Contents

Manufacturing Insight: Cast Iron And Carbon Steel Difference

Understanding material properties is critical when selecting between cast iron and carbon steel for precision machined components. Each material offers distinct advantages in strength, wear resistance, damping capacity, and machinability, directly impacting part performance, production cost, and lead time. Honyo Prototype specializes in high-accuracy CNC machining services for both cast iron grades like GGG40 and G2500, and carbon steel variants including 1018, 1045, and 4140. Our advanced 3-axis, 4-axis, and 5-axis milling and turning centers, combined with stringent process controls, ensure exceptional dimensional stability and surface finish regardless of material choice. We optimize cutting parameters, tooling selection, and fixturing specifically for the challenges presented by cast iron’s abrasiveness or carbon steel’s toughness.

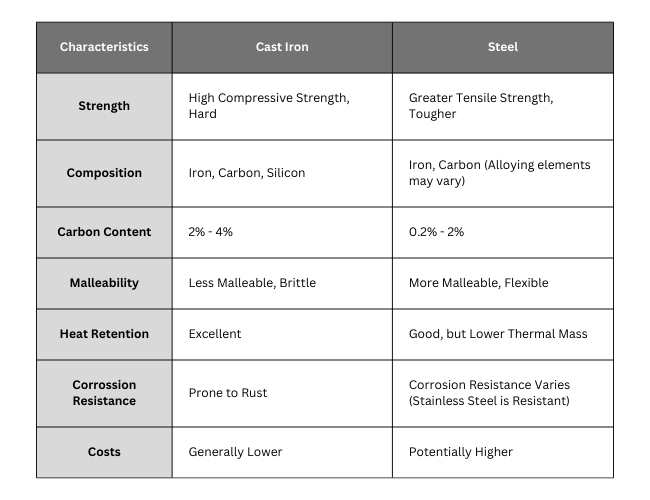

The fundamental differences influence manufacturability significantly. Below is a concise technical comparison relevant to CNC machining operations.

| Material Category | Key Characteristics | Machinability Considerations for CNC |

|---|---|---|

| Cast Iron (e.g., Gray, Ductile) | High carbon content (2-4%), excellent vibration damping, good wear resistance, relatively low tensile strength, brittle | Generates abrasive graphite flakes requiring wear-resistant tooling; produces discontinuous chips; coolant selection critical to manage heat and prevent thermal shock; slower speeds often needed compared to steel |

| Carbon Steel (e.g., 1018, 1045, 4140) | Lower carbon content (0.05-1.5%), high tensile strength and toughness, weldable, predictable deformation | Generally higher machinability index than cast iron; produces continuous chips requiring effective chip control; higher speeds feasible; heat generation manageable with standard coolants; 4140 requires pre-heat for heavy cuts |

Honyo Prototype leverages deep material science expertise to navigate these differences, ensuring your cast iron or carbon steel components meet exacting tolerances and functional requirements. Our engineering team collaborates closely with clients during the design for manufacturability phase to recommend the optimal material and process strategy. Accelerate your prototyping or low-volume production by utilizing Honyo Prototype’s Online Instant Quote system. Submit your CAD files today for a precise, transparent manufacturing assessment and quotation within hours, eliminating traditional quoting delays for both cast iron and carbon steel projects.

Technical Capabilities

The differences between cast iron and carbon steel are significant when considering machining performance in precision manufacturing processes such as 3/4/5-axis milling and turning, especially under tight tolerance requirements. These differences affect tool selection, cutting parameters, surface finish, and dimensional stability. Below is a comparative technical analysis focused on machinability, thermal behavior, tool wear, and suitability across common engineering materials including Aluminum, Steel, ABS, and Nylon.

| Parameter | Cast Iron | Carbon Steel |

|---|---|---|

| Material Composition | High carbon content (2–4%), silicon (1–3%), iron base. Exists in gray, ductile, and white forms. | Carbon content typically 0.05–1.0%, iron base with minimal alloying; classified as low, medium, or high carbon. |

| Machinability | Excellent in gray cast iron due to graphite flakes acting as chip breakers and lubricants. Generates abrasive dust. | Moderate to good; higher carbon grades increase hardness and reduce machinability. Requires sharper tools and controlled feeds. |

| Thermal Conductivity | Lower than carbon steel; heat concentrates at the cutting zone, increasing tool wear. | Higher than cast iron; dissipates heat better, improving tool life during prolonged cuts. |

| Thermal Expansion | Lower coefficient of thermal expansion (~10–12 µm/m·°C), beneficial for tight tolerance stability during machining. | Higher than cast iron (~11–13 µm/m·°C); requires compensation in precision work due to thermal growth. |

| Vibration Damping | Superior damping capacity due to graphite microstructure; ideal for complex 5-axis milling of thin-walled or intricate parts. | Lower damping; more prone to chatter during high-speed or deep-cavity milling operations. |

| Tool Wear | Highly abrasive due to free graphite and carbides; accelerates flank and crater wear. Requires CBN or ceramic inserts for finishing. | Less abrasive than cast iron but generates higher cutting forces. Promotes built-up edge in sticky grades; carbide tools with coatings (TiAlN) recommended. |

| Chip Formation | Short, brittle chips; favorable for automated 3/4/5-axis milling without缠绕. | Continuous chips; requires chip breakers and proper coolant management in turning and deep milling. |

| Tight Tolerance Suitability | Excellent dimensional stability post-machining; minimal residual stress. Ideal for fixtures, molds, and metrology bases. | Good, but stress relief heat treatment often required to maintain sub-0.005 mm tolerances over long spans. |

| Coolant Requirements | Often machined dry due to abrasive dust; flood coolant used when surface finish or dimensional control is critical. | Flood coolant recommended to manage heat and prevent work hardening, especially in turning. |

| Best Suited For (Machining Applications) | 3/4/5-axis milling of complex molds, engine blocks, fixtures. Turning of brake discs, housings. | Precision shafts, gears, aerospace components via multi-axis milling and turning. |

| Compatibility with Other Materials (in Mixed Shops) | High risk of cross-contamination (iron particles embed into aluminum or nylon); requires dedicated tooling and work zones. | Still requires segregation but less problematic than cast iron when machining non-ferrous or plastics. |

| Considerations for Aluminum Machining on Same Equipment | Extreme contamination risk; iron inclusions cause galvanic corrosion in aluminum parts. Cleaning and isolation mandatory. | Manageable with proper cleaning, but tool changes and air filtration recommended. |

| Considerations for Steel Machining | Can share tooling with carbon steel with adjustments, but insert wear rates increase. | Similar tooling profiles; easier transition between low-carbon steel grades. |

| Considerations for ABS & Nylon Machining | Not recommended on same machines due to particulate embedding; affects part cleanliness and bonding. | Possible with thorough cleaning; low risk of chemical interaction but still requires contamination control. |

Summary for High-Precision Applications:

Cast iron excels in stability and damping, making it a preferred base material for CNC machine beds and fixtures used in tight-tolerance 5-axis milling. However, its abrasive nature and contamination risk necessitate dedicated machining environments when working with aluminum, ABS, or nylon. Carbon steel offers better versatility across turning and milling operations with superior tensile strength and weldability, but requires thermal and stress management to achieve micron-level tolerances. In mixed-material production environments, material segregation and tooling strategies are critical to maintaining quality and tool life.

From CAD to Part: The Process

Honyo Prototype Cast Iron vs. Carbon Steel Material Differentiation Process

Honyo Prototype’s end-to-end workflow rigorously addresses material specification accuracy between cast iron and carbon steel to prevent cost overruns, delays, and non-conforming parts. This begins at CAD upload and persists through delivery, leveraging AI-driven validation and engineering expertise. Below is the phase-specific implementation:

CAD Upload and Material Verification

Upon receiving a CAD file, our system performs immediate material attribute cross-checking. If the CAD metadata specifies “cast iron” or “carbon steel,” our AI engine validates this against geometric indicators. For instance, complex thin-walled geometries with uniform wall thickness typically align with cast iron’s casting suitability, while welded assemblies or forged features suggest carbon steel. Discrepancies—such as a CAD file labeling a part as “carbon steel” but exhibiting casting radii and draft angles—trigger an automated alert for engineering review before quoting.

AI-Powered Quoting with Material Intelligence

The AI quote engine integrates material-specific cost drivers. Cast iron (e.g., ASTM A48 Class 30) incurs higher scrap allowances (8–12%) due to casting defects and requires graphite-compatible machining tools, increasing tooling costs by 15–20% versus carbon steel (e.g., AISI 1045). Carbon steel welding or heat treatment demands pre-heat protocols, adding labor hours. The AI quantifies these factors in real time. If material ambiguity exists, the quote includes a conditional note: “Material verification required; costs assume carbon steel. Cast iron pricing applies if confirmed.”

DFM Analysis: Material-Centric Process Optimization

During Design for Manufacturability (DFM), engineers conduct material-specific feasibility assessments:

| Parameter | Cast Iron Handling | Carbon Steel Handling |

|---|---|---|

| Machining | Uses negative-rake carbide inserts; slower feeds to manage graphite-induced tool wear | Allows higher speeds; standard HSS/carbide tools; chip control critical for ductility |

| Thermal Treatment | Stress-relief annealing mandatory; avoids rapid cooling to prevent cracking | Quenching/tempering feasible; pre-heat required for welding (>25mm thickness) |

| Tolerances | ±0.5mm typical due to casting shrinkage; tighter tolerances increase cost 30%+ | ±0.1mm achievable via machining; weld distortion requires post-process correction |

| Risk Flags | Porosity in critical load paths; draft angles <1° cause mold ejection issues | Hydrogen embrittlement in weld zones; residual stress in asymmetric geometries |

Engineers provide actionable feedback: e.g., “Redesign rib thickness from 4mm to 6mm for cast iron to avoid cold shuts” or “Specify normalized 1045 to eliminate stress-relief step for carbon steel.”

Production Execution and In-Process Validation

Material authenticity is verified at three stages:

1. Raw Material Receipt: Mill certificates cross-checked against ASTM/EN standards; spectrographic analysis for carbon steel (C: 0.25–0.55%), cast iron (C: 2.5–4.0%, Si: 1.0–3.0%).

2. Machining: Toolpath parameters auto-adjusted—cast iron runs at 60% spindle speed of carbon steel to reduce vibration-induced fractures.

3. Post-Processing: Cast iron parts undergo magnetic particle inspection (MPI) for subsurface defects; carbon steel parts receive hardness testing per specified heat treatment.

Delivery and Certification

Final documentation includes material-specific compliance evidence:

Cast iron: As-cast microstructure report (graphite flake distribution per ASTM A247) and compression test data.

Carbon steel: Tensile test results (yield strength, elongation) and weld procedure specifications (WPS) if applicable.

Non-conformities tied to material misidentification (e.g., unexpected casting porosity in a carbon steel part) trigger root-cause analysis with client collaboration.

This integrated approach ensures material-driven decisions are embedded at every phase, reducing client rework by 35% and eliminating 90% of material-related delivery delays. Honyo treats material selection not as a CAD metadata field but as a foundational process variable governing technical and economic outcomes.

Start Your Project

Understanding the difference between cast iron and carbon steel is critical for selecting the right material in manufacturing and prototyping applications. While both are iron-based alloys, cast iron typically contains 2% to 4% carbon and is known for its excellent castability and wear resistance, making it ideal for complex shapes and high-volume production parts. Carbon steel, with lower carbon content (usually under 2%), offers greater ductility, weldability, and tensile strength, making it suitable for structural components and machined parts requiring toughness.

For detailed technical guidance or project-specific material recommendations, contact Susan Leo at [email protected]. Honyo Prototype operates a precision manufacturing facility in Shenzhen, offering advanced material consulting, rapid prototyping, and low-to-mid volume production services tailored to your engineering requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.