Introduction: Navigating the Global Market for cf8m stainless steel

In the ever-evolving landscape of industrial materials, sourcing high-quality CF8M stainless steel presents a unique set of challenges for international B2B buyers. The complexities of varying specifications, applications, and supplier reliability can often lead to costly mistakes and project delays. This guide aims to simplify the procurement process by providing comprehensive insights into CF8M stainless steel, a versatile alloy known for its exceptional corrosion resistance and mechanical properties.

Throughout this resource, you will discover a detailed exploration of the different types of CF8M stainless steel, their typical applications across industries—from chemical processing to marine environments—and the critical factors to consider when vetting suppliers. Additionally, we will delve into cost considerations and provide actionable strategies for negotiating favorable terms.

By equipping B2B buyers, particularly those from Africa, South America, the Middle East, and Europe—including regions like Saudi Arabia and Nigeria—with the knowledge needed to make informed purchasing decisions, this guide aims to foster stronger supply chain relationships and enhance operational efficiency. Whether you’re looking to understand the nuances of CF8M’s composition or seeking reliable suppliers, this guide serves as your essential resource for navigating the global market of CF8M stainless steel.

Understanding cf8m stainless steel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CF8M | Cast austenitic stainless steel, enhanced corrosion resistance due to molybdenum | Chemical processing, food processing, marine applications | Pros: Excellent corrosion resistance, good weldability. Cons: Requires post-welding treatment to restore properties. |

| CF8M-L | Low carbon variant of CF8M, minimizing carbide precipitation | High-temperature applications, nuclear components | Pros: Reduced risk of intergranular corrosion. Cons: Slightly lower mechanical strength compared to standard CF8M. |

| CF3M | Similar to CF8M but with lower chromium content | Applications in less corrosive environments | Pros: More cost-effective for specific applications. Cons: Lower overall corrosion resistance than CF8M. |

| CF8C | High carbon variant providing increased strength | Heavy-duty industrial applications | Pros: Enhanced mechanical properties. Cons: Lower corrosion resistance than standard CF8M. |

| CF8M-Plus | Modified version with additional alloying elements for extreme environments | Oil and gas, chemical processing in harsh conditions | Pros: Superior resistance to pitting and stress corrosion cracking. Cons: Higher material cost. |

What are the Key Characteristics of CF8M Stainless Steel?

CF8M stainless steel is a versatile cast austenitic alloy known for its excellent corrosion resistance, particularly in chloride-rich environments. It contains 2-3% molybdenum, which enhances its ability to withstand pitting and crevice corrosion. This makes CF8M a preferred choice for various applications, including chemical processing and marine environments. However, it is essential for buyers to consider the need for post-weld annealing to restore its corrosion resistance after fabrication.

How Does CF8M-L Differ from Standard CF8M?

CF8M-L is a low carbon variant of CF8M, designed to minimize the risk of intergranular corrosion during high-temperature applications. This makes it particularly suitable for nuclear components and other critical applications where corrosion resistance is paramount. While it offers reduced susceptibility to corrosion, buyers should note that it may have slightly lower mechanical strength compared to standard CF8M, which could impact performance in specific applications.

What are the Applications for CF3M Stainless Steel?

CF3M stainless steel features a lower chromium content than CF8M, making it more suitable for less corrosive environments. It is often used in applications where budget constraints are a consideration, allowing for a more cost-effective solution without the need for the highest levels of corrosion resistance. However, buyers should be aware that this trade-off may limit its use in more demanding environments.

What Advantages Does CF8C Offer?

CF8C is a high carbon variant of CF8M that provides enhanced mechanical properties, making it ideal for heavy-duty industrial applications. While it offers increased strength, it is important for buyers to consider its lower corrosion resistance compared to standard CF8M. This variant is suitable for applications where mechanical strength is prioritized over corrosion resistance.

Why Choose CF8M-Plus for Extreme Environments?

CF8M-Plus is a modified version of CF8M that incorporates additional alloying elements to enhance its performance in extreme environments. This variant is particularly effective in oil and gas applications and chemical processing under harsh conditions. Buyers should weigh the benefits of superior resistance to pitting and stress corrosion cracking against the higher material costs associated with this advanced alloy.

Key Industrial Applications of cf8m stainless steel

| Industry/Sector | Specific Application of cf8m stainless steel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Chemical Processing | Piping and valve components | Excellent corrosion resistance in harsh chemicals | Ensure compliance with ASTM A351 for quality assurance |

| Food Processing | Equipment for food handling and processing | Non-reactive and hygienic, ensuring product safety | Verify FDA compliance and certifications |

| Marine Engineering | Components for pumps and marine vessels | Superior resistance to seawater corrosion | Assess the alloy’s performance in specific marine conditions |

| Nuclear Industry | Flow control components | High integrity and reliability in critical applications | Confirm adherence to safety standards and specifications |

| Environmental Protection | Wastewater treatment systems | Durability and resistance to corrosive environments | Evaluate environmental regulations and certifications |

How is CF8M Stainless Steel Used in Chemical Processing?

In the chemical processing industry, CF8M stainless steel is primarily utilized for piping and valve components due to its exceptional resistance to corrosion from aggressive chemicals. This is crucial for maintaining system integrity and safety, especially in environments rich in chlorides. For international buyers, particularly in regions like Africa and the Middle East, sourcing CF8M requires ensuring that suppliers adhere to ASTM A351 standards to guarantee quality and performance under demanding conditions.

What Role Does CF8M Stainless Steel Play in Food Processing?

CF8M stainless steel is an ideal material for food processing equipment, including tanks, conveyors, and other machinery. Its non-reactive nature ensures that no harmful substances leach into food products, which is vital for consumer safety and regulatory compliance. Buyers in Europe and South America should prioritize suppliers that can provide documentation of FDA compliance and hygienic certifications to meet industry standards.

Why is CF8M Stainless Steel Essential in Marine Engineering?

In marine engineering, CF8M stainless steel is favored for components in pumps and marine vessels due to its superior resistance to seawater corrosion. This capability extends the lifespan of marine equipment, reducing maintenance costs and downtime. Buyers in regions like Saudi Arabia and Nigeria should look for suppliers with proven expertise in marine applications to ensure that the material meets the specific environmental challenges of their operational waters.

How is CF8M Stainless Steel Used in the Nuclear Industry?

The nuclear industry relies on CF8M stainless steel for flow control components, where high integrity and reliability are paramount. The alloy’s strength and resistance to corrosion under extreme conditions make it suitable for critical applications. International buyers should ensure that their sourcing partners meet stringent safety standards and specifications to mitigate risks in these high-stakes environments.

What Benefits Does CF8M Stainless Steel Provide in Environmental Protection?

CF8M stainless steel is extensively used in wastewater treatment systems, where its durability and resistance to corrosive agents are essential for long-term performance. This material helps prevent system failures and ensures compliance with environmental regulations. Buyers should evaluate suppliers based on their ability to meet local environmental standards and provide evidence of the alloy’s performance in similar applications.

3 Common User Pain Points for ‘cf8m stainless steel’ & Their Solutions

Scenario 1: Challenges with Corrosion in Harsh Environments

The Problem:

B2B buyers in industries such as chemical processing and marine applications often face significant challenges with corrosion resistance when using stainless steel components. CF8M stainless steel, while known for its excellent corrosion resistance, can still be susceptible to pitting and crevice corrosion in chloride-rich environments. This is particularly problematic in applications such as seawater piping or chemical storage, where the integrity of components is critical to operational safety and efficiency.

The Solution:

To mitigate the risk of corrosion, it’s essential to select CF8M stainless steel components specifically designed for your application. Ensure that the material is sourced from reputable suppliers who can provide certification for its chemical composition and mechanical properties. Additionally, consider implementing protective measures such as applying anti-corrosive coatings or using cathodic protection systems. Regular maintenance and inspections can also help identify potential corrosion issues before they lead to failure. Furthermore, educating your engineering team on the specific environments where CF8M will be used can help in designing systems that minimize exposure to corrosive agents.

Scenario 2: Difficulty in Welding and Fabrication

The Problem:

Many B2B buyers encounter challenges when welding CF8M stainless steel due to its unique properties. While CF8M is known for its weldability, improper welding techniques can lead to issues such as reduced corrosion resistance and compromised mechanical properties. Buyers in sectors like food processing or nuclear energy, where precision and durability are paramount, may find that poorly executed welds result in costly rework or, worse, component failure.

The Solution:

To ensure successful welding of CF8M stainless steel, it is vital to follow specific welding guidelines. Start by using appropriate filler materials that match the alloy’s composition, such as ER316L. Preheating the material and maintaining proper interpass temperatures during welding can also minimize the risk of cracking. After welding, a solution annealing process is recommended to restore the material’s corrosion resistance and mechanical properties. Collaborating with experienced welders who understand the nuances of CF8M can further enhance the quality of the welds. Additionally, investing in training for your fabrication team can foster a better understanding of best practices and lead to improved outcomes.

Scenario 3: Navigating Regulatory Compliance and Standards

The Problem:

B2B buyers in industries such as pharmaceuticals, food processing, and defense often face complex regulatory requirements regarding material specifications. CF8M stainless steel must meet various ASTM and ISO standards, which can vary by region and application. Buyers may struggle to ensure compliance with these standards while also balancing cost and performance requirements, leading to potential delays in project timelines or legal liabilities.

The Solution:

To navigate regulatory compliance effectively, it’s crucial to stay informed about the specific standards applicable to your industry and region. Create a checklist of relevant standards such as ASTM A351, A743, and A744 for CF8M to ensure your procurement processes align with regulatory demands. Collaborate closely with suppliers to obtain the necessary documentation, including material certifications and test reports, to demonstrate compliance. Additionally, consider engaging a compliance consultant or legal advisor familiar with industry regulations to review your processes and materials. By establishing a proactive approach to compliance, you can reduce the risk of regulatory issues and ensure that your projects proceed smoothly and on schedule.

Strategic Material Selection Guide for cf8m stainless steel

What Are the Key Properties of CF8M Stainless Steel?

CF8M stainless steel, commonly recognized as a cast version of 316 stainless steel, is renowned for its excellent mechanical properties and corrosion resistance. It typically contains 18-21% chromium, 9-12% nickel, and 2-3% molybdenum, which enhances its resistance to pitting and crevice corrosion in chloride-rich environments. The alloy exhibits good tensile strength and ductility, making it suitable for applications that demand both toughness and formability. Its temperature and pressure ratings are suitable for a range of industrial applications, particularly in harsh environments.

What Are the Advantages and Disadvantages of Using CF8M Stainless Steel?

Advantages

- Corrosion Resistance: The high molybdenum content provides superior resistance against corrosive media, particularly in marine and chemical processing environments.

- Fabrication Ease: CF8M is readily machinable and weldable, allowing for efficient manufacturing processes. However, it is crucial to re-anneal after welding to restore its corrosion resistance.

- Versatile Applications: Its balanced properties make it ideal for a wide range of applications, including food processing, nuclear components, and pump and valve manufacturing.

Disadvantages

- Cost: CF8M can be more expensive than other stainless steel grades due to its alloying elements, which may impact budget-sensitive projects.

- Magnetism: Unlike its wrought counterpart, CF8M can exhibit slight magnetism, which may be a concern in specific applications where non-magnetic properties are essential.

- Casting Limitations: The casting process can impose limitations on the complexity of designs, impacting the final product’s suitability for certain applications.

How Does CF8M Stainless Steel Impact Specific Applications?

CF8M’s compatibility with various media, including aggressive chemicals and saline environments, makes it highly suitable for industries such as chemical processing and marine applications. Its excellent performance in high-temperature and high-pressure conditions further enhances its applicability in sectors like nuclear energy and oil & gas. However, international buyers must consider the specific requirements of their applications, including compliance with local standards and regulations.

What Should International B2B Buyers Consider When Selecting CF8M Stainless Steel?

For B2B buyers in regions like Africa, South America, the Middle East, and Europe, understanding local compliance standards (such as ASTM, DIN, or JIS) is crucial. Buyers should also assess the availability of CF8M stainless steel in their region, as sourcing can vary significantly. Additionally, factors such as the cost of raw materials, shipping logistics, and the potential for tariffs should be evaluated to ensure a smooth procurement process.

Summary Table of CF8M Stainless Steel Material Selection

| Material | Typical Use Case for cf8m stainless steel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| CF8M Stainless Steel | Chemical processing, marine components | Superior corrosion resistance | Higher cost compared to alternatives | High |

| 316 Stainless Steel | Food processing, medical instruments | Excellent mechanical properties | Slightly magnetic in cast form | Medium |

| Super Austenitic Steel | Oil & gas applications, heat exchangers | Enhanced resistance to pitting | More expensive due to alloying | High |

| Ferritic Stainless Steel | Automotive components, structural parts | Cost-effective and good strength | Lower corrosion resistance | Low |

This guide provides a comprehensive overview of CF8M stainless steel, focusing on its properties, advantages, and considerations for international B2B buyers. Understanding these factors will enable informed decision-making in selecting the right material for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for cf8m stainless steel

What Are the Key Stages in the Manufacturing Process of CF8M Stainless Steel?

The manufacturing process of CF8M stainless steel involves several critical stages that ensure the alloy’s integrity and performance. Understanding these stages is essential for B2B buyers looking to procure high-quality CF8M products.

Material Preparation: What Is Involved in Preparing Raw Materials?

The first step in manufacturing CF8M stainless steel is the preparation of raw materials. This includes selecting high-grade stainless steel scrap and alloying elements such as chromium, nickel, and molybdenum. The quality of these raw materials directly impacts the final product’s properties. Chemical analysis is performed to verify that the materials meet the required specifications before they enter the melting process.

How Is CF8M Stainless Steel Formed?

The forming stage typically involves melting the prepared raw materials in an electric arc furnace (EAF) or induction furnace. The molten metal is then poured into molds to create the desired shapes, which may include castings for pumps, valves, and other components. The casting process for CF8M is often done using sand casting or investment casting techniques, depending on the complexity and precision required.

Following casting, the components may undergo heat treatment, specifically solution annealing, to enhance their mechanical properties. This step is crucial for restoring the corrosion resistance that may be diminished during the casting process.

What Finishing Techniques Are Commonly Used for CF8M Products?

Finishing processes can include machining, grinding, and polishing to achieve precise dimensions and surface finishes. Machining is essential for creating components that fit seamlessly in their applications, especially in industries like chemical processing and marine environments where tight tolerances are critical. Surface finishing not only improves aesthetics but also enhances corrosion resistance, making it a vital step in the manufacturing process.

What Quality Assurance Measures Are Critical for CF8M Stainless Steel?

Quality assurance is a fundamental aspect of the manufacturing process for CF8M stainless steel. It ensures that the final products meet international standards and customer specifications.

Which International Standards Should B2B Buyers Look for in CF8M Products?

B2B buyers should be aware of several international quality standards when assessing suppliers. ISO 9001 is a general quality management standard that applies to any organization, ensuring consistent quality in products and services. Additionally, industry-specific standards such as CE marking for European markets and API standards for the oil and gas industry can also be relevant, depending on the application of the CF8M products.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is typically structured around several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before production begins. Materials are verified against specifications to ensure they meet the required chemical composition.

-

In-Process Quality Control (IPQC): During manufacturing, various parameters such as temperature, pressure, and alloy composition are monitored. This ensures that the processes are within specified limits and helps in identifying any deviations early.

-

Final Quality Control (FQC): This stage involves comprehensive testing of the finished products. Common testing methods include mechanical testing (tensile strength, yield strength), corrosion resistance tests, and dimensional inspections. Non-destructive testing (NDT) methods, such as ultrasonic testing or radiography, may also be employed to detect internal flaws.

How Can B2B Buyers Verify Supplier Quality Assurance?

When sourcing CF8M stainless steel, B2B buyers can take several steps to verify supplier quality assurance:

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their quality management systems and manufacturing processes. This includes reviewing their adherence to ISO 9001 and other relevant standards.

-

Quality Reports and Certifications: Requesting documentation such as test reports and certifications can help verify that products meet specified standards. Look for detailed reports that outline the tests performed, results, and compliance with international standards.

-

Third-Party Inspections: Engaging independent third-party inspection agencies can add an extra layer of assurance. These agencies can conduct on-site evaluations and testing to confirm that products meet quality specifications before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, especially those from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

-

Regulatory Compliance: Different countries may have varying regulations regarding material standards and certifications. Understanding these requirements can help ensure compliance and avoid potential delays or issues during importation.

-

Cultural Considerations: Building strong relationships with suppliers may require an understanding of cultural differences in business practices. Regular communication and transparency can foster trust and improve quality outcomes.

-

Local Standards vs. International Standards: While international standards like ISO 9001 are widely recognized, local standards may also exist. Buyers should familiarize themselves with both sets of standards to ensure comprehensive compliance.

Conclusion: Why Quality Assurance Is Essential for CF8M Stainless Steel Procurement

In summary, the manufacturing processes and quality assurance measures for CF8M stainless steel are integral to ensuring the material’s performance and longevity in demanding applications. By understanding these processes, B2B buyers can make informed decisions and establish partnerships with reliable suppliers, ultimately leading to successful procurement outcomes in global markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cf8m stainless steel’

Introduction

Sourcing CF8M stainless steel, a versatile alloy known for its superior corrosion resistance and mechanical properties, requires careful planning and execution. This guide provides international B2B buyers with a practical checklist to streamline the procurement process, ensuring that they select the right material and supplier for their specific needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it is essential to outline your technical requirements for CF8M stainless steel. This includes defining the desired chemical composition, mechanical properties (like tensile and yield strength), and any specific standards (e.g., ASTM A351).

- Why It Matters: Clearly defined specifications help prevent misunderstandings with suppliers and ensure that the material meets your application needs.

- What to Look For: Consult industry standards and technical datasheets to ensure your requirements align with CF8M’s capabilities.

Step 2: Identify Potential Suppliers

Conduct thorough research to identify reputable suppliers specializing in CF8M stainless steel. Look for manufacturers or distributors with a proven track record in your industry.

- Why It Matters: A reliable supplier can significantly impact the quality of your products and the efficiency of your operations.

- What to Look For: Supplier certifications (ISO, ASTM), product range, and years of experience in the market are key indicators of reliability.

Step 3: Evaluate Supplier Certifications

Ensure that your potential suppliers hold relevant certifications that affirm their compliance with international quality standards. This may include ISO 9001 for quality management systems or specific material certifications like ASTM.

- Why It Matters: Certifications provide assurance that the supplier adheres to industry standards, which is crucial for quality control and regulatory compliance.

- What to Look For: Request documentation of certifications and verify their validity through issuing organizations.

Step 4: Request Samples and Specifications

Before finalizing your order, ask for samples of CF8M stainless steel from shortlisted suppliers. This allows you to assess the material’s quality firsthand.

- Why It Matters: Evaluating samples can help you identify any discrepancies in quality and ensure that the material meets your specifications.

- What to Look For: Examine the mechanical properties, surface finish, and overall appearance of the samples.

Step 5: Assess Pricing and Payment Terms

Compare pricing from different suppliers while considering the total cost of ownership, which includes shipping, taxes, and potential tariffs. Additionally, clarify payment terms and conditions.

- Why It Matters: Understanding the full financial implications of your purchase helps you budget effectively and avoid unexpected costs.

- What to Look For: Look for transparent pricing structures and favorable payment terms that align with your cash flow requirements.

Step 6: Negotiate Delivery and Lead Times

Discuss delivery timelines and logistics with your chosen supplier to ensure that they can meet your project deadlines. Confirm shipping methods and any associated costs.

- Why It Matters: Timely delivery is critical to maintaining project schedules and minimizing downtime.

- What to Look For: Obtain a clear timeline and ensure that the supplier has a reliable logistics plan in place.

Step 7: Finalize the Purchase Agreement

Once you are satisfied with the supplier’s offerings, finalize the purchase agreement, including all terms related to quality, delivery, and payment.

- Why It Matters: A well-defined contract protects both parties and ensures that all expectations are clearly outlined.

- What to Look For: Ensure that the agreement includes clauses for quality assurance, return policies, and dispute resolution mechanisms.

By following this checklist, B2B buyers can effectively navigate the procurement of CF8M stainless steel, ensuring they secure the right material for their applications while establishing a productive relationship with their suppliers.

Comprehensive Cost and Pricing Analysis for cf8m stainless steel Sourcing

Analyzing the cost structure and pricing for CF8M stainless steel sourcing requires a thorough understanding of the various components that contribute to the overall cost, as well as the factors that can influence pricing. This guide aims to provide actionable insights for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components of CF8M Stainless Steel?

-

Materials: The primary cost driver for CF8M stainless steel is the raw material itself, which typically includes iron, chromium, nickel, and molybdenum. The prices of these metals can fluctuate based on market demand and geopolitical factors. Buyers should monitor commodity prices closely to anticipate changes in material costs.

-

Labor: Labor costs vary significantly depending on the manufacturing location. Regions with higher wage standards will naturally incur higher labor costs. However, skilled labor is essential for processes like casting and machining CF8M, and investing in quality labor can enhance product quality and reliability.

-

Manufacturing Overhead: This encompasses utilities, maintenance, and operational expenses related to the manufacturing facility. Efficient production processes can help keep these costs lower, allowing suppliers to offer more competitive pricing.

-

Tooling: Custom tooling for specific applications can add to the initial investment. However, this cost can often be amortized over larger production runs, making it more manageable for high-volume orders.

-

Quality Control (QC): Ensuring compliance with international standards (such as ASTM A351) incurs costs associated with testing and certification. Buyers should look for suppliers that maintain rigorous QC processes, as this can prevent costly issues later in the supply chain.

-

Logistics: Shipping costs, customs duties, and insurance are crucial components of total costs. The geographic location of suppliers can significantly impact logistics expenses, especially for international buyers. Consideration of Incoterms is vital to understand who bears the shipping and insurance costs.

-

Margin: Suppliers will include a profit margin in their pricing. This margin can vary based on market competition and the perceived value of the product. Buyers should assess supplier reliability and product quality to ensure they are receiving fair value for their investment.

What Influences the Pricing of CF8M Stainless Steel?

-

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQ) to achieve better pricing.

-

Specifications and Customization: Custom specifications or additional certifications can increase costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Materials Quality and Certifications: Higher quality materials or those with specific certifications (like ISO or ASME) may carry a premium. Buyers should evaluate whether these certifications are necessary for their applications.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but offer better quality assurance and delivery reliability.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and liability. Choosing the right Incoterms can help manage costs effectively.

How Can Buyers Negotiate for Better Pricing on CF8M Stainless Steel?

-

Leverage Volume: Buyers should consolidate their orders to increase volume, which can lead to better pricing from suppliers.

-

Long-term Relationships: Establishing long-term partnerships with suppliers can lead to more favorable pricing terms and priority service.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with quality, maintenance, and potential downtime. A slightly higher upfront cost may result in lower TCO.

-

Market Research: Conduct thorough market research to understand prevailing prices and supplier capabilities. This knowledge can empower buyers during negotiations.

What Pricing Nuances Should International Buyers Be Aware Of?

International buyers should be aware of currency fluctuations, which can impact costs when sourcing from different regions. Additionally, understanding local regulations and tariffs is crucial, as these can affect overall pricing and delivery timelines. Finally, be mindful of cultural differences in negotiation styles and communication, as these can influence the purchasing process.

Disclaimer

The prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and specific buyer requirements. It is advisable for buyers to obtain quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing cf8m stainless steel With Other Solutions

Introduction to Alternatives in Stainless Steel Solutions

In the competitive landscape of materials for industrial applications, CF8M stainless steel is recognized for its corrosion resistance, strength, and versatility. However, various alternatives may also fulfill similar roles depending on specific project requirements, environmental conditions, and budget constraints. Understanding these alternatives can empower B2B buyers to make informed decisions tailored to their unique operational needs.

Comparison of CF8M Stainless Steel with Alternatives

| Comparison Aspect | CF8M Stainless Steel | Duplex Stainless Steel | Carbon Steel |

|---|---|---|---|

| Performance | Excellent corrosion resistance, high ductility, good strength | Superior strength and corrosion resistance, especially in chloride environments | Moderate strength, lower corrosion resistance |

| Cost | Higher initial cost due to alloying elements | Generally higher than CF8M due to alloy complexity | Low initial cost, economical for large-scale applications |

| Ease of Implementation | Good weldability but requires post-weld annealing | More challenging to weld, requiring specialized techniques | Easy to work with, widely available |

| Maintenance | Low maintenance due to corrosion resistance | Low maintenance; however, more care is needed during welding | Higher maintenance due to susceptibility to rust and corrosion |

| Best Use Case | Chemical processing, marine applications, food industry | Oil and gas, marine, and chemical processing | Construction, automotive, and general manufacturing |

Detailed Breakdown of Alternatives

Duplex Stainless Steel

Duplex stainless steel combines both austenitic and ferritic microstructures, offering enhanced strength and excellent corrosion resistance, particularly in harsh environments like offshore oil rigs. Its higher strength allows for lighter structures, which can reduce overall material costs in applications where weight is a concern. However, its weldability can be complex, often requiring specialized training and equipment, which may increase initial project costs and timelines.

Carbon Steel

Carbon steel is a widely used material known for its affordability and ease of fabrication. It is suitable for many general applications, especially in construction and manufacturing. However, carbon steel’s lower corrosion resistance means it may require protective coatings or regular maintenance in environments exposed to moisture or corrosive substances. While it presents a lower upfront investment, the long-term costs associated with maintenance and potential replacements should be factored into the decision-making process.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate material for industrial applications, B2B buyers should carefully consider the specific requirements of their projects, including environmental conditions, budget constraints, and performance expectations. CF8M stainless steel offers a robust solution for environments demanding high corrosion resistance and durability, but alternatives like duplex stainless steel or carbon steel may provide viable options depending on the application. Assessing the trade-offs between performance, cost, and maintenance will guide buyers toward the most effective and economical choice for their operational needs.

Essential Technical Properties and Trade Terminology for cf8m stainless steel

What Are the Key Technical Properties of CF8M Stainless Steel?

1. Material Grade and Composition

CF8M stainless steel, categorized under the UNS J92900, is an austenitic alloy similar to SS316 but specifically designed for casting applications. Its chemical composition typically includes 18-21% chromium, 9-12% nickel, and 2-3% molybdenum. These elements confer superior corrosion resistance, especially against chlorides, making it ideal for marine and chemical processing environments. Understanding the material grade is crucial for B2B buyers as it directly affects the performance and longevity of components in harsh conditions.

2. Mechanical Properties

CF8M exhibits impressive mechanical properties, including a tensile strength of up to 70 ksi (483 MPa) and a yield strength of approximately 30 ksi (207 MPa). The elongation rate of around 30% indicates good ductility, allowing for effective forming and shaping during manufacturing. These properties are vital for industries that require components to withstand high pressures and stresses, such as in pumps and valves.

3. Corrosion Resistance

The addition of molybdenum in CF8M enhances its resistance to pitting and crevice corrosion, especially in chloride-rich environments. This characteristic is crucial for B2B buyers in sectors like food processing, chemical, and marine applications, where materials are regularly exposed to aggressive substances. A thorough understanding of corrosion resistance helps in selecting the right materials for specific applications, potentially reducing maintenance costs and increasing service life.

4. Weldability and Fabrication

CF8M stainless steel is known for its good weldability, allowing for seamless integration into various structures and components. However, it is essential to perform post-weld heat treatment, specifically re-annealing, to restore its corrosion resistance. For B2B buyers, this means that while CF8M is versatile, they must ensure proper welding practices are followed to maintain the integrity of the components.

5. Casting Standards

CF8M complies with ASTM A351, A743, and A744 standards, which outline specifications for cast stainless steels. This classification is critical for ensuring that the components meet industry regulations and quality benchmarks. For international buyers, understanding these standards helps in assessing supplier capabilities and ensuring that the products meet specific application requirements.

What Are Common Trade Terminology Terms Related to CF8M Stainless Steel?

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of CF8M stainless steel, OEMs often require high-quality materials for their products. Understanding OEM relationships is essential for buyers to ensure they are sourcing the right materials for their manufacturing needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For CF8M stainless steel components, knowing the MOQ is critical for B2B buyers, especially when planning budgets and inventory. This information helps in assessing whether a supplier can meet both large-scale and smaller project demands.

3. RFQ (Request for Quote)

An RFQ is a formal document sent to suppliers requesting pricing and other details for specific products. When dealing with CF8M stainless steel, submitting an RFQ allows buyers to gather competitive pricing and lead times, facilitating better purchasing decisions. This step is vital for international buyers who may need to compare multiple suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in global transactions. Understanding these terms is crucial for B2B buyers in international markets, as they dictate shipping responsibilities, risk transfer, and cost obligations associated with the purchase of CF8M stainless steel products.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. For CF8M stainless steel, understanding lead times is essential for project planning and inventory management. This insight helps businesses avoid delays in production schedules and ensures timely delivery of components.

By familiarizing themselves with these properties and terms, B2B buyers can make informed decisions when sourcing CF8M stainless steel, ultimately enhancing operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the cf8m stainless steel Sector

What are the Current Market Dynamics and Key Trends in the CF8M Stainless Steel Sector?

The CF8M stainless steel market is experiencing robust growth driven by several global factors. Increased demand for corrosion-resistant materials in sectors such as chemical processing, food and beverage, and marine applications is propelling the market forward. The ongoing industrialization in regions like Africa and South America, coupled with the Middle East’s expanding oil and gas industry, creates significant opportunities for B2B buyers seeking durable materials. Additionally, Europe’s stringent regulations on environmental safety and material quality continue to shape purchasing decisions, emphasizing the need for reliable suppliers.

Emerging B2B technology trends, such as digital procurement platforms and supply chain analytics, are transforming how international buyers source CF8M stainless steel. These technologies enable companies to optimize their procurement processes, reduce costs, and enhance supplier transparency. Moreover, the rise of e-commerce in industrial materials is allowing buyers from regions like Saudi Arabia and Nigeria to access a broader range of suppliers, thus fostering competition and improving pricing strategies.

Another key trend is the increasing preference for customized solutions. As industries evolve, the demand for tailored grades and specifications of CF8M to meet specific application requirements is on the rise. This shift encourages suppliers to innovate and adapt, ensuring they remain competitive in a dynamic marketplace.

How is Sustainability and Ethical Sourcing Influencing the CF8M Stainless Steel Sector?

Sustainability has become a pivotal concern in the sourcing of CF8M stainless steel, significantly influencing purchasing decisions among international B2B buyers. The environmental impact of steel production—including energy consumption, greenhouse gas emissions, and waste generation—has prompted many companies to seek materials that align with their sustainability goals. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to eco-friendly practices, such as utilizing recycled materials or implementing energy-efficient manufacturing processes.

Ethical sourcing is equally important, as businesses face growing scrutiny over their supply chains. Buyers are expected to conduct thorough due diligence to ensure that their suppliers adhere to ethical labor practices and environmental standards. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming crucial benchmarks for assessing supplier reliability.

Incorporating ‘green’ certifications into procurement strategies not only enhances brand reputation but also aligns with regulatory pressures and consumer expectations for sustainability. As a result, B2B buyers are encouraged to engage with suppliers who can provide transparency regarding their sourcing practices and demonstrate a genuine commitment to reducing their environmental footprint.

What is the Brief Evolution and History of CF8M Stainless Steel in the B2B Context?

CF8M stainless steel, recognized as a cast form of the widely used 316 stainless steel, has evolved significantly since its introduction. Originally developed to meet the increasing demand for materials that could withstand harsh environments, CF8M has become synonymous with durability and corrosion resistance in applications ranging from marine to chemical processing. The alloy’s formulation, which includes molybdenum for enhanced resistance to pitting and crevice corrosion, has positioned it as a preferred choice for industries requiring reliable performance under challenging conditions.

Over the decades, advancements in casting technology and material science have further refined CF8M’s properties, making it more accessible to international markets. Today, it serves as a benchmark for quality in stainless steel castings, with standards established by organizations like ASTM guiding its production and use. As industries continue to advance, the evolution of CF8M will likely focus on enhancing its environmental credentials and adapting to the specific needs of diverse global markets, particularly in regions experiencing rapid industrial growth.

Frequently Asked Questions (FAQs) for B2B Buyers of cf8m stainless steel

-

How do I ensure the quality of CF8M stainless steel from suppliers?

To ensure the quality of CF8M stainless steel, it’s crucial to verify that suppliers adhere to relevant industry standards, such as ASTM A351, A743, and A744. Request material test reports (MTRs) that include chemical composition and mechanical properties to confirm compliance. Additionally, consider sourcing from suppliers with ISO certifications, as this indicates a commitment to quality management systems. Regular audits and inspections can also help maintain quality throughout the supply chain. -

What is the best application for CF8M stainless steel?

CF8M stainless steel is best suited for applications requiring high corrosion resistance, such as in marine environments, chemical processing, and food processing industries. Its excellent ductility and strength make it ideal for components like pumps, valves, and heat exchangers. Additionally, its ability to withstand chloride exposure without significant degradation makes it a preferred choice for industries operating in harsh conditions. -

What are the standard payment terms for international B2B transactions involving CF8M stainless steel?

Standard payment terms for international transactions typically include options such as advance payment, letters of credit (LC), or payment against documents. The choice of terms often depends on the buyer-supplier relationship, order size, and country-specific practices. It’s advisable to discuss and agree upon terms upfront, ensuring clarity on the payment schedule, currency, and any applicable taxes or tariffs that may influence total costs. -

How can I determine the minimum order quantity (MOQ) for CF8M stainless steel?

The MOQ for CF8M stainless steel can vary significantly among suppliers based on their production capabilities and inventory levels. To determine the MOQ, directly communicate with potential suppliers and inquire about their policies. Factors influencing MOQ may include the complexity of the casting process, customization requirements, and the cost-effectiveness of production runs. Establishing a relationship with suppliers may also provide opportunities to negotiate lower MOQs. -

What is the lead time for sourcing CF8M stainless steel internationally?

Lead times for sourcing CF8M stainless steel can range from a few weeks to several months, depending on factors such as production capacity, order complexity, and shipping logistics. When placing an order, it’s important to confirm lead times with suppliers and factor in potential delays due to customs clearance and transportation. Building a strong relationship with suppliers can also help expedite the process, ensuring timely delivery of materials. -

How do I vet potential suppliers of CF8M stainless steel?

Vetting potential suppliers involves assessing their reputation, financial stability, and production capabilities. Start by reviewing their certifications, customer testimonials, and case studies. Conduct background checks and request references from previous clients. Additionally, consider visiting their facilities if possible, to evaluate their manufacturing processes and quality control measures. Engaging with suppliers who are members of industry associations can also enhance credibility. -

Can CF8M stainless steel be customized for specific applications?

Yes, CF8M stainless steel can be customized to meet specific application requirements. Suppliers often offer various options such as different dimensions, finishes, and mechanical properties. When discussing customization, provide detailed specifications and application contexts to ensure the final product meets performance expectations. Collaborating closely with suppliers during the design phase can lead to better outcomes and more efficient manufacturing processes. -

What logistics considerations should I keep in mind when importing CF8M stainless steel?

When importing CF8M stainless steel, consider logistics factors such as shipping methods, customs regulations, and potential tariffs. Choose reliable freight forwarders who can navigate international shipping complexities and ensure compliance with local regulations. Additionally, assess the total landed cost, including shipping, insurance, and handling fees. Planning for contingencies, such as delays or damage during transit, is also essential to mitigate risks associated with international logistics.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Cf8M Stainless Steel Manufacturers & Suppliers List

1. Novacast – Stainless Steel SA-351 CF8M

Domain: novacast.co.uk

Registered: 2000 (25 years)

Introduction: Stainless Steel SA-351 CF8M is a molybdenum bearing modification of CF8 austenitic steel alloy and is the cast equivalent of wrought AISI 316 stainless steel. It offers increased general corrosion resistance and resistance to pitting by chlorides. Common applications include valves, flanges, fittings, and other pressure-containing parts. CF8M is suitable for products requiring excellent overall co…

2. Grainger – General-Purpose Manual Ball Valves

Domain: grainger.com

Registered: 1994 (31 years)

Introduction: This company, Grainger – General-Purpose Manual Ball Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. American Valve – 4001 CF8M Stainless Steel Flanged Ball Valve

Domain: americanvalve.com

Registered: 1997 (28 years)

Introduction: {“model”:”4001 CF8M Stainless Steel Flanged Ball Valve”,”material”:”Cast 316 Stainless Steel (CF8M)”,”features”:[“PFA Fused Solid Stainless Steel Ball”,”Class VI Positive Shutoff”,”Reinforced PTFE Seats”,”ISO Mounting Pad for Easy Actuation”,”API Fire-Safe Design”,”Full Port”,”Lockable in Full Open or Closed Positions”],”pressure_rating”:{“WSP”:”150″,”WOG”:”300″},”max_temperature”:”366° F”,”size_o…

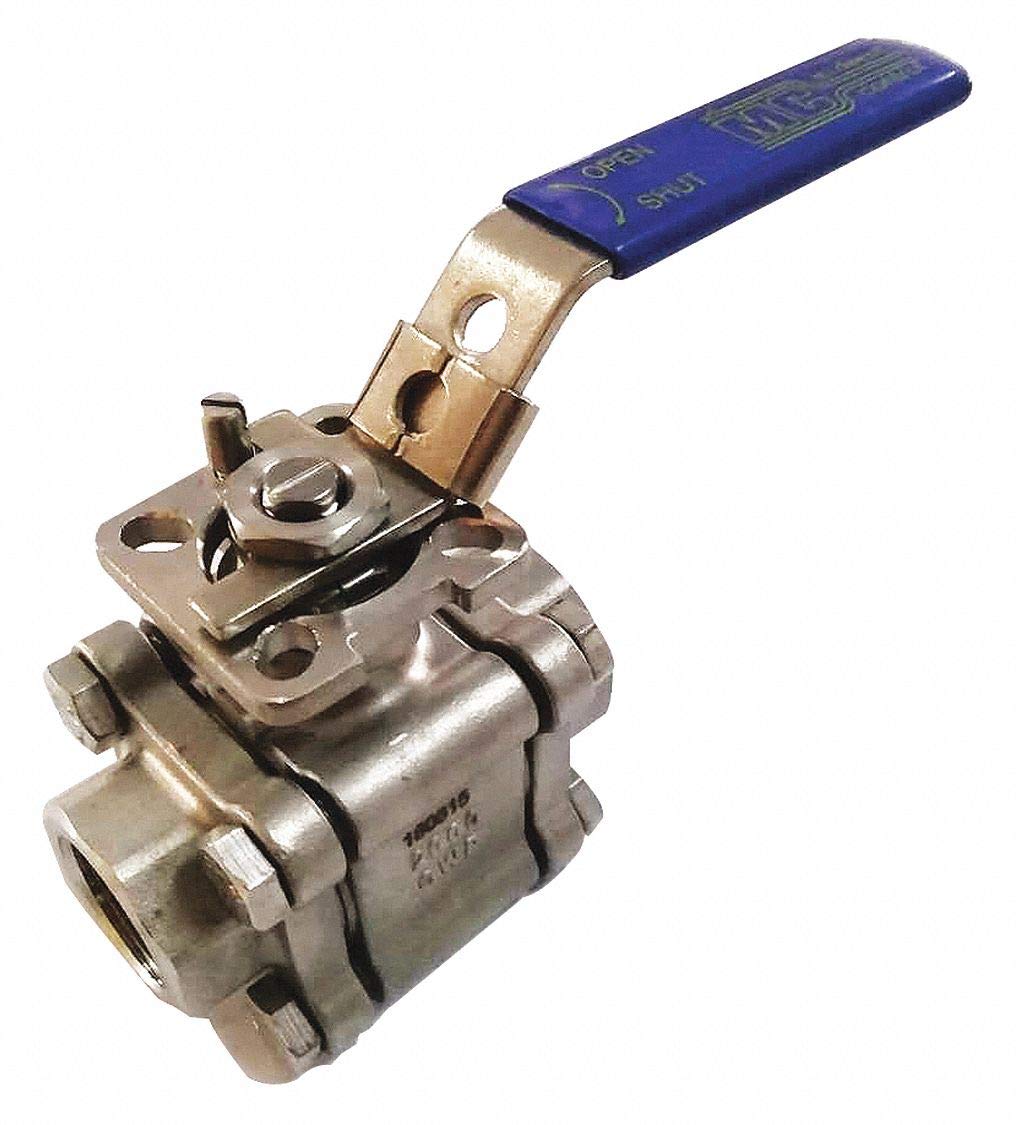

4. Dultmeier – CF8M Stainless Steel 3-Piece Ball Valve

Domain: dultmeier.com

Registered: 1996 (29 years)

Introduction: {“Product Type”:”Ball Valve”,”Design”:”3-Piece”,”Material”:”CF8M Stainless Steel Body”,”Certification”:”UL Listed”,”Pressure Rating”:”1000 WOG (PSI)”,”Max Temperature”:”500°F”,”Max Vacuum Rating”:”29” Hg”,”Wetted Surfaces Lead Content”:”Less than .25%”,”Leak Testing”:”100% Leak Tested”,”Repair Kits”:”Available”,”Handle Type”:”Latch-Lock handle (can be locked in open or closed position)”,”Features”…

Strategic Sourcing Conclusion and Outlook for cf8m stainless steel

In the competitive landscape of global manufacturing, strategic sourcing of CF8M stainless steel offers significant advantages for businesses across diverse industries. This versatile alloy, known for its excellent corrosion resistance and mechanical properties, is particularly well-suited for applications in chemical processing, food production, and marine environments. Its enhanced molybdenum content not only improves durability but also ensures reliability in chloride-rich settings, making it an ideal choice for industries operating in harsh conditions.

For international buyers from regions such as Africa, South America, the Middle East, and Europe, sourcing CF8M stainless steel involves careful consideration of supplier capabilities, quality assurance, and compliance with international standards like ASTM A351. Establishing partnerships with reputable suppliers can enhance supply chain resilience and ensure access to high-quality materials.

As the demand for robust and corrosion-resistant materials continues to rise, now is the time to engage with suppliers who can meet your specific needs. By prioritizing strategic sourcing, you can position your business for success and innovation in a rapidly evolving market. Explore opportunities today to secure your supply of CF8M stainless steel and elevate your operational capabilities for the future.