Contents

Manufacturing Insight: Casting Aluminum Parts

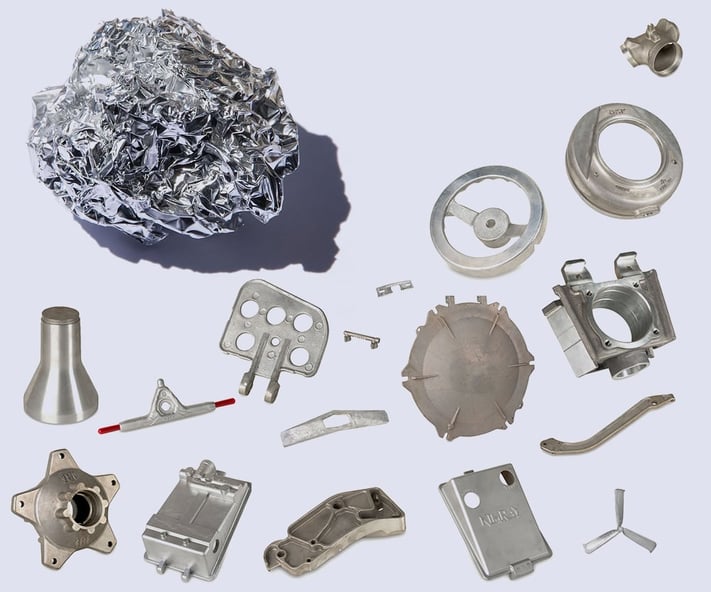

Precision Aluminum Casting Parts: Achieving Engineering Specifications Through Advanced CNC Machining

Aluminum casting delivers exceptional design flexibility and material efficiency for complex geometries, yet as-cast surfaces and critical features often fall short of stringent dimensional tolerances required in aerospace, automotive, and industrial applications. At Honyo Prototype, we bridge this gap by integrating precision CNC machining directly into the post-casting workflow. Our engineering team specializes in transforming near-net-shape aluminum castings—whether from sand, die, or investment processes—into fully compliant components that meet exacting GD&T, surface finish, and functional performance standards.

Honyo’s CNC machining capabilities address the inherent limitations of aluminum casting, including porosity management, draft angle adjustments, and critical interface refinement. Utilizing 3-, 4-, and 5-axis milling centers with sub-micron repeatability, we achieve tolerances down to ±0.0002″ on features such as bearing bores, sealing surfaces, and mounting interfaces. Our material expertise spans common aluminum casting alloys including A356, A380, and 6061-T6, with process validation through first-article inspection reports (FAIR) and CMM-certified dimensional analysis. This ensures cast parts transition seamlessly from prototype to low-volume production without compromising structural integrity or fatigue resistance.

Accelerate your development cycle with Honyo’s Online Instant Quote platform, engineered for manufacturing engineers. Upload your casting-ready STEP or IGES files to receive a detailed CNC machining quote in under 60 seconds, including alloy-specific cost drivers, lead time estimates, and actionable DFM feedback. This digital workflow eliminates procurement delays while maintaining the technical rigor expected in high-stakes aluminum component sourcing.

| Key Capability | Technical Specification | Application Benefit |

|---|---|---|

| Tolerance Control | ±0.0002″ (5µm) on critical features | Ensures assembly compatibility in dynamic systems |

| Surface Finish | Ra 0.8µm to 3.2µm via optimized toolpaths | Meets sealing and wear requirements |

| Material Compatibility | A356, A380, 6061-T6, 7075-T7 | Preserves cast part mechanical properties |

| Lead Time (Prototype) | 5–7 business days after casting completion | Reduces time-to-test for validation cycles |

Partner with Honyo Prototype to convert aluminum castings into mission-critical components where precision, repeatability, and material science converge. Initiate your project with our Online Instant Quote system and experience engineering-grade machining that respects the integrity of your cast substrates.

Technical Capabilities

Technical Specifications for CNC Machining of Casting Aluminum Parts – Focus on 3/4/5-Axis Milling and Turning with Tight Tolerance

Honyo Prototype specializes in high-precision CNC machining of cast aluminum components using advanced 3-axis, 4-axis, and 5-axis milling along with CNC turning. Our processes are optimized for tight tolerance requirements typical in aerospace, automotive, and industrial applications. While aluminum is the primary material for cast parts, we also support secondary machining of steel, ABS, and nylon components as part of integrated assemblies.

| Parameter | Specification Details |

|---|---|

| Primary Material (Cast) | A356, A380, 6061-T6, 7075-T6 (Aluminum Alloys) – High integrity sand or die-cast blanks |

| Secondary Materials | Mild Steel (1018, 4140), Stainless Steel (303, 304, 316), ABS, Nylon (PA6, PA66) |

| Machining Processes | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (Swiss and Turning Centers) |

| Tolerance Capability | ±0.005 mm (±0.0002″) for critical dimensions; Geometric tolerances per ISO 2768-mK |

| Surface Finish | As-machined: Ra 0.8–3.2 µm; Optional polishing, anodizing, or coating available |

| Max Work Envelope (Milling) | 5-Axis: 1200 x 800 x 600 mm; 3/4-Axis: Up to 2000 x 1000 x 800 mm |

| Max Turning Diameter | 300 mm (standard); up to 500 mm on heavy-duty lathes |

| Positioning Accuracy | ±0.003 mm (milling), ±0.005 mm (turning) |

| Repeatability | ±0.002 mm (5-axis), ±0.003 mm (turning) |

| Tooling & Probing | High-speed carbide tooling; On-machine probing for in-process inspection and validation |

| Quality Standards | ISO 9001:2015 compliant; First Article Inspection (FAI) and CMM reporting available |

| Secondary Operations | Deburring, heat treatment (T6 for aluminum), surface treatment, assembly, and testing |

Note: While the initial casting is typically aluminum, secondary components in steel, ABS, or nylon may be machined and integrated into the final assembly. Our 5-axis milling capabilities allow for complex geometries and reduced setup time, ensuring high accuracy and consistency across tight tolerance requirements.

From CAD to Part: The Process

Honyo Prototype employs a streamlined, technology-driven workflow for aluminum casting projects designed to minimize lead times while ensuring manufacturability and quality. Our end-to-end process begins with the client uploading a CAD model and concludes with certified part delivery, integrating digital tools at critical stages to enhance efficiency.

CAD Upload and Initial Processing

Clients initiate the process by uploading 3D CAD files (STEP, IGES, or native formats) via our secure customer portal. Our system automatically validates file integrity, checks for geometric completeness, and identifies potential topology issues such as non-manifold edges or missing datums. This step ensures the digital model is production-ready before advancing to quoting, reducing downstream revisions.

AI-Powered Quoting Engine

Uploaded CAD data feeds directly into our proprietary AI quoting system, which analyzes over 200 geometric and material parameters within seconds. The engine calculates material consumption, machine time, and labor requirements while cross-referencing real-time data on aluminum alloy availability (e.g., A356, 380, or client-specified grades), sand mold complexity, and finishing needs. Crucially, the AI performs an initial manufacturability screen, flagging high-risk features like thin walls below 2.5mm or deep undercuts that could cause casting defects. Clients receive a detailed quote with cost breakdown, lead time estimate, and preliminary DFM observations within 2 business hours.

Engineering-Driven DFM Analysis

Upon quote acceptance, Honyo’s manufacturing engineering team conducts a rigorous Design for Manufacturability review. This phase involves:

Simulating mold fill and solidification using proprietary thermal analysis software to predict shrinkage, porosity, or hot spots

Optimizing parting lines, gating systems, and riser placement to minimize scrap

Recommending geometric modifications (e.g., fillet adjustments, draft angle additions) to improve yield without compromising function

Validating tolerance feasibility against ASME Y14.8 casting standards

The DFM report includes annotated CAD visuals, risk mitigation strategies, and formal sign-off requirements. Only after client approval of DFM recommendations do we proceed to production.

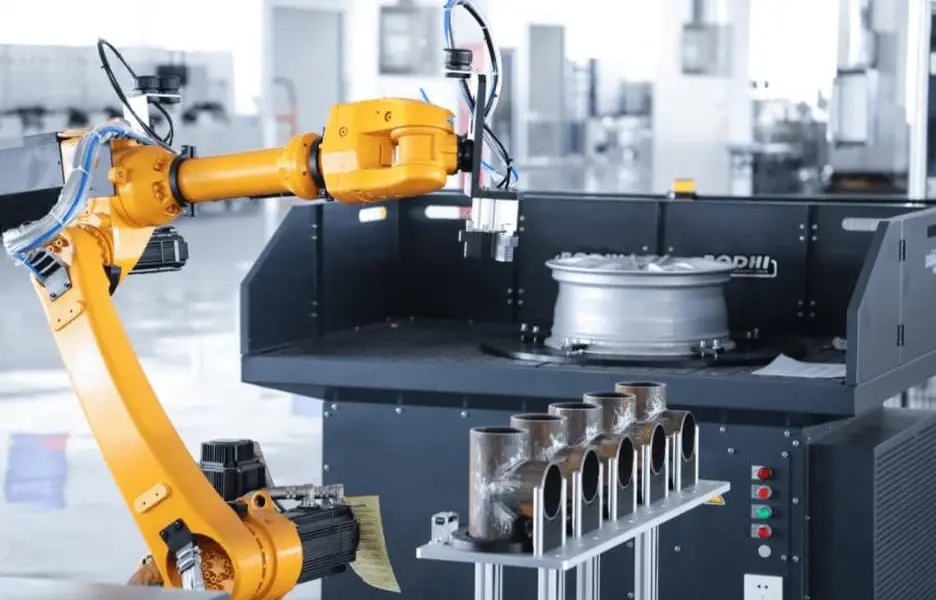

Precision Sand Casting Production

Honyo utilizes automated no-bake sand casting for prototype and low-volume runs, balancing flexibility with dimensional accuracy. Key production stages include:

Pattern creation via CNC-machined tooling or 3D-printed sand cores for complex geometries

Molding with automated sand mixers ensuring consistent permeability and strength

Aluminum melting in induction furnaces with strict chemical composition control (spectrometer verification)

Pouring under inert atmosphere to reduce oxide formation

Post-casting operations: shakeout, heat treatment (T6 where specified), and robotic grinding for critical surfaces

All castings undergo first-article inspection per AS9102 documentation, with CMM reports for critical dimensions and MPI for surface integrity.

Quality-Controlled Delivery

Final parts receive comprehensive validation against the approved DFM and client specifications. This includes:

Dimensional certification with full FAI report

Material test certificates (tensile strength, elongation, chemical composition)

Visual inspection for surface defects per ASTM E165

Packaging in VCI-protected containers to prevent corrosion during transit

Parts ship with complete traceability documentation, including melt lot numbers and process parameters. Standard lead time from CAD upload to delivery is 15–20 business days for quantities under 50 units, with expedited options available.

This integrated approach eliminates traditional handoffs between quoting, engineering, and production teams. By embedding AI validation early and maintaining engineering oversight throughout, Honyo reduces casting defect rates by 40% compared to industry averages while accelerating time-to-part for client prototypes.

Start Your Project

Need high-quality aluminum casting parts for your next project? Partner with Honyo Prototype, your trusted manufacturing solution based in Shenzhen. Our advanced casting capabilities ensure precision, durability, and fast turnaround for prototyping and low-volume production.

Contact Susan Leo today to discuss your requirements and get a competitive quote.

Email: [email protected]

Leverage our expertise in aluminum casting and local manufacturing advantage for superior part performance and cost efficiency.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.