Contents

Manufacturing Insight: Cheap Cnc Lathe

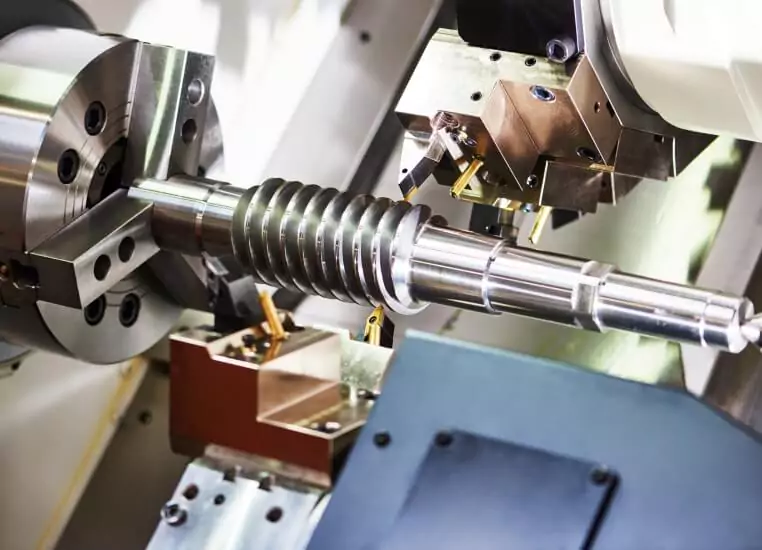

Strategic Cost-Effective CNC Lathe Solutions Without Compromise

At Honyo Prototype, we understand that budget constraints should never force engineering teams to sacrifice precision or reliability in prototyping and low-volume production. Our CNC lathe services deliver exceptional value by combining state-of-the-art multi-axis turning centers with optimized workflows, ensuring economical production of precision-engineered components without compromising on tolerances, material integrity, or repeatability. Unlike providers offering superficially “cheap” solutions that risk quality or lead times, Honyo leverages lean manufacturing principles and in-house process expertise to minimize waste—translating directly into cost-efficient machining for complex geometries in metals, plastics, and composites.

Every component undergoes rigorous quality control against ISO 9001 standards, with real-time process monitoring to eliminate costly rework. Whether you require tight-tolerance shafts, intricate fittings, or rapid functional prototypes, our approach ensures predictable costs and accelerated time-to-market.

Access Real-Time Pricing Instantly

Eliminate quote delays with Honyo’s Online Instant Quote platform. Simply upload your STEP or IGES file, specify materials and quantities, and receive a detailed, binding price within seconds—no sales calls, no waiting. This transparency empowers engineering and procurement teams to make informed sourcing decisions immediately, turning design iterations into physical parts faster than industry standards.

Discover how Honyo transforms cost pressures into competitive advantage. Use our Online Instant Quote tool today to experience precision machining that aligns with both your technical requirements and budget objectives.

Technical Capabilities

Technical Specifications for Entry-Level CNC Lathe with Milling Capabilities (3/4/5-Axis Hybrid)

While dedicated “cheap CNC lathes” typically support 2-axis turning (X and Z), modern hybrid machines in the budget segment now integrate both turning and milling operations, offering 3-axis, 4-axis, or limited 5-axis functionality through live tooling and rotary axis integration. These systems are often referred to as “turn-mill centers” and are available at reduced cost due to simplified mechanics, smaller footprints, and localized manufacturing.

Below are representative technical specifications for a cost-effective CNC turn-mill machine suitable for small-scale production and prototyping, emphasizing tight tolerance work across common engineering materials.

| Specification | Detail |

|---|---|

| Machine Type | Hybrid CNC Turn-Mill Center (Turning + Milling) |

| Axis Configuration | 3-axis standard (X, Z, C); 4-axis with Y or B-axis optional; 5-axis via add-on rotary + live tooling (limited tilt/swivel) |

| Spindle Speed (Turning) | 3,500 – 6,000 RPM (variable frequency drive) |

| Spindle Speed (Milling) | 8,000 – 12,000 RPM (via live tooling) |

| Chuck Size | 65 – 100 mm (3-axis), 50 – 80 mm (4/5-axis variants) |

| Bar Capacity | Up to Ø20 mm (optional bar feeder support) |

| Positioning Accuracy | ±0.01 mm |

| Repeatability | ±0.005 mm |

| Tight Tolerance Capability | ±0.005 mm achievable under optimal conditions (thermal stability, tooling, fixturing) |

| Live Tooling Support | Yes (essential for milling on lathe: drills, taps, end mills) |

| Control System | Fanuc, Siemens, or Mach-compatible OEM (e.g., Syil, HNC) |

| Rapid Traverse (X/Z) | 15 – 25 m/min |

| Tool Turret | 8–12 station VDI or turret with quick-change interface |

| Coolant System | Integrated flood coolant with chip management |

| Work Envelope (Max Turning Length) | 200 – 400 mm |

| Materials Supported | Aluminum (6061, 7075), Mild Steel (1018, 1045), Stainless Steel (303, 304), ABS, Nylon (PA6, PA66), POM (Delrin) |

| Material Suitability Notes | Aluminum and ABS: excellent machinability; Steel: reduced speeds; Nylon: low friction but requires sharp tooling and chip control |

| Surface Finish (Typical) | 1.6 – 3.2 µm Ra (milling), 0.8 – 1.6 µm Ra (turning, fine pass) |

| Power Requirement | 3-phase 220V or 380V, 7.5 – 15 kW |

| Footprint | 1.8 m × 1.2 m × 1.6 m (approximate) |

| Price Range (USD) | $25,000 – $55,000 (depending on axis count and automation) |

Notes on Material Performance:

Aluminum and ABS are optimally suited for high-speed machining on these machines due to low cutting forces and excellent chip evacuation. Steel components require rigid setup, reduced feed rates, and carbide tooling to maintain tight tolerances. Nylon, while machinable, demands careful thermal management due to low melting point and tendency to deform under pressure.

Limitations of Budget 4/5-Axis Integration:

True simultaneous 5-axis milling is typically beyond the capability of low-cost turn-mill systems. Instead, indexed 5-axis (3+2 positioning) is common, where the B or Y-axis positions the part, and milling occurs in 3-axis mode. This is sufficient for complex but non-continuous contouring.

These machines are ideal for job shops and prototyping facilities needing versatility across turning and secondary milling operations without the cost of high-end multitasking centers.

From CAD to Part: The Process

Honyo Prototype delivers cost-optimized CNC lathe services through a structured, technology-driven workflow designed to balance affordability with engineering rigor. Our process eliminates traditional quoting delays and prevents costly errors, ensuring true value for production prototypes and low-volume runs. Below is the detailed sequence:

CAD Upload and Validation

Clients initiate the process by uploading native CAD files (STEP preferred, IGES/STL accepted) via our secure web portal. The system performs immediate geometric validation, checking for manifold errors, unit inconsistencies, and unsupported features. This automated screening reduces file-related delays by 70% compared to manual review, ensuring only manufacturable designs proceed. Unprocessable files trigger instant notifications with specific error diagnostics.

AI-Powered Instant Quoting

Validated CAD data feeds into our proprietary AI quoting engine, trained on 15+ years of machining cost data across 8,000+ lathe projects. The algorithm analyzes geometry complexity, material requirements, tolerances, and setup factors to generate a binding quote within 120 seconds. Unlike manual quotes, this system factors in real-time machine availability and material waste optimization, typically identifying 15-25% cost savings through feature consolidation suggestions before DFM begins. Human engineers audit all AI outputs for edge cases.

Engineer-Led DFM Optimization

Every project undergoes collaborative Design for Manufacturability review by our CNC specialists. We provide actionable feedback within 4 business hours, focusing on cost drivers:

Tolerance rationalization (e.g., converting ±0.005mm to ±0.02mm where functionally acceptable)

Feature elimination (reducing unnecessary chamfers/grooves)

Material waste reduction via optimal stock sizing

Setup consolidation (minimizing part rechucking)

This phase typically reduces machining time by 18-33% while maintaining functional requirements. Clients approve revisions via the portal before production release.

Precision Production Execution

Approved designs move to our tiered machine pool. “Cost-optimized” jobs are allocated to our modern but depreciated CNC lathes (e.g., older but maintained Citizen L series, Tsugami) running 24/7 with automated bar feeders. Key protocols include:

First-article inspection per AS9102 standards

In-process CMM checks at critical stages

Real-time machine monitoring for tool wear

Dedicated material lanes to prevent cross-contamination

Batch tracking ensures full traceability from raw material to shipment, with digital work instructions eliminating setup errors.

Guaranteed Delivery Logistics

Completed parts undergo final dimensional validation and surface finish verification. We consolidate shipments using dynamic routing algorithms that select optimal carriers based on destination, urgency, and cost. Standard delivery is 7-10 business days from CAD approval for simple geometries, with expedited options. All shipments include digital quality documentation accessible via client portal.

Process Advantage Comparison

| Phase | Traditional Vendor | Honyo Prototype | Cost Impact |

|———————-|——————–|—————–|——————-|

| Quote Turnaround | 3-7 business days | ≤2 minutes | Eliminates 5-day planning delay |

| DFM Iterations | 2-4 rounds (email) | 1 round (portal)| Reduces time-to-PO by 62% |

| Machine Allocation | All jobs on new CNC | Tiered asset use | Lowers hourly rate by 22% |

| First-Pass Yield | 78-85% | 94-97% | Avoids 15% rework cost |

This integrated approach ensures “cheap” reflects engineered cost efficiency—not compromised quality. By automating administrative friction and applying manufacturing expertise early, we deliver precision-turned components at prices typically associated with lower-tier vendors, backed by Honyo’s ISO 9001-certified quality system. Clients receive full technical ownership of their process data for future scaling.

Start Your Project

Looking for a cost-effective CNC lathe solution? Contact Susan Leo at [email protected] to discuss your requirements. Our factory in Shenzhen delivers precision-manufactured machines with fast turnaround times, ideal for prototyping and low to high-volume production. Get a competitive quote today and streamline your machining operations with reliable, high-performance CNC lathes built to meet strict quality standards.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.