Introduction: Navigating the Global Market for cheap cnc machine for metal

In the competitive landscape of metal fabrication, sourcing a cheap CNC machine for metal can pose a significant challenge for international buyers. As manufacturers and businesses strive to optimize production while controlling costs, the demand for affordable yet high-quality CNC solutions has surged. This comprehensive guide is designed to assist B2B buyers from diverse regions—including Africa, South America, the Middle East, and Europe—in navigating the intricacies of the global market for CNC machines specifically tailored for metalworking.

Within these pages, you will discover an array of topics, including various types of CNC machines, their applications across different industries, and essential criteria for vetting suppliers. Understanding these elements is crucial for making informed purchasing decisions that align with your operational needs and budget constraints. Additionally, this guide will delve into cost considerations, financing options, and maintenance insights, empowering you to select a machine that not only meets your immediate requirements but also supports long-term growth.

By equipping yourself with the knowledge contained in this guide, you can confidently engage with suppliers and make strategic investments that enhance your manufacturing capabilities. Whether you are a small workshop in Brazil or a burgeoning enterprise in Vietnam, this resource is tailored to help you thrive in an increasingly demanding marketplace.

Understanding cheap cnc machine for metal Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Router | Primarily used for cutting softer materials like wood and plastics; can also handle light metal milling. | Prototyping, Sign-making, Woodworking | Pros: Versatile, affordable, easy to use. Cons: Limited to softer metals; not suitable for heavy-duty tasks. |

| CNC Mill | Designed for more precise and comprehensive machining of metal materials; typically equipped with a robust spindle. | Tool & Die Making, Heavy Lifting Operations | Pros: High precision, capable of heavy cuts. Cons: Higher initial investment; requires more floor space. |

| Plasma Cutter | Utilizes plasma technology for cutting metals; ideal for thicker stock and complex shapes. | Metal Fabrication, Heavy Machinery Manufacturing | Pros: Fast and efficient; capable of cutting thick metals. Cons: Limited to metal only; requires proper ventilation. |

| CNC Lathe | Ideal for turning operations, shaping cylindrical items with high precision and minimally wasted material. | Engine Parts Manufacturing, Automotive Sector | Pros: Excellent for cylindrical forms; high-quality finishes. Cons: Limited to cylindrical workpieces; requires skilled operators. |

| Hybrid CNC Machine | Combines CNC milling and lathe functionalities, providing versatile machining options. | Custom Parts Production, Prototyping | Pros: Multi-functional, saves space. Cons: Higher complexity and cost which can deter small-scale operations. |

What Are the Characteristics of a CNC Router?

CNC Routers are widely used in various industries due to their versatility. They are particularly suitable for cutting softer materials like wood, plastics, and occasionally lighter metals. For B2B buyers, the affordability and ease of operation make them an attractive choice for businesses involved in prototyping, sign-making, and woodworking. When considering a CNC Router, it’s important to evaluate the specific materials you will be working with and the precision required for your applications.

How Do CNC Mills Differ from Other CNC Machines?

CNC Mills are designed for more rigorous applications, allowing businesses to work with materials like steel, brass, and aluminum while providing high precision. Manufacturers in the tool and die sector appreciate CNC Mills for their ability to create complex parts and perform heavy-duty tasks. However, the initial investment and space requirements can be a consideration for smaller operations looking to maintain budget-friendly solutions.

Why Should You Consider a Plasma Cutter?

Plasma cutters are notable for their speed and efficiency in cutting metals, making them ideal for companies in metal fabrication and heavy machinery manufacturing. These machines are designed to handle thick materials and can produce intricate designs quickly. B2B purchasers should consider the ventilation requirements and safety measures necessary for operating plasma cutters, as these machines generate considerable fumes and heat.

What Advantages and Disadvantages Come With CNC Lathes?

CNC Lathes are excellent for manufacturing cylindrical components with exceptional accuracy. They are commonly employed in sectors like automotive and engine parts production, where precision is critical. Although they offer high-quality finishes, the operational expertise required and their limitation to cylindrical work can be drawbacks for businesses looking for versatile solutions.

How Do Hybrid CNC Machines Enhance Production Efficiency?

Hybrid CNC Machines serve as a multifunctional solution, combining milling and lathe capabilities into one unit. This versatility can significantly boost production efficiency for businesses engaged in custom parts production. While they occupy less floor space compared to acquiring separate machines, buyers should weigh the complexity and cost against their specific operational requirements to determine if a hybrid model is the best fit for their needs.

Key Industrial Applications of cheap cnc machine for metal

| Industry/Sector | Specific Application of cheap cnc machine for metal | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Precision component fabrication | Reduces production time and increases accuracy | Machine reliability, ease of maintenance, and support |

| Automotive | Custom parts production | Enables rapid prototyping and cost-effective production | Availability of compatible tooling and software |

| Aerospace | Lightweight structural components | Enhances performance while minimizing weight | Compliance with industry standards and certifications |

| Metal Art and Sculpture | Artistic metalwork and sculptures | Allows for intricate designs and unique creations | Material compatibility and versatility of machine |

| Electronics | Enclosure and chassis manufacturing | Streamlines production and improves design flexibility | Precision capabilities and software integration |

How is a cheap CNC machine for metal utilized in manufacturing?

In the manufacturing sector, cheap CNC machines are invaluable for precision component fabrication. They can efficiently produce intricate parts from metals such as aluminum and steel, significantly reducing production time while enhancing accuracy. For international buyers, particularly from regions like Africa and South America, the ability to procure affordable machines that require minimal training and maintenance is crucial. Buyers should consider the machine’s reliability and the availability of technical support to ensure uninterrupted operations.

What role does a cheap CNC machine for metal play in automotive applications?

In the automotive industry, cheap CNC machines are frequently used for custom parts production. These machines facilitate rapid prototyping, allowing manufacturers to iterate designs quickly and reduce time-to-market for new vehicles. For businesses in the Middle East and Europe, where automotive standards are stringent, it is essential to choose machines that can accommodate specific tooling and software that align with local regulations. Cost-effectiveness is a key benefit, enabling smaller firms to compete with larger manufacturers.

How does a cheap CNC machine for metal contribute to aerospace manufacturing?

In aerospace, lightweight structural components are critical for performance and safety. Cheap CNC machines enable manufacturers to create complex parts that meet stringent weight and strength requirements. International buyers, especially those in Europe, must consider machines that comply with industry standards and certifications, ensuring that all produced components meet safety regulations. The ability to maintain precision while working with advanced materials is vital for success in this highly regulated sector.

How are cheap CNC machines for metal used in metal art and sculpture?

Artists and sculptors increasingly turn to cheap CNC machines to create intricate metalwork and sculptures. These machines allow for the design and production of unique pieces that would be difficult to achieve through traditional methods. For buyers in regions like South America and Africa, where access to advanced manufacturing techniques may be limited, investing in affordable CNC technology can open new avenues for artistic expression. Buyers should prioritize machines with versatility in material compatibility to enhance their creative options.

What advantages do cheap CNC machines for metal offer in electronics manufacturing?

In electronics, cheap CNC machines are essential for manufacturing enclosures and chassis that protect sensitive components. By streamlining production processes, these machines improve design flexibility, allowing companies to adapt quickly to market demands. International buyers should look for machines that offer high precision and compatibility with various software platforms to ensure smooth integration into existing workflows. The reduction in production costs can significantly enhance profitability, especially for startups and small businesses.

3 Common User Pain Points for ‘cheap cnc machine for metal’ & Their Solutions

Scenario 1: Inconsistent Cutting Quality in Metal Components

The Problem: B2B buyers often face challenges with the cutting quality when using cheap CNC machines for metal. Inconsistent results can lead to high scrap rates, increased labor costs, and dissatisfied customers. For instance, a small manufacturing firm in Brazil may invest in an affordable CNC machine, only to find that the machine struggles with different types of metal, resulting in jagged edges and poor finishes. This inconsistency not only affects product quality but also damages the company’s reputation in a competitive market.

The Solution: To address cutting quality issues, buyers should carefully evaluate the specifications of the CNC machine before purchase. Look for machines that offer adjustable speed and feed rates, which can be crucial for working with various metal types. Additionally, invest in high-quality cutting tools specifically designed for the materials being processed. Regular maintenance and calibration of the CNC machine will also ensure consistent performance. Buyers should consider establishing a routine maintenance schedule and utilizing a reliable technical support service to troubleshoot any issues that arise. This proactive approach will help maintain high standards of quality and efficiency.

Scenario 2: Limited Technical Support and Resources

The Problem: Another common pain point is the lack of adequate technical support for cheap CNC machines. Many international buyers, particularly from regions like Africa or the Middle East, may encounter challenges when trying to set up or troubleshoot their machines due to language barriers, time zone differences, or insufficient resources. When a machine breaks down or requires specific adjustments, the inability to access timely and effective support can result in prolonged downtime and lost revenue.

The Solution: To mitigate this issue, buyers should prioritize manufacturers that offer robust technical support and training resources. Before purchasing, inquire about the availability of support in your preferred language and the responsiveness of their service teams. Additionally, look for companies that provide comprehensive online resources, such as video tutorials, user forums, and FAQs, to assist users in troubleshooting common problems independently. Establishing a relationship with local distributors or service technicians can also provide an additional layer of support, ensuring that help is available when needed.

Scenario 3: Difficulty in Sourcing Compatible Accessories and Upgrades

The Problem: B2B buyers often struggle with sourcing compatible accessories and upgrades for their cheap CNC machines. This challenge is particularly pronounced for businesses in developing regions, where access to a wide range of parts and tools may be limited. For example, a metal fabrication shop in South America may find that their CNC machine lacks essential features, such as automatic tool changers or advanced software capabilities, which are critical for scaling production and improving efficiency.

The Solution: To effectively source compatible accessories, buyers should research manufacturers known for their modular and upgradeable machines. When selecting a CNC machine, inquire about the availability of add-ons and their compatibility with existing equipment. Additionally, joining industry forums or local CNC user groups can provide valuable insights into where to find parts and how to implement upgrades efficiently. Establishing connections with suppliers who specialize in CNC equipment can also streamline the sourcing process, allowing businesses to enhance their machinery as needed without facing significant delays or compatibility issues. By planning for upgrades at the time of purchase, companies can ensure that their CNC machines remain competitive and adaptable to evolving production needs.

Strategic Material Selection Guide for cheap cnc machine for metal

What Are the Key Materials for Cheap CNC Machines for Metal?

When selecting materials for cheap CNC machines designed for metalworking, it’s essential to consider their unique properties, advantages, and limitations. This analysis focuses on four common materials: Aluminum, Mild Steel, Stainless Steel, and Brass. Each material has distinct characteristics that influence its suitability for various applications, especially in international markets.

How Does Aluminum Perform in CNC Machining?

Aluminum is a lightweight yet strong material, making it a popular choice for CNC machining. It boasts excellent corrosion resistance and thermal conductivity, which is advantageous for applications requiring heat dissipation. The material is relatively easy to machine, allowing for intricate designs and faster production rates.

Pros: Its lightweight nature reduces transportation costs, while its corrosion resistance extends the lifespan of the final product. Additionally, aluminum’s recyclability aligns with sustainability goals, appealing to environmentally conscious buyers.

Cons: Aluminum can be more expensive than other materials like mild steel, and its lower strength compared to steel may limit its use in high-stress applications. Furthermore, it can be prone to deformation under heavy loads.

What Are the Advantages of Mild Steel in CNC Applications?

Mild steel, known for its toughness and ductility, is widely used in CNC machining for various applications. It can withstand high temperatures and pressures, making it suitable for structural components and heavy machinery.

Pros: Mild steel is cost-effective and readily available, making it an attractive option for budget-conscious buyers. Its machinability allows for complex shapes and designs, while its strength makes it ideal for load-bearing applications.

Cons: Mild steel is susceptible to corrosion, requiring protective coatings or treatments for outdoor or humid environments. Additionally, its weight can increase shipping costs, particularly for large components.

Why Choose Stainless Steel for CNC Machining?

Stainless steel is renowned for its corrosion resistance and durability, making it ideal for applications in harsh environments. It maintains its strength at elevated temperatures and is often used in the food and medical industries due to its hygienic properties.

Pros: The longevity and aesthetic appeal of stainless steel make it suitable for high-end applications. Its resistance to rust and staining ensures that products maintain their appearance over time.

Cons: The higher cost and complexity of machining stainless steel can deter some buyers. Specialized tooling and equipment may be required, increasing initial investment costs.

How Does Brass Compare in CNC Machining?

Brass is a copper-zinc alloy known for its excellent machinability and corrosion resistance. It is often used in applications requiring good electrical conductivity, such as electrical connectors and fittings.

Pros: Brass is easy to machine, allowing for precise components with smooth finishes. Its antimicrobial properties make it suitable for medical applications, while its aesthetic appeal is favored in decorative items.

Cons: Brass can be more expensive than aluminum and mild steel, which may impact budget-sensitive projects. Additionally, its lower tensile strength limits its use in high-stress applications.

Summary Table of Material Properties for Cheap CNC Machines

| Material | Typical Use Case for cheap cnc machine for metal | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components, automotive parts | Lightweight and corrosion-resistant | Prone to deformation under heavy loads | Medium |

| Mild Steel | Structural components, machinery frames | Cost-effective and readily available | Susceptible to corrosion, heavier weight | Low |

| Stainless Steel | Food processing equipment, medical devices | Durable and corrosion-resistant | Higher machining costs, requires specialized tools | High |

| Brass | Electrical fittings, decorative items | Excellent machinability and aesthetic appeal | Higher cost, lower tensile strength | Medium |

This strategic material selection guide provides international B2B buyers with insights into the properties, advantages, and limitations of common materials used in cheap CNC machines for metal. Understanding these factors can help in making informed purchasing decisions that align with specific application needs and budget constraints.

In-depth Look: Manufacturing Processes and Quality Assurance for cheap cnc machine for metal

What Are the Main Stages in the Manufacturing Process of Cheap CNC Machines for Metal?

The manufacturing process of affordable CNC machines for metal consists of several key stages: material preparation, forming, assembly, and finishing. Understanding these stages can help B2B buyers assess the quality and reliability of the machines before making a purchase.

How Is Material Prepared for CNC Machine Manufacturing?

The first step in manufacturing CNC machines involves sourcing high-quality raw materials. Common materials include aluminum, steel, and plastic. In this stage, materials are inspected for consistency and defects. Suppliers often prioritize materials that meet international standards, ensuring they have the right mechanical properties for precision machining.

Once the material is sourced, it undergoes cutting and machining to achieve the desired dimensions and shapes. Techniques such as laser cutting or waterjet cutting are often employed to create initial parts with high precision, reducing wastage and enhancing quality.

Which Forming Techniques Are Commonly Used in CNC Machine Manufacturing?

The forming stage involves several advanced techniques that shape the components of the CNC machine. Common processes include:

- CNC Machining: Components like frames and brackets are machined using CNC milling or turning, which allows for precise cuts based on programmed designs.

- Casting or Forging: For larger components, casting or forging techniques may be used to create solid pieces that require additional strength.

- Welding: Structural integrity is enhanced through welding, which joins various metal components and ensures durability.

During this phase, it is critical to ensure that all parts are manufactured to the exact specifications outlined in the design documentation. Quality checks are performed to guarantee harmonization between different parts, ensuring they will fit together accurately during assembly.

What Does the Assembly Process of CNC Machines Entail?

Once the individual components are formed, they proceed to the assembly stage. This includes:

- Sub-assembly: Smaller units such as electronic enclosures and drive assemblies are first put together before the main assembly.

- Final Assembly: Components are integrated, which includes mounting motors, controllers, and other necessary parts according to strict guidelines.

It is during assembly that attention to detail becomes paramount. Operators utilize tools that often require calibration to reduce errors. Additionally, assembly lines may be equipped with sensors that monitor the fitting of components to ensure they meet the pre-established tolerances.

How Is the Finishing Process Executed for CNC Machines?

The finishing stage may involve surface treatments to enhance durability and aesthetics. Methods such as powder coating, anodizing, or painting can be applied to metal components to prevent corrosion and improve finish quality. Furthermore, any burrs or rough edges are smoothed out as part of the quality control protocols.

In the finishing phase, thorough inspections are made to ensure that the machines meet both functionality and visual standards. Sub-par finishes can undermine the perceived quality of the machine, which could affect market reputation.

What Quality Assurance Practices Should B2B Buyers Expect?

Quality assurance is an essential part of CNC machine manufacturing, with various internal controls and international standards to guide practices. Here’s what important to note:

What International Standards Govern the Quality of CNC Machines?

Many manufacturers comply with ISO 9001, which outlines a framework for ensuring consistent quality in products and services. Compliance indicates correct documentation practices, management oversight, and continuous improvement efforts throughout the production process.

Which Industry-Specific Certifications Are Relevant?

Depending on the market, suppliers may also hold industry-specific certifications such as CE (European Safety Compliance) or various API (American Petroleum Institute) standards. These certifications ensure that the machines meet specific regional safety and operational requirements.

How Are Quality Control Checkpoints Structured in CNC Manufacturing?

Quality checks occur at multiple stages throughout the manufacturing process, often referred to as:

- Incoming Quality Control (IQC): This initial checkpoint examines raw materials upon receipt.

- In-Process Quality Control (IPQC): Inspections are performed during the manufacturing process to catch any defects early.

- Final Quality Control (FQC): The completed product undergoes a thorough inspection to verify that it meets all specifications before shipping.

Common testing methods include dimensional checks, operational tests, and performance evaluations, often guided by predetermined acceptance criteria.

How Can B2B Buyers Verify Supplier Quality Control Measures?

To reinforce their confidence, B2B buyers have several options for verifying the quality control processes of their suppliers:

- Supplier Audits: Conducting site audits helps buyers assess the manufacturing environment, compliance with safety standards, and adherence to quality processes.

- Quality Reports: Request documented evidence of quality inspections and test results. Genuine suppliers should provide reports detailing their quality checks.

- Third-Party Inspections: Engaging independent inspectors to perform quality audits can provide impartial verification of the manufacturer’s capabilities.

What Unique QC and Certification Considerations Exist for International B2B Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe need to consider various logistical factors when dealing with international suppliers. These include:

- Customs Regulations: Import regulations may require specific documentation related to certifications, impacting lead times.

- Local Compliance: Understanding local laws and certifications can ensure that the machine meets regional safety and operational standards.

- Cultural and Communication Differences: Developing effective lines of communication can help mitigate misunderstandings related to quality expectations and requirements.

By taking a thorough approach to assessing manufacturing processes and quality assurance, B2B buyers can make informed decisions to ensure they procure high-quality, cost-effective CNC machines that meet their business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cheap cnc machine for metal’

Introduction

When sourcing a budget-friendly CNC machine for metal, it’s essential to navigate the complexities of specifications, suppliers, and support effectively. This guide provides a step-by-step checklist to help international B2B buyers make informed decisions that align with their operational needs and financial constraints.

Step 1: Define Your Technical Specifications

Before beginning your search, clearly outline the technical requirements for the CNC machine. Consider the types of metals you plan to work with, the thickness of materials, and the desired precision.

– Material Compatibility: Ensure the machine can handle the specific metals (e.g., aluminum, steel, brass) you intend to process.

– Cutting Capacity: Look for machines that meet your size requirements, including the maximum workpiece dimensions.

Step 2: Set a Realistic Budget

Establish a budget that considers not just the initial purchase price but also ongoing costs such as maintenance, software, and tooling.

– Total Cost of Ownership: Factor in potential financing options and warranty services, which can provide long-term savings.

– Cost vs. Value: Compare the features of various machines within your price range to ensure you are getting the best value for your investment.

Step 3: Research Potential Suppliers

Thoroughly investigate potential suppliers to ensure they are reputable and capable of meeting your needs.

– Supplier Background: Look for companies with a proven track record in CNC manufacturing, especially those with experience in your region or industry.

– Customer Reviews: Seek testimonials or case studies from other buyers to gauge satisfaction levels and machine performance.

Step 4: Verify Certifications and Compliance

Ensure that the machines meet relevant safety and quality standards, which can vary by region.

– ISO Certifications: Check if the supplier holds ISO or similar certifications that indicate adherence to international quality standards.

– Compliance with Local Regulations: Verify that the machines comply with local safety regulations and import/export laws, particularly if you are sourcing from abroad.

Step 5: Request Demonstrations and Samples

Whenever possible, request a demonstration or sample parts produced by the CNC machine.

– Hands-On Experience: A demo allows you to assess the machine’s capabilities and ease of use firsthand.

– Sample Quality: Evaluate the quality of the sample parts to ensure they meet your specifications and standards.

Step 6: Inquire About Technical Support and Training

Support is crucial, especially for businesses new to CNC machining.

– Technical Assistance: Confirm what type of technical support is available post-purchase, including warranty terms and after-sales service.

– Training Programs: Ask if the supplier offers training for your team to maximize machine utilization and minimize downtime.

Step 7: Finalize Your Purchase and Logistics

Once you’ve selected a supplier, finalize the purchase by discussing logistics and delivery timelines.

– Shipping Arrangements: Clarify shipping costs and timelines, especially if you are importing the machine.

– Installation Support: Inquire about installation services or support to ensure the machine is set up correctly and operational as quickly as possible.

By following this structured checklist, B2B buyers can streamline their sourcing process and make informed decisions when investing in a cheap CNC machine for metal.

Comprehensive Cost and Pricing Analysis for cheap cnc machine for metal Sourcing

When sourcing cheap CNC machines for metal, understanding the cost structure and pricing nuances is essential for international B2B buyers. This analysis delves into the various cost components that contribute to the overall pricing of these machines, along with the factors influencing prices and practical tips for buyers in regions like Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in CNC Machine Pricing?

-

Materials: The choice of materials significantly impacts the cost of CNC machines. Common materials used in manufacturing CNC machines include steel, aluminum, and high-density plastics. The quality and sourcing of these materials can vary widely, affecting the final price. For instance, high-grade aluminum may increase the upfront cost but can enhance durability and performance.

-

Labor: Labor costs are a critical component of the overall cost structure. In regions with higher labor costs, such as Europe and North America, the manufacturing price will be higher compared to countries with lower labor costs, like Vietnam or Brazil. Additionally, skilled labor for setup and maintenance can further influence pricing.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs, which can translate into lower prices for buyers.

-

Tooling: The initial investment in tooling for CNC machines can be substantial. Custom tooling tailored for specific applications may raise costs, while standard tooling can keep expenses in check. Buyers should evaluate the tooling options available with their machines to determine the best value.

-

Quality Control (QC): Ensuring quality through rigorous QC processes is vital but adds to the overall cost. Machines with robust quality certifications may come at a premium, yet they can provide peace of mind regarding performance and reliability.

-

Logistics: Shipping costs can vary based on the size and weight of the machine, as well as the shipping method chosen. Buyers must consider potential tariffs, insurance, and customs duties when calculating total logistics costs, especially for international shipments.

-

Margin: The profit margin set by manufacturers can vary based on market demand, competition, and brand reputation. Understanding the margin expectations can help buyers negotiate better deals.

How Do Price Influencers Affect CNC Machine Costs?

Several factors can influence the pricing of CNC machines for metal:

-

Volume/MOQ: Purchasing in larger volumes can lead to significant discounts. Establishing a minimum order quantity (MOQ) can help secure better pricing.

-

Specifications/Customization: Customized machines tailored to specific operational needs often come at a higher price point. Buyers should carefully assess their requirements to avoid unnecessary customization costs.

-

Materials and Quality: Machines made with higher-quality materials or advanced technology may command higher prices. Buyers should weigh the benefits of quality against their budget constraints.

-

Supplier Factors: The reputation, location, and reliability of the supplier can affect pricing. Established suppliers may offer better support and warranty options, justifying a higher price.

-

Incoterms: Understanding Incoterms can help buyers estimate total costs associated with delivery terms. These terms define the responsibilities of buyers and sellers in shipping arrangements, impacting final pricing.

What Are the Best Tips for Negotiating Prices?

-

Negotiate: Don’t hesitate to negotiate prices with suppliers. Being informed about the market and understanding the cost structure can provide leverage.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the purchase price. This includes maintenance, operational costs, and potential downtime, which can significantly affect long-term expenses.

-

Consider Local Support: For buyers in regions like Africa and South America, sourcing from suppliers with local support can reduce logistics costs and ensure easier access to parts and service.

-

Be Aware of Pricing Nuances: International buyers should be mindful of currency fluctuations and varying economic conditions that could impact pricing.

Disclaimer on Indicative Prices

While indicative pricing can provide a baseline for budgeting, it is essential to obtain specific quotes tailored to your needs from suppliers. Prices can vary based on customization, location, and market conditions, making direct communication with manufacturers crucial for accurate cost assessments.

By understanding these components and strategies, international B2B buyers can make informed decisions when sourcing cheap CNC machines for metal, optimizing both cost and operational efficiency.

Alternatives Analysis: Comparing cheap cnc machine for metal With Other Solutions

When evaluating manufacturing solutions, businesses often seek the most cost-effective methods that do not compromise on quality or performance. While ‘cheap CNC machines for metal’ offer a budget-friendly entry point into metal fabrication, it is essential to consider various alternatives that may also meet operational needs. Below is a comprehensive comparison of ‘cheap CNC machines for metal’ against two viable alternatives: 3D printing with metal materials and manual machining using traditional lathes and mills.

| Comparison Aspect | Cheap CNC Machine For Metal | 3D Metal Printing | Manual Machining |

|---|---|---|---|

| Performance | High precision, suitable for complex shapes | Excellent for intricate designs; lesser material waste | Varies widely; highly skilled operator required |

| Cost | Lower initial investment, but maintenance adds up | Higher upfront costs but lower long-term cost due to less material waste | Low equipment costs, but labor and skilled trades are expensive |

| Ease of Implementation | Requires operator training and setup | Familiarity with 3D printing software needed | Requires experienced machinists for setup and operation |

| Maintenance | Regular maintenance required for optimal performance | Generally lower; machines are robust but may require software updates | High; consistent need for calibration and repairs |

| Best Use Case | Ideal for batch production and prototyping | Best for both rapid prototyping and unique, complex products | Excellent for bulk production of simple parts |

In-depth Look at Alternatives

What Are the Benefits and Drawbacks of 3D Metal Printing?

3D metal printing has emerged as a transformative technology in manufacturing. Its primary advantage lies in its ability to produce complex geometries that traditional machining cannot achieve. Furthermore, it generates significantly less waste by building parts layer by layer. The downside is the higher initial investment and the need for specialized knowledge in 3D modeling and printing software. Additionally, for mass production, 3D printing can be slower compared to traditional CNC milling.

What Is the Value of Manual Machining in the Metalworking Industry?

Manual machining—using tools like lathes and mills—has been a stalwart method in the metalworking industry. Its strengths lie in the significant cost savings regarding equipment and flexibility for small-scale production runs. Operators can often craft parts to high specifications without elaborate programming. However, the reliance on skilled machinists introduces operational risks like human error and limited scalability. Furthermore, the speed of production may not keep up with that of CNC technology or 3D printing.

How Should Buyers Decide on the Right Manufacturing Solution?

B2B buyers should assess their operational requirements carefully when choosing between ‘cheap CNC machines for metal’ and its alternatives. Consider key factors such as production volume, complexity of designs, and workforce skills. If high precision and consistency are paramount and raw material waste is a concern, investing in 3D printing might be worthwhile. Conversely, for businesses looking to maintain a small-scale, cost-effective production process, manual machining could be the solution. Ultimately, aligning the chosen method with business objectives, budget, and available expertise will ensure the most effective outcomes in metal fabrication.

Essential Technical Properties and Trade Terminology for cheap cnc machine for metal

What Are the Key Technical Specifications of Affordable CNC Machines for Metal?

When considering the procurement of affordable CNC machines for metalworking, understanding critical technical specifications is essential. Here are the key specifications that B2B buyers should focus on:

-

Material Compatibility: This refers to the range of materials the CNC machine can effectively cut, such as aluminum, steel, brass, and titanium. Buyers must ensure the machine can handle the specific metals they plan to work with to avoid investing in equipment that won’t meet their fabrication needs.

-

Cutting Tolerance: Tolerance describes the allowable deviation in sizing during the cutting process, typically measured in millimeters or inches. A tighter tolerance is crucial for applications requiring high precision, as any deviation can lead to errors in assembly and function. Understanding tolerance levels can help buyers choose a machine that meets their production quality standards.

-

Power and Motor Specifications: The power output and specifications of the machine’s motor significantly affect its cutting capacity and performance. More powerful motors allow for cutting thicker materials at higher speeds without compromising accuracy. Decision-makers must assess whether the machine’s power rating aligns with the anticipated workload.

-

Working Envelope Size: This dimension denotes the maximum size of materials the machine can accommodate and process. Knowing the working envelope helps buyers ensure that the CNC can handle the dimensions of their materials, preventing future restrictions on production capabilities.

-

Spindle Speed and Torque: The spindle speed, measured in revolutions per minute (RPM), combined with torque, determines how effectively the machine can perform various cuts. High spindle speeds are essential for quick, efficient production, while sufficient torque is vital for cutting tougher materials. Assessing these specifications allows buyers to gauge a machine’s capability for complex and varied machining tasks.

-

Software Compatibility: The ease of use and compatibility of the CNC machine’s control software is a crucial consideration. An open-source, user-friendly platform allows for seamless programming and operation, reducing the learning curve and maintenance time. This can influence overall productivity, particularly for businesses with limited technical expertise.

What Are the Common Trade Terms Related to Affordable CNC Machines for Metal?

Familiarity with industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some essential terms:

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the CNC industry, understanding OEM relationships can help buyers assess product quality and support options.

-

MOQ (Minimum Order Quantity): This specifies the smallest quantity of an item that a supplier is willing to sell. Buyers should understand MOQ when negotiating bulk orders to avoid overcommitting resources to inventory that may exceed their production needs.

-

RFQ (Request for Quotation): An RFQ is a document sent by a buyer to suppliers requesting pricing and terms for specific products or services. Utilizing RFQs is essential for obtaining competitive bids, particularly when sourcing CNC machines and related components from multiple suppliers.

-

Incoterms (International Commercial Terms): These are universally recognized rules that define responsibilities of buyers and sellers regarding shipping, delivery, and customs. Familiarity with Incoterms ensures clarity in shipping risks and costs associated with global trade, helping companies avoid unexpected expenses during import/export operations.

-

Lead Time: This term describes the amount of time from placing an order to receiving it. Understanding lead time is crucial for supply chain planning to avoid production delays that could impact business operations.

-

Warranty: A warranty is a guarantee provided by the manufacturer regarding the longevity and performance of the machine. Buyers should thoroughly understand warranty terms to ensure they have adequate support and product protection should defects or failures occur.

Understanding technical specifications and industry terminology empowers B2B buyers to make informed decisions when investing in affordable CNC machines for metal. Proper assessment of these factors can lead to efficiency gains and reduced costs in production processes.

Navigating Market Dynamics and Sourcing Trends in the cheap cnc machine for metal Sector

What Are the Key Market Drivers and Trends for Cheap CNC Machines for Metal?

The global market for cheap CNC machines for metal is witnessing significant growth, driven by advancements in manufacturing technologies, increasing automation in various sectors, and the demand for cost-effective production solutions. Emerging economies in Africa, South America, and the Middle East are particularly keen on adopting CNC technology to enhance their manufacturing capabilities and improve productivity. The trend towards miniaturization and lightweight designs in various industries is pushing manufacturers to invest in CNC machines that can handle a diverse range of materials, including metals, plastics, and composites.

International B2B buyers are also increasingly focused on sourcing machines that offer flexibility and scalability. Companies are looking for affordable solutions that allow them to upgrade as their needs evolve. This has led to the popularity of modular CNC machines that can be expanded with additional capabilities over time. The rise of e-commerce platforms and online marketplaces is facilitating easier access to various CNC machine suppliers, allowing buyers to compare features, prices, and support options more effectively.

Moreover, the integration of Industry 4.0 principles is reshaping the CNC landscape. B2B buyers are now looking for machines that can seamlessly connect to IoT devices, enabling real-time monitoring and data analytics to optimize production processes. This shift is particularly relevant for manufacturers in Brazil and Vietnam, where the demand for smart manufacturing solutions is growing.

How Important Is Sustainability and Ethical Sourcing in the CNC Machine Industry?

Sustainability is becoming a crucial consideration for B2B buyers in the CNC machine sector. The environmental impact of manufacturing processes is under scrutiny, leading companies to seek machines that are designed with energy efficiency in mind. Buyers are increasingly favoring CNC machines that utilize renewable energy sources or have energy-efficient operational modes, which can significantly reduce operational costs in the long run.

Ethical sourcing is also gaining traction among international buyers. Companies are looking for suppliers that demonstrate a commitment to ethical manufacturing practices, which includes fair labor conditions and responsible sourcing of materials. Certifications like ISO 14001 for environmental management and ISO 9001 for quality management are becoming essential for suppliers aiming to appeal to conscientious buyers.

Moreover, the use of ‘green’ materials in the construction of CNC machines is a growing trend. Manufacturers are exploring biodegradable lubricants, recyclable components, and non-toxic materials, which not only reduce the environmental footprint but also enhance the machine’s overall appeal in markets that prioritize sustainability. B2B buyers are encouraged to engage with suppliers who can provide transparency in their sourcing and manufacturing processes, ensuring that their investments align with their sustainability goals.

How Has the CNC Machine Market Evolved Over Time?

The evolution of CNC machines has been marked by significant technological advancements and a shift in market dynamics. Initially, CNC technology was predominantly used in large-scale industrial applications due to high costs and complexity. However, as technology progressed, the introduction of affordable CNC machines has democratized access, allowing small and medium enterprises (SMEs) to leverage this technology for metalworking and other applications.

The early 2000s saw a surge in interest from hobbyists and small business owners, leading to the development of compact, user-friendly CNC machines tailored for various materials, including metals. This trend was further accelerated by the rise of online communities and resources that provided support and education for new users. Today, CNC machines are integral to various industries, from automotive to aerospace, reflecting their versatility and the ongoing demand for precision manufacturing solutions.

In conclusion, the cheap CNC machine market for metal is evolving rapidly, driven by technological advancements and changing buyer expectations. As international B2B buyers navigate this landscape, understanding market dynamics, prioritizing sustainability, and recognizing the historical context of CNC technology will empower them to make informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of cheap cnc machine for metal

-

How do I choose the right CNC machine for metal fabrication?

Selecting the right CNC machine involves assessing your specific needs, including the types of materials you will work with and the complexity of your projects. Consider factors such as cutting area, precision, and the machine’s capabilities with different metals. Additionally, evaluate your budget and any long-term scalability you may require. Research different manufacturers, read reviews, and seek recommendations from industry peers to identify machines that offer the best balance of performance and cost-effectiveness. -

What are the essential features to look for in an affordable CNC machine for metal?

When sourcing an affordable CNC machine for metal, prioritize features like cutting speed, precision, and versatility. Look for machines that can handle a variety of metals, including aluminum and steel, and those with a robust build quality to withstand rigorous use. Advanced control systems and user-friendly software can enhance productivity and ease of operation. Additionally, ensure the machine has reliable technical support and warranty options to safeguard your investment. -

What is the typical lead time for delivery of CNC machines internationally?

Lead times for CNC machines can vary significantly based on the manufacturer, machine type, and shipping logistics. Generally, you can expect a lead time of 4 to 8 weeks for production and delivery. However, it’s essential to discuss specific timelines with your supplier, particularly for international shipments, as customs clearance and transportation can introduce additional delays. Always confirm shipping options and expected arrival dates before finalizing your purchase. -

How can I vet suppliers when sourcing CNC machines internationally?

Vetting suppliers is crucial to ensure quality and reliability. Start by researching the supplier’s history, customer reviews, and industry reputation. Request references from previous clients and check their certifications and compliance with international standards. Additionally, consider conducting a factory visit if feasible, or utilize third-party inspection services to assess manufacturing capabilities. Engaging in direct communication with the supplier can also provide insight into their customer service and responsiveness. -

What are common payment terms when purchasing CNC machines for international trade?

Payment terms can vary by supplier but typically include options like a deposit upfront (often 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer financing options or letters of credit for larger purchases. It’s important to clarify payment methods accepted (e.g., bank transfer, PayPal) and ensure you understand any additional costs, such as shipping, customs duties, and taxes, that may apply to your purchase. -

Can I customize a cheap CNC machine to meet my specific needs?

Many manufacturers offer customization options for CNC machines, allowing you to tailor features such as size, tooling, and software to suit your specific requirements. When discussing your needs with suppliers, inquire about available upgrades or add-ons that can enhance the machine’s capabilities. Be sure to consider the long-term implications of customization on maintenance and support, as some modifications may affect warranty coverage. -

What quality assurance measures should I expect from CNC machine suppliers?

Reputable suppliers should have established quality assurance protocols to ensure their machines meet industry standards. Look for suppliers that provide detailed specifications, performance testing results, and warranties on their products. Additionally, inquire about their quality control processes, including inspections during manufacturing and pre-shipment testing. Suppliers who are ISO certified or adhere to similar standards often demonstrate a commitment to maintaining high-quality production practices. -

How do I handle logistics and shipping for my CNC machine purchase?

Handling logistics for international CNC machine purchases involves coordinating with the supplier and logistics providers. Discuss shipping methods, costs, and estimated delivery times with your supplier. It’s advisable to choose a freight forwarder experienced in heavy machinery transport to ensure safe and compliant shipping. Additionally, familiarize yourself with customs regulations in your country to avoid unexpected delays or fees upon arrival. Consider insurance options for added protection during transit.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Cheap Cnc Machine For Metal Manufacturers & Suppliers List

1. Comgrow – Robo CNC Machine

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Comgrow Robo CNC machine, priced at $240 USD (on sale for $200), designed after professional gantry CNC machines, features beefier parts than typical 3D printer designs, work area is almost letter size, spindle upgrade available for $25, not suitable for machining metal until user gains experience.

2. MillRight CNC – Power Route Plus

Domain: millrightcnc.com

Registered: 2016 (9 years)

Introduction: This company, MillRight CNC – Power Route Plus, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Tormach – Affordable CNC Machines

Domain: tormach.com

Registered: 2002 (23 years)

Introduction: Tormach offers a range of affordable CNC machines, including mills (1500MX, 1100MX, 770MX, 1100M, 770M, PCNC 440), lathes (8L, 15L Slant-PRO), routers (24R CNC Router, xsTECH Pro Router, xsTECH Router), bandsaws (AF50), plasma tables (1300PL), and automation solutions. Their machines run on single-phase power and utilize the free, open-source control software PathPilot®. Tormach machines are desig…

4. Practical Machinist – Affordable CNC Mill for Engine Parts

Domain: practicalmachinist.com

Registered: 2000 (25 years)

Introduction: CNC Mill under $10,000 capable of cutting steel; suitable for creating parts for 6-cylinder and 8-cylinder engines (e.g., Land Cruiser Prado, Lexus); intended use for smaller engine and car parts made of aluminum or steel; required x-axis reach: 10″-20″; required z-axis reach: 7″-15″; considered machines include Tormach 440/770, CNC Express from Microkinetics, CNC Baron Mill, PRO4824, older models…

5. MatterHackers – CNC Machines

Domain: matterhackers.com

Registered: 2012 (13 years)

Introduction: CNC Machines are used for shaping, cutting, and engraving materials like metal, wood, and plastics. They come in various sizes and configurations, from compact benchtop models to large-scale industrial units. Key features include high precision, consistent repeatability, and capability to work with a diverse array of materials. Featured collections include Shaper Tools, Bantam Tools, Carbide 3D, L…

6. STYLECNC – Affordable Metal CNC Routers

Domain: stylecnc.com

Registered: 2015 (10 years)

Introduction: Affordable Metal CNC Machines | 2025 Best Metal CNC Routers – STYLECNC. CNC metal router machines are automatic power tools using computer numerical control, high-speed spindles, and high hardness router bits for various metals including aluminum, brass, copper, iron, steel, and alloys. Features include continuous operation after power failure, automatic error correction, and 3 to 5 axis capabilit…

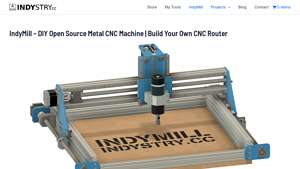

7. Indystry – IndyMill CNC Machine

Domain: indystry.cc

Registered: 2020 (5 years)

Introduction: IndyMill is a DIY open-source metal CNC machine project developed by Nikodem Bartnik, designed as an upgrade to the Dremel CNC. It aims to provide an accessible CNC machine that can be easily built and replicated worldwide using widely available components. The machine has a working area of approximately 520x400x115mm, with outside dimensions of 760x660x360mm. Parts required for building IndyMill …

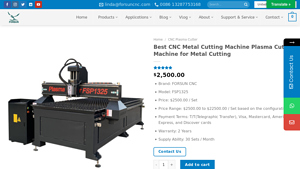

8. FORSUN CNC – CNC Plasma Cutting Machine

Domain: forsuncnc.com

Registered: 2020 (5 years)

Introduction: {“Product Name”: “CNC Plasma Cutting Machine”, “Brand”: “FORSUN CNC”, “Model”: “FSP1325”, “Price”: “$2500.00”, “Price Range”: “$2500.00 to $22500.00”, “Payment Terms”: [“T/T”, “Visa”, “Mastercard”, “American Express”, “Discover”], “Warranty”: “2 Years”, “Supply Ability”: “30 Sets / Month”, “Cutting Thickness”: “1mm to 30mm”, “Working Size Options”: [“4×4 ft”, “4×8 ft”, “600×900 mm”, “1500×3000 mm”…

9. Hobby Machinist – Affordable CNC Milling Solutions

Domain: hobby-machinist.com

Registered: 2010 (15 years)

Introduction: Inexpensive CNC mill options for hobbyists; suitable for steel and aluminum; budget range of $500 to $6000; G0704/PM25 mill costs about $1800; additional $1000 for CNC software, motors, and basic tooling; used CNC machines available around $7k; CNC routers available for $4-5k; CAD/CAM software necessary for operation; conversational programming available on higher-end controllers; suggestions for …

Strategic Sourcing Conclusion and Outlook for cheap cnc machine for metal

In today’s competitive landscape, the strategic sourcing of affordable CNC machines for metal processing is essential for businesses aiming to enhance productivity and reduce operational costs. By investing in machines that offer reliability, versatility, and ease of use, companies can optimize their manufacturing processes and achieve quicker returns on investment. The availability of financing options further empowers international buyers to make these crucial investments without significant upfront capital.

Key players like MillRight CNC and Tormach demonstrate the importance of selecting machines that not only meet immediate production needs but also allow for scalability as business demands evolve. Their commitment to customer support and technical assistance ensures that buyers can maximize their equipment’s potential over time.

As markets in Africa, South America, the Middle East, and Europe continue to grow, the demand for cost-effective CNC solutions will only increase. Businesses are encouraged to leverage this opportunity by exploring strategic partnerships with reputable suppliers. By doing so, they can secure the best value for their investments and position themselves for future success. Now is the time to take action and elevate your manufacturing capabilities with affordable CNC technology.