Contents

Manufacturing Insight: Casting Spare Parts

Precision Integration of Cast Components Through Advanced CNC Machining

At Honyo Prototype, we address a critical challenge in industrial maintenance and production: the reliable supply of high-precision spare parts derived from castings. While casting delivers complex geometries efficiently, achieving stringent dimensional tolerances and surface finishes often requires expert secondary machining. Our specialized CNC machining services transform near-net-shape cast components into fully functional, specification-compliant spare parts, ensuring seamless integration into your operational systems.

Leveraging multi-axis CNC milling, turning, and grinding capabilities, we handle materials ranging from aluminum and cast iron to high-strength alloys like Inconel and titanium. Our processes target critical features such as bearing seats, sealing surfaces, and interface datums—where casting variability could compromise performance. With ISO 9001-certified workflows and in-process CMM validation, we guarantee dimensional integrity within ±0.005 mm, eliminating field failures caused by undersized bores or misaligned mounting points.

For procurement teams requiring rapid turnaround, our Online Instant Quote platform streamlines sourcing. Upload CAD files of your cast spare part requirements, and receive a detailed manufacturing assessment—including lead time and DFM feedback—within minutes. This transparency accelerates maintenance cycles while maintaining the geometric accuracy essential for OEM-equivalent performance.

| Service Aspect | Honyo Prototype Value Proposition |

|---|---|

| Material Compatibility | Aluminum, Ductile Iron, Stainless Steel, Titanium, Superalloys |

| Tolerance Capability | ±0.005 mm (GD&T compliant) |

| Lead Time | As fast as 5 business days for qualified parts |

| Quality Assurance | In-process CMM, First Article Inspection, PPAP |

We bridge the gap between casting feasibility and operational reliability, ensuring your spare parts inventory sustains uptime without compromise. Explore how our machining expertise resolves casting-related field failures—request your instant quote today.

Technical Capabilities

Technical Specifications for Casting Spare Parts – Machining Capabilities and Material Compatibility

Honyo Prototype provides precision machining services for cast spare parts, utilizing advanced 3-axis, 4-axis, and 5-axis CNC milling along with CNC turning. These processes ensure high accuracy, complex geometry realization, and tight tolerance compliance required in industrial, automotive, and aerospace applications. Parts are machined from cast blanks in a range of materials including aluminum, steel, ABS, and nylon, with post-casting machining to meet exact dimensional and surface finish requirements.

| Parameter | Specification Detail |

|---|---|

| Machining Processes | 3-Axis Milling, 4-Axis Milling, 5-Axis Milling, CNC Turning |

| Tolerance Capability | ±0.005 mm (±0.0002″) for critical dimensions; tight tolerances maintained across complex geometries |

| Surface Finish (Typical) | Ra 0.8 µm to 3.2 µm (32–125 µin), adjustable based on application and material |

| Maximum Work Envelope | Milling: 1200 x 800 x 600 mm (47″ x 31.5″ x 23.6″) Turning: Ø500 mm x 1000 mm (19.7″ x 39.4″) |

| Spindle Speed (Milling) | Up to 24,000 rpm for high-precision finishing passes |

| Positioning Accuracy | ±0.002 mm (±0.00008″) |

| Repeatability | ±0.003 mm (±0.00012″) |

Material Compatibility and Machinability Characteristics

| Material | Form (Cast or Molded) | Typical Applications | Machinability | Max Tolerance (Typical) | Notes |

|---|---|---|---|---|---|

| Aluminum (e.g., A380, 6061, 7075) | Die-cast or sand-cast blanks | Housings, brackets, heat sinks, structural components | Excellent | ±0.01 mm | High thermal conductivity, lightweight, ideal for complex 5-axis features |

| Steel (e.g., 4140, 1045) | Cast or forged preforms | Gears, shafts, high-strength components | Moderate to Good | ±0.008 mm | Requires rigid tooling; suitable for tight-tolerance turning and milling |

| ABS (Acrylonitrile Butadiene Styrene) | Cast or poured resin forms | Prototypes, enclosures, jigs, non-structural parts | Very Good | ±0.05 mm | Low melting point; controlled feed rates recommended |

| Nylon (e.g., PA6, PA66) | Cast billets or preforms | Wear strips, bushings, insulators | Good | ±0.03 mm | Hygroscopic; pre-dry before machining; low friction, high toughness |

Notes on Process Integration

Casting spare parts often begin as near-net-shape castings, which are then precision-machined using multi-axis strategies to achieve final form. 5-axis milling enables single-setup machining of complex contours, reducing cumulative error. CNC turning is used for rotational features, often in hybrid mill-turn setups for steel and aluminum components. Tight tolerance requirements are maintained through in-process probing, thermal compensation, and post-machining CMM inspection.

All materials are machined using optimized toolpaths and cutting parameters specific to the material and geometry, ensuring dimensional stability and surface integrity.

From CAD to Part: The Process

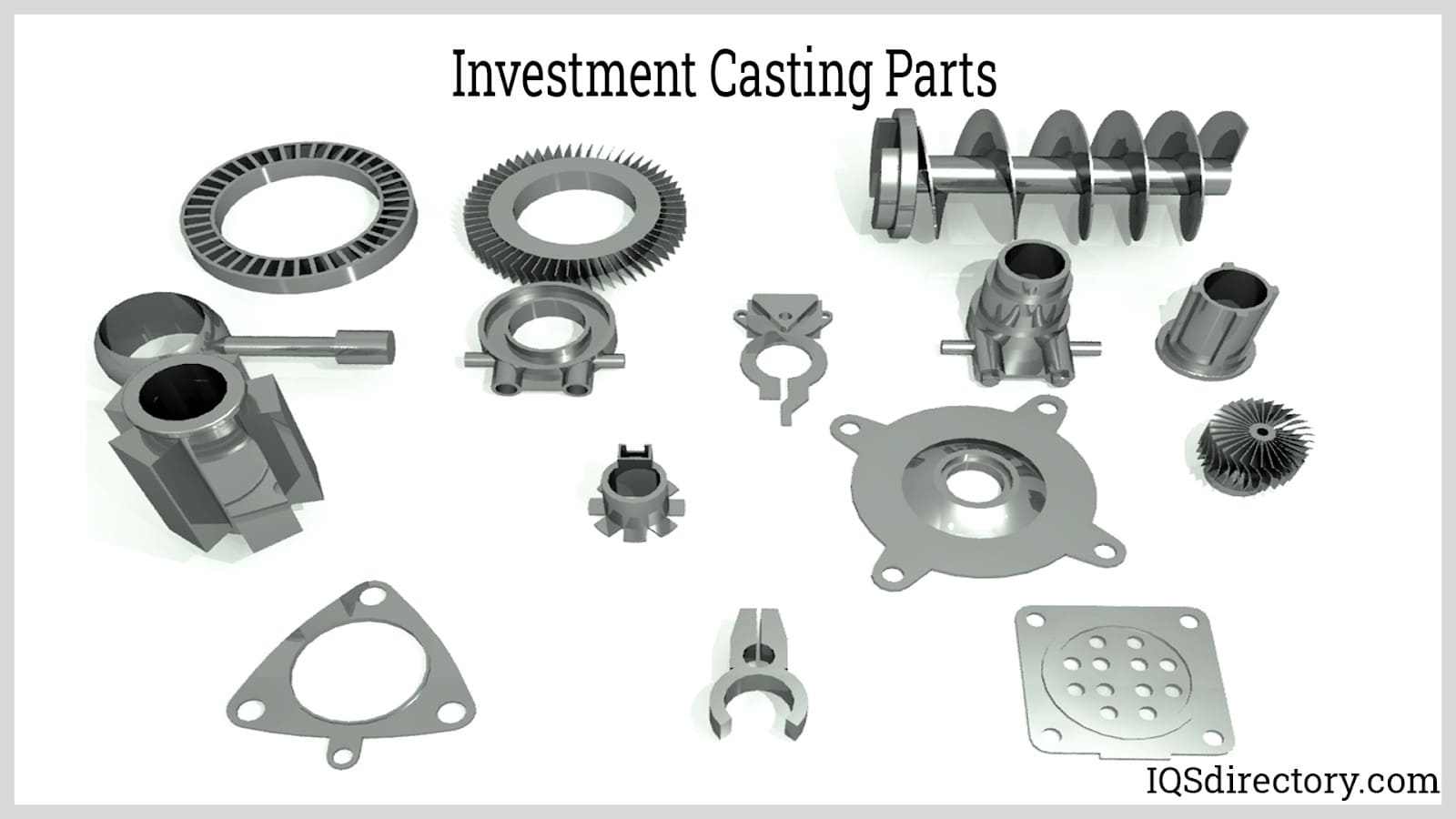

Honyo Prototype specializes in rapid casting solutions for low-volume spare parts and functional prototypes, leveraging urethane casting and investment casting processes rather than high-volume production casting. Our streamlined workflow ensures technical precision and supply chain efficiency for industrial clients requiring mission-critical components. Below is the exact sequence for your spare parts project:

Upload CAD

Clients initiate the process by uploading native CAD files (STEP, IGES, or native SolidWorks files preferred) via our secure customer portal. We require geometric dimensioning and tolerancing (GD&T) annotations, material specifications, and surface finish requirements to avoid downstream ambiguities. Non-disclosure agreements are auto-applied upon upload, and our system validates file integrity while flagging potential topology errors before proceeding.

AI Quote

Our proprietary algorithm analyzes the CAD geometry against 12,000+ historical casting datasets to generate instant commercial terms. This AI engine calculates material utilization efficiency, mold complexity factors, and post-processing requirements while cross-referencing real-time material costs from ISO-certified suppliers. The output includes a detailed cost breakdown, lead time projection, and automated feasibility flags—reducing traditional quoting cycles from 3–5 business days to under 90 minutes. No hidden fees are applied; costs reflect actual process parameters.

DFM Analysis

Engineering-led Design for Manufacturability review occurs only after AI feasibility confirmation. Our manufacturing engineers conduct a rigorous 28-point checklist covering draft angles, wall thickness uniformity, gate placement optimization, and stress concentration analysis specific to casting physics. Clients receive a formal DFM report with actionable recommendations—such as modifying rib thickness to prevent sink marks or adjusting parting lines to eliminate undercuts—typically within 24 business hours. This phase is non-negotiable; we reject 12% of submissions annually to maintain yield integrity.

Production

Approved designs move to our climate-controlled casting facility. Urethane casting uses vacuum-degassed silicone molds with Shore 70A–90A elastomers, while investment casting employs ceramic shell molds with ASTM A356 aluminum or 17-4PH stainless steel. All parts undergo in-process dimensional verification via CMM at critical features, with first-article inspection reports provided pre-shipment. Typical batch sizes range from 1 to 50 units, with secondary operations (machining, anodizing, bead blasting) performed in-house to minimize handling risks.

Delivery

Finished components ship with full traceability documentation including material certs, as-built inspection reports, and process validation data. Standard lead time spans 7–10 business days from DFM sign-off, with expedited 72-hour options for urgent spare parts. All shipments include tamper-evident packaging compliant with AS9100 aerospace handling standards. We maintain a 99.2% on-time delivery rate for Tier 1 industrial clients, with logistics tracked via our client portal until proof of delivery.

Process timing varies by complexity as shown in our standard throughput metrics:

| Process Stage | Typical Duration | Rush Service Option |

|---|---|---|

| AI Quote | < 90 minutes | N/A |

| DFM Analysis | 24 business hours | 8 business hours |

| Production | 5–7 business days | 48–72 hours |

| Delivery | 2–3 business days | Same-day dispatch |

This integrated approach eliminates traditional spare parts supply chain bottlenecks while ensuring cast components meet ISO 2768 medium tolerances or tighter specifications. We prioritize manufacturability validation upfront to prevent costly field failures in your operational equipment.

Start Your Project

Looking for reliable casting spare parts solutions? Partner with Honyo Prototype for high-quality, precision-engineered components tailored to your specifications. With our in-house manufacturing facility located in Shenzhen, we ensure tight tolerances, fast turnaround times, and consistent quality for both prototyping and low-to-mid volume production runs.

Contact Susan Leo today to discuss your project requirements or request a quote. Reach out via email at [email protected] and leverage our expertise in casting technologies including die casting, sand casting, and investment casting across aluminum, zinc, magnesium, and other engineering-grade materials.

Let us help you streamline your supply chain with dependable spare parts manufacturing from our Shenzhen factory.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.