Contents

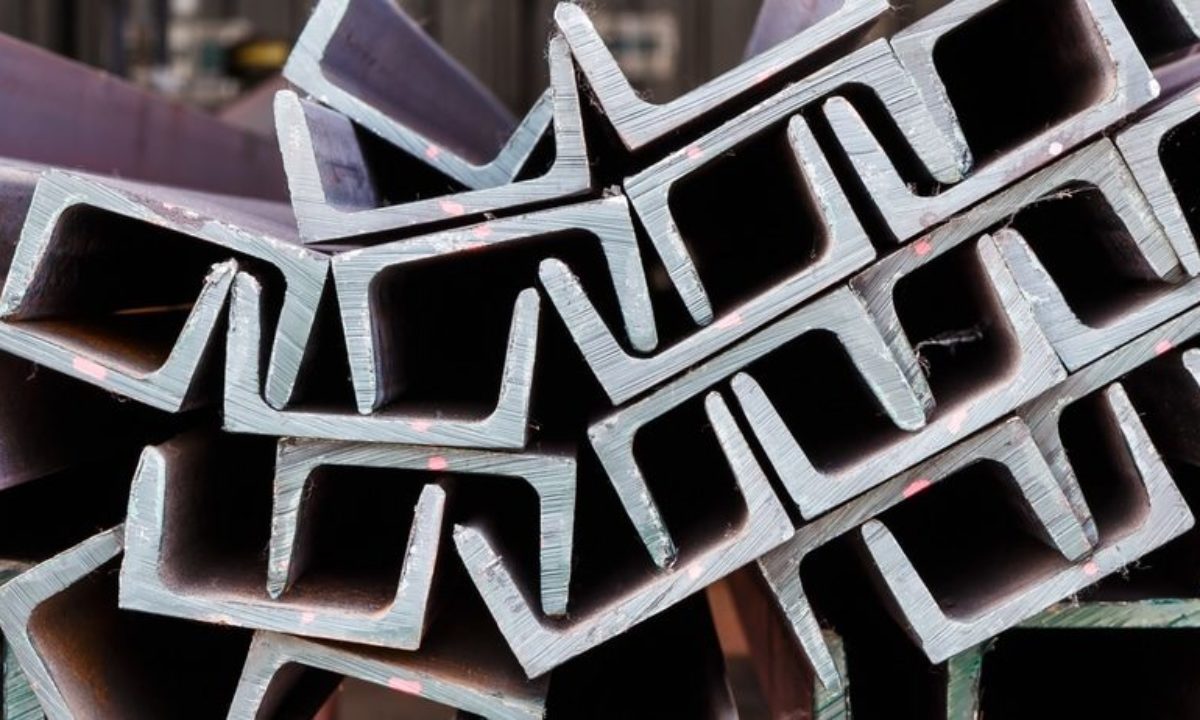

Manufacturing Insight: Channels Steel

Precision CNC Machining for Structural Steel Channels

Honyo Prototype delivers advanced CNC machining solutions specifically engineered for structural steel channels, including C-channels, U-channels, and custom profiles. Our ISO-certified facility leverages state-of-the-art 3-, 4-, and 5-axis milling and turning centers to achieve tight tolerances (±0.005mm) and superior surface finishes on materials ranging from mild steel to hardened alloys. We address critical challenges in channel fabrication—such as flange warpage, inconsistent web thickness, and complex end-machining requirements—through optimized toolpaths, rigid fixturing, and real-time process monitoring.

Our end-to-end capabilities encompass precision cutting, drilling, tapping, countersinking, and secondary operations like deburring and chamfering, ensuring channels meet exact dimensional and functional specifications for aerospace, construction, and industrial machinery applications. Unlike conventional fabricators, Honyo integrates material science expertise with CNC precision to minimize waste, eliminate secondary rework, and accelerate time-to-assembly for high-integrity structural components.

Accelerate your prototyping or production timeline with Honyo’s Online Instant Quote system. Upload CAD files (STEP, IGES, DWG) for automated DFM analysis and receive a detailed, binding quote in under 2 hours—no manual back-and-forth or delays. This seamless digital workflow ensures rapid validation of manufacturability while providing transparent cost and lead-time visibility from day one. Partner with Honyo to transform structural steel channel requirements into precision-engineered realities, backed by engineering support and on-time delivery.

Technical Capabilities

Technical Specifications for Channel Steel in Precision Machining Applications

Channel steel, commonly referred to as C-channel or structural channel, is a hot-rolled or cold-formed steel profile with a C-shaped cross-section. While traditionally used in construction and structural applications, precision-machined channel steel components are increasingly utilized in industrial fixtures, enclosures, and mechanical systems requiring high rigidity and dimensional accuracy. When machined using 3/4/5-axis milling and turning processes, channel steel can achieve tight tolerances suitable for high-performance applications.

Below are the technical considerations and capabilities for machining channel steel and similar materials (including Aluminum, Steel, ABS, and Nylon) with an emphasis on multi-axis CNC operations and tight tolerance requirements.

| Parameter | Aluminum (6061-T6) | Steel (A36 / 4140) | ABS (Acrylonitrile Butadiene Styrene) | Nylon (PA6 / PA66) |

|---|---|---|---|---|

| Machinability | Excellent – low cutting forces, high MRR | Moderate (A36), Good with annealing (4140) | Excellent – low tool wear, smooth finish | Good – slight stickiness, requires sharp tools |

| Typical Tolerance (Milling) | ±0.005 mm (±0.0002″) | ±0.010 mm (±0.0004″) | ±0.025 mm (±0.001″) | ±0.025 mm (±0.001″) |

| Tight Tolerance Capability | Up to ±0.0025 mm (±0.0001″) with thermal control | Up to ±0.005 mm (±0.0002″) with process stability | ±0.012 mm (±0.0005″) with moisture control | ±0.012 mm (±0.0005″) with fixturing control |

| Surface Finish (Milling) | 0.8–1.6 μm Ra | 1.6–3.2 μm Ra | 0.8–2.0 μm Ra | 1.6–3.2 μm Ra |

| Tooling Requirements | Carbide end mills, high rake angles | Carbide or HSS with coolant, lower speeds | Standard carbide, high-speed cutting | Carbide, sharp cutting edges, low adhesion coatings |

| 3-Axis Milling Suitability | High – ideal for complex cavities and profiles | High – robust for structural components | High – excellent for prototypes and housings | Medium – requires dimensional stability management |

| 4-Axis Milling Suitability | High – indexing for flanges and holes | High – used for rotational symmetry features | Medium – limited by material stability | Medium – fixturing challenges due to creep |

| 5-Axis Milling Suitability | Excellent – for complex, integrated channel systems | Good – for high-strength, precision parts | Limited – not typically required for ABS | Limited – used only in high-precision wear components |

| Turning Capability | Excellent – for round pins, shafts, inserts | Good – for threaded rods, bushings | Fair – rarely turned, used for bushings | Fair – used for wear sleeves and bushings |

| Thermal Sensitivity | Moderate – thermal expansion affects tight tolerances | Low – stable under thermal variation | High – prone to warping and expansion | High – hygroscopic, absorbs moisture |

| Fixturing Considerations | Soft jaws recommended to avoid deformation | Standard clamping, high rigidity | Vacuum or soft clamping to prevent stress | Semi-rigid fixturing to avoid creep deformation |

Notes on Application in Multi-Axis Machining:

For tight tolerance machining of channel steel and alternative materials, Honyo Prototype employs advanced 5-axis CNC centers with thermal compensation and in-process probing. Aluminum channels are frequently machined for aerospace and automation frames due to their strength-to-weight ratio. Steel channels (especially 4140) are chosen for high-load applications requiring tight geometric control. ABS and Nylon channels are typically used in non-structural, high-complexity enclosures or insulating components where electrical isolation or corrosion resistance is critical.

Material selection must account for environmental exposure, mechanical load, and dimensional stability. All materials are subject to post-process inspection using CMM and optical measurement systems to ensure conformance to GD&T specifications.

From CAD to Part: The Process

Honyo Prototype applies a standardized, rigorously controlled workflow for all sheet metal fabrication projects including structural steel channels. This process ensures precision, cost efficiency, and adherence to engineering specifications from initial design to final shipment. The workflow is not unique to channels steel but is optimized for its geometric and material properties.

CAD Upload

Clients initiate the process by uploading native or neutral-format CAD files (STEP, IGES, DWG) through our secure customer portal. For steel channels, we specifically require fully dimensioned 3D models showing critical features such as flange widths, leg lengths, bend radii, and hole patterns. Incomplete geometries or ambiguous tolerances trigger immediate client notification to prevent downstream rework.

AI-Assisted Quoting

Our proprietary AI engine analyzes the CAD geometry against real-time material costs, machine capabilities, and historical production data. For structural channels, the system factors in steel grade-specific considerations: minimum bend radii for ASTM A36/A500, kerf compensation for plasma/laser cutting, and forming tonnage requirements. The AI generates a preliminary quote within 2 business hours, but all quotes undergo mandatory review by a senior manufacturing engineer to validate feasibility and cost assumptions—particularly for channel intersections or compound bends.

DFM Analysis

This phase is critical for channel steel due to its susceptibility to warpage and tolerance stack-up. Our engineers perform a detailed Design for Manufacturability review using in-house rules based on ISO 2768-mK and MIL-STD-12D. Key channel-specific checks include:

| DFM Parameter | Channel Steel Requirement | Common Issue Mitigation |

|---|---|---|

| Bend Sequencing | Minimum flange width ≥ 3x material thickness | Redesign leg geometry or suggest alternative profiles |

| Hole Placement | ≥ 2.5x hole diameter from bend line | Recommend relocated features or secondary operations |

| Tolerance Stack-up | ±0.5mm cumulative on critical mounting faces | Propose datum shifting or modular assembly |

| Material Utilization | Nesting efficiency >85% for structural steel | Adjust channel lengths to standard mill cuts |

Clients receive a formal DFM report with actionable recommendations. No project proceeds to production without written client approval of the DFM findings.

Production

Approved channel steel orders enter production with strict controls:

Material is certified to ASTM standards and traced via batch numbers. Cutting uses fiber laser systems with anti-shear algorithms to maintain channel integrity. Press brakes employ real-time tonnage monitoring to prevent distortion on long channel runs. All weldments follow AWS D1.1 structural steel protocols with 100% visual inspection. In-process gauging verifies critical dimensions after each operation—particularly leg perpendicularity and flange flatness.

Delivery

Finished channels undergo final inspection against the original CAD model using CMM or optical comparators. Each shipment includes:

Material test reports with chemical composition

Dimensional inspection report (ASME Y14.5 GD&T)

Serialized packaging for traceability

Protective end caps for channel legs

Standard lead time is 7–10 business days post-DFM approval. Expedited shipping options include real-time logistics tracking with delivery guarantees. All channels are packaged on custom cradles to prevent deformation during transit.

This integrated workflow reduces channel steel prototyping lead times by 40% compared to industry averages while maintaining first-pass yield rates above 98%. The process is certified to ISO 9001:2015 with full documentation available for aerospace and structural engineering clients.

Start Your Project

For inquiries about channels steel, contact Susan Leo at [email protected]. Honyo Prototype operates a manufacturing facility in Shenzhen, ensuring efficient production and timely delivery for your project requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.