Contents

Manufacturing Insight: Casting Service

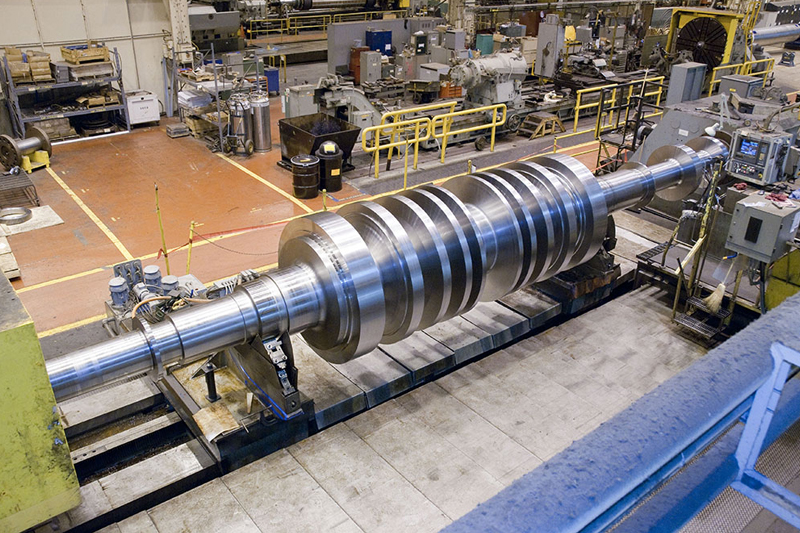

Precision Casting Solutions Enhanced by Integrated CNC Machining Expertise

At Honyo Prototype, we redefine casting prototyping by seamlessly integrating high-accuracy CNC machining capabilities into every project lifecycle. While our advanced casting services—including investment, sand, and die casting—deliver near-net-shape components with exceptional material integrity, it is our in-house CNC machining expertise that ensures critical features meet stringent dimensional tolerances and surface finish requirements. Many casting applications require post-casting precision machining for functional interfaces, tight-tolerance geometries, or assembly-critical surfaces; attempting these on unqualified shop floors risks part failure or costly rework. Honyo eliminates this risk through vertically integrated manufacturing: our engineering team designs casting tooling with machinability in mind, then executes secondary operations on state-of-the-art 3-, 4-, and 5-axis CNC centers using the same material batch. This unified workflow guarantees seamless transitions from casting to finished prototype, reducing lead times by up to 40% compared to fragmented supplier models.

Our commitment to engineering-grade outputs extends to accessibility. Leverage our Online Instant Quote platform to receive validated manufacturability feedback and competitive pricing within hours—not days—for both casting and CNC machining scopes. Simply upload your CAD file, specify material and finish requirements, and our AI-driven system cross-references geometric complexity against proven process parameters. This transparency empowers design teams to iterate faster while ensuring producibility from day one.

For prototyping projects demanding metallurgical reliability paired with micron-level precision, Honyo Prototype delivers a single-source solution where casting expertise and CNC mastery converge. Initiate your next project with confidence through our instant quoting system and experience how integrated manufacturing accelerates time-to-test.

Technical Capabilities

Technical Specifications for Casting Service with Precision Machining Capabilities

Honyo Prototype offers advanced casting services integrated with high-precision CNC machining to deliver complex, tight-tolerance components for prototyping and low-to-mid volume production. Our capabilities include 3-axis, 4-axis, and 5-axis milling, as well as multi-axis turning, ensuring exceptional accuracy and surface finish on cast parts. We support a wide range of materials including Aluminum, Steel, ABS, and Nylon, enabling versatile applications across aerospace, medical, automotive, and industrial sectors.

All machined cast components are held to tight tolerances of ±0.005 mm (±0.0002″) for critical features, with geometric tolerances maintained per ISO 2768-m or customer-specified GD&T standards. First article inspection (FAI) and CMM reporting are available upon request.

| Parameter | Specification |

|---|---|

| Machining Capabilities | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning (2-axis and multi-axis) |

| Tolerance Range | Standard: ±0.01 mm (±0.0004″) Tight: ±0.005 mm (±0.0002″) with inspection |

| Surface Finish | Ra 0.8 µm (32 µin) standard; down to Ra 0.4 µm (16 µin) with polishing or grinding |

| Maximum Work Envelope (Milling) | 5-axis: 1200 x 800 x 600 mm (47″ x 31″ x 24″) 3/4-axis: 1500 x 1000 x 750 mm (59″ x 39″ x 30″) |

| Maximum Turning Diameter | 350 mm (13.8″) Maximum Length: 1000 mm (39.4″) |

| Materials – Metals | Aluminum (6061, 7075, 2024, A380 casting alloy) Steel (1018, 4140, 17-4 PH) |

| Materials – Plastics | ABS (standard, high-impact) Nylon (6, 66, GF-filled variants) |

| Secondary Operations | Heat treatment, anodizing (Type II & III), passivation, bead blasting, painting, threading |

| Quality Standards | ISO 9001:2015 compliant, first article inspection (FAI), CMM reporting, GD&T |

| Lead Time | 7–15 business days for machined cast prototypes, depending on complexity |

Our casting-to-machining workflow ensures dimensional stability and repeatability, especially for complex geometries requiring tight tolerances and high surface integrity. Material selection is optimized based on mechanical requirements, corrosion resistance, and post-processing needs.

From CAD to Part: The Process

Honyo Prototype Casting Service Process Overview

Honyo Prototype delivers precision casting services through a streamlined, technology-driven workflow designed for efficiency and manufacturability. Our process begins with client CAD submission and progresses through integrated stages to ensure optimal outcomes. Below is a detailed explanation of each phase.

CAD Upload

Clients initiate the process by uploading 3D CAD models via our secure online portal. Supported formats include STEP, IGES, and native files from major CAD platforms. The system performs an initial validation check for file integrity, units, and basic geometric completeness. This step establishes the digital foundation for subsequent analysis and quotation.

AI-Powered Quotation

Uploaded CAD data undergoes automated analysis using Honyo’s proprietary AI engine. This system evaluates geometry complexity, material suitability, dimensional tolerances, and surface finish requirements against our foundry capabilities. The AI generates a preliminary quote within 2 hours, including cost estimates, lead time projections, and critical manufacturability flags. Crucially, this phase identifies potential high-risk features such as undercuts, thin walls, or excessive draft angles requiring human review.

DFM Analysis and Engineering Review

All projects advance to a mandatory Design for Manufacturability (DFM) review by our senior casting engineers. The AI-generated flags are validated, and engineers provide actionable feedback to optimize the design for casting efficiency. This includes recommendations for:

Adjusting wall thickness to prevent shrinkage

Modifying draft angles for mold release

Redesigning gating systems to minimize turbulence

Material selection guidance based on mechanical requirements

Clients receive a formal DFM report with annotated CAD markups. Revisions are collaboratively refined until design stability is achieved, typically within 1–3 business days.

Production Execution

Upon DFM sign-off, the project enters production. Honyo manages end-to-end manufacturing:

Pattern/Tooling Fabrication: CNC-machined patterns or 3D-printed molds are produced in-house based on casting method (sand, investment, or die casting).

Casting Process: Parts are poured using certified alloys under controlled foundry conditions. Real-time process monitoring ensures compliance with ASTM/EN standards.

Post-Processing: Includes precision machining, heat treatment, surface finishing, and non-destructive testing (NDT) as specified. All critical dimensions undergo first-article inspection (FAI) per AS9102.

Delivery and Quality Assurance

Finished components undergo final dimensional validation and material certification checks. Parts are packaged to prevent transit damage using custom crating for fragile geometries. Comprehensive documentation—including material test reports, FAI data, and process certifications—is delivered digitally and physically. Standard lead times range from 10–25 days depending on complexity, with expedited options available. Post-delivery technical support ensures seamless integration into the client’s assembly process.

This integrated approach reduces time-to-part by 30% compared to traditional casting workflows while maintaining rigorous quality control. Honyo’s fusion of AI-driven quoting and expert engineering oversight ensures cost-effective, production-ready castings on schedule.

Start Your Project

Looking for reliable casting services? Contact Susan Leo at [email protected] to discuss your project requirements. With our advanced manufacturing capabilities and quality-driven processes at our Shenzhen factory, Honyo Prototype delivers precision casting solutions tailored to your needs. Let us support your next product development cycle with speed, accuracy, and cost efficiency. Reach out today to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.