Introduction: Navigating the Global Market for cheap cnc lathe

In the rapidly evolving landscape of manufacturing, sourcing an affordable CNC lathe can pose a significant challenge for international B2B buyers. As industry demands shift, buyers in regions such as Africa, South America, the Middle East, and Europe, including Nigeria and Brazil, seek powerful yet budget-friendly solutions to optimize their production processes. This comprehensive guide to cheap CNC lathes addresses the critical concerns around types, applications, procurement strategies, and cost considerations, ensuring buyers have the knowledge needed to make informed purchasing decisions.

Within these pages, industry professionals will discover a range of CNC lathe options tailored to various needs, from those looking for light production units to those requiring robust machines for more demanding applications. The guide will also delve into essential best practices for vetting suppliers, highlighting what to look for in terms of quality, reliability, and support services. By unpacking the cost structures associated with cheap CNC lathes, readers will gain insights into potential hidden expenses, financing options, and long-term value, enabling them to navigate the market confidently.

As manufacturing flourishes across global economies, this guide provides the tools and insights necessary for making strategic investments in CNC technology, ultimately empowering buyers to enhance productivity while staying within budget.

Understanding cheap cnc lathe Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mini CNC Lathe | Portable, compact design for tight spaces | Hobbyist projects, prototyping | Pros: Affordable, easy to use. Cons: Limited power and capacity. |

| Vertical CNC Lathe | Vertical spindle orientation, larger capacity | Heavy-duty production, large part manufacturing | Pros: Excellent for larger parts, high precision. Cons: Generally more expensive. |

| Swiss CNC Lathe | High precision, ability to work on multiple axes | Precision components in medical and aerospace | Pros: Extreme accuracy, ideal for small parts. Cons: Often higher starting investment. |

| Benchtop CNC Lathe | Small footprint, often includes integrated controls | Small workshops, educational settings | Pros: Cost-effective, space-saving. Cons: Limited functionality compared to industrial models. |

| Used CNC Lathe | Pre-owned machines at reduced prices | Various small to medium manufacturing applications | Pros: Significant cost savings. Cons: Potential for wear and outdated technology. |

What Characteristics Make Mini CNC Lathes Ideal for Entry-Level Users?

Mini CNC lathes are characterized by their compact design, making them suitable for small shops or personal workshops. With a reduced power capacity, they offer basic functionality, allowing users to create intricate parts and practice CNC machining. B2B buyers seeking cost-effective, entry-level solutions will find that mini lathes offer manageable speeds and feeds, suitable for prototyping and hobbyist projects without the steep investment, though they may prioritize small tasks over large-scale production.

Why Choose a Vertical CNC Lathe for Heavy-Duty Projects?

Vertical CNC lathes utilize a vertical spindle orientation that enables the processing of heavier and larger parts efficiently. These machines are ideal for industries focused on heavy-duty production, such as automotive or aerospace, where precision is crucial. For B2B buyers, investing in a vertical CNC lathe means securing the capability to manufacture robust parts with high tolerances. However, the initial investment is generally higher, which requires careful consideration of return on investment potential.

How Do Swiss CNC Lathes Stand Out for Precision Work?

Swiss CNC lathes are designed for high precision and efficiency, allowing for multi-axis operation that accommodates complex machining tasks. Particularly beneficial for industries such as medical and aerospace where component accuracy is paramount, these machines deliver superior performance in batch production of small, intricate parts. B2B buyers should evaluate their need for precision versus their budget, as Swiss lathes often come with higher upfront costs but can provide significant savings on labor and material over time.

What Are the Benefits of Benchtop CNC Lathes for Smaller Operations?

Benchtop CNC lathes are a space-efficient option that combines electronic controls with raw machining capability, making them a favored choice for small workshops or educational environments. These machines allow for quick learning curves and are cost-effective. In the B2B context, buyers should consider benchtop lathes for projects that do not require heavy-duty production capability. While they are cost-effective and easy to manage, limitations on size and material types may affect the project’s scope.

Why Consider Used CNC Lathes for Cost Savings?

The availability of used CNC lathes presents a significant opportunity for buyers looking to reduce capital expenditures. These pre-owned machines can be found at dramatically lower prices, allowing smaller manufacturers to access technology that may have been previously unattainable. However, B2B buyers should conduct thorough inspections and evaluations to mitigate risks associated with wear and technological obsolescence. Understanding the machine’s history and performance can help secure a worthwhile investment in a used CNC lathe.

Key Industrial Applications of cheap cnc lathe

| Industry/Sector | Specific Application of cheap cnc lathe | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Prototyping and Production of Precision Parts | Streamlined production process, reduced lead times | Availability of support resources, machine reliability |

| Automotive | Custom Components for Vehicles | Enhanced ability to manufacture specialized parts on-demand | Compatibility with existing equipment and specific part designs |

| Aerospace | Small Batch Production of Aerospace Components | High precision needed for safety-critical components | Compliance with safety and quality standards |

| Oil & Gas | Fabrication of Custom Tooling and Equipment | Improved turnaround times for critical machinery | Sourcing for heavy-duty materials and machining capabilities |

| Electronics | Creation of Housings and Mounting Brackets | Cost-effective solutions for small batch electronic assemblies | Accurate dimensions and finishes, adaptable programming |

How is a cheap CNC lathe utilized in manufacturing sectors?

In the manufacturing sector, a cheap CNC lathe plays a pivotal role in both prototyping and full-scale production of precision parts. For small and medium-sized enterprises, affordability and compact design mean they can integrate this technology into their workshops without significant capital expenditure. This flexibility allows for quicker product iterations and adaptations to customer specifications, ultimately streamlining their production processes. International buyers from regions such as Africa and South America should ensure that their chosen CNC lathe meets local electrical standards and includes comprehensive support solutions to address potential downtime.

What applications can be found in the automotive industry with affordable CNC lathes?

In automotive manufacturing, cheap CNC lathes are often used to produce custom components tailored to specific vehicle models. This application is particularly beneficial for shops that cater to niche markets, allowing them to respond quickly to evolving consumer preferences while managing production costs effectively. By using CNC lathes, automotive suppliers can create parts like gears and brackets in small batches without compromising quality. Accordingly, buyers should focus on the lathe’s ability to work with a variety of materials and its compatibility with advanced automotive alloys.

How do aerospace companies benefit from using a budget-friendly CNC lathe?

For the aerospace industry, where safety and precision are paramount, cheap CNC lathes enable manufacturers to produce small batches of high-tolerance components that meet stringent regulatory standards. Utilizing such machinery helps companies reduce lead times for crucial components while maintaining rigorous quality checks. Potential buyers in this sector, particularly from Europe and the Middle East, should prioritize lathes with solid build quality, detailed specifications, and the ability to perform complex machining tasks, ensuring they fit industry-specific compliance requirements.

In what ways does the oil and gas sector employ inexpensive CNC lathes?

The oil and gas industry utilizes affordable CNC lathes for fabricating custom tools and machinery essential for their operations. These lathes allow for the rapid production of specialized components that facilitate exploration and extraction, significantly enhancing operational efficiency. Companies must, however, consider factors like the material capabilities of the lathe, as heavy-duty operations typically require equipment capable of machining high-strength materials. Additionally, service dependencies and the availability of spare parts are crucial for minimizing project downtime.

How can electronics manufacturers leverage the functionality of affordable CNC lathes?

In the electronics sector, cheap CNC lathes are employed to create housings and mounting brackets for components such as circuit boards and connectors. This capability allows manufacturers to introduce new products rapidly while managing costs effectively. The precision of these lathes ensures that the final products meet the tight tolerances required in electronics assembly. International buyers, especially from developing markets, should assess the machining versatility of the lathe, its software capabilities for programming, and the availability of technical support to optimize production efficiencies.

3 Common User Pain Points for ‘cheap cnc lathe’ & Their Solutions

Scenario 1: Limited Budget Constraints Affecting Production Quality

The Problem: In many emerging markets such as Nigeria and Brazil, businesses often grapple with tight budgets, leading them to opt for cheaper CNC lathes. While the initial investment may be low, these machines can fail to deliver the desired precision or durability, often resulting in poor-quality output. This is particularly challenging for companies trying to maintain competitiveness. The long-term consequences include increased waste, rework costs, and potential damage to their reputation, especially if they aim to export products.

The Solution: To mitigate the risks associated with cheaper CNC lathes, buyers should invest time in evaluating vendors and machine specifications carefully. Look for brands like Tormach known for providing affordable machines that don’t compromise on quality. Ensure that features like easy programmability, reliable materials handling, and included software tools (such as PathPilot®) are part of the package. Furthermore, assess whether the lathe supports a variety of materials conducive to your production line, allowing for greater flexibility and efficiency. Additionally, seeking out social proof—such as reviews from similar businesses or case studies—can help make an informed decision that balances cost with quality.

Scenario 2: Technical Challenges in Machine Operation and Maintenance

The Problem: Many smaller manufacturers in regions like the Middle East and Africa encounter significant technical challenges when operating cost-effective CNC lathes. Users may struggle with complexities in machine programming, operation, and maintenance, causing downtime that negatively impacts productivity. Lack of easy-to-understand documentation or inadequate training facilities can exacerbate these issues, causing frustration and leading to underutilization of the equipment.

The Solution: To alleviate these operational hurdles, buyers must look for CNC lathes that offer comprehensive training and support. A machine like the Tormach 8L CNC lathe stands out because it includes intuitive conversational programming and a user-friendly interface that simplifies operations. It is essential to prioritize lathes that come with robust customer support and accessible online resources for troubleshooting. In addition, manufacturers should consider establishing partnerships with local suppliers that offer training sessions on machine operation and best practices in maintenance. This approach not only eases the transition to CNC machining but enhances staff competence and confidence in utilizing these machines.

Scenario 3: Sourcing Reliable Components and Accessories for Long-term Use

The Problem: As businesses expand and their production needs evolve, finding reliable components and accessories for cheap CNC lathes can become a significant concern. Companies often struggle when it comes time to source replacement parts or add-ons, risking equipment downtime and project delays. This scenario is particularly prevalent in South America and parts of Europe where local suppliers may not stock parts for less-common, affordably priced machines.

The Solution: To navigate this issue effectively, it is important for buyers to select CNC lathes from manufacturers that provide a clear and comprehensive warranty, as well as ongoing support. A machine like the Tormach 8L not only includes numerous free accessories but also has a transparent parts sourcing policy that discourages hidden fees. Buyers should also focus on selecting models that utilize standardized components widely available in the market, such as popular collet styles or compatible tool posts. Additionally, establishing a relationship with manufacturers or authorized dealers can give users direct access to parts and accessories, ensuring they don’t face unexpected downtimes due to sourcing issues. Developing a proactive maintenance strategy, including regular checks and timely component replacements, can enhance the lifespan and reliability of the CNC lathe, ensuring that production keeps running smoothly.

Strategic Material Selection Guide for cheap cnc lathe

What Are the Key Materials for CNC Lathes and Their Properties?

When selecting materials for a cheap CNC lathe, it’s essential to understand how different materials can affect the machine’s performance, durability, and application suitability. Here, we will examine four common materials: aluminum, stainless steel, titanium, and plastic.

How Does Aluminum Perform in CNC Lathe Applications?

Aluminum is widely used in CNC applications due to its excellent machinability, low density, and resistance to corrosion. Its key properties include a relatively low melting point (around 660 °C) and a good strength-to-weight ratio.

Pros: Aluminum is lightweight, which simplifies handling and reduces wear on machine tools. Additionally, it is often more cost-effective than harder metals, making it suitable for low-budget projects.

Cons: While aluminum is versatile, it may not withstand high temperatures or extreme stress compared to other materials. This can limit its use in heavy-duty applications.

Impact on Application: Aluminum is compatible with various media and is often used in parts requiring moderate strength and corrosion resistance, such as automotive components.

Considerations for Buyers: International buyers, especially in Africa and Brazil, should consider local aluminum grades conforming to standards like ASTM or ISO for reliable quality control.

What Advantages Does Stainless Steel Offer for CNC Lathe Projects?

Stainless steel is noted for its impressive corrosion resistance and high strength at elevated temperatures, making it ideal for components exposed to harsh environments.

Pros: Stainless steel can endure mechanical stress and maintain structural integrity over a wide temperature range. It’s an excellent choice for parts that require durability and resistance to rust.

Cons: One of the key limitations of stainless steel is its higher cost and lower machinability compared to aluminum. The increased wear on tools can add to production costs over time.

Impact on Application: Ideal for the food and medical equipment industries, stainless steel components must meet strict hygiene standards, often requiring further compliance checks.

Considerations for Buyers: Buyers in regions with high humidity or corrosive environments should prioritize high-grade stainless steel, aligning with standards like ASTM A240 for sheet and plate applications.

How Does Titanium Compare as a Material for CNC Lathes?

Titanium is celebrated for its exceptional strength-to-weight ratio and corrosive resistance, making it suitable for advanced engineering applications.

Pros: Titanium is highly durable and can perform well under extreme temperature and pressure conditions. Its lightweight nature is advantageous in aerospace and defense applications.

Cons: The main drawbacks include a significantly higher cost and complex machining processes that require specialized tools and techniques, potentially raising manufacturing complexity.

Impact on Application: Titanium is particularly beneficial for applications such as aerospace components, where the material must withstand stress while remaining lightweight.

Considerations for Buyers: Buyers in industries like aerospace must ensure compliance with stringent materials standards, such as ASTM B348 or B265, to guarantee quality and safety.

What Role Do Plastics Play in Affordable CNC Lathe Manufacturing?

Plastic materials are increasingly used in various CNC applications for their versatility, low cost, and ease of fabrication.

Pros: Plastics are typically lightweight, chemically resistant, and easy to mold or machine into complex shapes. They offer significant cost savings for mass production of low-stress parts.

Cons: The main limitations of plastics include lower strength and temperature resistance compared to metals. They may degrade under UV exposure or high temperatures, restricting their use in some applications.

Impact on Application: Plastics are commonly utilized in consumer products and components that do not require high structural integrity or extreme durability.

Considerations for Buyers: International buyers should be aware of plastic grades, ensuring conformity to quality standards like ASTM D5203 to maintain material integrity and performance.

Summary Table of Material Selection for Cheap CNC Lathe

| Material | Typical Use Case for cheap cnc lathe | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Automotive components, lightweight structures | Lightweight and cost-effective | Limited high-temperature performance | Low |

| Stainless Steel | Food processing, medical applications | Strong and corrosion-resistant | Higher cost and lower machinability | Medium |

| Titanium | Aerospace parts, high-performance components | Excellent strength-to-weight ratio | High cost and complex machining | High |

| Plastic | Consumer products, lightweight non-structural parts | Versatile and low-cost | Lower strength and temperature limits | Low |

By reframing your material selection within these parameters, you can enhance performance while also optimizing your manufacturing process for cost and compliance in target markets.

In-depth Look: Manufacturing Processes and Quality Assurance for cheap cnc lathe

What Are the Key Manufacturing Processes for Cheap CNC Lathes?

The manufacturing processes of affordable CNC lathes incorporate several pivotal stages that ensure efficiency and precision. Understanding these stages helps B2B buyers make informed decisions when sourcing machinery for their operations.

How Is Material Prepared for CNC Lathe Manufacturing?

The first step in manufacturing cheap CNC lathes begins with material preparation. Manufacturers typically utilize high-grade materials like stainless steel, aluminum, and various alloys, which are selected based on the lathe’s intended applications.

During material preparation, suppliers ensure that the raw materials meet strict quality standards and are free from defects. Rigorous checks and testing are essential, as any flaws can affect the machine’s longevity and performance. Suppliers may provide material certifications that outline the chemical properties and mechanical strengths, beneficial for buyers demanding specific material grades.

What Are the Forming Techniques Used in CNC Lathe Production?

The forming stage is where raw materials are shaped into usable parts. Techniques typically used include precision machining and casting.

Precision Machining: This involves the use of tooling to cut raw materials into specified shapes and sizes. CNC machines employ numerical control systems to facilitate high-accuracy cuts and shapes. This adds to the lathe’s precision capability, aligning with the requirements of B2B buyers who prioritize quality.

Casting: In some cases, parts may be produced through casting. Metal is poured into molds to form complex shapes that would be challenging to achieve through machining alone. For lower-cost lathes, this can reduce material waste and production time, enhancing the overall cost-effectiveness.

How Does the Assembly Process Work for CNC Lathes?

The assembly process encompasses integrating individual components into a coherent machinery unit. This includes the installation of critical components such as the spindle, control systems, and drive mechanisms.

Skilled technicians often oversee this process to ensure that each part fits correctly and functions properly. Manufacturers may use fixtures to guarantee precision alignment during assembly, which is crucial for maintaining operational integrity. For buyers, understanding assembly quality can be assessed through inspection reports provided by the manufacturer, outlining quality checks performed during assembly.

What Finishing Techniques Are Used in Cheap CNC Lathes?

Finishing techniques enhance the lathe’s usability and appearance. Common methods include:

- Surface Treatment: Processes such as anodizing or powder coating both protect the machine’s surfaces and enhance aesthetic appeal.

- Calibration and Testing: Finished machines undergo calibration to ensure accurate operation. This involves testing various components to confirm they meet performance specifications.

Buyers should inquire about the specific finishing processes used, as these can affect the durability and performance of the lathe in different operating environments.

How Is Quality Assured in the Manufacturing of Cheap CNC Lathes?

To maintain competitiveness, manufacturers of cheap CNC lathes must adhere to quality assurance processes that meet both domestic and international standards. Understanding these standards is critical for B2B buyers aiming to verify product quality.

What Are the International Quality Standards for CNC Lathes?

ISO 9001 is among the most recognized international quality management standards. This certification indicates that a company follows quality management principles that enhance customer satisfaction through consistent quality and service improvement.

For specialized applications or sectors, additional certifications may be pertinent, including CE marking for European markets, API specifications for oil and gas industries, or others relevant to buyers from regions like Africa or South America who may have specific compliance requirements.

What Are the Stages of Quality Control in CNC Lathe Manufacturing?

Quality control (QC) in CNC lathe production commonly involves several checkpoints:

- Incoming Quality Control (IQC): Inspection of materials upon arrival to ensure they meet predetermined quality standards.

- In-Process Quality Control (IPQC): Ongoing checks during production to catch defects before they affect the final product. This may involve monitoring machine tolerances and calibration.

- Final Quality Control (FQC): A rigorous examination of finished products before delivery. Testing may include operational tests, load testing, and dimensions checks against specifications.

Each of these QC stages is integral to reducing defects and ensuring the finished product meets buyer expectations.

How Can B2B Buyers Verify Supplier Quality Assurance?

Buyers looking to verify the quality of CNC lathes should consider several approaches:

- Supplier Audits: Periodic audits of the manufacturing facility can reveal a lot about adherence to quality standards. Buyers can assess operational processes and compliance with quality assurance practices during these visits.

- Certification and Documentation Requests: Manufacturers should provide copies of relevant quality certifications and inspection reports. This documentation is crucial in ensuring that the supplier operates according to established quality standards.

- Third-Party Inspections: Engaging independent third-party inspectors to evaluate the machinery before it ships can offer an added layer of assurance. This step is particularly beneficial for buyers in regions with varying quality control practices, such as Africa or the Middle East.

What Are the Unique Considerations for International B2B Buyers?

International buyers must navigate various nuances in quality assurance and compliance due to differing regional regulations. It’s advisable for buyers in Africa, South America, or Europe to:

- Research Regulatory Requirements: Each region may have specific standards that suppliers must meet. Understanding these can help buyers ensure their suppliers comply with local regulations.

- Establish Clear Contracts: Including quality benchmarks, compliance certifications, and testing requirements in contracts can help set clear expectations for both parties.

By comprehensively analyzing the manufacturing processes and stringent quality assurance measures for CNC lathes, B2B buyers can make well-informed decisions, ensuring they select reliable suppliers capable of meeting their production needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cheap cnc lathe’

To assist you in procuring a cost-effective CNC lathe that meets your business needs, this guide provides a structured checklist. The following steps will help you navigate the complexities of sourcing while ensuring you make informed decisions.

Step 1: Define Your Technical Specifications

Identifying your exact technical requirements is the first and most critical step in sourcing a CNC lathe. Consider factors such as the materials you intend to work with, required spindle speed, and operational space constraints. Be specific about the axis of movement needed, whether you need features like rigid tapping or conversational programming capabilities.

- Materials Handling: Know whether you’ll be machining metals like titanium or softer materials like plastics.

- Operational Constraints: Evaluate the workspace where the lathe will be installed to ensure it fits the physical dimensions and power requirements.

Step 2: Conduct Market Research

Understanding the market landscape is vital for locating affordable options. Investigate various manufacturers and models, focusing on those acclaimed for performance and reliability. Pay attention to market reviews and case studies that showcase real-world performance in similar applications.

- Key Players: Research well-known manufacturers such as Tormach, Haas, and Mazak, and compare their offerings.

- User Experiences: Seek feedback from current users in regions similar to yours, such as Africa or South America, to understand usability and support.

Step 3: Evaluate Potential Suppliers

Before finalizing any decisions, thoroughly vet potential suppliers. Request detailed company profiles to gauge their experience and reliability in the CNC industry. References from other businesses, especially those within your sector, can provide deep insights into the supplier’s performance.

- Documentation: Ask for case studies and testimonials that showcase projects relevant to your operational needs.

- Support Structure: Investigate the supplier’s customer support options, including warranty terms and available maintenance services.

Step 4: Verify Certifications and Compliance

Ensure the lathe complies with international standards and certifications relevant to your region. This adherence not only guarantees quality but also ensures safety and reliability in operations.

- Safety Standards: Look for certifications like CE, ISO, or local equivalents that verify the machine meets safety and environmental standards.

- Supplier Certification: Confirm that the supplier holds relevant quality assurance certifications, indicating their commitment to excellence.

Step 5: Request Comprehensive Quotes

When you’ve narrowed down your options, request quotes from multiple suppliers to compare not just pricing, but also included features and services. Look for any hidden costs such as shipping, installation, or software licensing that could affect your overall budget.

- Package Breakdown: Ensure the quote details what’s included with the purchase—accessories, training, and after-sales support.

- Payment Terms: Clarify payment options and whether financing solutions are available to ease your cash flow.

Step 6: Assess After-Sales Support and Training

After purchasing, the availability of support and training can significantly impact how well you utilize the CNC lathe. Inquire whether the supplier offers training for your operators and what customer service channels are available post-purchase.

- Training Programs: Confirm if hands-on or online training is included in the purchase.

- Technical Support: Check the supplier’s response time for troubleshooting and support queries.

Step 7: Finalize the Purchase with Due Diligence

Once you’ve evaluated all aspects, finalize your purchase by double-checking all agreements and terms before signing. Ensure you have a clear understanding of the machine’s warranty conditions and any return policies.

- Legal Review: If possible, have a legal advisor review contracts to safeguard your interests.

- Document Everything: Keep records of all communications and agreements for future reference to mitigate any disputes.

By following these structured steps, you can confidently source a CNC lathe that balances affordability with operational efficiency, aligning with your specific business requirements.

Comprehensive Cost and Pricing Analysis for cheap cnc lathe Sourcing

What Are the Key Cost Components for Sourcing Cheap CNC Lathes?

When considering the acquisition of inexpensive CNC lathes, understanding the underlying cost structure is essential for B2B buyers. The costs associated with CNC lathes typically encompass several components:

-

Materials: The raw materials for manufacturing CNC lathes include steel, aluminum, and various electronics. The choice of material directly influences the durability and operational efficiency of the lathe. Higher-quality materials usually result in a price premium.

-

Labor: Manufacturing CNC lathes requires skilled labor for assembly and quality control. The labor costs can vary significantly based on geographical location. Countries in regions like Europe may have higher labor costs compared to those in Asia or South America.

-

Manufacturing Overhead: This includes costs associated with running the factory such as utilities, depreciation of machinery, and administrative expenses. These overheads are generally factored into the product price and can vary depending on the manufacturer’s operational efficiency.

-

Tooling and QC (Quality Control): Tooling costs refer to the equipment needed to manufacture the various parts of the CNC lathe. Additionally, implementing a stringent QC process ensures that the machines produced meet industry standards, which can increase the overall cost.

-

Logistics: Transportation costs for shipping CNC lathes can be influenced by package size, weight, and the distance from the manufacturer to the buyer. Logistics options—from air freight to sea freight—vary widely in cost and delivery timelines.

-

Margin: Suppliers typically add a margin to cover their expenses and profit, which can significantly influence the pricing structure. This margin is often affected by competitive pressures and market demand.

What Factors Influence Pricing for Cheap CNC Lathes?

Several factors play a critical role in determining the pricing of CNC lathes, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk often leads to substantial discounts. Buyers should aim for a clear understanding of MOQ terms to maximize their cost efficiency.

-

Specifications and Customization: Custom-built solutions can lead to increased costs. Understanding the balance between standard options and customized features allows buyers to optimize their investment according to specific needs.

-

Quality and Certifications: Machines that meet international quality standards require rigorous testing and certification, often resulting in higher prices. Certifications such as ISO can be crucial for buyers seeking reliable machinery.

-

Supplier Factors: Supplier reputation, relationship history, and reliability can significantly influence negotiations. Established suppliers may offer better warranties, customer support, and after-sales services, justifying higher initial costs.

-

Incoterms: Understanding Incoterms (International Commercial Terms) can help buyers navigate additional costs like customs duties, insurance, and shipping. This knowledge is essential for calculating the total cost of ownership.

What Buyer Tips Can Help in Sourcing CNC Lathes Effectively?

-

Negotiation: Buyers should be prepared to negotiate prices and terms. Excellent negotiation can lead to lower prices or enhanced service offerings, such as extended warranties or maintenance packages.

-

Exploring Total Cost of Ownership (TCO): Evaluating TCO beyond the initial purchase price is vital. Consider ongoing costs such as maintenance, tooling, and operational efficiency. Lower initial costs may not always correlate with lower long-term expenses.

-

Understanding Pricing Nuances for International Buyers: Buyers from regions like Africa or South America should be vigilant about additional costs, including tariffs and taxes. Engaging with local distributors or agents who understand regional challenges can enhance procurement success.

-

Conduct Thorough Market Research: Knowledge of market trends, competitor pricing, and supplier offerings is indispensable. Staying informed can provide leverage during negotiations and help buyers secure better deals.

Disclaimer on Indicative Prices

Prices for CNC lathes fluctuate based on market conditions, currency fluctuations, and supplier pricing structures. The figures indicated in various sources may serve as guidelines, but actual quotations may differ significantly. It is vital for buyers to obtain updated quotes directly from suppliers to ensure accurate budgeting during the sourcing process.

Alternatives Analysis: Comparing cheap cnc lathe With Other Solutions

Understanding Alternatives to Cheap CNC Lathes for Precision Manufacturing

When considering the purchase of a cheap CNC lathe, it is essential to understand various alternatives that fulfill similar manufacturing needs. These alternatives can provide options that cater to distinct requirements such as budget constraints, production capacity, space considerations, and material compatibility.

Comparison Table of Manufacturing Solutions

| Comparison Aspect | Cheap CNC Lathe | Vertical Machining Center (VMC) | Manual Lathe |

|---|---|---|---|

| Performance | Moderate, capable of light production | High precision, suitable for complex parts | Limited, depends on operator skill |

| Cost | Starting at $12,473 | $25,000 – $100,000+ | $1,000 – $10,000 |

| Ease of Implementation | Generally user-friendly | Requires skilled operation and programming | Simple but labor-intensive |

| Maintenance | Low; user-serviceable | Moderate, professional service needed | High, requires regular tuning |

| Best Use Case | Prototyping and small batch production | Large-scale production & complex geometries | Hobbyists/DIY projects |

Analyzing the Alternatives in Detail

Vertical Machining Center (VMC)

Vertical machining centers represent a step up in terms of manufacturing capabilities. They allow for high-precision operations and are equipped to handle complex geometric shapes. While the initial investment is significantly higher than a cheap CNC lathe, VMCs deliver consistent output for large-scale production. However, they generally require skilled operators familiar with programming and machine setup. Maintenance costs are also a concern, as these machines may necessitate professional servicing to ensure optimal performance.

Manual Lathe

For small shops or those with budget limitations, manual lathes remain a popular choice. Their low entry cost, ranging from $1,000 to $10,000, makes them accessible for hobbyists or small-scale operators. However, the performance largely depends on the operator’s skill, which can lead to inconsistent results. Additionally, manual lathes require regular maintenance and frequent tuning to keep the machinery working effectively. This solution is best suited for simple tasks or educational environments where operators can build foundational machining skills.

Making the Right Choice for Your Manufacturing Needs

Choosing the right solution—whether a cheap CNC lathe, VMC, or manual lathe—depends on several factors, including production volume, material types, budget, and operator skill levels. B2B buyers must assess their specific operational requirements and future growth potential. A cheap CNC lathe may be ideal for smaller firms engaging in prototyping or limited production runs, while larger manufacturers with demands for precision might find greater utility in a vertical machining center. In contrast, manual lathes could appeal to businesses looking to minimize initial costs and focus on simplicity, albeit at the cost of speed and accuracy.

Investing in the right equipment will ultimately enhance the efficiency of manufacturing processes and contribute positively to overall business success.

Essential Technical Properties and Trade Terminology for cheap cnc lathe

Understanding the technical specifications and terminology associated with CNC lathes is crucial for international B2B buyers, especially those in emerging markets like Africa, South America, the Middle East, and Europe. Here are some essential properties and trade terms that will facilitate informed purchasing decisions.

What Are the Key Technical Specifications for a Affordable CNC Lathe?

-

Spindle Speed (RPM)

The spindle speed indicates how fast the lathe spins its workpiece and is usually measured in revolutions per minute (RPM). Higher spindle speeds can improve efficiency and the range of materials processed. For instance, a lathe capable of speeds between 180 to 5,000 RPM offers versatility for both softer materials (like plastics) and harder materials (like titanium). -

Power Requirements

Understanding the power requirements of a CNC lathe is critical for operational efficiency and compatibility with local infrastructure. Most affordable CNC lathes operate on single-phase power, typically at 115 Vac. This energy requirement ensures that even small workshops can utilize these machines without the need for complex electrical setups. -

Maximum Swing Over Bed

This specification denotes the maximum diameter of the workpiece that can be rotated in the lathe. A common measurement might be around 8 inches (200 mm). Adequate swinging capacity is vital for accommodating diverse project sizes, making the lathe suitable for various applications, from prototyping to small-scale manufacturing. -

Travel Specifications (X and Z Axis)

The travel range on the X-axis (often linear movement across the width) and Z-axis (linear movement along the length of the machine) indicates the lathe’s operational capability. For example, an X-axis travel of 4.5 inches and a Z-axis travel of 10 inches is beneficial when working on longer components. -

Feed Rate

This parameter tells you how quickly the cutting tool moves during operation, usually measured in inches per minute (IPM). A maximum feed rate of around 150 IPM allows for enhanced productivity, particularly in processes requiring extensive material removal. -

Tooling System

The tooling system, often described in terms like “quick change tool post,” is crucial for efficiency in switching tools during production. An efficient tooling system minimizes downtime and enhances flexibility for various machining tasks, an important consideration for budget-conscious operations.

Which Common Trade Terms Are Important When Purchasing a CNC Lathe?

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that may be marketed by another company. Understanding OEM relationships can help buyers identify genuine parts and service quality, ensuring better support for machines like CNC lathes. -

MOQ (Minimum Order Quantity)

MOQ specifies the smallest quantity a supplier is willing to sell. This term is vital for buyers looking to manage costs effectively while ensuring they have sufficient machines or repairs available without overcommitting financially. -

RFQ (Request for Quotation)

Buyers employ RFQs to solicit price proposals from suppliers. An RFQ includes details about required specifications and quantities, allowing for comparative analysis across multiple offers, which is essential for making informed investment decisions. -

Incoterms

International Commercial Terms (Incoterms) outline the responsibilities and risks involved in international shipments. Understanding these terms helps B2B buyers comprehend their obligations regarding shipping costs and liability, which can significantly impact total machine costs. -

Lead Time

This refers to the time between placing an order and receiving the product. Knowledge of lead times is crucial for planning production schedules, particularly for industries requiring a rapid response to market demands. -

Tolerancing

Tolerancing describes the allowable deviation from a specified dimension in machining. High tolerance levels ensure that produced parts meet quality standards, a key aspect for industries where precision is non-negotiable.

By familiarizing themselves with these specifications and terms, international B2B buyers can better navigate their purchasing journeys, making informed choices that align with both operational needs and budget considerations. Understanding these fundamentals not only aids in identifying the right CNC lathe but also enhances communication with suppliers and manufacturers, fostering seamless transactions in a competitive global landscape.

Navigating Market Dynamics and Sourcing Trends in the cheap cnc lathe Sector

Market Overview & Key Trends in the Cheap CNC Lathe Sector

The global cheap CNC lathe market is witnessing substantial growth, driven by several interrelated factors. Notably, the surge in the manufacturing sector, particularly in emerging markets such as Nigeria, Brazil, and Middle Eastern countries, is propelling increased demand for cost-effective and versatile machining solutions. As industries adopt automation to enhance productivity, the integration of cutting-edge technologies—like CAD and CAM systems—has become essential. This is particularly true among small to medium-sized enterprises (SMEs) that rely on compact and affordable CNC lathes for diverse applications, including prototyping and light production.

Emerging trends also indicate a shift toward smarter manufacturing processes. Digitization and the Internet of Things (IoT) are being increasingly incorporated into manufacturing strategies, enabling real-time monitoring and data collection. This can lead to more efficient operations and minimized downtime, attracting international buyers looking to optimize their production capabilities. In regions like Africa and South America, where traditional manufacturing practices are rapidly evolving, cheap CNC lathes with robust automation features are becoming fundamental.

Additionally, the focus on sustainability is influencing buyer preferences. As global competition intensifies, businesses are increasingly looking for CNC solutions that not only enhance efficiency but also contribute to environmental goals. This creates an opportunity for suppliers who can offer products that align with sustainable practices and demonstrate tangible benefits.

How is Sustainability & Ethical Sourcing Integrated into the Cheap CNC Lathe Market?

Sustainability and ethical sourcing are becoming critical considerations for B2B buyers in the cheap CNC lathe sector. As manufacturers face mounting pressure to reduce their environmental footprint, they seek CNC lathes made with sustainable materials and designed to enhance energy efficiency. The environmental impact of manufacturing processes has grown increasingly apparent, influencing end-users to opt for machines that utilize less energy, generate less waste, and feature recyclable components.

Moreover, buyers are prioritizing supply chains with ethical practices. Transparency in sourcing is essential, as companies aim to mitigate risks associated with unethical labor practices and environmental degradation. Obtaining ‘green’ certifications such as ISO 14001 can significantly enhance a manufacturer’s appeal, providing assurance to prospective buyers about their commitment to environmental standards.

In the context of cheap CNC lathes, international suppliers that prioritize sustainable materials and practices not only strengthen their brand reputation but also resonate with the growing number of buyers in regions like Europe and Africa, where ethical sourcing is increasingly prioritized. Introducing innovations like eco-friendly lubricants and energy-efficient systems can further align products with the values of conscientious buyers.

What is the Brief Evolution of the Cheap CNC Lathe Market?

The evolution of the cheap CNC lathe market can be traced back to the early days of manufacturing automation. Originally, conventional lathes dominated the industry, relying heavily on manual operations. The advent of CNC technology in the late 20th century transformed the landscape, offering precision and efficiency unattainable with earlier methods. As costs began to decrease, affordable CNC lathes became accessible to smaller enterprises, democratizing access to advanced machining technologies.

The introduction of compact designs and user-friendly interfaces has further broadened the appeal of the cheap CNC lathe market. Today, machines like the Tormach 8L CNC Lathe exemplify this progress, catering to specialized needs in tight spaces with the ability to work on diverse materials. The continued advancement of integrated software solutions and enhanced capabilities will undoubtedly shape the next generation of affordable CNC lathes, making them an invaluable asset for international buyers looking to innovate within their sectors.

Frequently Asked Questions (FAQs) for B2B Buyers of cheap cnc lathe

-

How can I determine the right CNC lathe for my production needs?

To choose the right CNC lathe, assess your production requirements, including material types, part dimensions, and production volume. Consider factors like spindle speed, horsepower, and axis capabilities. Evaluate whether you need features like rigid tapping and conversational programming for ease of use. It’s advisable to consult with suppliers to discuss your specific needs; many will offer tailored recommendations based on your application. -

What are the key specifications to look for in a cheap CNC lathe?

When evaluating cheap CNC lathes, prioritize key specifications such as spindle speed range, motor power, and axis travel distances. The control system, tooling compatibility, and ease of programming are essential for operation efficiency. Look for additional features like increased memory capacity for G-code and support for various materials. Reviews and warranty options can also guide your choice, ensuring reliability for your investment. -

What should I consider when vetting CNC lathe suppliers for international trade?

Verify supplier credentials by checking for certifications and industry experience. Look into customer feedback and case studies to assess their product quality and service reliability. Evaluate their production capabilities, lead times, and after-sales support. Additionally, inquire about compliance with international trade regulations and shipping policies, especially regarding tariffs and customs documentation, to ensure a smooth buying experience. -

What payment terms can I expect when purchasing a CNC lathe internationally?

Payment terms can vary widely among suppliers. Common payment options include upfront payments, letter of credit, or staggered payments based on milestones. Ensure to discuss payment methods, including currency options that mitigate exchange rate risks. It’s best to have clear agreements regarding the timeline and conditions of payments, as well as any penalties for late payments included in your purchase contract. -

What are the Minimum Order Quantities (MOQ) for CNC lathes?

Most suppliers of cheap CNC lathes have different MOQs. It’s common for manufacturers to set a MOQ based on production costs and shipping efficiencies. If you’re not purchasing large quantities, inquire about options for single-unit purchases or negotiate for lower MOQs. Some manufacturers may offer flexible arrangements for smaller businesses in emerging markets, so don’t hesitate to explore available options. -

How does customization affect the cost of a CNC lathe?

Customization can significantly impact the cost of a CNC lathe. Specific modifications—like additional tooling, tailored programming features, or unique size adjustments—often come with extra charges. However, investing in a customized lathe may enhance productivity and operational efficiency in the long term. Discuss customization options with your supplier, ensuring that the potential cost increases are balanced against long-term benefits. -

What quality assurance measures should I expect for cheap CNC lathes?

Reputable suppliers should provide a robust quality assurance process that includes inspections at various manufacturing stages. Look for documents like inspection certificates or compliance with international quality standards (like ISO). Warranties or service agreements can also indicate a supplier’s confidence in their product quality. Don’t hesitate to ask for detailed QA protocols before completing your purchase to ensure the lathe meets industry standards. -

How can I manage logistics and delivery for international purchases of CNC lathes?

Effective logistics management is crucial when purchasing CNC lathes internationally. Confirm with your supplier about their shipping methods, delivery timelines, and whether they handle customs clearance. Use a reliable freight forwarder to facilitate shipping and delivery, and ensure they are familiar with the import regulations in your country. Plan for potential delays by factoring in local customs processing times and be prepared for import duties that may arise.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Cheap Cnc Lathe Manufacturers & Suppliers List

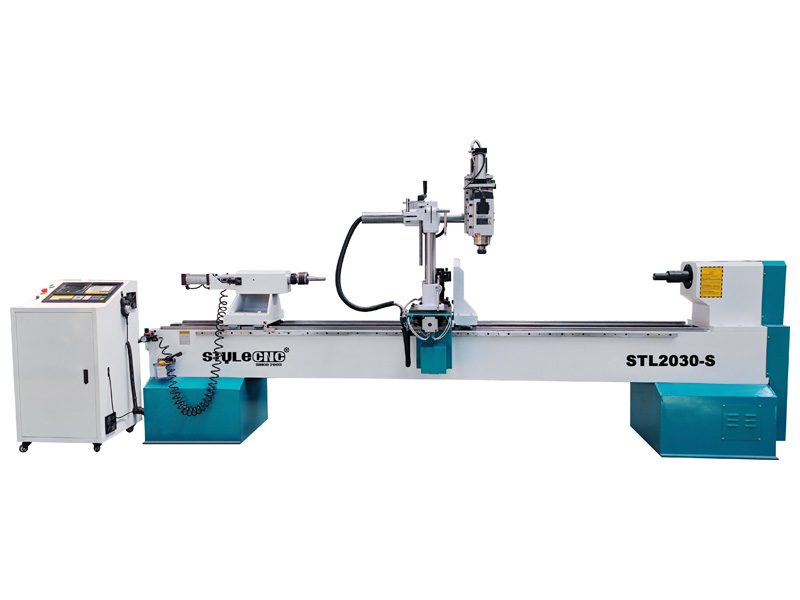

1. Tormach – 8L CNC Lathe

Domain: tormach.com

Registered: 2002 (23 years)

Introduction: {“Product Name”: “8L CNC Lathe”, “Price”: “$12,473”, “Financing Options”: “Payments as low as $264/mo.”, “Capabilities”: “Cuts materials like titanium, stainless steel, hardened steel, plastic, and wood.”, “Power Requirements”: “Single-Phase 115 Vac, 50/60 Hz, 15A breaker”, “Dimensions”: {“Machine Footprint”: “50 in. x 26 in. (1.2m x .7m)”, “Overall Height”: “52 in. (1.3 m)”, “Typical Weight”: “83…

2. Haas – TL-1

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Looking for recommendations for affordable, entry-level industrial CNC lathes suitable for producing small metal parts (0.2-30 mm) for customizing pens. Discussions mention the Haas TL-1 and Tormach’s small CNC lathe, with advice to consider used industrial machines for better cost-to-quality ratio. Some users advocate for Swiss lathes for tiny parts.

3. CNC Lathes – Various Models for Sale

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: CNC lathes for sale on eBay, including various models and types such as: Hardinge CHNC III CNC Lathe, 36” Bullard Vertical Turret Lathe, Nakamura-Tome TMC-15 CNC Turning Center, 2012 Haas ST-20T CNC Lathe, and Mori Seiki SL-25 CNC Lathe. Price ranges from under $7,260 to over $15,800. Options for new and used machines available. Brands include Bolton, Daewoo, DMG MORI, Doosan, Emco, FANUC, Haas, H…

4. CNC Machines – Lathe Overview

Domain: cncmachines.com

Registered: 1997 (28 years)

Introduction: CNC Lathe information includes:

1. **Year**: Newest – Oldest.

2. **Description**: CNC lathes automate and speed up manual lathe processes, controlled by machine tool paths and programmed via CAD languages.

3. **Manufacturers**: Includes Haas, Mazak, DMG Mori, Doosan, Johnford.

4. **Types/Models Available**:

– Haas Lathe

– Mazak Lathe

– DMG Mori Lathe

– Doosan Lathe

– Swiss Lathe

…

5. Hardinge – CHNC CNC Lathe

Domain: practicalmachinist.com

Registered: 2000 (25 years)

Introduction: Best Budget CNC Lathe Recommendations:

1. Hardinge CHNC:

– Retrofitted with Fanuc 21i-T control (1999)

– Price: £5,000 (including delivery and site setup, excluding VAT)

– Weight: 1250 kg

– Known for limited capacities and potential maintenance issues, but repairs can be cheap.

– Not advised due to lack of part support from Hardinge.

2. Emco Turn 325:

– Fanuc 21TB contro…

6. Mazak – Used CNC Lathes for Sale

Domain: resellcnc.com

Registered: 2008 (17 years)

Introduction: Used CNC Lathes available for sale and auction, including a wide range of brands and sizes. Specializing in used Mazak lathes and Haas machines. Inventory includes 288 products from various brands like DN Solutions, Hwacheon, Star, Doosan, Okuma, and more. Key product features include various CNC lathe types, with options for bar feeds, live tooling, B/C-Axis, sub-spindles, and multitasking capabi…

Strategic Sourcing Conclusion and Outlook for cheap cnc lathe

The strategic sourcing of affordable CNC lathes presents a significant opportunity for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. Essential considerations involve identifying machines that merge cost-effectiveness with robust technical capabilities, such as the ability to handle various materials and an intuitive operating interface.

Investing in a low-cost CNC lathe not only streamlines production processes but also enhances the precision and versatility of manufacturing operations. For international buyers, ensuring suppliers provide transparent pricing and comprehensive maintenance support is vital, as these factors influence long-term cost-efficiency and operational reliability.

Looking ahead, the market for cheap CNC lathes is poised for growth, driven by advancements in technology and expanding manufacturing needs. Now is the opportune moment to engage with reputable suppliers, evaluate available options, and leverage innovative features that enhance productivity. As you consider your next investment, prioritize establishing partnerships that can support your operational goals while ensuring that your company stays competitive in an increasingly dynamic marketplace. Explore your options today and empower your business for a successful future.