quality and reliability in your purchase.

- Customer Reviews: Look for reviews from previous buyers, particularly those in your industry or region.

- Certifications: Ensure the supplier has necessary certifications, such as ISO or CE standards, indicating compliance with international quality and safety regulations.

Step 4: Evaluate Machine Features and Capabilities

Examine the features of the CNC machines you are considering. Different models come with various capabilities that may impact your operations.

- Precision and Speed: Assess the machine’s cutting accuracy and speed, which are vital for efficient production.

- Ease of Use: Look for user-friendly interfaces and software that facilitate quick learning and operation.

Step 5: Verify After-Sales Support and Warranty

Understanding the after-sales support and warranty options is essential for long-term satisfaction with your purchase.

- Technical Support: Ensure the supplier provides robust technical support, including troubleshooting and maintenance assistance.

- Warranty Terms: Review the warranty conditions, including what parts are covered and for how long, to safeguard your investment.

Step 6: Request Samples or Demonstrations

Before finalizing your purchase, request samples or demonstrations of the CNC machine in action. This step allows you to assess the machine’s performance firsthand.

- Test Cuts: Ask for sample projects to evaluate the machine’s cutting quality and precision.

- In-Person Demonstrations: If possible, visit the supplier’s facility to see the machine operating live, providing insights into its capabilities.

Step 7: Finalize Shipping and Delivery Arrangements

Once you have made your selection, confirm shipping and delivery details to ensure a smooth transition to your facility.

- Lead Times: Clarify the expected delivery time and any associated costs, especially for international shipping.

- Installation Services: Inquire whether the supplier offers installation services or if you need to arrange this separately.

By following this structured checklist, B2B buyers can make informed decisions when sourcing a cheap CNC machine for wood, ensuring they choose a reliable product that meets their business needs.

Comprehensive Cost and Pricing Analysis for cheap cnc machine for wood Sourcing

What Are the Key Cost Components for Cheap CNC Machines for Wood?

When sourcing cheap CNC machines for wood, understanding the cost structure is crucial. The primary components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s margin.

-

Materials: The type and quality of materials used in manufacturing CNC machines significantly affect costs. Common materials include aluminum, steel, and plastics. Higher-grade materials can enhance durability and performance but will increase the price.

-

Labor: Labor costs vary based on location and expertise. Regions with lower labor costs, such as parts of Asia or Eastern Europe, may offer competitive pricing, but it’s essential to consider the trade-offs in quality and service.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and equipment depreciation. A supplier with optimized operations may pass on savings to buyers.

-

Tooling: The investment in tooling for precision machining affects production costs. More advanced tooling can lead to better quality and faster production times, influencing the final price.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and performance. However, these processes can add to the overall cost. Buyers should evaluate the QC standards of suppliers when comparing prices.

-

Logistics: Shipping costs can vary widely depending on the supplier’s location and the buyer’s destination. International shipping might involve customs duties and tariffs, impacting the total cost.

-

Margin: Suppliers’ profit margins vary based on market positioning, brand reputation, and competition. Understanding the margin can help in negotiations.

How Do Price Influencers Affect the Cost of CNC Machines?

Several factors influence the pricing of CNC machines, particularly for international B2B buyers:

-

Volume/MOQ: Many manufacturers offer tiered pricing based on order volume. Higher quantities can significantly reduce per-unit costs. Buyers should assess their needs to leverage better pricing.

-

Specifications and Customization: Customized machines may incur additional costs. Buyers should balance their specific needs against budget constraints, opting for standard models when possible to save costs.

-

Materials and Quality Certifications: Machines built with certified materials or meeting specific industry standards may carry a premium price. Buyers should evaluate whether these certifications are necessary for their applications.

-

Supplier Factors: The reputation and reliability of the supplier play a critical role. Established suppliers may charge higher prices for better service, warranties, and support.

-

Incoterms: Understanding shipping terms (like FOB or CIF) can significantly impact total costs. Buyers should clarify these terms to avoid unexpected expenses.

What Buyer Tips Can Help Optimize Costs in CNC Machine Sourcing?

To navigate the complexities of sourcing cheap CNC machines for wood, consider the following tips:

-

Negotiate Wisely: Engage in discussions with suppliers about pricing, especially if you plan to place larger orders. Suppliers may be willing to offer discounts or better payment terms.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operational costs, and potential downtime. A cheaper machine may lead to higher long-term costs if it requires frequent repairs.

-

Understand Pricing Nuances for International Buyers: Different regions may have varying pricing structures due to local economic conditions, tariffs, and import duties. Buyers from Africa, South America, the Middle East, and Europe should be aware of these factors when comparing prices.

-

Request Samples and Demonstrations: Before making a significant investment, request samples or demonstrations. This can provide insight into the machine’s performance and help justify the cost.

-

Consider After-Sales Support: The level of technical support and warranty offered can influence the overall value of the purchase. Investing in a machine with robust after-sales support may reduce future costs associated with troubleshooting and repairs.

Conclusion

Sourcing cheap CNC machines for wood requires a comprehensive understanding of cost components, price influencers, and strategic buying tips. By evaluating these aspects, international B2B buyers can make informed decisions, ensuring they achieve the best value for their investment while meeting their operational needs.

Alternatives Analysis: Comparing cheap cnc machine for wood With Other Solutions

Introduction to CNC Alternatives for Woodworking Solutions

When considering woodworking solutions, businesses often evaluate various methods and technologies to find the most cost-effective and efficient option. While cheap CNC machines for wood provide a versatile and automated approach, alternatives such as traditional woodworking methods and laser cutting systems can also deliver satisfactory results. This analysis will compare the cheap CNC machine for wood against two viable alternatives: traditional woodworking techniques and laser cutting machines.

Comparison Table

| Comparison Aspect | Cheap CNC Machine for Wood | Traditional Woodworking Techniques | Laser Cutting Machines |

|---|---|---|---|

| Performance | High precision and automation | Variable precision based on skill | Very high precision |

| Cost | $999 – $5,500 | Low initial investment, high labor | $3,000 – $20,000+ |

| Ease of Implementation | Moderate; requires setup | High; requires skill and experience | Moderate; requires training |

| Maintenance | Low; routine checks needed | High; tools require regular upkeep | Moderate; needs lens cleaning |

| Best Use Case | Repetitive and intricate designs | Custom and artistic projects | Detailed designs and prototypes |

Detailed Breakdown of Alternatives

Traditional Woodworking Techniques

Traditional woodworking involves manual tools and craftsmanship, allowing artisans to create unique and customized pieces. This method is cost-effective initially, as it requires minimal investment in tools. However, the performance can vary significantly based on the skill level of the operator, leading to inconsistencies in quality. Maintenance of tools can be labor-intensive, and the learning curve can be steep for beginners. Traditional methods excel in artistic and bespoke projects where the human touch adds value, making it ideal for custom furniture or intricate woodcraft.

Laser Cutting Machines

Laser cutting technology offers precise and intricate cutting capabilities, especially for detailed designs and prototypes. The performance is generally superior to CNC machines in terms of detail, as lasers can achieve finer cuts and engravings. However, the initial cost can be considerably higher, making it less accessible for smaller businesses or startups. Laser machines also require moderate maintenance, including cleaning and calibration. They are best suited for detailed designs and materials like acrylic, wood, and certain metals, making them ideal for signage, intricate patterns, and prototyping.

Conclusion: Choosing the Right Solution for Your Business Needs

Selecting the right woodworking solution hinges on the specific needs of your business. If precision, automation, and the ability to handle repetitive tasks are paramount, a cheap CNC machine for wood could be the best fit. However, if your focus is on custom artistry and you have skilled labor available, traditional woodworking may offer greater flexibility and uniqueness. On the other hand, if your projects demand extremely detailed work and you can accommodate a higher budget, laser cutting machines could enhance your production capabilities. Ultimately, understanding your operational requirements and budget constraints will guide you in choosing the most suitable woodworking technology for your business.

Essential Technical Properties and Trade Terminology for cheap cnc machine for wood

What Are the Essential Technical Properties of a Cheap CNC Machine for Wood?

When evaluating a cheap CNC machine for wood, understanding key technical specifications is crucial for ensuring that the equipment meets your operational needs. Here are several critical properties to consider:

-

Working Area Dimensions

– This specification defines the maximum size of the material that can be processed. For instance, a machine with a 4′ x 8′ working area can accommodate full sheets of plywood, enabling larger projects without the need for cutting material down to size. This is essential for optimizing workflow and reducing waste. -

Spindle Power and Speed

– The spindle power, usually measured in horsepower (HP), determines the machine’s cutting capabilities. A higher spindle speed, typically in RPM (revolutions per minute), allows for faster and more efficient cutting. This directly affects productivity, especially for businesses looking to complete projects quickly and cost-effectively. -

Material Compatibility

– Different CNC machines are designed to work with various materials. A versatile machine should handle wood, plastics, and possibly soft metals. Understanding material compatibility is vital for businesses that require flexibility in their production processes. -

Precision and Tolerance

– Precision is measured in terms of the machine’s ability to reproduce designs accurately, often expressed in thousandths of an inch (mm). Tolerance refers to the acceptable limits of variation in a manufacturing process. High precision and tight tolerances are essential for applications requiring intricate designs and consistent quality, such as furniture manufacturing. -

Software Compatibility

– The machine’s compatibility with CAD/CAM software is a significant factor. Software allows for the design and control of cutting operations, and ease of use is crucial for operators. A user-friendly interface can reduce training time and improve operational efficiency. -

Warranty and Support

– A solid warranty and reliable technical support are essential for ensuring long-term operational success. A one-year parts warranty, for example, can provide peace of mind, while ongoing technical support can assist with troubleshooting and maintenance.

What Are Common Trade Terms Relevant to CNC Machines for Wood?

Understanding industry jargon can help streamline communications and negotiations with suppliers. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce equipment or components that are used in another company’s end products. In the CNC market, OEMs may provide machines or parts to businesses that integrate them into their own production processes. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. This is a critical consideration for buyers, particularly when sourcing CNC machines, as it can affect cash flow and inventory management. -

RFQ (Request for Quotation)

– An RFQ is a document that a buyer submits to suppliers to solicit price quotations for specific products or services. Providing detailed specifications in an RFQ can lead to more accurate and competitive pricing from manufacturers. -

Incoterms (International Commercial Terms)

– These are internationally recognized rules that define the responsibilities of sellers and buyers for the delivery of goods. Familiarity with Incoterms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), is vital for international transactions, as they impact shipping costs and risk management. -

Lead Time

– Lead time refers to the amount of time from when an order is placed until it is delivered. Understanding lead times is essential for planning production schedules and managing customer expectations. -

T-slot Table

– A T-slot table is a type of work surface used in CNC machines that allows for the secure mounting of workpieces. This feature enhances flexibility in setting up projects, making it particularly useful for complex woodworking tasks.

By familiarizing yourself with these technical specifications and trade terms, you can make informed decisions when purchasing a cheap CNC machine for wood, ensuring that it aligns with your business goals and operational requirements.

Navigating Market Dynamics and Sourcing Trends in the cheap cnc machine for wood Sector

What Are the Current Market Dynamics and Key Trends Affecting the Cheap CNC Machine for Wood Sector?

The market for cheap CNC machines designed for woodworking is experiencing robust growth, driven by several global factors. Increased demand for precision machining in various industries, particularly furniture manufacturing, has led to a surge in the adoption of CNC technology. Emerging economies in Africa and South America are witnessing a notable rise in woodworking industries, driven by urbanization and increased consumer spending on home furnishings. Additionally, countries in the Middle East, like Saudi Arabia, are diversifying their economies away from oil dependence, further fueling demand for manufacturing technologies.

Current trends indicate a growing interest in automation and smart manufacturing solutions. International buyers are increasingly sourcing CNC machines equipped with advanced features such as IoT connectivity and user-friendly software, which streamline operations and enhance productivity. Furthermore, the rise of e-commerce has encouraged small businesses to invest in affordable CNC technology to meet the growing demand for customized products. As a result, manufacturers are focusing on producing budget-friendly, high-performance machines that cater to both novice and experienced woodworkers.

How Are Sustainability and Ethical Sourcing Influencing the Cheap CNC Machine for Wood Market?

Sustainability is becoming a cornerstone of purchasing decisions in the B2B landscape, particularly in the woodworking sector. As environmental concerns rise, buyers are increasingly prioritizing CNC machines that are manufactured using eco-friendly processes and materials. This shift is prompting suppliers to adopt more sustainable practices, such as using recycled materials and ensuring energy-efficient manufacturing processes.

Ethical sourcing is also gaining traction, with international buyers seeking suppliers that adhere to fair labor practices and environmental regulations. Certifications such as CE, ISO, and FSC (Forest Stewardship Council) are becoming essential indicators of a supplier’s commitment to sustainability. These certifications not only help in ensuring compliance with international standards but also enhance the credibility of products in the eyes of B2B buyers. As a result, companies that prioritize sustainable and ethical practices in their supply chains are likely to gain a competitive edge in the market.

What Is the Evolution of CNC Technology and Its Relevance to B2B Buyers?

The evolution of CNC technology has significantly transformed the woodworking industry over the past few decades. Initially, CNC machines were prohibitively expensive, limiting their accessibility to large manufacturers. However, technological advancements and increased competition have led to a decline in prices, making CNC machines more affordable for small to medium-sized enterprises (SMEs) and hobbyists alike.

The introduction of user-friendly interfaces and software has simplified the operation of CNC machines, allowing non-experts to engage in complex woodworking tasks. This democratization of technology is particularly relevant for international B2B buyers in emerging markets who are looking for cost-effective solutions to enhance their production capabilities. Today, cheap CNC machines not only cater to basic cutting and engraving needs but also offer advanced functionalities that meet diverse woodworking applications, from furniture making to intricate crafts. This evolution underscores the importance of staying informed about the latest developments and sourcing trends to make informed purchasing decisions in this dynamic market.

Frequently Asked Questions (FAQs) for B2B Buyers of cheap cnc machine for wood

1. How do I choose the right CNC machine for woodworking?

Selecting the right CNC machine depends on your specific needs, such as the type of wood, the complexity of the designs, and production volume. Consider factors like working area size, precision, and the machine’s capabilities (e.g., cutting, engraving). For small to medium-scale operations, a machine like a 4×8 CNC router is often ideal due to its balance of size and versatility. Additionally, assess the support services offered by suppliers, such as training and technical support, which can be crucial for successful operation.

2. What are the advantages of purchasing a cheap CNC machine for wood?

Affordable CNC machines offer a cost-effective entry point for businesses looking to automate their woodworking processes. They provide significant labor savings, improve precision and consistency, and allow for complex designs that would be difficult to achieve manually. Furthermore, modern low-cost machines often come equipped with user-friendly software, making them accessible to beginners and small businesses aiming to expand their capabilities without a substantial financial commitment.

3. How can I verify the reliability of a CNC machine supplier?

To ensure a supplier’s reliability, check their industry reputation through online reviews and testimonials from previous customers. Request references and inquire about their experience with the specific CNC machines they offer. Additionally, verify if the supplier provides warranties, after-sales support, and technical assistance. Engaging with suppliers through direct communication can also provide insight into their responsiveness and customer service quality.

4. What are the typical payment terms when sourcing CNC machines internationally?

Payment terms for international CNC machine purchases can vary widely. Common options include a deposit upfront (often 30% to 50%) with the balance due upon shipment or delivery. Some suppliers may offer financing options or letter of credit arrangements, especially for larger orders. It’s essential to clarify payment terms in the contract and ensure that they align with your financial capabilities and cash flow management.

5. How do I manage logistics for importing CNC machines?

Managing logistics involves coordinating shipping methods, customs clearance, and delivery timelines. Work with a freight forwarder experienced in machinery transport, as they can navigate international shipping regulations and ensure compliance with local customs. Confirm that the supplier provides packaging suitable for transport to prevent damage. It’s also advisable to plan for potential delays in shipping, especially when dealing with international suppliers.

6. What should I consider regarding machine customization options?

Customization options can vary by supplier and may include specific features, sizes, or capabilities tailored to your business needs. When discussing customization, clearly outline your requirements, such as the types of materials you plan to work with and any specific software needs. Be sure to ask about lead times for customized machines, as these can differ from standard models. Additionally, inquire about the costs associated with customization and whether it affects warranty conditions.

7. What is the minimum order quantity (MOQ) for CNC machines?

The MOQ for CNC machines can differ based on the manufacturer and the specific model. Some suppliers may offer single units for smaller businesses, while others might have a minimum order requirement to ensure cost-effectiveness in production. Always confirm the MOQ before proceeding with negotiations. If you’re considering multiple machines, inquire about bulk pricing or discounts that could make larger orders more economical.

8. How can I ensure quality assurance for my CNC machine purchase?

To ensure quality assurance, request detailed specifications and certifications for the CNC machines from the supplier. Verify that the machines comply with international quality standards, such as ISO certifications. It’s beneficial to ask about the manufacturing process, quality control measures, and any testing procedures the machines undergo before shipment. Establishing clear return and warranty policies can also protect your investment and provide recourse if the equipment does not meet your expectations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Cheap Cnc Machine For Wood Manufacturers & Suppliers List

1. CNC Machines – Affordable Home Solutions

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: CNC machines for home use are available at an affordable price, typically starting around $2000 for the machine itself. However, the total investment to properly set up a small capable machine can reach approximately $4000 when considering additional equipment like cutters, clamps, dust collection, measuring tools, and a PC. This price point makes CNC machining more accessible compared to professi…

2. STYLECNC – STM1325

Domain: stylecnc.com

Registered: 2015 (10 years)

Introduction: {“Brand”:”STYLECNC”,”Model”:”STM1325″,”Table Size”:”4′ x 8′ (48″ x 96″, 1300mm x 2500mm)”,”Price Range”:”$4,380 – $5,500″,”Stock Availability”:”360 Units in Stock Available for Sale Every Month”,”Warranty”:”One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)”,”Money Back Guarantee”:”30-Day Money Back Guarantee for Your Purchase”,”Technical Support”:”Free Li…

3. MillRight CNC – Alpha Arc Plasma Table

Domain: millrightcnc.com

Registered: 2016 (9 years)

Introduction: {“products”:[{“name”:”Alpha Arc Plasma Table”,”price”:”$8,000.00″,”cutting_area”:”50×50″”,”capabilities”:”Cuts 26 gauge to 1/2″ steel plate, edge start up to 5/8″ steel plate, sever 1″ steel plate”,”lead_time”:”Approximately 5 weeks”},{“name”:”Mega V 2″,”price”:”$2,299.00″,”capabilities”:”CNC router for hobby and business use”},{“name”:”MillRight CNC Power Route Plus”,”price”:”$3,999.00″,”lead_tim…

4. Woodcraft – CNC Machines

Domain: woodcraft.com

Registered: 1995 (30 years)

Introduction: This company, Woodcraft – CNC Machines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. LumberJocks – Hobby CNC Machine for Wood Boxes

Domain: lumberjocks.com

Registered: 2005 (20 years)

Introduction: 1. Budget: Under $500

2. Intended Use: Hobby level CNC machine for small wood boxes (gift, keepsake, jewelry)

3. Key Functions:

– Engraving logos or custom messages

– Cutting out sides of boxes

– Cutting out centers of boxes made from solid 2 to 3 inch thick hardwood blocks

4. Suggested Products:

– Millright CNC (starting around $500)

– V1 Engineering Mostly Printed CNC (MPCNC) ro…

6. Carbide3D – Shapeoko

Domain: forum.makerforums.info

Registered: 2019 (6 years)

Introduction: This company, Carbide3D – Shapeoko, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. MillRight CNC – Power Route Plus XL

Domain: chiefdelphi.com

Registered: 1998 (27 years)

Introduction: This company, MillRight CNC – Power Route Plus XL, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. DB CNC Routers – Affordable 4×8 Options

Domain: woodweb.com

Registered: 1995 (30 years)

Introduction: Affordable 4 x 8 CNC router options discussed in a forum. Key suggestions include: 1. DB CNC Routers offering machines around $7000 with stepper motors on all axes, lead screws on X and Z, rack and pinion on Y, Mach3 software, and a tower PC. 2. Second-hand options available for around $5000, reconditioned with servo motors and controllers. 3. Importing from China as a potential option. 4. Conside…

9. Sainsmart – Genmitsu 3018 PROver

Domain: cncsourced.com

Registered: 2020 (5 years)

Introduction: [{‘name’: ‘Sainsmart Genmitsu 3018 PROver’, ‘price’: ‘$345’, ‘working_area’: ‘300 x 180 x 45 mm’, ‘precision’: ‘Around 0.003″‘, ‘material_compatibility’: ‘Wood, MDF, acrylic, polycarbonate, and PCB’, ‘pros’: [‘Easy to set up’, ‘Very affordable’, ‘Works with a variety of materials’, ‘Optional laser engraver upgrade option’], ‘cons’: [‘More expensive brands are sturdier and more powerful’, ‘Limited …

Strategic Sourcing Conclusion and Outlook for cheap cnc machine for wood

As international B2B buyers explore the landscape of cheap CNC machines for wood, strategic sourcing emerges as a vital component in optimizing operational efficiency and cost-effectiveness. The market offers a variety of options, from entry-level models like the STM1325 to robust machines such as the Mega V series, catering to diverse needs and budgets. Key takeaways include the importance of understanding specific business requirements, evaluating machine capabilities, and considering long-term support and warranty options.

Investing in a CNC router not only enhances production capabilities but also fosters innovation in woodworking applications, from intricate furniture designs to large-scale manufacturing. Buyers should leverage the competitive pricing and technological advancements available in the market to maximize their return on investment.

Looking ahead, the demand for affordable CNC solutions is set to rise, driven by growing industries across Africa, South America, the Middle East, and Europe. Engage with suppliers who prioritize customer support and flexible financing options, ensuring that your business remains agile and competitive. Seize this opportunity to elevate your woodworking operations—request quotes, compare models, and make informed decisions that align with your business goals.